2

Mareli Systems

• “Mareli Systems” expresses its gratitude towards the clients who purchased the manufactured products.

• “Mareli Systems” provides the present manual as an aid to the team, which will install, adjust and main-

tain the device, as well as to the client which will exploit it.

• “Mareli Systems” requires that the technicians who will carry out the above mentioned procedures have

passed a training course on the activities, associated with this product.

ATTENTION! For Your safety, it’s necessary to read carefully this manual as well as the exploitation and instal-

lation manual of the automated pellet burner before attempting any installation, adjustment and exploitation

activities. Also read the installation and exploitation manual of the pellet bunker if the device is provided with

one. e non-fulllment of prescriptions and violation of active regulations and directives may lead to damage

and unexpected consequences for which “Mareli Systems” accepts no responsibility.

Do not discharge into garbage container!!!

is sign on the burner means that the product must be disposed of only in an a specially designated for

that purpose space for the collection and recycling of waste. Disposal of this device falls under the regulation

of the Directive on waste of electrical and electronic equipment (EEE) of the European Union. Dear custom-

ers, let us contribute to the preservation of the environment!

•

is appliance is not intended for use by persons (including children) with limited physical, sensory or

mental abilities or lack of experience and knowledge. e installation must be performed by a qualied

expert in the eld of heating installations or authorized by “Marelli Systems’ service. e place and way

of connecting the product should be selected carefully in accord with the safety instructions. Install

away from ammable objects!

•

Never try to make changes to the torch! It is forbidden to use ammable liquids for ignition! Servicing

the burner decorating your done by an adult who is familiar with the operating conditions!

•

Introduction of inammable liquids in room with a working burner is strictly prohibited!

•

Children should not be le unattended in the room where the product is installed!

•

Safe distances: When installing the product a safe distance of at least 200 mm must be respected. is

distance applies to the product located near materials of B or C ammability level. e safe distance is

doubled if the product is close to materials of C3 combustion level.

1. Description and advantages of pellet burner “SMB 50 Rotary”

Pellet burners of this series are designed to utilize wood pellets. It has a welded steel construction. e result-

ing heat is absorbed by the heat exchange surface of the boiler body and transmitted in the heating system.

ese boilers used for heating in local heating systems, but also for heating domestic water.

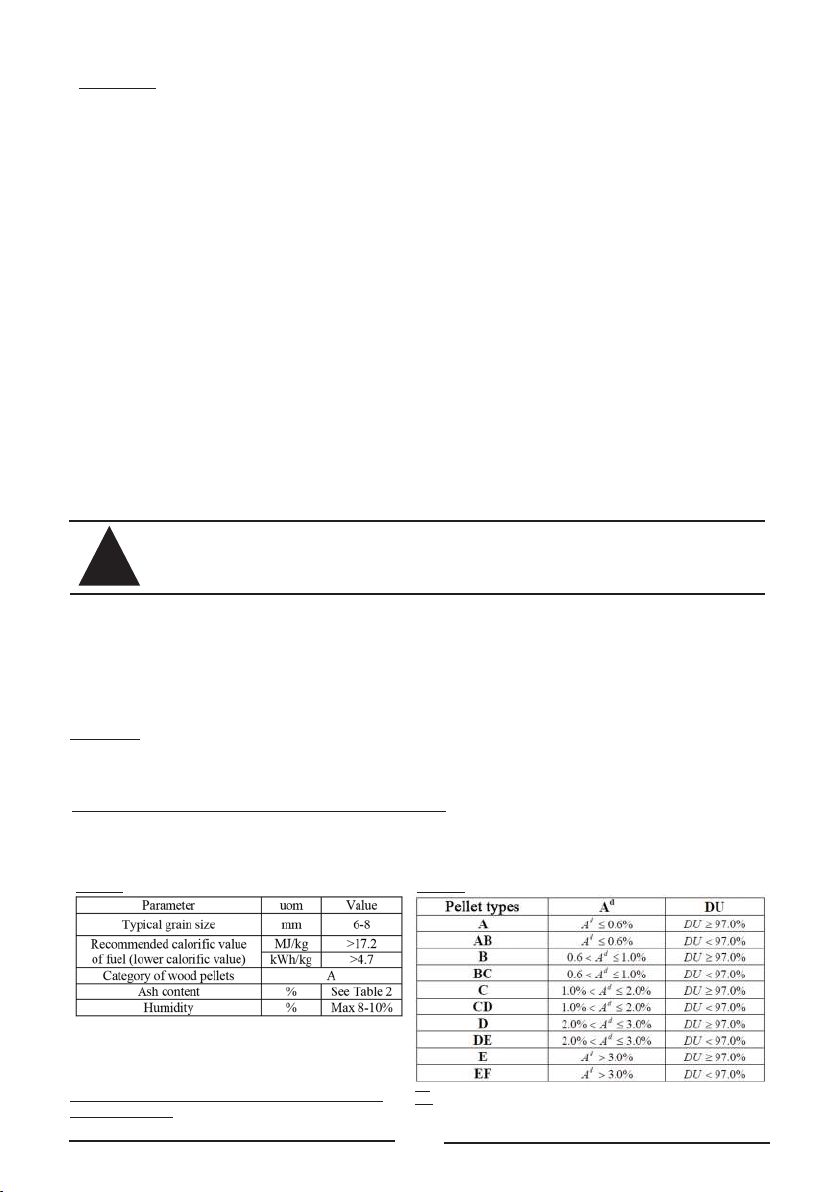

Automated pellet burner is part of the system and can utilize the following types of fuel: Wood pellets size 6

and 8 mm Class A;

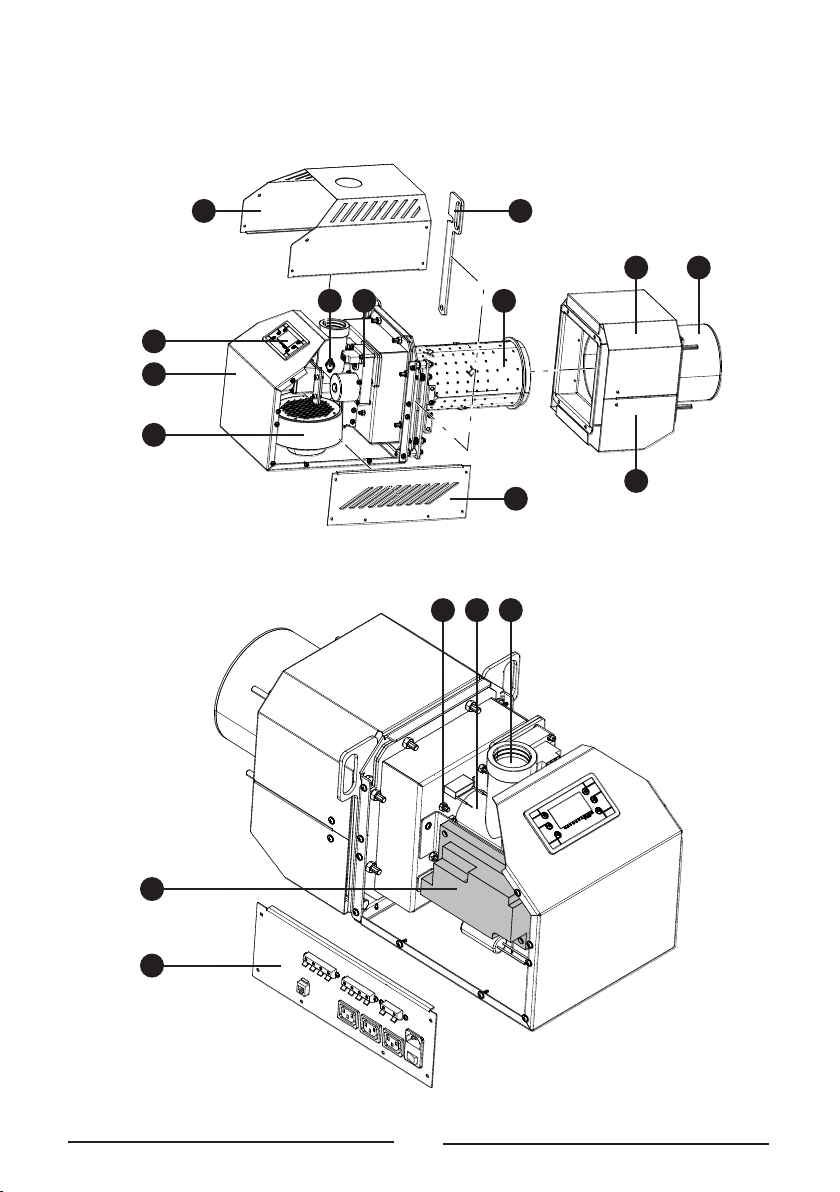

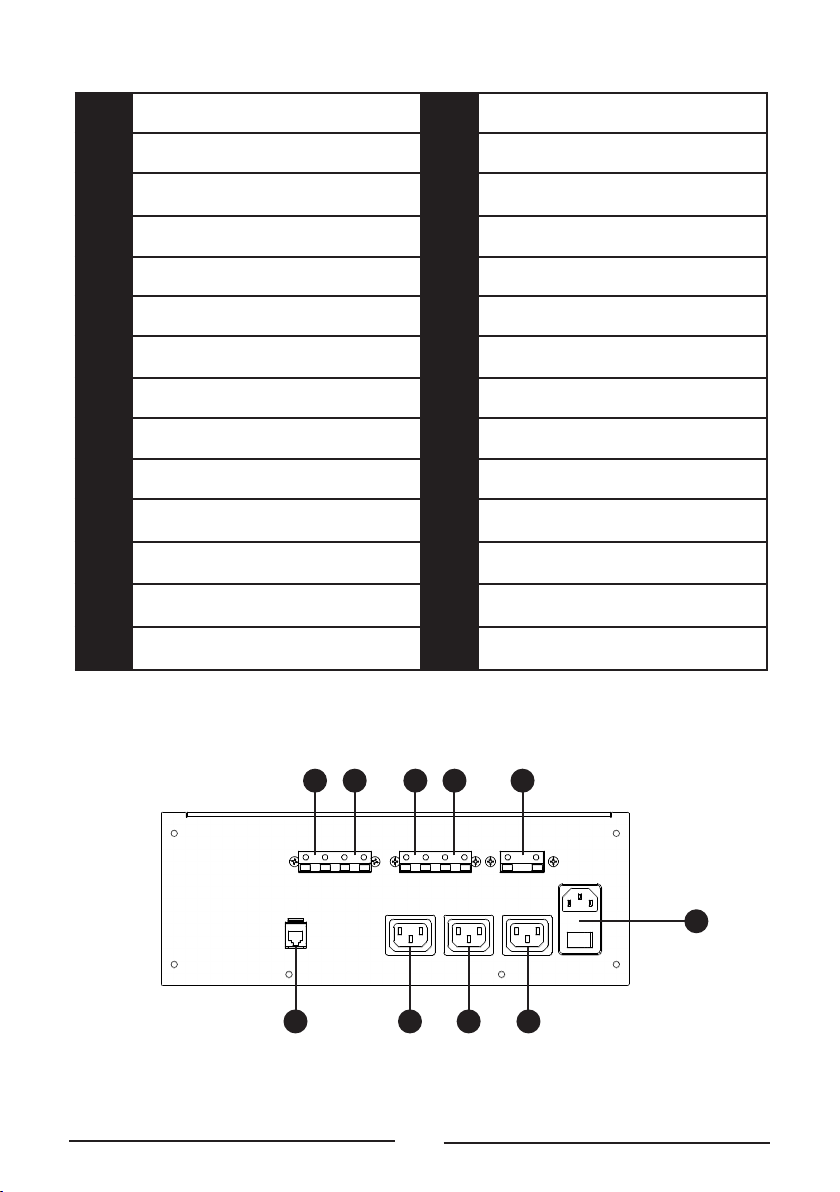

e kit comprises: pellet burner equipped with a control panel;

Advantages of the product:

• Designed to utilize pellets, making it cleaner for the environment;

• Product is highly automated and can be used in systems with programmable room thermostat ensuring

maximum thermal comfort and fuel economy;

• Eciency;

• Low emissions;

• Compact design allowing for simple installation and easy maintenance and cleaning;

• Opportunity for domestic hot water (DHW);

• Minimal operating costs;

Basic information of pellet burner:

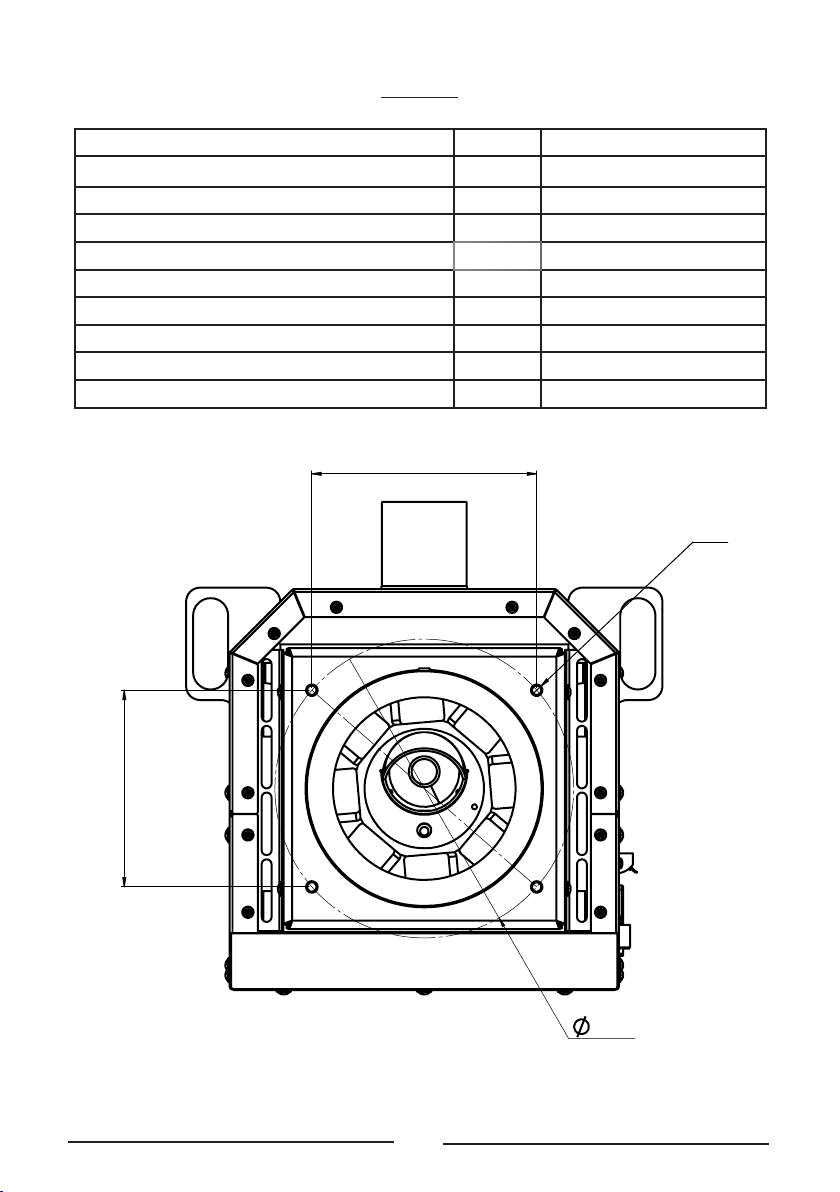

• e pellet burner is mounted horizontally secured by M8 screws.

• e pellet burner is an independent module that can be mounted on already installed boilers making it

compatible with wood pellets as a fuel source.

• e burner is equipped with a control panel.

• Wood pellets allow easy automation of the process of combustion and give high eciency. However, the

wood pellets and any other solid fuel also create ash as a bi-product, but its amount is less than what

remains from rewood or coal.