marinco 10108 User manual

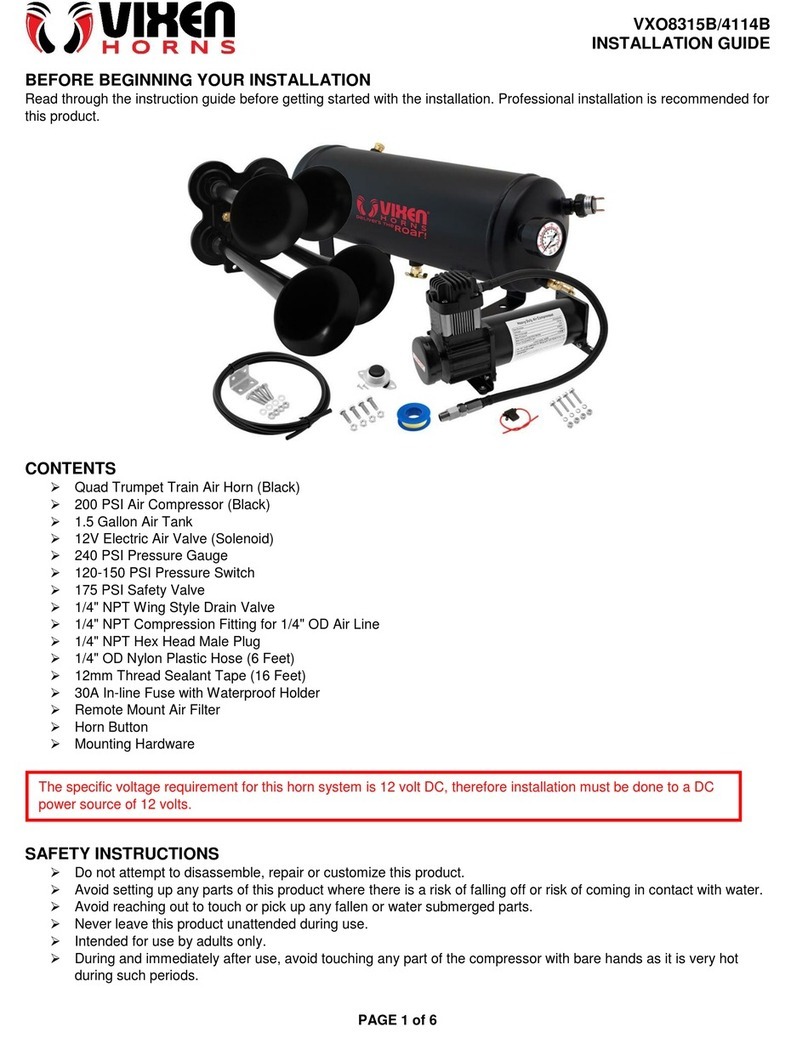

Dual Trumpet Mini Air Horn

10108 & 10121

Installation Instructions

www.marinco.com | 800.307.6702

Dual Trumpet Mini Air Horn

10108 & 10121

2

Required for Installation and Not Included With this Horn:

• #10 Size Pan-head Mounting Screws (2)

• 8mm Bolt (1) or 1/4” Pan-Head Screws (2) (For Compressor Mounting)

• 1/4” Female Quick-Connect Tabs (2)

• Horn Button Rated For 20 Amps

• 20 Amp Fuse & Fuse Carrier

• Red Stranded Wire (For Positive)*

• Black Stranded Wire (For Negative)*

* See Wiring Chart For Wire Size

Tools Required for Installation:

• Phillips-Head Screwdriver

• 7/16” Drill Bit

• Electric Drill

• Soldering Gun & Solder (Optional)

• Crimping/Cutting Pliers

If any hardware components are missing, please contact Marinco Customer

Service at 1-800-307-6702.

www.marinco.com | 800.307.6702

Installation Instructions

3

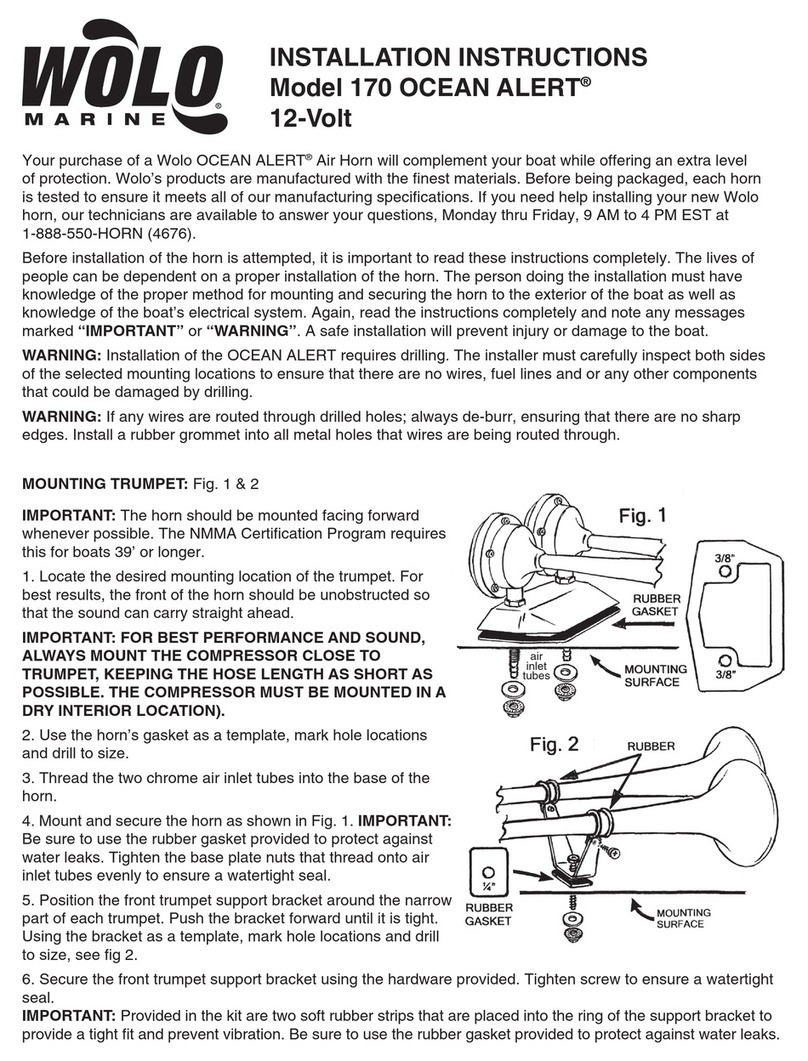

Horn Installation

1) Determine the mounting position of the horn. Be careful to select a location

with minimum deck curvature and where a minimum amount of spray will hit

the horn when the boat is underway. Whenever possible, the horn should be

mounted with the two trumpets pointing downward so that it does not collect

water spray.

2) Screw the tubing connector into the nut on the base of the horn and tighten

securely.

Note: The tubing connector provided will work for decks up to 3/4” thick.

For thicker decks, counter-bore the deck hole from under the deck surface.

3) Using the horn base gasket as a template, determine the location for the

tubing connector hole.

4) Mark and drill a 7/16” hole through the deck. Before drilling, check to make

sure you are not going to drill through something vital, such as wiring or

plumbing.

5) Place the gasket on the horn base. Place the horn assembly on the deck

with the tubing connectors fitted into the holes.

6) From under the deck surface, place the washer and nut on the tubing

connector and tighten until snug.

7) Cut two 4” lengths of air hose. Connect each 4” air hose to the tubing

connectors by sliding them over the fittings and pressing them up about 3/4”.

Connect the other end of each 4” air hose to the three-prong tee fitting. If you

have difficulty getting the air hose onto the tee fitting, heat the air hose by

placing it into a pan of hot (not boiling) water until it is soft, then slide it over

the tee fitting.

www.marinco.com | 800.307.6702

Dual Trumpet Mini Air Horn

10108 & 10121

4

www.marinco.com | 800.307.6702

Installation Instructions

5

Compressor Installation

1) For maximum efficiency the compressor should be mounted as close as

possible to the horn. A shorter length of air hose will improve performance.

The compressor should be mounted on a firm surface where it will be

protected from moisture and high temperatures, but is still accessible for

maintenance purposes. The compressor should be mounted vertically with

the air port facing up.

2) The compressor can be mounted two ways: by using the metal mounting

strap or the mounting side-bracket on the compressor.

Strap

• Place the strap over the center of the compressor.

• Install the strap nut and bolt through the holes in the bottom of the strap

and tighten until the strap is snug around the compressor.

• Mount the compressor and strap using two 1/4” size pan-head screws of

appropriate length.

Side-bracket

• install an 8mm bolt and “hang” the compressor on the bolt.

3) Trim the air hose to the proper length using a sharp knife.

4) Install the air hose onto the compressor by sliding it over the air port opening.

Be sure there are no kinks in the air hose that will impede air flow.

5) Lubricate the compressor every 4-5 months to prevent possible loss of

air volume. To lubricate the compressor, remove the air hose from the

compressor air port and place 3 to 4 drops of light machine oil into the air

port opening. Do not over lubricate. Let the oil set for a few minutes and

then activate the compressor momentarily to distribute the oil.

Failure to activate the compressor before re-connecting the air hose may

result in oil being blown onto the horn diaphragm and contaminating it.

6) Re-connect the air hose.

www.marinco.com | 800.307.6702

Dual Trumpet Mini Air Horn

10108 & 10121

6

Compressor Wiring

NOTE: The following items are needed to complete the wiring of the horn and are

NOT included: horn button, 20-amp fuse and fuse carrier, two 1/4” female quick-

connect tabs and the proper length and gauge of stranded wire (see Wire Size

chart).

1) Select the proper stranded wire size for the length of wire you will need from

the Wire Size chart.

2) The length of wire should be sufficient to allow enough slack to prevent

undue tension at the connection points.

3) Connect the wires as shown in the wiring diagram. It is recommended that

the quick-connect tabs be soldered to the stranded wire for the best and most

reliable connection to the compressor. Suggestion: Use the Marinco Direct

Connect Multi Connection Battery Terminals (Part #12VTR) to connect the

wiring to the battery.

4) If horn volume is weak, recheck all the wiring and air hose connections.

Wire Size Chart for 12V Installation

Length of Wire* Wire Size

0-20 Feet (0-5 Meters) 14 AWG (1.9 mm)

21-30 Feet (6-9 Meters) 12 AWG (2.3 mm)

31-50 Feet (10-15 Meters) 10 AWG (3.0 mm)

51-80 Feet (16-24 Meters) 8 AWG (4.0 mm)

Over 80 Feet (Over 24 Meters) 6 AWG (5.3 mm)

To replace an electric horn with this air horn you may need to replace the wiring with a

heavier gauge wire and fuse that will carry 20 amps as shown in the Wire Size Chart.

AWG: American Wire Gauge

*As measured from the battery to the compressor and back to the battery (round trip).

www.marinco.com | 800.307.6702

Installation Instructions

7

Troubleshooting Tips

If the air horn does not produce any sound or is low in volume, check the

following:

1) Check to see if the 20A fuse has blown.

2) Check the air hose for kinks that could impede air flow.

3) Check the wiring for broken or frayed wires. Check the compressor with a DC

volt meter. Make sure there is 12 volts across the two compressor terminals

while the horn button is being pushed.

4) Check the horn diaphragm. Remove the 5 phillips head screws on the

horn end cap and remove the plastic diaphragm. Inspect the diaphragm

for contamination. If there is dirt or oil on it, clean with a soft dry cloth and

re-install. In the unlikely event that the diaphragm is torn, call AFI customer

service for replacement part #20147.

5) Check compressor lubrication. If the compressor has not been lubricated on

a regular basis (every 4-5 months) it could lose air volume. Lubricate as per

instruction #4 under “Mounting The Compressor”.

6) It is very important that when lubricating the compressor, the oil is allowed

to settle and the compressor is activated BEFORE re-attaching the air hose.

Failure to do this may result in oil being blown onto the diaphragm and

contaminating it.

www.marinco.com | 800.307.6702 | FAX 800.799.3779

12/2012 20142

Warranty information: www.marinco.com/limited-warranty

This manual suits for next models

1

Table of contents

Popular Horn manuals by other brands

Elk Products

Elk Products 45 user manual

Valcom

Valcom V-1050C user manual

Cooper Wheelock

Cooper Wheelock DB3 Series specification

Altec Lansing

Altec Lansing 811B HF HORN manual

RF Elements

RF Elements UltraHorn CC Series quick start guide

Edwards Signaling

Edwards Signaling 869DSTR-G1 Series Installation sheet