10

Marvair ComPac Installation & Operation Manual

12/2017 Rev.16

Hot Gas Bypass (Non-Economizer Models Only) Not available on the AVPA12/24

Used in specialty applications; i.e., Magnetic Resonance Imaging (MRI) buildings, to prevent magnetic

voltage disturbance caused by compressor cycling. Two hot gas bypass option packages are available

to allow operation to 20°F (-7°C) or minus 20°F (-29°C). Please refer to Hot Gas Bypass Application

Bulletin for details.

Electric Reheat Dehumidication Not available on the AVPA12

A humidity controller allows electric heat and cooling to operate simultaneously. Marvair®air conditioners

equipped with the dehumidication option allow the indoor humidity of the controlled environment

to be maintained at or below a certain humidity set point. These units do not have the ability to add

humidity to the building.

IMPORTANT

The electrical wire and breaker or fuses must be sized for simultaneous operation

of the electric heater and the air conditioner. Refer to the data sticker on the unit or

the appropriate Air Conditioner Product Data Sheet for the sizing information.

Dehumidication is achieved by operating mechanical cooling in conjunction with electric reheat. The

strip heat is sized approximately to the sensible capacity of the total tonnage of the machine (i.e., on a

24,000 BTU unit the strip heat is sized at approximately 20,000 BTU). Because the strip heat is sized

to the approximate sensible cooling capacity, only selected models are available.

Operation:

When the humidity rises above the set point on the humidity controller both mechanical cooling and

electric reheat operate to temper the air and lower the humidity. If the temperature in the controlled

environment rises above the set point of the thermostat and the unit is operating in the dehumidication

mode, the call for cooling will override the call for dehumidication and the strip heat is disengaged

until the thermostat is satised. This assures the environment temperature is maintained as rst priority

and humidity control is second.

In applications where a shelter has redundant air conditioning units and is controlled by a lead lag control-

ler (CommStat Touch, CommStat 4, CommStat 3 HVAC Controller), most times the dehumidication

option is only necessary on one of the two units. It is possible for one unit to be operating in the cooling

mode while the unit with dehumidication is operating at the same time. If the cooling unit does not

maintain the shelter temperature set point, the unit with dehumidication will go into the cooling mode.

It does not matter whether the unit with dehumidication is the lead or lag unit.

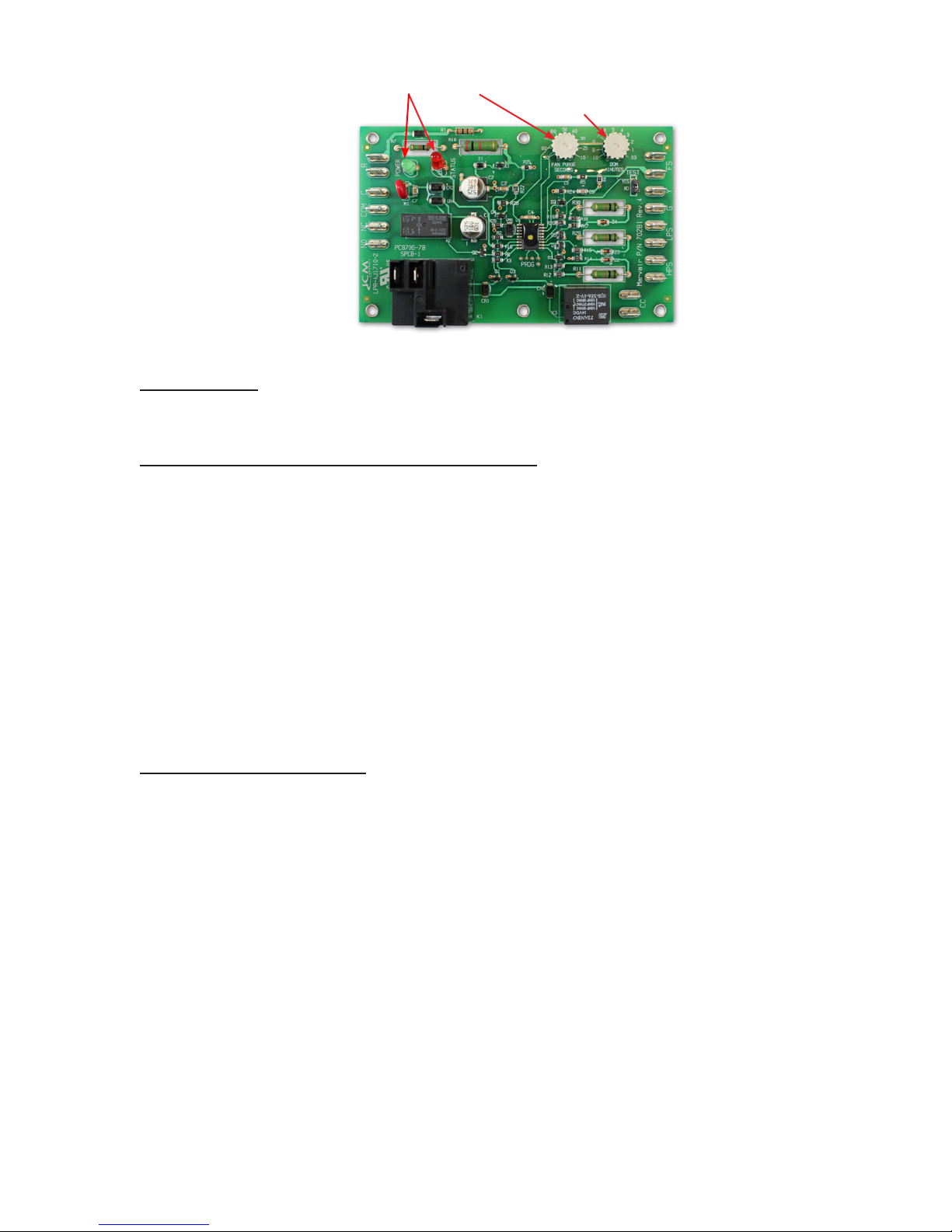

Three Phase Voltage Monitor

Continuously measures the voltage of each of the three phases. The monitor separately senses low

and high voltage, voltage unbalance including phase loss and phase reversal. An LED indicator glows

when all voltages are acceptable. Automatically resets when voltages and phases are within operating

tolerances. Not required on 1ø units.

Dirty Filter Indicator (Not Available on the AVPA12)

A diaphragm type of indicator measures the air pressure on either side of the lter and when the pressure

drops below the set point, a red LED is illuminated. The set point is adjustable.

Protective Coil Coatings

Either the condenser or evaporator coil can be coated, however, coating of the evaporator coil is not

common. For harsh conditions, e.g., power plants, paper mills or sites were the unit will be exposed to

salt water, the condenser coil should be coated. Note: Cooling capacity may be reduced by up to 5%

on units with coated coils.