RJ12

2 RJ12_v1_EN_220223

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . 3

1.1 Important user information . . . . . . . . . . 3

1.2 About this manual. . . . . . . . . . . . . . .3

1.3 Intended use . . . . . . . . . . . . . . . . . 3

1.4 Regulatory information . . . . . . . . . . . . 3

1.5 Nameplate . . . . . . . . . . . . . . . . . . 4

1.6 Recycling information . . . . . . . . . . . . .4

2 Safety. . . . . . . . . . . . . . . . . . . . 5

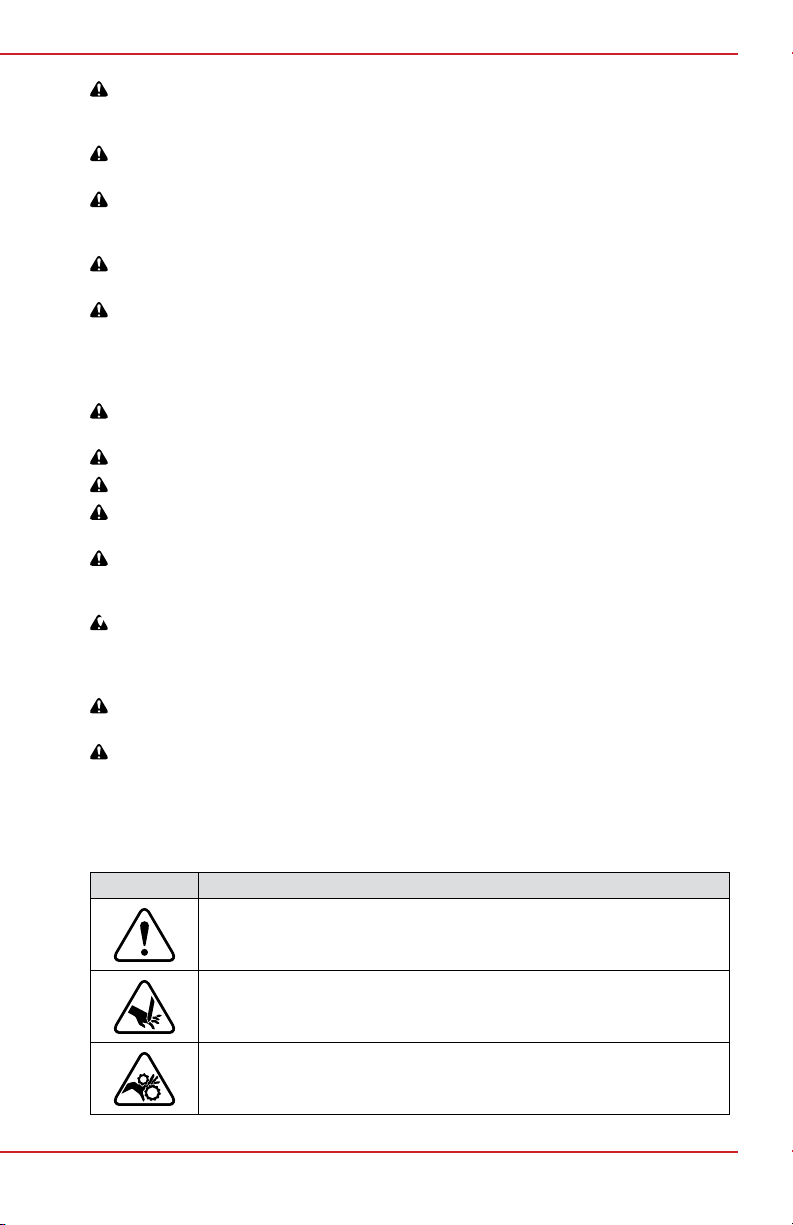

2.1 Safety notices . . . . . . . . . . . . . . . . .5

2.2 Safety instructions . . . . . . . . . . . . . . 5

2.2.1 Work area safety. . . . . . . . . . . .5

2.2.2 Electrical safety . . . . . . . . . . . . 5

2.2.3 Personal safety . . . . . . . . . . . . 6

2.2.4 Power tool use and care. . . . . . . .6

2.2.5 Service. . . . . . . . . . . . . . . . .7

2.3 Signs and symbols . . . . . . . . . . . . . . 7

3 Product Description. . . . . . . . . . . . . 9

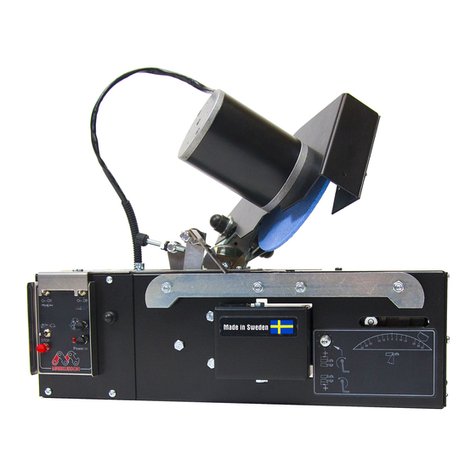

3.1 Product overview . . . . . . . . . . . . . . . 9

3.2 Front view . . . . . . . . . . . . . . . . . . .9

3.3 Back view . . . . . . . . . . . . . . . . . . 10

3.4 Grinding head . . . . . . . . . . . . . . . 11

3.5 Controls . . . . . . . . . . . . . . . . . . . 12

3.6 Chain overview . . . . . . . . . . . . . . . 13

3.7 Technical data. . . . . . . . . . . . . . . . 13

4 Installation . . . . . . . . . . . . . . . . . 14

4.1 Safety during installation . . . . . . . . . . 14

4.2 Site requirements . . . . . . . . . . . . . . 14

4.3 Unpack the machine . . . . . . . . . . . . 14

4.4 Bench-mount the machine . . . . . . . . . 15

4.5 Install and center the grinding wheel . . . . 15

4.6 Test the machine before first use . . . . . . 16

5 Operation . . . . . . . . . . . . . . . . . .17

5.1 Safety during operation . . . . . . . . . . . 17

5.2 Prepare for operation . . . . . . . . . . . . 17

5.2.1 Prepare the grinding wheel . . . . . 17

5.2.2 Set the head-tilt angle . . . . . . . . 18

5.2.3 Set the top-plate angle. . . . . . . . 18

5.2.4 Insert the chain . . . . . . . . . . . 19

5.2.5 Set the chain pusher. . . . . . . . . 19

5.2.6 Set the grinding depth . . . . . . . . 20

© 2022 Markusson Professional Grinders AB - All rights reserved.

5.2.7 Set the cutter top plate to

equal lengths . . . . . . . . . . . . 21

5.2.8 Center the grinding disc . . . . . . . 21

5.2.9 Set the grinding length. . . . . . . . 21

5.2.10 Test the grinding settings . . . . . . 22

5.3 Operate the machine . . . . . . . . . . . . 22

5.4 Depth gauge grinding . . . . . . . . . . . . 24

6 Maintenance and Service. . . . . . . . . .26

6.1 Safety during maintenance . . . . . . . . . 26

6.2 Frequency of maintenance . . . . . . . . . 26

6.3 Change the grinding wheel

and fit the grinding wheel guard . . . . . . 27

6.4 Fasten the chain lock . . . . . . . . . . . . 27

6.5 Check and adjust the wire . . . . . . . . . 28

6.6 Service . . . . . . . . . . . . . . . . . . . 29

7 Troubleshooting. . . . . . . . . . . . . . .30

7.1 Troubleshooting procedure . . . . . . . . . 30

7.2 Sharpening test . . . . . . . . . . . . . . . 30

7.3 Issues . . . . . . . . . . . . . . . . . . . . 31

8 Accessories and Spare Parts. . . . . . . .32

8.1 Ordering information . . . . . . . . . . . . 32

8.2 List of accessories. . . . . . . . . . . . . . 32

8.3 Spare parts . . . . . . . . . . . . . . . . . 33

9 Declaration of conformity . . . . . . . . . .35