Specication

GCLAMP/F

Fused Drummond G Clamp

ELECTRICAL SPECIFICATIONS

Applied electrical contact force: 40N +/- 5N

Maximum working voltage: 600V AC

Maximum working current: 10A

GENERAL SPECIFICATIONS

Temperature & Humidity:

Operating: -15°C to 60°C ≤80% R.H.

Storage: -15°C to 60°C ≤80% R.H.

Altitude: up to 2000m

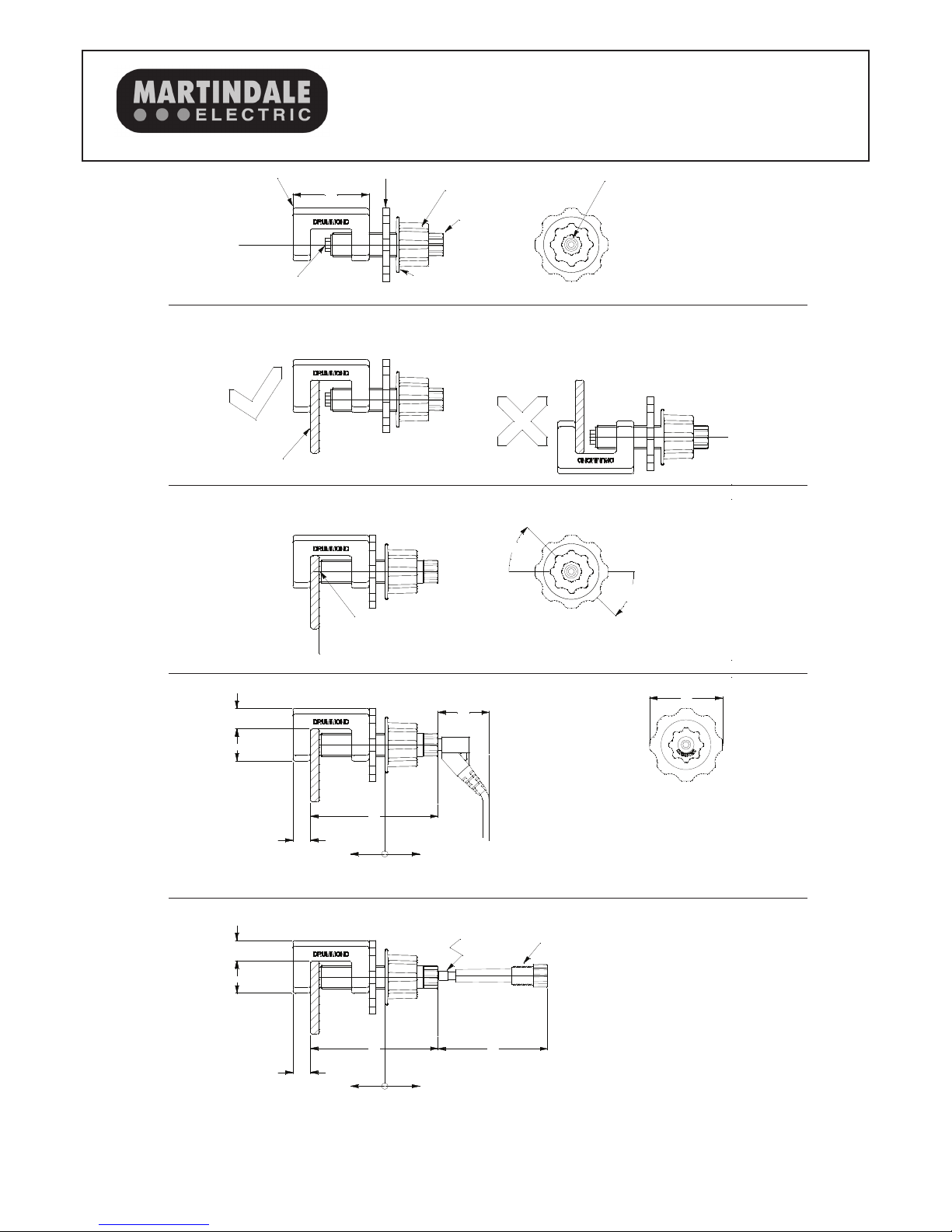

Dimensions

Length behind bus bar: 12mm

Length in front of bus bar: 87mm (+ 35mm as minimum

allowance for 4mm plug)

Height above top of bus bar: 14mm

Width: 50mm for locking ring nut

Clearance: Required to withdraw fuse holder 75mm

Bus bar

Suitable for rectangular bus bar ONLY. Not suitable for round

conductor.

Minimum Bar width: 20mm

Minimum bar thickness: 4mm

Maximum bar thickness: 26mm

Materials

Nylon 66, reinforced with 13% glass fibre.

Flammability: V2

Brass contact pin

Safety

Conforms to BS EN61010

Installation Overvoltage Rating CAT IV 600V

Pollution Degree: 2

IP rating: IP40

Fuse: 6.35 x 32mm 600V 0.5A HBC

For enhanced safety, the fuse is fully recessed inside the fuse

holder until the fuse holder is withdrawn.

RISK ASSESSMENT IS REQUIRED BEFORE

INSTALLATION.

The Drummond G Clamp makes connecting to bus bars straight

forward. The clamp-on design eliminates the need to drill bus

bars and makes for a much safer reliable connection via a

standard 4 mm socket.

Ideal for connecting power monitoring and measuring equipment,

the new colour coded clamps make phase identification easy.

The insulated materials reduce the hazard to the operator and

the spring loaded contact pin and locking ring ensure reliable

results throughout extended logging periods.

The G Clamp can be tightened by hand when wearing PPE

gloves, eliminating the need to use tools in the bus bar chamber.

They are available in Brown, Black and Grey. The standard

fused version is supplied with a replaceable 0.5A fuse within the

clamping screw providing protection at the source. Other fuse

ratings are available on request.

Available individually and in 3 phase connection kit sets including

a blue unfused G clamp for the neutral connection which requires

25mm less clearance in front of the bus bar.

Individual G clamps

DRUGCLAMP/F0.5/BK (Fused 0.5A Black)

DRUGCLAMP/F0.5/BR (Fused 0.5A Brown)

DRUGCLAMP/F0.5/GY (Fused 0.5A Grey)

DRUGCLAMP/BL (Unfused Blue)

Connection Kit 1

GCK/F/KIT1

Set of four G Clamps, black, brown, grey fused and blue unfused.

Connection Kit 2

GCK/F/KIT2

Set of four G clamps black, brown, grey fused and blue unfused

with 4m heavy duty colour coded CATIV test leads. The leads are

terminated with 45 degree 4mm safety plugs at both ends.

Due to policy of continuous development, Martindale Electric reserves the right to alter equipment specication and description outlined in this document without prior notice. No part of this

document shall be deemed to be part of any contract for the equipment unless specically referred to as an inclusion within such contract. © 2012 Martindale Electric Co. Ltd.

Martindale Electric Company Ltd.

Metrohm House, Imperial Park, Imperial Way, Watford, Hertfordshire, WD24 4PP, UK

Tel: 01923 441717 Fax: 01923 446900