Maktek Epsilon ECO 24 User manual

®

CONDENSING BOILER

TS EN ISO 9001:2015 Please Keep

Please Read

rev.no:01

30.05.2019

USER'S GUIDE

Epsilon ECO

24 kW - 30 kW

2

2

3

4

5

5

6

7

9

9

9

10

10

10

11

12

13

13

15

15

15

16

17

18

20

21

22

22

22

23

23

23

24

25

26

27

28

1. SAFETY WARNING

1.1 SYMBOL KEY

1.2 GENERAL WARNINGS

1.3 GENERAL EXPLANATIONS

2. INTRODUCTION OF THE DEVICE

2.1 APPERANCE AND EXTERNAL DIMENSIONS

2.2 INTERNAL STRUCTURE AND COMPONENT LIST

2.3 CONTROL PANEL

3. INSTALLATION DATA

3.1 ELECTRICITY CONNECTION

3.2 OPENING THE BOX

3.3 WALL MOUNTING

3.4 POINTS TO BE CONSIDERED AT INSTALLATION

3.5 SPACES TO BE LEFT DURING INSTALLATION

3.6 CONNECTION OF CONDENSATE WATER DISCHARGE

3.7 INSTALLATION CONNECTION DIAGRAM

3.8 INSTALLATION CONNECTIONS

3.9 CHIMNEY CONNECTION

4. FLUSHING TO THE SYSTEM AND MONITORING WATER PRESSURE

5. START-UP

5.1 PRE- CONTROLS BEFORE START-UP

5.2 START-UP OPERATION

5.3 PRESSURE CURVE of THE CIRCULATION PUMP

6. USING OF THE BOILER

7. TECHNICAL SPECIFICATIONS

8. ELECTRICITY CONNECTION SCHEMA

9. SAFETY SYSTEMS AND TROUBLE SHOOTING

9.1 NO BURNING, MISLEADING FLAME

9.2 LOW – HIGH WATER PRESSURE

9.3 OVERHEAT LIMIT TERMOSTAT

9.4 ANTI CALCER SYSTEM

10. GAS PRESSURE SETTING

11. CLEANING AND MAINTENANCE

12. GUARANTEE CONDITIONS

13. IMPORTANT INFORMATIONS FOR YOUR SAFETY

14. EFFICIENT USE OF BIOLERS IN TERMS OF ENERGY CONSUMPTION

15. POINTS TO BE CONSIDERED WHILE MOVING AND TRANSPORTING

16. USAGE WITH LPG 28

CONTENT Page

1

Dear Valued Maktek Customer,

By choosing Maktek Epsilon Eco, we are honored to announce that you

have carried the harmony of the latest technology and the modern design

to your homes.

We advise you to read this guide carefully. This guide is an important

source for both installation and utilization. Moreover, since it contains

practical and technical information, you can easily benefit from it.

Maktek Epsilon Eco Boiler provides you safe and comfortable life with

conscious utilization.

Please keep this manual for using when needed.

We are stronger with you...

ATTENTION; THESE DEVICES CAN OPERATE WITH NATURAL GAS,

LPG OR WITH PROPAN. Contact with Maktek Authorized Service to

change the type of gas which is specified on the package.

The operations which are performed by unqualified services or people

invalidate the product’s warranty.

ATTENTION; gas transformation should be performed by the authorized

service according to the criteria in the attached table.

2

1.SAFETY WARNING

1.1 Symbol Key

This symbol expresses the risk of personal injury unless taking care of

warnings.

This symbol expresses the conditions can cause harms on

environment, animals or goods unless taking care of warnings.

Do not open the protective cover of the device.

Electric shock as a result of the contact with electrical items.

Personal injury like burnt as a result of contact with overheated surfaces

or cut as a result of contact with sharp surface.

Do not remove the device from the place of mounting, do not

disconnect (Get in contact with authorized service)

Flood as a result of demounted water installation.

Explosion, fire or poisoning danger as a result of demounted gas

installation. Protect the energy cable against damages.

Electric shock danger as a result of contact with not izolated open wires.

Do not leave tools or staff on the device.

Injury resulted from falling objects from device becuse of vibration.

Harms on things or animals resulted from falling objects from device

because of vibration.

Do not climb on device.

Personal injury as a result of fall down with device or fall down of device

itself. Damage risk on staff under device as a result of fall down

from the place installed.

Do not stamp on chair, stool, ladder or other things which are not

strong enough.

Personal injury resulted from falling down from heigh or cuts can be

resulted from a rapid closing of ladder.

Do not clean the device unless switching it to off position or

disconnecting energy link.

Use the device for only heating the house and getting hot

water.Damage risk resulted from inappropriate using and overloading.

Damage risk of the place resulted from inappropriate using.

Do not allow children or people who can not use the device, to

intervene in device.

Damage to device risk resulted from wrong use.

3

•Follow the instructions in this manual while using the device.

Manufacturer can not be held responsible from breakdowns and

damages from wrong use.

•Start-up, maintenance and repairs can be done by only MAKTEK

AUTHORISED SERVICES. Otherwise device will go out of

gurantee and manufacturer will not be responsible for breakdowns

or damages.

•It is dangerous and forbidden to use flammable/combustible

materials at the site of the boiler.

•Thinner, benzine etc. flammable materials must be kept away from

the place that boiler runs.

•Device must be mounted to a suitable location at a distance of at

least 2.5 meters from each side of easily flammable household

goods and flammable materials.

•Minimum ambient temperature must be 5°C when the boiler

installed in a partly covered place like balcony.When the ambient

temperature is lower, boiler must be isolated within a proper

keeping stuff.

•Only authorised service can intervene the all parts and sections

that (when) leakage is observed.

Disconnect the main energy connection, shut down the main gas

valve, open all the windows, move away the place and call for

help in case of burning smell or smoke from device.

Personal injury from burnts, breathing smoke or poisoning.

Shut down the main gas valve, open all windows, avoid from

sparkling and move away call for help if there is a gas smell in

place.

Explosion, fire or poisioning danger.

Pay attention not harming the electric cables and pipes inside

wall while making holes on wall for metal hangers.

Electric shock as a result of the contact with electrical items.

Explosion and fire danger results from gas pipe puncure.

Flood risk results from water pipe puncture.

Suitable profiled cables must be used in all electric connections.

Fire risk results from overheated law profiled cables

1.2 GENERAL WARNINGS

4

1.3 GENERAL EXPLANATIONS

Epsilon Eco Condensing Boiler provides the heating by central boiler

heating system and radiators connected to the sytem, and provides hot

water by heat exchanger.

Installation and services must be in accordance with recent standarts,

directives and instructions which will be explained in this manual.

Producer cannot be held liable for damages caused from wrong

installation and usage.

ATTENTION; Installation, start-up and maintenance must be done by

Maktek staff or staff authorized by Maktek.

ATTENTION; In case of a leakage, firstly close the gas inlet valve and

ventilate the environment, then call authorised service immediately.

WARNING !

This instruction manual is extremely important and must be kept as a

reference guide.

Follow the instructions on manual to run the boiler. Manufacturer is not

responsible for the failures and damages resulted from improper use.

Optimum lifetime of the boiler is 15 years. It should be replaced with a

new one at the end of this period.

The boiler is under warranty of the manufacturer if the product complies

with conditions specified in the warranty.

It is recommended to making annual periodic maintenance in accordance

with data on maintenance chapter. Only Maktek authorised services can

intervene the boiler.

5

2. INTRODUCTION OF THE DEVICE

2.1 APPEARANCE AND EXTERNAL DIMENSIONS

6

2.2 INTERNAL STRUCTURE AND COMPONENT LIST

1. Prosestat

2. Fan

3. Burning Room Isolation and Side Cap

4. Bimetal Limit Thermostat

5. Ionisation Electrode

6. 3 Way Motor Valve

7. Gas Valve Modulation Bobin

8. Heat Sensor Of The System

9. Hot Water Circuit Temperature Sensor

10. Pressure Gauge (Transducer)

11. Plate Exchanger

12. Gas Valve

13. Filling Valve

14. Water Flow Sensor

15. Condensing Water Reservoir

16. Circulation Pump

17. Ignition Electrode

18. Burner

19. Combustion Chamber

20. Heating Circuit Exchanger

21. Top Smoke Chest

22. Rekuperator (Condensing

Exchanger)

23. Fresh Air Entrance Flange

24. Chimney Outlet

25. Chimney Limit Thermostat

26. Expansion Tank

27. 3 Bar Safety Ventile

28. Panel Bottom Support Sheet

7

2.3 CONTROL PANEL

All functions required to run the boiler is done via two buttons on the

control panel. These functions are seen on the LCD sreen. All failure

reports are seen on screen via specific codes.

A. P1 KEY

DHW Adjustment: Temprature of the DHW is adjusted.

Desired temperature flashes on the screen.

DHW function is OFF.

Note: The boiler does not produce DHW.

TEST: Mode of adjustment by AUTHORISED SERVICE.

B. P2 KEY

OFF - RESET: The boiler is functionally switched off. In case of failure it

is used as a reset. Safety against frost and congestion are enabled.

Winter Mode: Both DHW and heating function is on. Heating

system adjustments are done. Desired temprature flashes on

the screen. DHW is priority.

Summer Mode: Only DHW function is on.

8

C. LCD SCREEN:

It shows running and failure conditions with the warning codes on screen.

These codes are:

S1 : °C (temperature) symbol.

S2 : (KS) DHW is heating.

S3 : (MS) Central System is heating

S4 : Bar (water pressure ) symbol.

S5 : Manual reset is required.

S6 : Burning initiated, boiler is running.

S7 : No burning

WARNING CODE EXPLANATION SOLUTION

E04 Low or high water pressure (page 22)

E01 No Flame (page 22)

E02 Limit thermostat (page 22)

E03 Chimney Thermostat Call authorised service.

E37 Circulation Failure Call authorised service.

E05 Heating system sensor error (page 23)

E06/E12 DHW sensor error (page 23)

E035 Misleading Flame Call authorised service.

9

3. INSTALLATION DATA

3.1 ELECTRICITY CONNECTION

•The boiler works with 230 v. 50 Hz. alternative current.

•Please make sure that the fuse supplied along with the boiler is

installed maximum 10 cm. away from the boiler.

•An electricity cable of 3x1,5 mm² must be laid out by an authorised

electrician.

•The boiler works with ground line. Both for your and the boiler's safety,

please make sure that the grounding is done properly.

•Please make the phase, neutral and ground line connection as shown

on the schema.

3.2 OPENING THE BOX

1. Put the box on the floor as arrows showing down and open the box by

cutting packing belts.

2. Open the covers by folding on 4 sides as shown in figure.

3. Turn down the box as shown in figure and pull box to up and remove it from

the box.

IMPORTANT

•The boiler does not operate when the connection is done

improperly.

•The cable of the boiler must be connected as shown:

Brown: Connect this to phase cable.

Blue: Connect this to neutral cable.

Yellow-Green: Connect this to ground cable.

Boiler

System

10

3.3 WALL MOUNTING

The installation of the gas boiler must be done by authorized dealers.

Start-up operation must be done by MAKTEK AUTHORISED SERVICE.

Your device will become out of guarantee if the installation and operation

terms indicated on this manual are not applied.

3.4 POINTS TO BE CONSIDERED AT INSTALLATION

•Pipings must be cleaned before the installation of the device.

•The gas connection of the unit must be done properly and controlled for

any leakages.

•Condensing boilers run on closed burning chamber principle. They

supply the air from outside for burning, and then exhausts the burned

gases to the environment. For this reason, the exhaust gas outlet pipe

must be installed in contact with the outside atmosphere.

•Exhaust gas pipes must not be put in closed areas where there is no air

circulation.

•Wall mounted boilers must be installed vertically on a strong wall that

can carry it.

•The unit must not be installed in connection with dirty and oily flue

where the kitchen appliances are connected to.

•Specific spaces must be left around the unit for the authorized service to

intervene in the event of a technical breakdown or maintenance. You

can find the minimum spaces required for installation indicated below.

•Installation accesories provided along with the boiler (wall plug, screw

and hooks) must be used during the installation.

•The proper installation checked by a water gauge is necessary for the

healthy operation of the boiler.

•The condensate drain hose of the appliance must be connected to a

suitable water drain as specified in this manual. (see page 11)

3.5 SPACES TO BE LEFT DURING INSTALLATION

Following ranges must be left along with installation in order to reach

internal parts of the device during maintenance and possible malfunctions.)

11

3.6 CONNECTION OF CONDENSATE WATER DISCHARGE

The condensate discharge water hose from the boiler must be connected

to a suitable acid-resistant pipe (plastic) at an angle of 2.5° towards the

floor. The pipe must be at least in 22 mm diameter and connected to a

suitable drain. The connection can be made in the following ways:

i) Connection can be done to a sink water drain inside the house. At least

75 mm siphon connection should be made when connecting.

ii) Connection can be done to a water drain outside the house.

The condensation water discharge connection should be made according

to the following figures.

Isolate pipes inside

of the building for

sealing

External pipe length maximum 3 meters

Open mouth of the pipe is connected

to the drain

Above water level, below ground

level

Ø 22 mm min.

Ø 22 mm min.

Open side of the pipe is

connected to the drain

Above water level, below

ground level

No length limit

Min 75 mm siphon

Sink

12

For such connections, the valid standards in that country must be complied

and the local public and health authorities' regulations, if any, must also be

observed. Condensation outlet pipe should be placed very carefully.

The pipe should not break when placed.

Pipe should not take the shape of a goose neck.

It should be clean.

Use the pipes in accordance with the applicable rules for the discharge of

condensate water.

Since the condensation water pH is close to 2 (acidity), necessary

precautions should be taken before any work is carried out. (Protective

gloves)

3.7 INSTALLATION CONNECTION DIAGRAM

Condensation

Water Outlet

Gas Connection 3/4”

DHW

Outlet

1/2”

Heating Water Outlet 3/4”

Filling Valve

Cold Water Inlet 1/2”

Return Water Inlet 3/4”

Condensation Tank

Cleaning Cover

Condensation Water

Outlet

13

3.8 INSTALLATION CONNECTIONS

•At DHW function, please make sure that the pressure of the city water

network on cold water inlet side is not more than 6 Bars. If the network

pressure is more than 6 Bars, a pressure regulator must be added. In

order to run DHW system, minimum pressure level of the network must be

0.8 Bar.

•In order to provide a good circulation in heating function, installation pipes

must be selected accordingly and diameter structure must not be allowed

at elbow passage. In selection of the pipe diameters, pipe resistances

above the pump capacity should be avoided by using the pump pressure

curve.

•When there is an excessive pressure increase at heating system, the

security ventile operates in order to discharge the excessive water.

•When radiator thermostatic valves are installed in the heating system and

when the heat balance is provided at all isolated sections, if the

thermostatic valves turn off the system: Automatic by-pass system

immediately runs in order to provide the minimum circulation in heat

exchanger .

•Gas installation connection must be done by gas tightness pastes. Never

use linen or teflon. The gas inlet pressure mentioned in this manual must

be strictly obeyed.

3.9 CHIMNEY CONNECTION

Mounting of condensing chimney kit must be in accordance with mounting

schema which is given with boiler.

1.Elbow Set

2.Extra Pipe Joint

3.Clips 37mm

4.Condensing Chimney

5.Elastic Wall Badge

82

82

14

ATTENTION: Chimney must be installed upward with a slope of 3% angle

in order to provide the leaking of condensing water flow into the condensing

tank in the boiler.

Chimney should not come into contact with flammable materials and get

through flammable wall material.

Part of the chimney which stays inside the wall, must be maximum 60 cm in

behind connections and must be maximum 40 cm in sidelong connections.

Allowed maximum chimney length is 4 m. If otherwise, please consult the

manufacturer for technical information.

Important: There is an air protestat inside the boiler to shutdown the boiler

in case of a possible failure inside of the chimney. In this case, please

contact your local service.

Maximum length 4 meter

Minimum length 0.5 meter

Standart connection

min slope 3°

chimney kit extension

min slope 3°

slope

Clamp

118 mm

150 mm

118

150 mm

ascending

slope

180 mm

150 mm

52 mm

3°

4000 mm

max

15

4. FLUSHING TO THE SYSTEM AND MONITORING WATER PRESSURE

Water pressure of the heating system is digitally displayed on LCD screen.

To display the pressure, turn P1 Knob to TEST position, and move P2 to

SUMMER position on the control panel (page 7). Water pressure will be

displayed as bar (unit of pressure).Air must be purged from radiators in the

initial flushing process. Please follow these steps to start initial flushing:

1- Open all purgers in central boiler installation and radiators.

Attention: Rotate directions of water evacuation holes and place a pot under

each purger in order to prevent environment from water damages.

2- Open the filling valve (page 12) which is placed underneath the boiler

and start filling water into the system.

3- Close all the purgers when blister-free water starts to come from purgers.

4- Continue to flush until the system pressure comes up to 1,5 Bar, then turn

off the filling valve.

Attention: It is recommended to make initial flushing with at least 2

people.While one person is controlling the radiators and closing the purgers,

the other one can control the pressure by standing over the boiler and close

the filling valve if needed.

In case of water shortage in closed circuit system after running of the boiler, it

is necessary to add water to system by opening filling valve. Radiators must

be checked if there is air in them or not.

5. START-UP

Boiler must be put into service by only Tecnical Services in order to run the

boiler efficient and safe, also for the validation of guarantee conditions.

5.1 PRE- CONTROLS BEFORE START-UP

1.The gas type and its pressure must be controlled.

2.Automatic purger fuse on the circulation pump must be loosened.

3.The pressure inside the system must be controlled from the manometer.

The pressure must be around 1,5 Bar.

4.In order to dispose the air from all of the system , take out the screw in front

of the pump. By this way, whether the pump mill is congested or not can be

controlled and any air that is congested can be discharged.

5.Dispose the air from the purgers on radiators.

6.Discharge the air in the hot water system by turning on hot water tap.

7.Check the installation of hermetic flue kit.

8.Check whether all valves in the system are turned on.

9.Check that the accuracy of condensate drain connection.

16

5.2 START-UP OPERATION

Start-up must be done by the Maktek Authorised Services to validate the

warranty conditions.

The below must be applied:

ATTENTION; The condensation reservoir of the boiler must be filled with

water during the first start-up. To ensure this, add 1/4 lt of water from the

boiler flue outlet as shown in the figure below before first operating.

ATTENTION; If there is not enough water in the condensation reservoir

of the boiler, device can run by emiting smoke for a while.

-Make sure that fuse switch, which enables the energy connection of

boiler, is open. If the boiler has waited for a long time after the installation

in OFF mode without start-up, authorised service must check the

circulation pump in case of any squeezing.

• Turn on all the valves on boiler and installation pipes.

• Closed circuit water pressure must be at 1,5 bar (page 15).

• Choose the position of use with the help of P1 and P2 buttons on control

panel (page 7 and 18).

• You can start using the boiler by setting temperature at desired level.

17

5.3 PRESSURE CURVE of THE CIRCULATION PUMP

3 speed circulation pump is used in MAKTEK Epsilon Eco Boiler. It is

possible to set the circulation with these three speeds according to resistance

required by installation.

EPSİLON ECO 24-30 kW

18

6. USING OF THE BOILER

P1 KEY SETTING MODES P2 KEY SETTING MODES

SUMMER MODE:

When Summer mode is chosen, boiler runs only to

get DHW (30-60°C) set by P1 key when there is

DHW demand.

Opening of the hot water tap is automatically

perceived and boiler generates the hot water

needed. Provides constant temperature comfort

with full modulation system.

In stand by mode when hot water is not demanded,

pressure value of the water inside boiler is

displayed on the screen.

OFF/RESET MODE:

In Off mode, boiler is shut down.

In OFF mode, automatic protective functions below

are in use:

•DHW Freezing Protection

•Central System Freezing Protection

•Pump Squeezing Protection

•3 Way Valve Squeezing Protection

When manually reset error occures, key should be

placed to RESET position and then should be placed

to previous position (before reset position). This

process resets your device. In this condition “OFF” is

displayed on LCD screen.

ATTENTION!: Electricity, gas and water connections should not be

disconnected in order to run the freezing protection function and other automatic

protection fuctions.

DHW

OPEN

DHW

CLOSED

TEST

CENTRAL SYSTEM

TEMPERATURE

SETTING

WINTER

SUMMER

OFF/RESET

CENTRAL

SYSTEM

TEMPERATURE

SETTING

This manual suits for next models

1

Table of contents

Other Maktek Boiler manuals

Popular Boiler manuals by other brands

UT KATILAI

UT KATILAI UT-100 User instructions

Unical

Unical KONe R 18 Installation and Servicing Manual

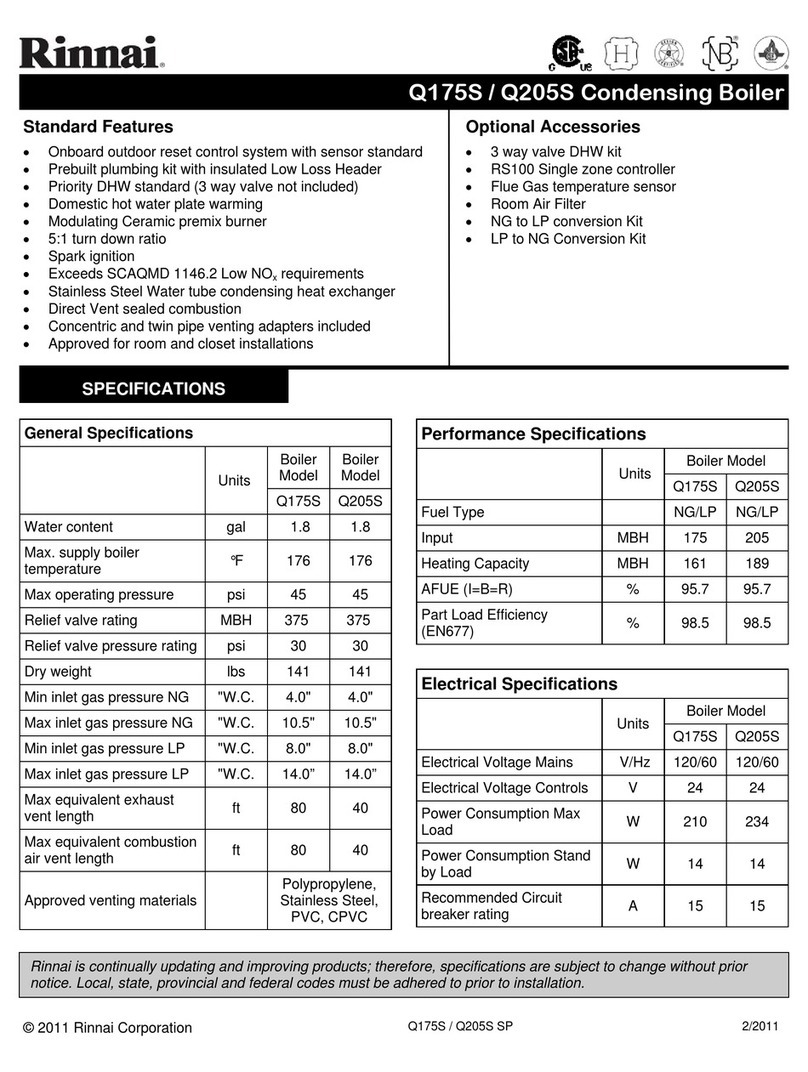

Rinnai

Rinnai Q175S Specifications

Viessmann

Viessmann VITORONDENS 200-T Service instructions

Buderus

Buderus Logano G225 Installation and service instructions

SANT ANDREA

SANT ANDREA MIRAGE E GAZ - SCHEMA manual