Mangrove Jack's Kegerator Series User manual

NO MORE BOTTLING!

PERFECTLY CARBONATED BEER ON TAP

FOR WHENEVER THE MOOD STRIKES.

Cheers!

KEGERATOR

INSTRUCTIONS

BREWING.

OUR OBSESSION.

IMPORTANT SAFETY INSTRUCTIONS

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance. If the supply

cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard. This appliance is intended to be used in household and similar

applications such as: – sta kitchen areas in shops, oces and other working environments;

– farm houses and by clients in hotels, motels and other residential type environments;

– bed and breakfast type environments; – catering and similar non-retail applications.

•If pressurised aerosol containers bear the word “flammable” and/or a flame symbol, do not store them

inside the Kegerator. If you do so, you may cause an explosion.

INFORMATION ON DISPOSAL

• Most of the packing materials are recyclable. Please dispose of those materials through your

local recycling depot or by placing them in appropriate collection containers.

• If you wish to discard this product, please contact your local authority and ask for the correct

method of disposal.

• This appliance contains insulation formed with flammable blowing gases. Avoid safety hazards

by carefully disposing of this appliance.

• When you dispose of your old refrigerator, remove any doors. Children can suocate if they get

trapped inside.

WWW.MANGROVEJACKS.COM

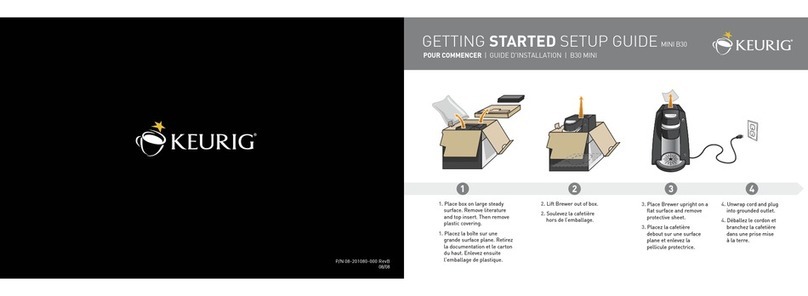

1. Remove trays and parts from inside Kegerator.

2. If you want the Kegerator on wheels then fit the wheels.

3. Fit the top rails.

4. Fit the CO2cylinder holder if required.

5. Thread the pipes attached to the tower into the Kegerator.

6. Secure the tower.

7. Crimp the black liquid disconnects to these tubes.

8. Attach spare tubing to prong of the brass gas splitter. Thread

that tube from the inside of the Kegerator through the hole

cover (insert a hole through the centre of the hole cover to do

this) at top right hand corner.

9. Crimp the regulator to this tube.

10. Leave the Kegerator upright in its final place for 1 hour before

turning it on.

ASSEMBLY IN BRIEF

BREWING.

OUR OBSESSION.

1. PREPARATION

• Remove all trays from inside the Kegerator body.

• Read your CO2Cylinder Safety Instructions that are provided with your cylinder.

• Sit ends of your tubing that are not connected to anything in a jug of warm water to

make the ends more malleable and easier to fit on to attachments if you wish to.

• Remove any plastic protective layer on the stainless steel. This layer can become

hard to remove if the unit is operated with it on.

2. FITTING THE WHEELS

• If you would like to fit the wheels to your Kegerator - Turn the Kegerator onto its side.

NOTE: You may like to lay down some cardboard first if assembling on a hard surface.

• Remove the 4 adjustable feet on the base of the Kegerator.

• Screw on the wheels using the screws from the larger bag of 16 screws.

The 2 locking swivel castors should be installed in the front of the Kegerator for

easy access.

• Position Kegerator back upright.

NOTE: The Kegerator body should be left upright for at least 1 hour before turning it on. This

allows for the refrigerant gas to settle, in order to work properly.

3. FITTING THE RAILS TO THE TOP OF KEGERATOR

• Place the 2 metal rails on top of the Kegerator so the curved sides face

upwards and the screw holes line up.

• Empty the remaining packet of screws.

• Using the 4 small screws, screw in the rails to the top of the Kegerator.

4. ATTACHING THE CO2CYLINDER SUPPORT

• Attach the cylinder support rack onto the 4 studs located at the back of the Kegerator.

Align the holes in the cylinder support with the studs and push down firmly.

WWW.MANGROVEJACKS.COM

5. FITTING YOUR CO2CYLINDER

• Slide your fully charged CO2cylinder into the stand.

NOTE: You will need to have purchased this separately.

• If your cylinder is too big, you can have this sitting on the ground behind

the Kegerator and may not need to attach the cylinder support.

6. ATTACHING THE BEER TOWER TO THE KEGERATOR

• Remove hole cover on top of Kegerator.

• Place the rubber gasket around the hole in the top of the Kegerator. Line up the screw

holes.

• Feed the tubes that run through the Beer Tower through the centre hole in the

top of the Kegerator and sit the Beer Tower on top lining up the screw holes

with the rubber gasket and the Kegerator top screw holes.

• Use the remaining screws to screw on the Beer Tower. Be sure to screw it

in tightly.

NOTE: Lift the cover at the base of the Beer Tower to find the screw holes.

• Reattach the Beer Tower lid.

• Screw on the black tap handles.

7. ATTACHING THE LIQUID DISCONNECTS

• Feed a clamp over one of the 3 m pieces of tubing in the inside of the Kegerator.

• Attach that tubing to a black liquid disconnect.

• Use a crimping tool or pliers to seal the clamp where the tubing meets the black

liquid disconnect.

• Repeat for the second 3 m piece of tubing and black liquid disconnect.

• If you have a third tap, do this for a third piece of tubing too.

• Coil the excessive hose and tie o with cable ties or similar to keep your hoses tidy.

BREWING.

OUR OBSESSION.

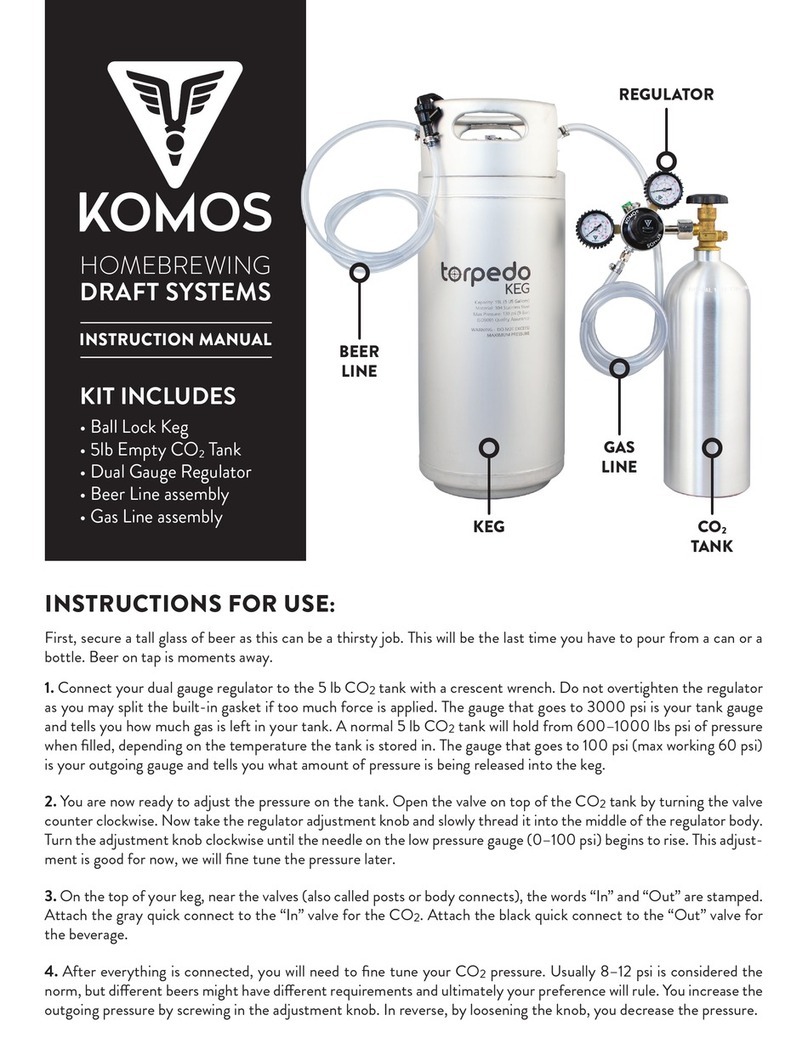

8. CONNECTING THE CO2CYLINDER

• Check your CO2Cylinder Safety Instructions for position of any nozzles and taps

before starting this step.

• You have a spare piece of 1 m tubing. Attach this to a prong on the brass gas splitter.

Feed on a clamp and using a crimping tool or pliers, seal the clamp where the tubing

meets the prong.

• Remove the hole cover at the back of the Kegerator. Insert a hole through the centre

of the hole cover. Put the hole cover back on.

• Feed this tube of the gas splitter through the hole in the hole cover at the back of the

Kegerator from the inside to the outside.

• Feed on a clamp.

• Attach this tubing to the regulator prong with the red control valve.

• Use a crimping tool or pliers to seal the clamp where the tubing meets

the prong.

• Fit the regulator to your CO2cylinder making sure the white nylon washer is in place.

• NOTE: Use a wrench to ensure it is tight enough so that no gas escapes.

WWW.MANGROVEJACKS.COM

9. FITTING AND CONNECTING YOUR KEGS

• Attach a grey gas disconnect to the “IN” side of one of the Kegs.

NOTE: To attach and detach you should push centre of disconnects down with your

thumbs while pulling the bottom up with your fore-fingers.

• Attach a black liquid disconnect to the “OUT” side of the same Keg.

• Repeat for second Keg (and third keg if you have a third tap) with remaining disconnects.

• Place Kegs inside the Kegerator ensuring that the tubing sits at the back and is not tangled.

• Place Kegerator where it has at least 30 cm clearance on either side and from the back of

the unit to the wall, to allow proper ventilation.

• Place drip tray on top of the Kegerator, turn it on and your Kegerator

is set up.

BREWING.

OUR OBSESSION.

USING YOUR KEGERATOR

1. OPENING THE CO2CYLINDER MAIN VALVE:

• Before opening the main valve located on the top

of the CO2cylinder, make sure the secondary

shut o valve located on the lower stem pipe of

the regulator is in the o position.

NOTE: When the secondary valve (handle) is

positioned horizontally, the valve is closed.

When the secondary valve (handle) is positioned

vertically, the valve is open. To open the main CO2

valve, (slowly) turn the main counter clockwise

until fully open. You will notice needles on both

gauges start to climb.

2. ADJUSTING THE CO2REGULATOR:

There are 2 pressure gauges on the CO2regulator.

The upper gauge, #1, monitors “LOW” internal Keg

pressure and must be adjusted to the correct

operating pressure of 10-12PSI/lbs. The lower

gauge, #2, monitors “HIGH” (CO2cylinder) pressure

and is not adjustable. The high pressure gauge also

acts as a fuel gauge to let you know when the CO2

cylinder needs refilling.

IMPORTANT: The internal operating pressure of

the beer keg should be adjusted and maintained

between 10-12 PSI. To adjust the “LOW” pressure

gauge;

*With your hands, turn the regulator adjustment

knob clockwise (follow the arrow on the knob)

this will increase “LOW” pressure. Counter

clockwise rotation of the adjustment knob will

decrease “LOW” pressure.

*When the required operating pressure is attained,

retighten the adjustment knob.

You are now ready to serve cold beer.

3. ELECTRONIC CONTROLS

The electronic control panel allows for total cabinet

temperature control as well as well as the option

for displaying (current) and modifying (setting) the

cabinet temperature in either degrees Celsius or

Fahrenheit.

• When you first plug in your Kegerator the LED

will display the ‘live’ cabinet temperature in

Fahrenheit and the thermostat will often be

set to 0˚C (32˚F). The following paragraphs

will explain how to modify the settings to suit

your requirements.

4. ADJUSTING THE TEMPERATURE:

*Press the up or down buttons once and release

to enter the ‘SET’ Mode. The LED display

will begin to flash and show the previous

temperature setting signifying the temperature

is ready to be adjusted.

*Use the up and down buttons to increase or

decrease the temperature by 1˚C/˚F.

5. CHANGING THE TEMPERATURE ON

THE DISPLAY:

*Press the circular selector button to alternate

the display between Celsius and Fahrenheit.

The corresponding pilot light adjacent to the

selector will aluminate to signify which unit of

temperature has been selected for display.

NOTE: In the event of a power failure, any modified

settings are lost and default settings are restored

once power resumes. We recommend using a

surge protector for this Kegerator.

6. BEER TEMPERATURE

Correct consistent temperature is an important

factor to consider when storing and dispensing

draught beer. Therefore, please adhere to the

follow guidelines:

• Beer can freeze, so it is important to select and

maintain proper operation temperatures inside

the Kegerator body.

NOTE: Beer will start to freeze at -2˚C (28˚F).

• Optimum temperatures for serving cold beer

are 2-4˚C (35.5-39˚F) (depending on the style of

beer and personal tastes).

• Temperatures that are too cool or too warm may

cause flavour loss, o tastes and dispensing

problems.

• Periodically monitor your Kegerator (adjust as

necessary).

• Keep the Kegerator door closed as much as

possible to avoid temperature fluctuations.

1. REPLACING AN EMPTY CO2CYLINDER

• Close the main cylinder valve by turning in a

clockwise direction.

• Close the secondary shut-o valve by turning to

a horizontal (east/west) position on the lower

stem pipe.

• Remove the empty cylinder.

• Remove dust cap from new and/or replacement

CO2 cylinder.

• Reattach regulator assembly to new/

replacement cylinder (tighten with wrench).

• Slowly open main valve all the way.

• Readjust regulator pressure (if necessary)

between 10 – 12PSI/lbs.

• Open the secondary shut-o valve by turning to

a vertical (north/south) position on the lower

stem pipe.

2. FILLING YOUR KEG

• Take o your Keg lid by pulling back the lid

lever. Clean and sterilise your Keg.

SEE CLEANING AND MAINTENANCE.

NOTE: You can fill it with CO2before filling it with

beer to ensure that there is no oxygen in the Keg if

you wish. Make sure you release the pressure from

the Keg before opening.

• To fill your Keg with beer, use an auto syphon to

transfer beer from your fermenter to the Keg. Do

not allow the beer to splash in the Keg as this

will introduce oxygen into your beer and create

o flavours.

• When you have finished adding your beer, put the

lid back on and close it by pulling the lever down

and make sure the Keg is sealed properly.

3. CARBONATING YOUR BEER

Attach the grey gas disconnect to the “IN” post on

your Keg.

• You can leave the beer to carbonate at 10-12PSI

over a week to fully carbonate. If you want your

beer to be carbonated faster you should increase

the PSI up to around 25PSI.

• Then 3 times over a 24 hour period rock the Keg

vigorously for 60 seconds to allow the CO2to

dissolve into the beer.

• Then release the pressure in the Keg. Do this until

your beer is carbonated to your liking.

• Before checking the carbonation of your beer

release the pressure by pulling up on the pin

pressure release valve and turn the serving

pressure down below 12PSI.

• Repeat process if not carbonated to the right level.

The Keg is now tapped and ready to draw beer.

4. DISPENSING BEER

Use the following techniques to dispense beer with

approximately 2 cm of head.

• Rinse a ‘beer clean’ (rinsed with water) glass

under cold water.

• Place glass beneath tap, and tilt at a 45˚ angle.

Leaving approximately 0.5 cm between the glass

and the tap.

• Fully draw the dispenser handle and fill the glass

to 2/3 full.

• Level the glass and finish topping o by

continuing the pour in the centre of the glass.

• Make sure the handle is fully returned to its

previous ‘o’ position when the draw

is complete.

DO NOT:

• Begin the draw with the glass in an upright

position.

• Use frosted glassware, as the temperature

between the frozen glass and the beer in the keg

can cause a ‘wild’ draw (too much foam).

• Partially (or slowly) draw the dispenser handle,

this will lead to unnecessary turbulence in the

dispenser tap as the beer travels through it,

causing a substantial amount of foam in

the glass.

5. A NOTE ON FINE TUNING YOUR KEGERATOR:

• There are three factors in fine tuning your

Kegerator, gas pressure, beer temperature and

pouring hose length. We supply 3 m hoses which

helps to reduce the pressure at the tap. This

allows you to have a higher pressure in your keg,

which adds more gas to the beer but still pours

without excessive frothing.

• The colder the beer the more gas it will hold.

3 m of hose will allow you to increase the gas

pressure on your keg to 14 PSI at 3°C and still

get a perfect pour. This should pour a beer with

a head, at a good speed and the beer should

have enough gas to continue to release gas

WWW.MANGROVEJACKS.COM

OPERATING INSTRUCTIONS

OUR OBSESSION.

BREWING.

OUR OBSESSION.

throughout the whole glass. If you want less gas

then reduce the pressure. If pouring is then too

slow then reduce the length of the tube.

• If you want warmer beer then reduce the

pressure.

CLEANING AND MAINTENANCE

Regular cleaning and maintenance is a key factor in

safe guarding the longevity of the Keg, the quality

of the dispensed beer as well as a trouble free day

to day operation of your Kegerator.

1. KEGERATOR BODY

• Always disconnect the power cord before

cleaning and/or servicing the appliance. Do not

use coarse or aggressive cleaning agents as they

can damage the control panel and/or painted

surfaces.

• Clean the exterior cabinet with warm water and

detergent, adding 1-2 spoonfuls of vinegar.

• After cleaning connect the appliance to

power supply.

• If you do not intend to use the appliance for long

periods of time, disconnect the power cord.

Clean the appliance and leave the door ajar to

reduce the mould/mildew from accumulating

inside the cabinet.

NOTE: There is no need to defrost the refrigerator,

because ice depositing on the evaporator is

defrosted automatically. Ice build up on the

evaporator during compressor operation will

(when the compressor has cycled o) defrost

automatically. Defrosted water collects inside the

drain trough and passes through the drain outlets

in the rear wall into a drain pan situated above the

compressor, where it evaporates.

2. DISPENSE SYSTEM

Beer lines have to be periodically cleaned

because of crystallised build up which forms

on the fittings, lines and taps, commonly

referred to as ‘beerstone’. If ‘beerstone’ is not

completely removed in a cleaning process it will

leave an unsanitary surface that can harbour

microorganisms which will cause undesirable

flavour and/or cause the beer to go flat. Sucient

‘beerstone’ will also lead to dispense problems

ranging from ‘wild’ beer, regardless of the

carbonation levels or quality (age) of the beer in

the Keg.

• We recommend that you clean your Kegs and

beer lines after each Keg.

• After rinsing any beer and residue out of the Keg,

add 2 tsp Mangrove Jack’s Cold Water Detergent

with 5 L of water. Put the lid on and shake well.

• Connect the gas and liquid disconnects and run

the liquid out through the tap. Work the tap a few

times to aid in cleaning. Once empty, rinse the

Keg out thoroughly, fill with 5 L of water and 2 tsp

Mangrove Jack’s No Rinse Steriliser and run this

through the tap to rinse.

NOTE: If you have trouble manipulating the tap

lever this is usually indicative that it may

require cleaning.

DO NOT apply force to move the handle in this

situation as it will likely lead to damage in the

handle and/or tap, and will not be covered by

your warranty.

Mangrove Jack’s Kegerator

• This Kegerator comes with a full 12 month warranty against any

manufacturer faults or defects

• This warranty does not cover any faults or defects caused by

power surges, exposure to excessive water or outside weather

conditions, or any operation outside the uses stated in the

instruction manual.

• For any warranty claims or informations

Contact:

Imake Australia Imake New Zealand

PO BOX 141 PO BOX 302860

Virginia North Harbour

QLD, 4014 Auckland, 0632

Australia New Zealand

Phone: 07 3630 8400 Phone: 09 415 1206

Email: ordersau@imake.pro Email: ordersnz@imake.pro

For user information contact:

info@mangrovejacks.com

or 1800 281 231 (AU Free Phone)

or 0800 003 548 (NZ Free Phone)

12 Month Warranty

WWW.MANGROVEJACKS.COM

Mangrove Jack’s Kegerator

12 Month Warranty

Fill out section below and return to your country’s address:

Imake Australia Imake New Zealand

PO BOX 141 PO Box 302860

Virginia North Harbour

QLD, 4014 Auckland, 0632

Australia New Zealand

Phone: 07 3630 8400 Phone: 09 415 1206

Email: ordersau@imake.pro Email: ordersnz@imake.pro

Unit Serial No.

Retail Outlet

Date of Purchase

Customer Name

Address

Phone

Email

BREWING.

OUR OBSESSION.

See Mangrove Jack’s for all your homebrewing

and beer dispensing needs.

Reorder: 72176

Version 6

WWW.MANGROVEJACKS.COM

BREWING.

OUR OBSESSION.

Other manuals for Kegerator Series

1

Table of contents

Other Mangrove Jack's Brewing System manuals

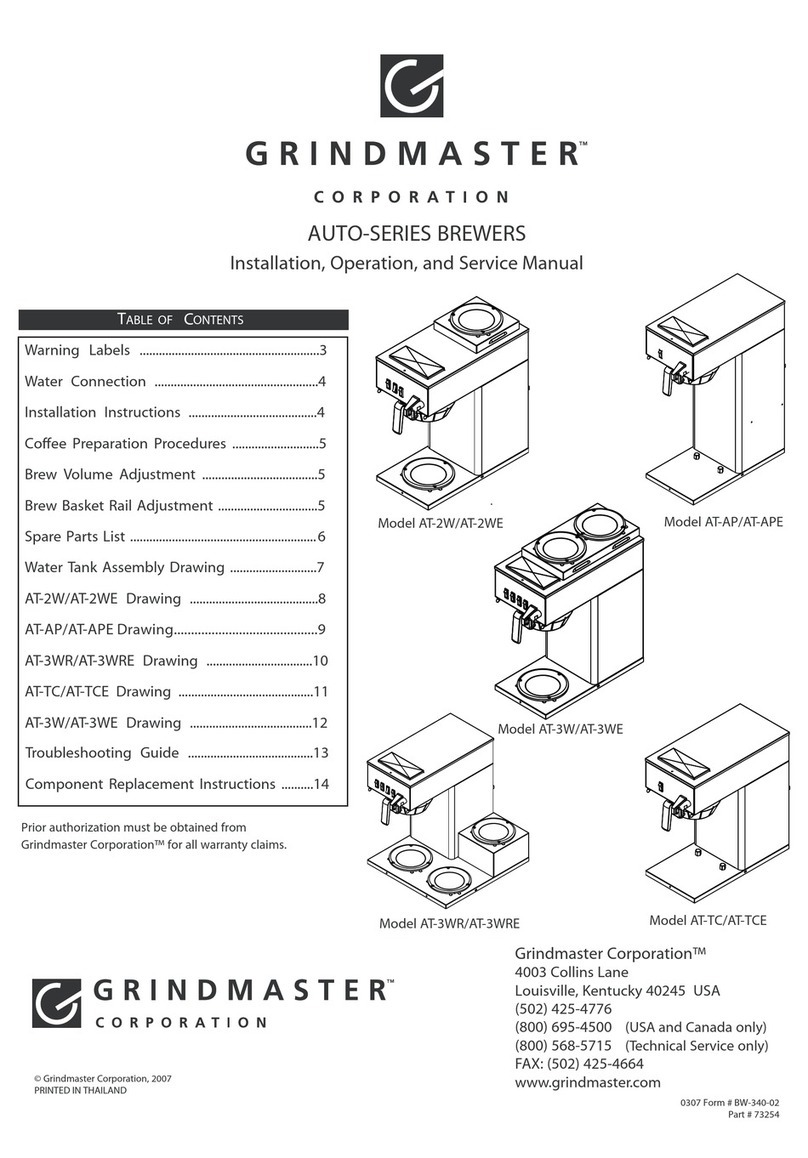

Popular Brewing System manuals by other brands

Wilbur Curtis Company

Wilbur Curtis Company Gemini GEM-612ILD instructions

BRAVILOR BONAMAT

BRAVILOR BONAMAT SPRSO English Manual

Blichmann Engineering

Blichmann Engineering TOWER of POWER Operation, Assembly & maintenance manual

Fetco

Fetco TBS-122D Users guide and operator instructions

BRAVILOR BONAMAT

BRAVILOR BONAMAT FreshMore user manual

BRAVILOR BONAMAT

BRAVILOR BONAMAT Bolero Series Technical manual