10DRNX SLM BY BROOD

TROUBLESHOOTING

QUICK SOLUTIONS

There is too much nitro The calibration knob is not

set correctly.

Follow steps in to decrease the level of infusion outlined in section “Nitrogen

Calibration”

Pouring Issue

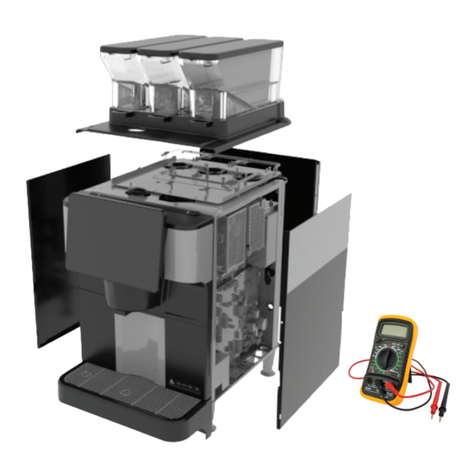

Any issue related to a bad pour is due

to a restriction in the tubes. This can

be isolated to either the beverage

tube going into the machine, or

inside the machine itself.

1. Can the pump be heard

running, but nothing, or very

little comes out of the spout?

If YES, there is a restriction in the beverage line going into the machine.

A) If using a keg, ensure it’s not pressurized.

B) Check for kinks in the beverage tube where it connects beneath the

machine. Ideally, have the beverage tube come from behind the machine

around the back leg.

C) Inspect the pre-filter for blockage by unscrewing it and cleaning the

stainless-steel mesh inside. Alternatively, bypass the pre-filter by

disconnecting the tube from the pre-filter and placing it in a container of

water. If the machine pours normally, the pre-filter is likely the issue.

D) Ensure the pre-filter isn’t reversed; it is directional, with a small arrow

indicating the flow.

E) Check that the white elbow connecting to the machine is fully inserted and

clipped in place.

F) Check that the white elbow connecting to the container is fully inserted and

clipped in place.

2. Does the pump shut o the

moment the pour button

is pressed?

If YES, there’s a blockage after the pump. To troubleshoot:

A) Turn o the machine for 4 hours to defrost any ice in the line (if present).

B) Unscrew the spout tip to check for blockage. Try pouring with the spout o.

C) Pour a cleaning solution through the machine and let it soak overnight to

lubricate and dislodge any buildup in the Module.

D) If the issue persists, reverse flush the Nitro Infusion Module. Please follow

this link for instructions on how to reverse flush the Nitrogen Infusion Module.

3. Is the flow on the NITRO

setting normal, but

lacking foam?

If YES, the Nitrogen Infusion Module requires cleaning. To troubleshoot:

A) Pour a cleaning solution through the machine and let it soak overnight to

lubricate and dislodge any buildup in the Module.

B) Unscrew the spout tip to check for blockage. Try pouring with the spout o.

4. Is the beverage spraying out of

the spout?

If the beverage sprays from the spout, it indicates a bloackage. To address this,

unscrew the cap and rinse it thoroughly.

5. Does liquid continuously drip out of

the spout?

If the liquid is dripping from the spout, it indicates that either the

Bag-in-Box (BiB) or container is empty, or the BiB/Container is positioned

above the machine.

Too many large bubbles Beverage tube is not pushed

in firmly.

Release the elbow fitting by pushing the spring underneath DRNX and

reconnect. If using a keg or a Bag-in-Box make sure that the coupler is

secured firmly.

Product is not cold enough. The temperature setting is

too high.

Check to see if the main switch underneath the machine is on. Follow the

instructions in the manual to change the temperature setting.

The cold brew in the container is too hot. The variance between the cold brew in your container and at the tap is 20°C.

This means if your cold brew is 22°C (room temperature), then the nitro cold

brew at the tap will be 2°C.

Pause for a moment betweenpours. If pouring more than 1.5 litres (48oz.) continuously and without stopping, then

it might be necessary to pause for a few minutes for the exhaust fan to turn o

until pouring a subsequent drink.