Mallinckrodt Nellcor NPB-70 User manual

SERVICE MANUAL

NPB-70 Handheld Capnograph

Caution: Federal law (U.S.) restricts this device to sale by or on the order of a physician.

To contact Mallinckrodt, Inc. representative: In the United States, call 1-800-635-5267: outside the United States,

call your local Mallinckrodt representative.

© 1999 Mallinckrodt Incorporated. All rights reserved. 061230A-1099

Mallinckrodt Inc.

675 McDonnell Boulevard

PO. Box 5840

St. Louis, MO 63134

Tel 314.654.2000

Toll Free 1.800.635.5267

Nellcor Puritan Bennett

4280 Hacienda Drive

Pleasanton, CA 94588

Mallinckrodt

Europe BV

Hambakenwetering 1

5231 DD ‘

s-Hertogenbosch

The Netherlands

Tel. +31.73.6485200

To obtain information about a warranty, if any, for this product, contact Mallinckrodt Technical Services or your local Mallinckrodt representative.

Purchase of this instrument confers no express or implied license under any Mallinckrodt patent to use the instrument with any sensor that is not

manufactured or licensed by Mallinckrodt.

Capnography covered by one or more of the following U.S. Patents and foreign equivalents: 4,755,675; 5,063,275; 5,300,859; and 5,657,750

+DQGKHOG&DSQRJUDSK

6HUYLFH0DQXDO

CI04185B

[This page intentionally left blank]

TABLE OF CONTENTS

List of Figures

List of Tables

Section 1: Introduction........................................................................1-1

1.1 Manual Overview...............................................................1-1

1.2 Warnings, Cautions, and Notes.........................................1-1

1.2.1 Warning..............................................................1-1

1.2.2 Caution...............................................................1-1

1.2.3 Note....................................................................1-1

1.3 Product Description ...........................................................1-2

Section 2: Required Equipment

..........................................................2-1

2.1 Required Equipment..........................................................2-1

Section 3: Cleaning

...........................................................................3-1

3.1 Cleaning ...........................................................................3-1

3.1.1 Procedure...........................................................3-1

Section 4: Service Mode

......................................................................4-1

4.1 Introduction........................................................................4-1

4.2 Service Level 1..................................................................4-1

4.2.1 Information Screen.............................................4-1

4.2.2 Event Messages Screen....................................4-1

4.2.3 Interface Test Screen.........................................4-2

4.2.4 Accessing Service Mode and Service Level 1...4-3

4.3 Service Level 2..................................................................4-5

4.3.1 Default Alarm Limits...........................................4-7

4.3.2 Default Settings..................................................4-8

4.3.3 Flow Calibration .................................................4-9

Section 5: Troubleshooting

.................................................................5-1

5.1 Introduction........................................................................5-1

5.2 Who Should Perform Repairs............................................5-1

5.3 Repair Level Supported.....................................................5-1

5.4 How to Use This Section ...................................................5-1

5.5 Obtaining Replacement Parts............................................5-1

5.6 Troubleshooting Guide ......................................................5-2

Section 6: Flow Calibration Check.....................................................6-1

6.1 Introduction........................................................................6-1

6.2 Flow Rate Check ...............................................................6-1

6.3 Flow Calibration Process...................................................6-2

Section 7: Disassembly Guide

............................................................7-1

7.1 Introduction........................................................................7-1

7.2. Opening the Handheld Capnograph Case.........................7-2

7.3 Replacing the CO2Board ..................................................7-4

7.4 Replacing the Pump Assembly..........................................7-5

7.5 Replacing the Flow System...............................................7-6

7.5.1 Replacing the lines to the pump.........................7-7

7.5.2 Replacing the lines to the solenoid ....................7-8

7.6 Replacing LCD and 7-Segment Display..........................7-10

7.6.1 Replacing the LCD...........................................7-10

7.6.2 Replacing the 7-Segment Display....................7-10

iii

Table of Contents

7.7 Replacing Housing Components.....................................7-11

7.7.1 ON/OFF Button and Gas outlet........................7-11

7.7.2 Keypads...........................................................7-11

7.7.3 Front Cover......................................................7-11

7.74 Rear Cover.......................................................7-11

7.8 Updating Software Version..............................................7-12

Section 8: Electrical Safety Tests.......................................................8

-1

8.1 Electrical Safety Tests.......................................................8-1

Section 9: Periodic Maintenance........................................................9-1

9.1 Periodic Maintenance........................................................9-1

Section 10: Performance Verification...............................................10-1

10.1 Flow System Leak Check................................................10-1

10.1.1 Flow System Leak Check Procedure...............10-1

10.2 Performance Verification Procedure................................10-2

Section 11: Packing For Shipment ...................................................11-1

11.1 General Instructions.........................................................11-1

11.2 Packing Handheld Capnograph in Original Carton..........11-1

11.3 Packing in a Different Carton...........................................11-1

Section 12: Specifications

.................................................................12-1

12.1 Physical .........................................................................12-1

12.1.1 Size..................................................................12-1

12.1.2 Weight..............................................................12-1

12.1.3 Noise Emission ................................................12-1

12.2 Environmental..................................................................12-1

12.2.1 Temperature.....................................................12-1

12.2.2 Relative Humidity.............................................12-1

12.2.3 Pressure and Altitude.......................................12-1

12.3 Safety Standards.............................................................12-1

12.4 Performance....................................................................12-2

12.5 Power Specifications .......................................................12-3

12.5.1 External Power Source ....................................12-3

12.5.2 Internal Power Source......................................12-3

12.6 Components and User interface......................................12-3

12.6.1 Displays............................................................12-3

12.6.2 Controls and Indicators....................................12-3

12.6.3 Connections.....................................................12-3

Section 13: Spare Parts

.....................................................................13-1

13.1 Spare Parts List...............................................................13-1

Glossary of Terms

iv

Table of Contents

LIST OF FIGURES 1-1 Handheld Capnograph.......................................................1-2

1-2 LCD Screen and 7-Segment Digital Display......................1-2

7-1 Removing the Battery Pack...............................................7-2

7-2 Removing Mounting Screws..............................................7-3

7-3 Separating Rear and Front Covers....................................7-3

7-4 Replacing CO2Board and Housing Components..............7-4

7-5 Replacing the Pump ..........................................................7-5

7-6 Flow System......................................................................7-6

7-7 Main Line...........................................................................7-7

7-8 Exhaust Line......................................................................7-7

7-9 Lines to Solenoid (Zeo line, Input line 1, Input line 2.........7-8

7-10 Zero line.............................................................................7-9

7-11 Replacing LCD and 7-Segment Display..........................7-10

7-12 Replacing EPROM...........................................................7-12

10-1 Leak Test Jig Connection.................................................101

10-2 Initialization Screen..........................................................10-2

10-3 Measuring Mode..............................................................10-2

10-4 Quick Guide.....................................................................10-3

10-5 Connecting the monitor to Printer/PC with

Communication Adapter Kit.............................................10-7

11-1 Packing the NPB-75 in Original Packing .........................11-2

LIST OF TABLES 4-1 Accessing Service Mode and Changing Parameter

Settings...................................................................4-3

4-2 Accessing Service Level 2.................................................4-5

4-3 Changing Default Alarm Limits..........................................4-7

4-4 Changing Default Settings.................................................4-8

4-5 Accessing Flow Calibration................................................4-9

5-1 Troubleshooting Guide ......................................................5-2

5-2 Advisory Message ............................................................5-4

5-3 Event Messages................................................................5-5

6-1 Flow Calibration.................................................................6-2

10-1 CO2Calibration Check.....................................................10-3

10-2 Calibration Process..........................................................10-5

10-3 Calibration Process -Troubleshooting..............................10-6

10-4 Accessing Handheld Capnograph Print Functions..........10-8

13-1 Spare Parts List...............................................................13-1

v

[This page intentionally left blank]

SECTION 1: INTRODUCTION

1.1 Manual Overview

1.2 Warnings, Cautions, and Notes

1.3 Product Description

1.1 MANUAL OVERVIEW

This manual contains information for servicing the Handheld

Capnograph (the monitor). Only qualified service personnel should

service this product. The Handheld Capnograph Operator’s Manual is an

integral part of the service procedures. Before servicing the monitor, read

the Operator’s Manual carefully for a thorough understanding of how to

operate the unit.

Only use the tools and test equipment as specified in this manual. Only

use original spare parts available from your local distributor.

Warning: Incorrect procedures may harm the patient, or damage

the monitor.

1.2 WARNINGS, CAUTIONS, AND NOTES

1.2.1 Warning

A warning precedes an action that may result in injury or death to the

patient or user. Warnings are boxed and highlighted in boldface type.

1.2.2 Caution

A caution precedes anaction thatmay result indamage to,or malfunction

of, the monitor. Cautions are highlighted in boldface type.

1.2.3 Note

A note gives information that requires special attention.

1-1

Section 1: Introduction

1-2

1.3 PRODUCT DESCRIPTION

The device is a Handheld Capnograph that continuously monitors end

tidal carbon dioxide (EtCO2) and respiratory rate. The monitor is for

attended monitoring only and must be used in the continuous presence of

a qualified healthcare provider. It is intended for use in any environment

where continuous, noninvasive monitoring of these parameters is desired,

including hospital and mobile use (when protected from excessive

moisture such as direct rainfall).

The monitor is intended for use on adult, pediatric, and infant/neonatal

patients.

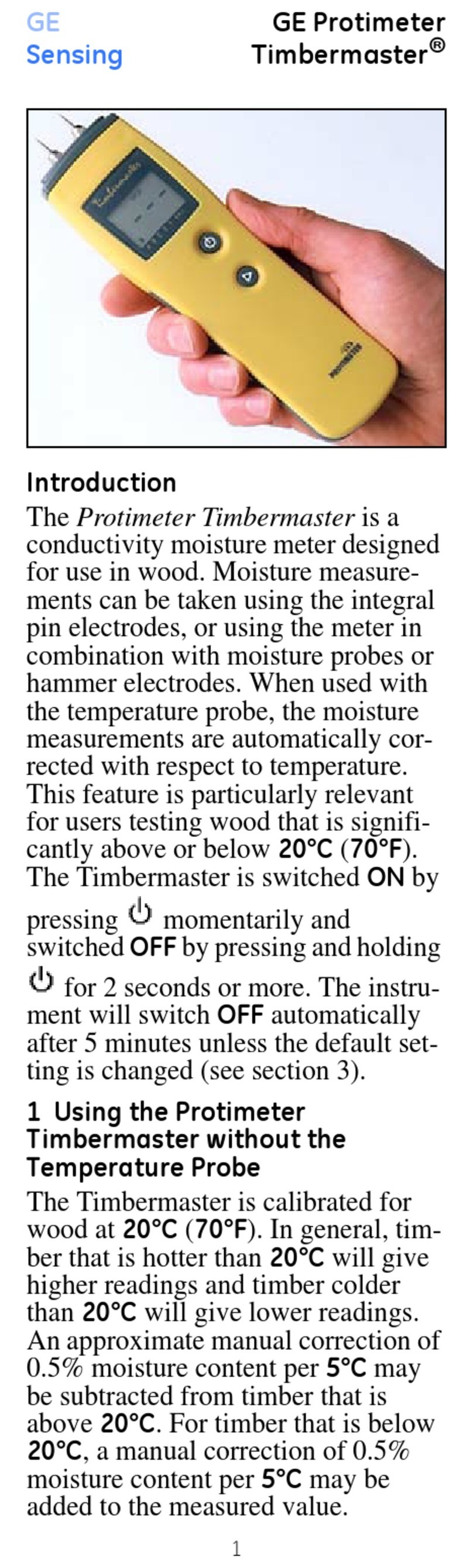

Figure 1-1: Handheld Capnograph

The monitor is operated using a four-key keypad. Measurements are

displayed on the front panel on the 7-segment LED digitaldisplays (LED)

and on the Liquid Crystal graphic display (LCD) as shown in Figure 1-2.

Refer to the Handheld Capnograph Operator’s Manual for complete

operating instructions.

Figure 1-2: LCD Screen and 7-Segment Digital Display

SECTION 2: REQUIRED EQUIPMENT

2.1 Required Equipment

2.1 REQUIRED EQUIPMENT

You will need the following equipment to disassemble, replace parts,

check, adjust, or calibrate the monitor.

Note: For ordering spare parts, contact your local distributor.

For Disassembly and Reasssembly:

• Phillips-head screwdriver (medium)

• IC Extractor for PLCC socket

• Threadlocker glue e.g. Loctite® 222 super screw lock

For Calibration, Checks and Adjustments:

• Calibration Gas (5% CO2in air)

• FilterLine or FilterLine H

• Leak Test Jig

• Vacuum manometer with a range of 0-500 mBar

e.g. MPB-3200-DM, Digital Manometer MicroPneumatic Logic, Inc.

• Communication Adapter Kit (only necessary to verify print and

PC functions)

• Seiko DPU-414 printer (only necessary to verify print functions)

• External power supply

• Handheld Capnograph Operator’s Manual

• Flow Meter e.g. Top Track Mass Flow Meter,

model: 822-13-OV1-PV1-V1, Sierra Instruments, Inc.

Warning: Observe ESD (electrostatic discharge) precautions

when handling, adjusting or performing any procedure with the

monitor internal components.

2-1

[This page intentionally left blank]

SECTION 3: CLEANING

3.1 Cleaning

3.1 CLEANING

Always clean the outer surface of the monitor before servicing.

Warning: Always wear latex or surgical gloves when cleaning

or servicing the Handheld Capnograph monitor after hospital

use.

Warning: Do not allow liquids to drip inside the housing.

Warning: Do not clean internal components.

Warning: Do not use cleaning materials based on: phenols,

halogen producing compounds, strong organic acids, or oxygen

producing compounds.

3.1.1 Procedure

1. Unplug the unit from AC mains supply.

2. With a damp cloth, gently wipe the outer case of the monitor with

a disinfectantbasd on aldheyde, alcohol or quaternary ammonium

producing compounds.

3-1

[This page intentionally left blank]

4-1

SECTION 4: SERVICE MODE

4.1 Introduction

4.2 Service Level 1

4.3 Service Level 2

4.1 INTRODUCTION

The monitorsupports aservice mode built into the instrument’s firmware.

The architecture of the monitor’s service mode divides the service mode

into two levels as described in the sections below.

• Service Level 1

• Service Level 2

To access the service mode (levels 1 and 2), refer to Tables 4-1 and 4-2.

4.2 SERVICE LEVEL 1

The Service Level 1 provides information and tools on three service

screens to test and calibrate specific functions without disassembling the

monitor.

• Information Screen

• Event Messages Screen

• Interface Test Screen

From these display screens the service technician can check the operating

hours counter and event messages, test the Human Interface functions

(HMI), set the light detection threshold, adjust the LCD contrast middle

point and do a calibration check and a calibration process, if necessary.

Refer to Table 4-1.

4.2.1 Information Screen

The information screen displays the monitor’s serial

CO2board number, the number of operating hours, and the

CO2board’s software version.

4.2.2 Event Messages Screen

The monitor automatically performs a series of built-in tests (BITs) at

start-up and during operation to check sub-systems and modules for

errors. The event messages screen lists the last five event messages, the

time each occurred relative to the unit’s operating hours, and a

recommended service action. There are two event messages and each has

a specific response as follows:

Event Message: Action:

CO2board Replace CO2board

Flow Replace Flow System and/or Pump

Refer to Section 5: Troubleshooting

Section 4: Service Mode

4-2

Note: To exit the service mode and save event messages, turn off the

monitor. Event messages will be erased when exiting the service

mode by a long press of .

4.2.3 Interface Test Screen

The interface test screen shows four parameters (listed below) that

provide tools for the user to test, adjust, and calibrate the unit’s

interfacing systems.

•HMITest

• Light Detector

• Contrast Cal. (Calibration)

•CO

2Calib. (Calibration)

4.2.3.1 HMI Test

When the HMI Test is turned on, the monitor performs a self-test of the

following sub-systems:

• Buzzer (sounds for one second)

• LCD graphic screen shows a checkerboard pattern

• 7-segment digital display (8s scroll left to right)

• Alarm bar (lights red, yellow, off)

• Backlight (turns on and off)

• Alarm silence indicator (light turns on and off)

When the HMI test is completed the status field returns automatically to

“OFF”.

4.2.3.2 Light Detector

The Light Detector parameter allows the service technician to set the

threshold value of the phototransistor. The default value is 1 and the

range is from 1 to 5 with 1 as the most sensitive (backlight on at all times)

and 5 as the least sensitive (backlight off). The threshold value should be

set according to the lighting conditions of the working enviroment. A

higher threshold value saves on battery power consumption.

Note: When the monitor’spower management is set toLow, the backlight

is off.

4-3

Section 4: Service Mode

4.2.3.3 Contrast Cal. (calibration)

The Contrast Cal. gives the service technician the option to change the

middle point default value of the contrast intensity of the LCD.

Table 4-1 describes how to change the contrast cal. settings.

4.2.3.4 CO2 Calib. (calibration)

The CO2Calib. allows the service technician to perform a calibration

check and calibration process to ensure the accuracy of the monitor.

Section 10: Performance Verification describes the calibration check and

calibration process procedure.

4.2.4 Accessing Service Mode and Service Level 1.

Table 4-1 describes how to access the service mode, change parameter

settings and how to change Contrast Cal. settings.

Table 4-1: Accessing Service Mode and

Changing Parameter Settings

Objective Action Response

To access Service Mode During self-test,

press and hold

simultaneously

and

Self-test occurs and the

Information Screen

appears:

To access Event

Messages long press

To access Interface

Test Screen long press

To change the

parameter setting or

value

short press

Section 4: Service Mode

4-4

To move to the next

parameter (moving to

the next parameter

accepts and saves

changed values)

short press

To change Contrast

Cal. setting to set short press

To start Contrast Cal. short press “Contrast Cal.” flashes.

To Adjust Contrast

Cal. middle point press

until desired

setting is reached.

(Pressing on theleft

lightens the screen,

and pressing on the

right darkens the

screen.)

Screen lightens or

darkens

To accept new setting short press

To reset and return to

measuring mode

(automatically erasing

the event messages

memory)

long press

To exit service mode

from any service

screen without erasing

the event messages

memory

Turn off the

monitor

Table 4-1: Accessing Service Mode and

Changing Parameter Settings (Continued)

4-5

Section 4: Service Mode

4.3 SERVICE LEVEL 2

The Service Level 2 gives the service technician tools on three service

screens:

• Default Alarm Limits

• Default Settings

• Flow Calibration

To access this service level, the service technician must enter a valid

password (1627), refer to Table 4-2.

Note: The password should not be disclosed to avoid unauthorized setting

of parameters.

Table 4-2: Accessing Service Level 2

Objective Action Response

To access Service

Level 2 After entering the

service mode

long press x3

Password Screen

appears

Enter Password: 1627

Enter the 1st digit short press (right)

x1

Pressing on the

right arrow scrolls

the numbers up,

the left arrow

scrolls the numbers

down.

Move to the next digit short press

Enter the 2nd digit short press (right)

x6

Repeat the same procedure as above for the next two digits (2, 7).

Section 4: Service Mode

4-6

Objective Action Response

To access the Alarm

Limits Menu after

entering last password

digit

short press

In case you entered a

wrong digit

To restart password

validation process long press

To reset and return to

measuring mode

(automatically erasing

event messages)

long press

To exit service mode

and save event

messages

Turn off the

monitor.

Table 4-2: Accessing Service Level 2 (Continued)

Table of contents

Popular Measuring Instrument manuals by other brands

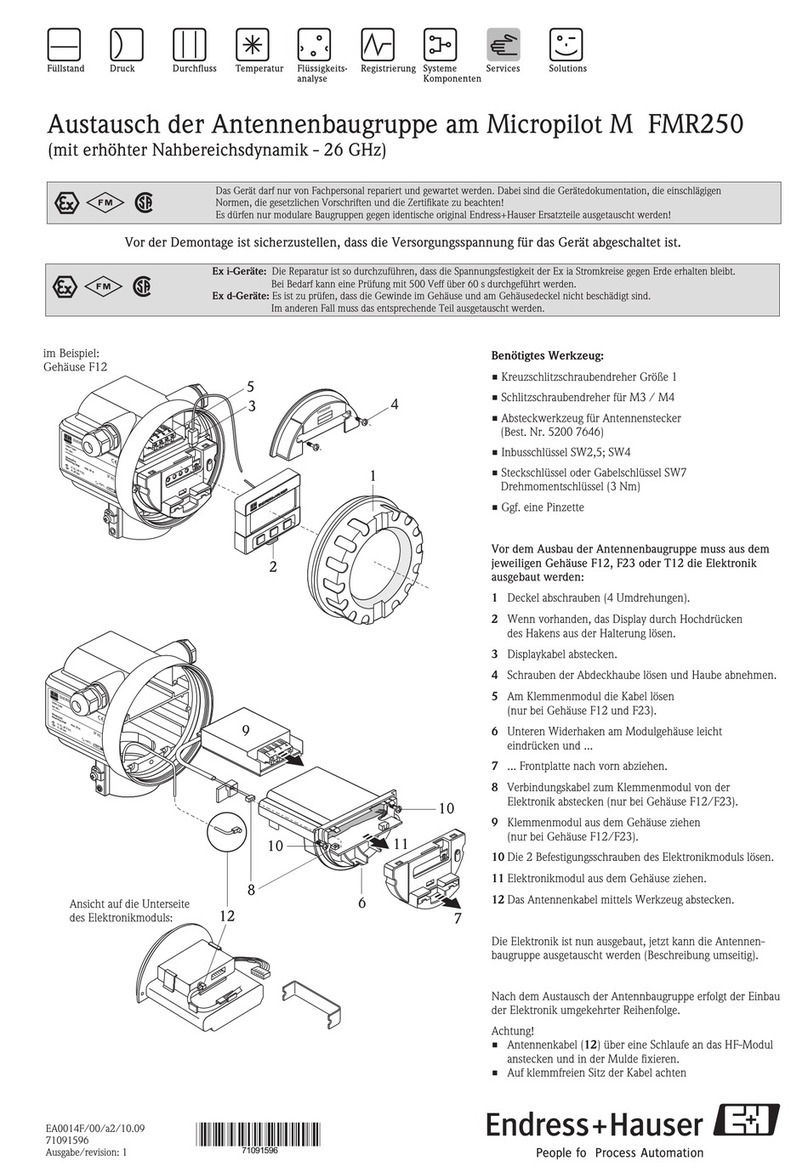

Endress+Hauser

Endress+Hauser Micropilot M FMR250 manual

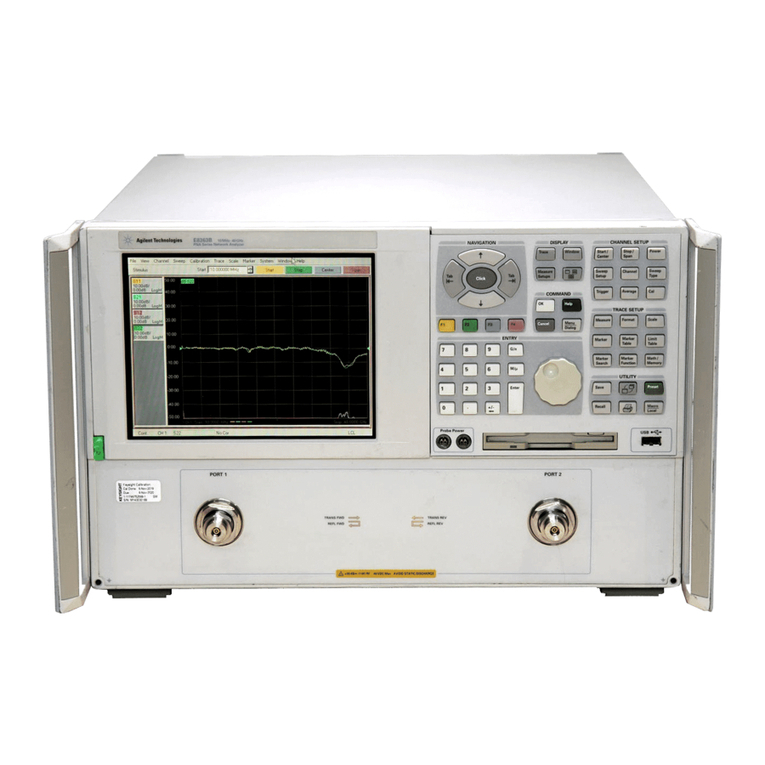

Agilent Technologies

Agilent Technologies E8362B Service guide

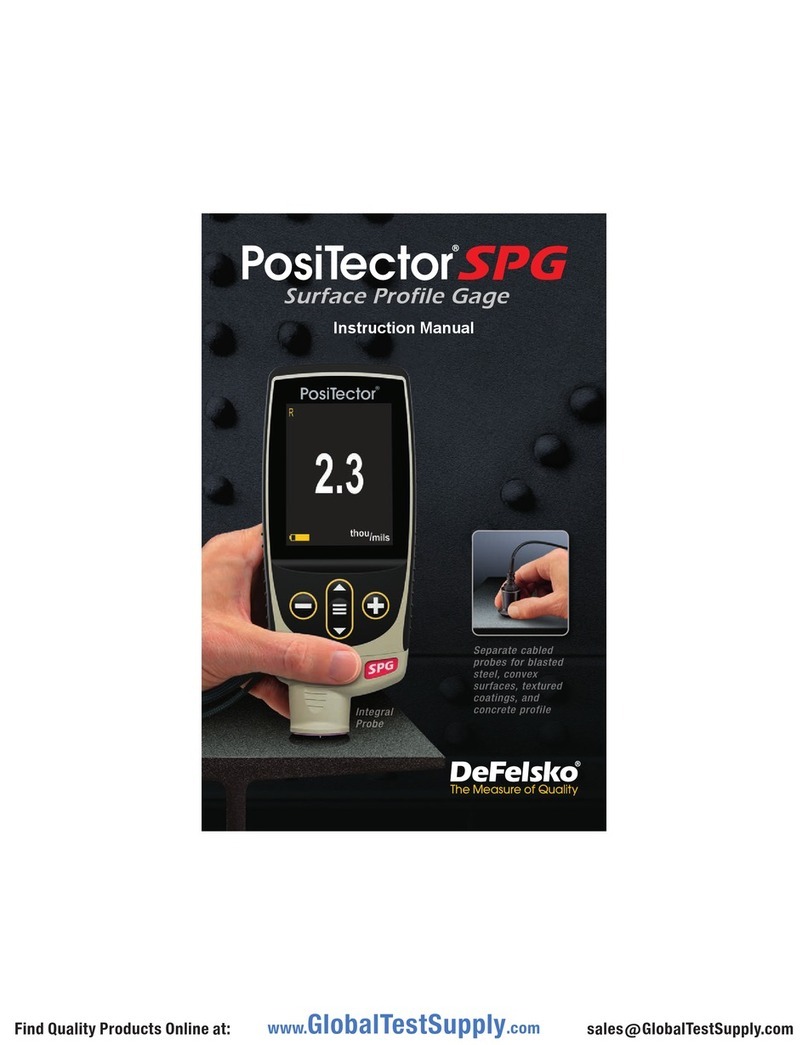

DeFelsko

DeFelsko PosiTector SPG instruction manual

Teledyne Lecroy

Teledyne Lecroy Frontline X240 quick start guide

Ametek

Ametek Western Research IPS-4 user manual

Wasatch Photonics

Wasatch Photonics XL Series quick start guide