RECOMMENDED EXTENSION CORD GAUGES

Length of Cord in Feet 115V 25 Ft.- 50 Ft. - 100 Ft. - 150 Ft. - 200 Ft. - 250

Ft. - 300 Ft. - 400 Ft. - 500 Ft.

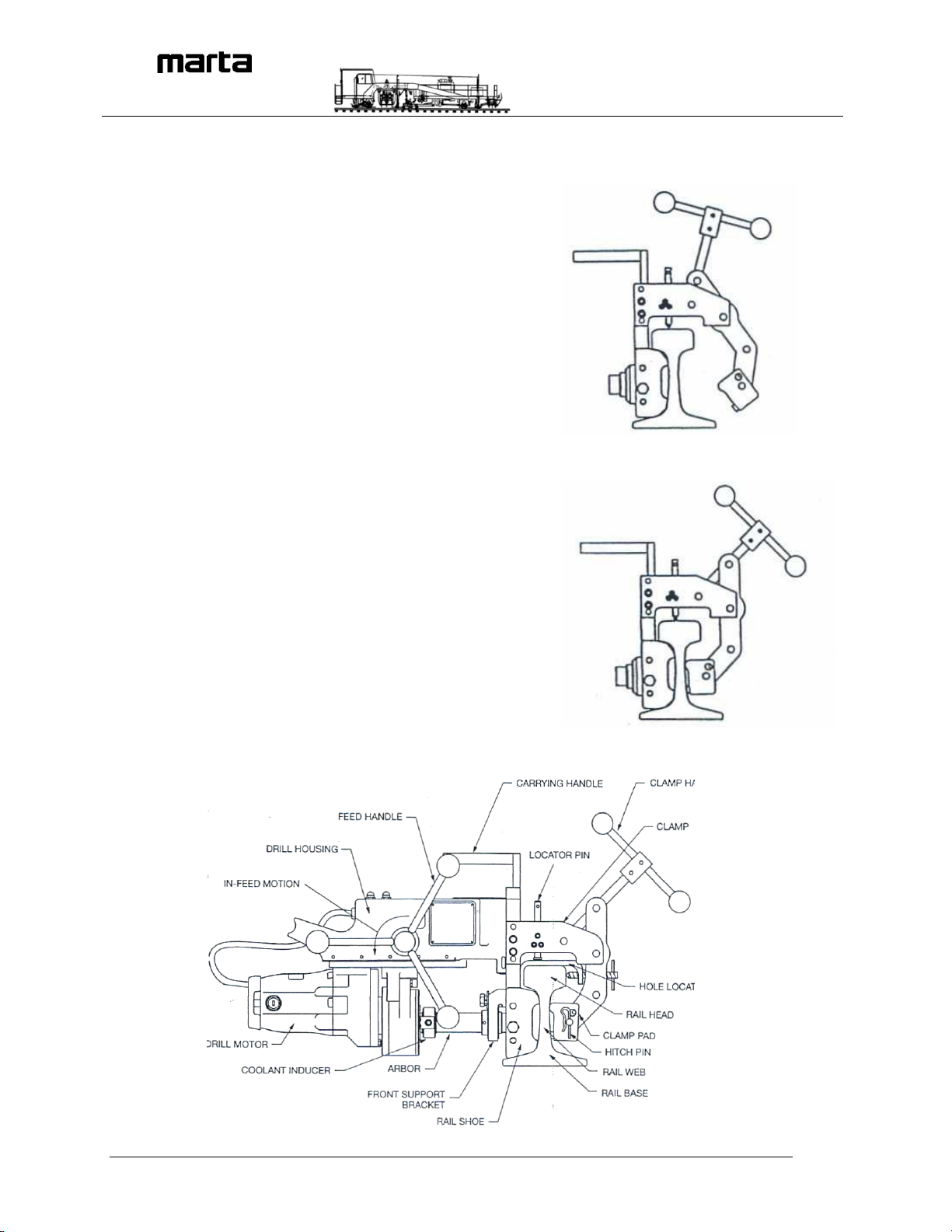

CHECK OUT CONTROLS BEFORE INSTALLING CUTTER

IMPORTANT: Before turning on the machine, it Is imperative that the operator

know and understand instructions for safe operation, correct operation

procedures and the location and interaction of control panel components and

other related features.

MOTOR START SWITCH - Starts the motor. (This is a relay operated motor

control. The unit will not restart after a power interruption without depressing

the start switch again.)

MOTOR STOP SWITCH - Deactivates Motor

LINE ON - Light indicates unit has power.

CIRCUIT BREAKER - Provides motor overloads protection with reset button

capabilities. Plug unit into proper 115 volt AC power source. ‘Line On’ light

should come on. DO NOT use with DC power.

CHECK OUT OPERATION OF CONTROLS BEFORE

INSTALLING A ROTABROACH CUTTER

IMPORTANT: Before turning on the machine, It Is

imperative that the operator know and understand

instructions for safe operation, correct operation

procedures and the location and interaction of control

panel components and other related features.

MOTOR START SWITCH - Starts the motor. (This is a relay operated motor

control. The unit will not restart after a power interruption without depressing

the start switch again.)