MGTE 1-1/2” METERED & TIMECLOCK

INSTALLATION

4

INSTALLATION INSTRUCTIONS

A. GENERAL

1. Shut off all water at main supply valve.

2. Shut off the fuel supply to water heater.

3. Open faucets (hot and cold) nearest pump or water meter to relieve pressure and drain system.

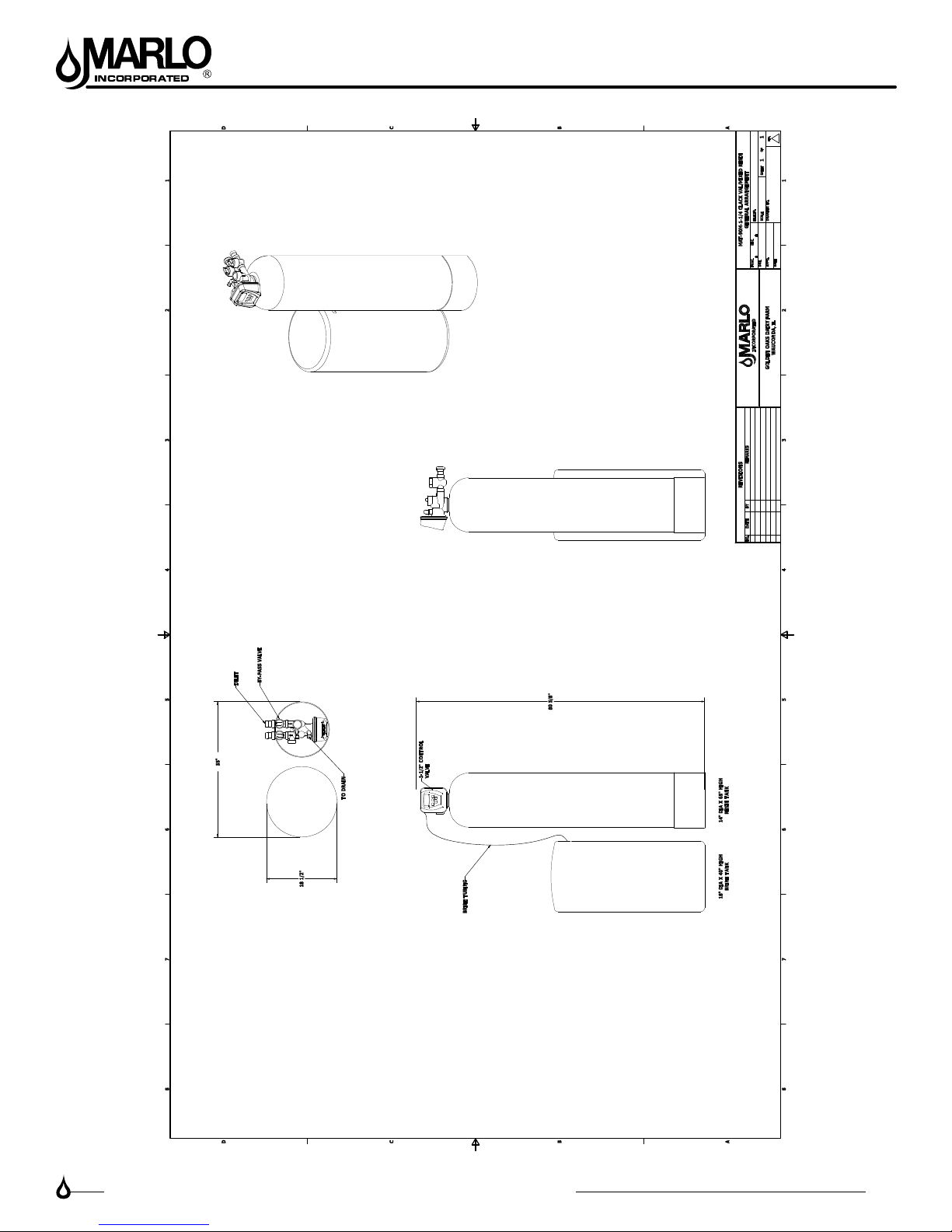

4. Move softener into the installation position.

5. Level the unit. Place shims under cabinet or brine tank as needed. (Do Not use metal shims.)

6. Cut the cold water supply line as required.

B. PLANNING INSTALLATION

1. All installation procedures must conform to local plumbing, electrical and sanitation codes and ordinances.

2. It is recommended that outside faucets for lawn service be on the hard water line, ahead of the softener, to

conserve softened water, save salt and prevent lawn damage.

3. CAUTION: The inlet water temperature MUST NOT exceed 1100 F.

4. Do not locate softener where ambient temperature drops below 400 F.

5. Allow space around the softener for ease of servicing.

6. The softener drain lines must never be solidly connected to the sewer line. (Always provide an air gap at

the END of the drain line). Valve drain line must not be elevated over 5’ from the top of the softener on well

systems, and not over 8’ on municipal water systems.

7. The salt storage cabinet or brine tank is a gravity drain, and this drain line must be lower than the drain t-

ting on the side wall of the cabinet.

8. Move the softener into position. MGTE-60 systems have been pre-loaded at the factory. For systems larger

than the MGTE-60, complete section C before continuing on to section D.

9. IMPORTANT: Be sure that the water inlet line is connected to the “inlet” side of the valve. If water lines

are reverse, (inlet/outlet) resin may be forced from the water softener into the plumbing system. If this

occurs,the plumbing system must be ushed clean.

C. LOAD SOFTENER TANK

Note: If the system is skid mounted, it will be prepiped and preloaded at the factory. Skip the following

instructions.

1. On Model MGTE-60 the softening media has been pre-loaded at the factory. Skip this section and go to

“Mounting Control Valve Assembly”.

2. Fill a tank approximately 1/3 full of water using a hose, bucket, etc. Plug the PVC distributor manifold ..

pipe using a plastic cap, cork, rag, etc. No gravel or resin should go into this distributor manifold pipe.

3. Verify the distributor manifold is center in the tank with the distributor resting on the bottom of the tank.

Verify the riser pipe is still plugged.

Note: Reference the specication table in the front of this manual for the correct quantities of gravel and

resin. Make sure you have the required amounts on site before you begin.

4. With care not to damage any lateral, pour in the gravel provided for each tank through the top opening in

the tank and level out evenly. This will cover the distributor assembly.

Note: Wetting the gravel in the bags before loading will eliminate the normal amount of dust.

5. When gravel is loaded and leveling is completed, proceed as follows:

6. With the distributor riser pipe still plugged, add the proper amount of resin supplied through the top

opening in the tank.

Caution: The softener resin is very slippery. Take care when stepping on any spilled resin. Remove spilled

resin from standing surface immediately.

7. When loading is complete, remove plastic cap, cork, or rag that was used to plug the distributor riser

pipe. Be careful not to let any foreign debris fall into the pipe. The result could be damage. Repeat steps 1-7

for each softener tank (if applicable).