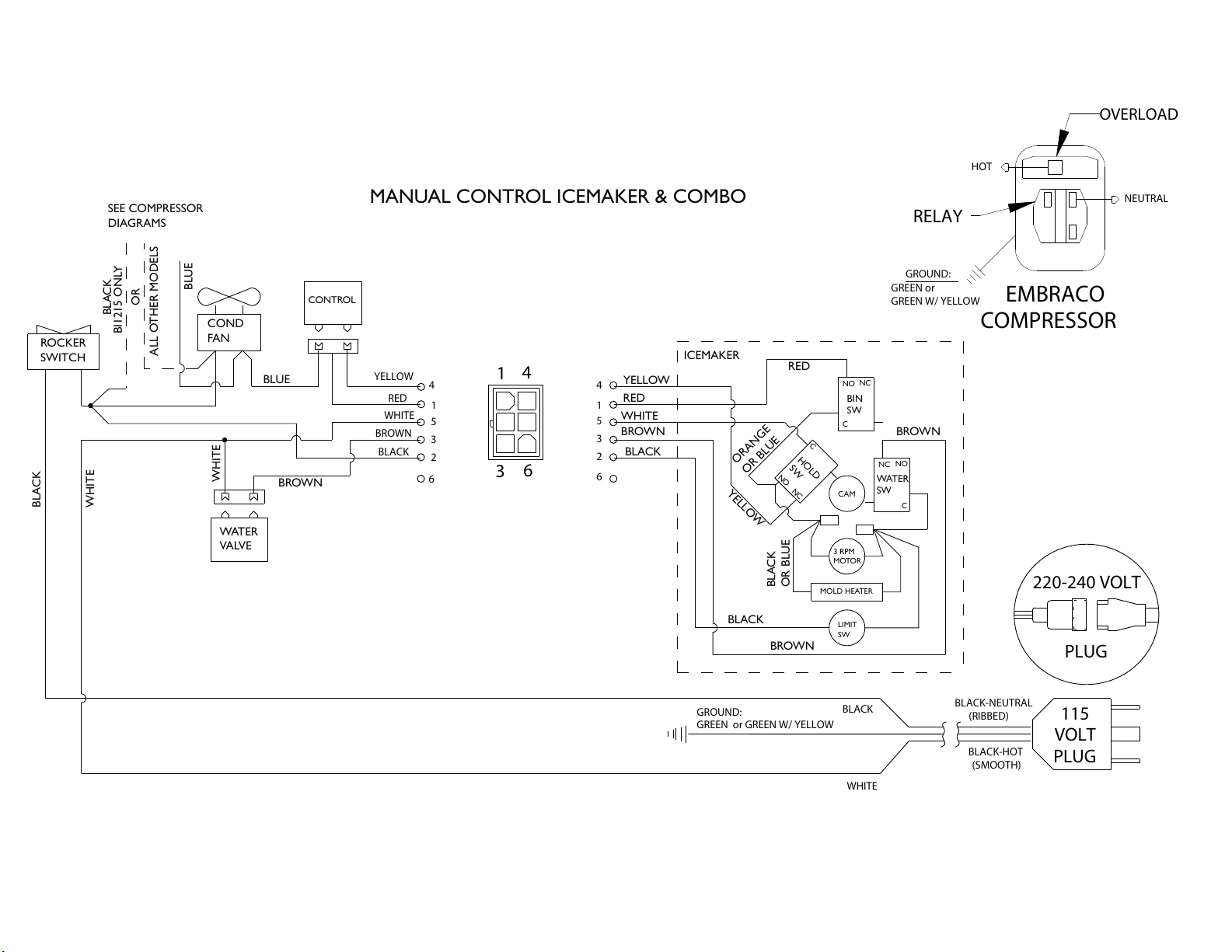

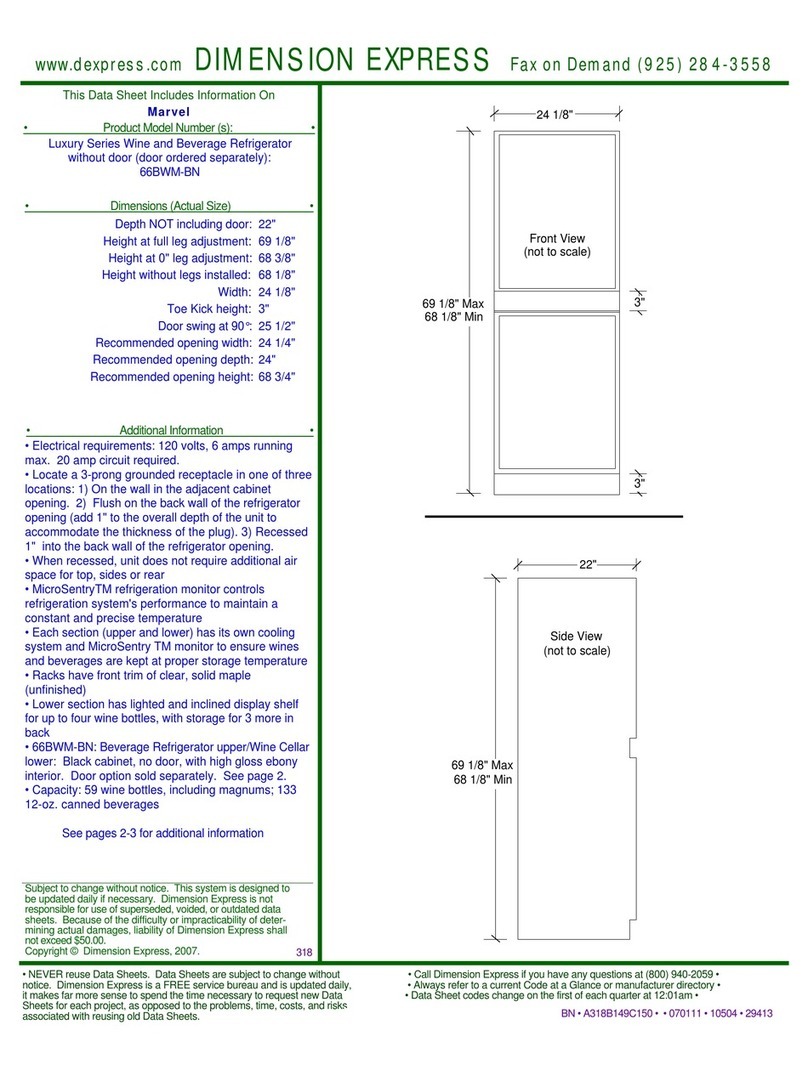

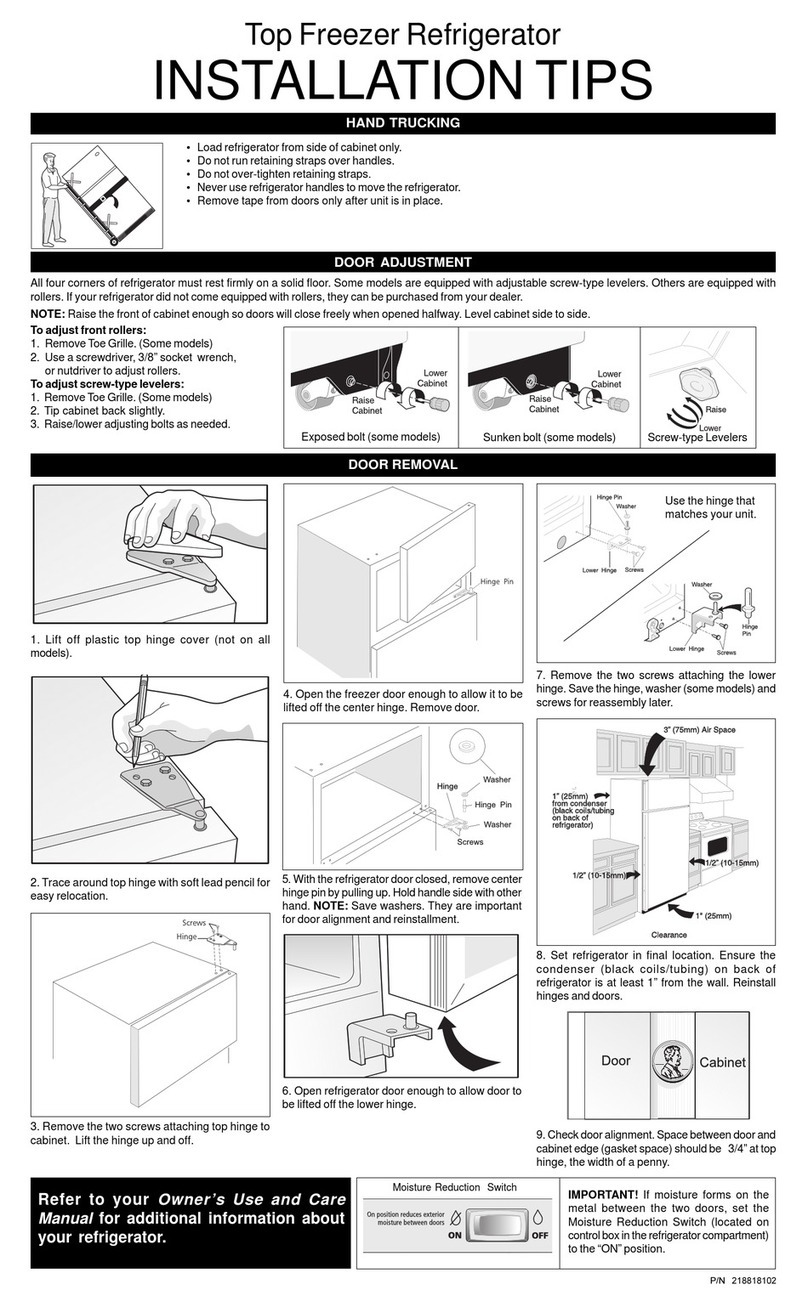

Ice Cube Thickness Adjustment

Interval - As Required.

On ice maker equipped models, adjust the cube size

by changing water amount injected into the ice maker

assembly as follows:

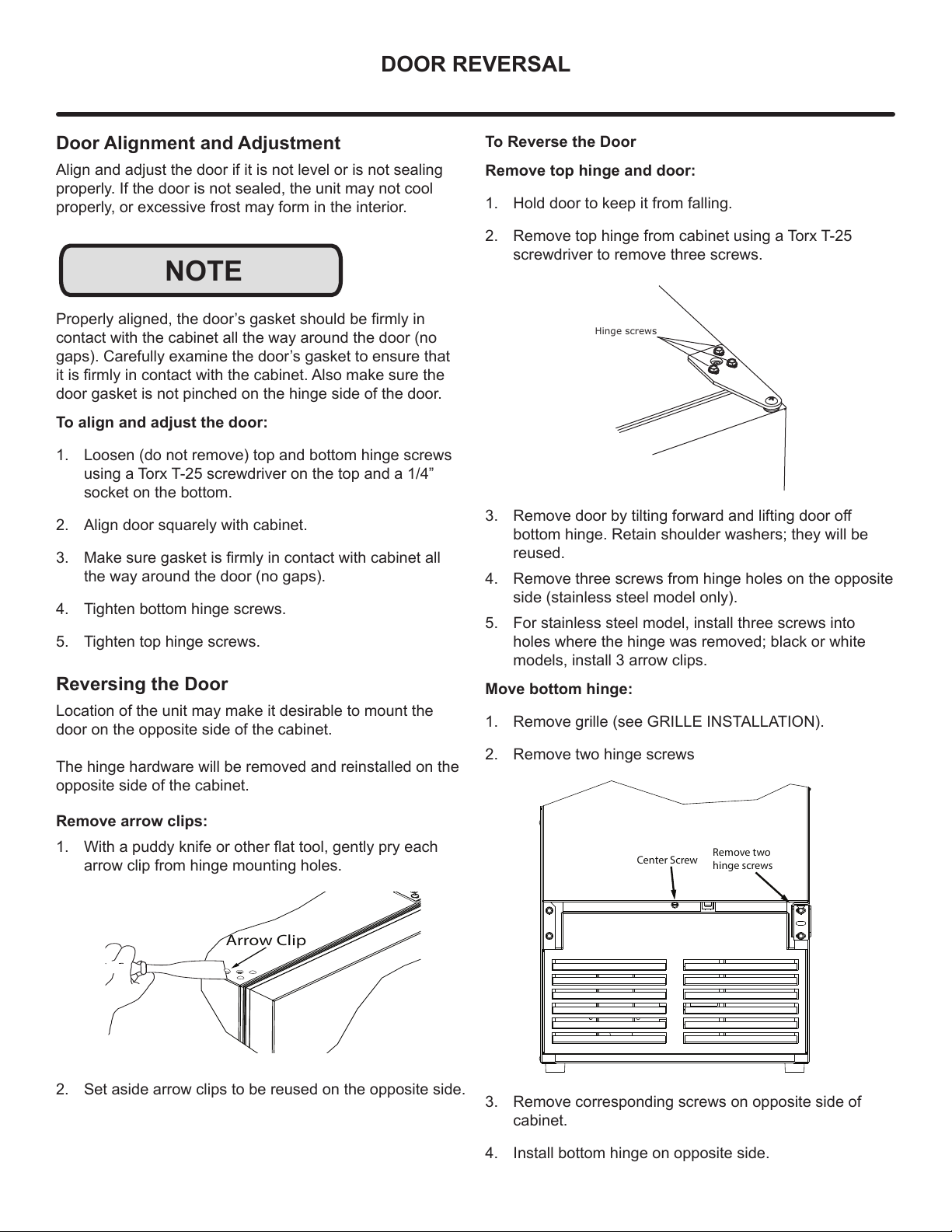

1. Remove the ice maker assembly

cover (1).

2. Find the adjusting screw on the ice

maker assembly control box (2).

The adjusting screw is just below

the minus (-) and plus (+) signs on

the control box.

Too large of an adjustment to the screw can cause the

ZDWHUWRRYHUÀRZWKHLFHPDNHUDQGFDQFDXVHSURSHUW\

damage.

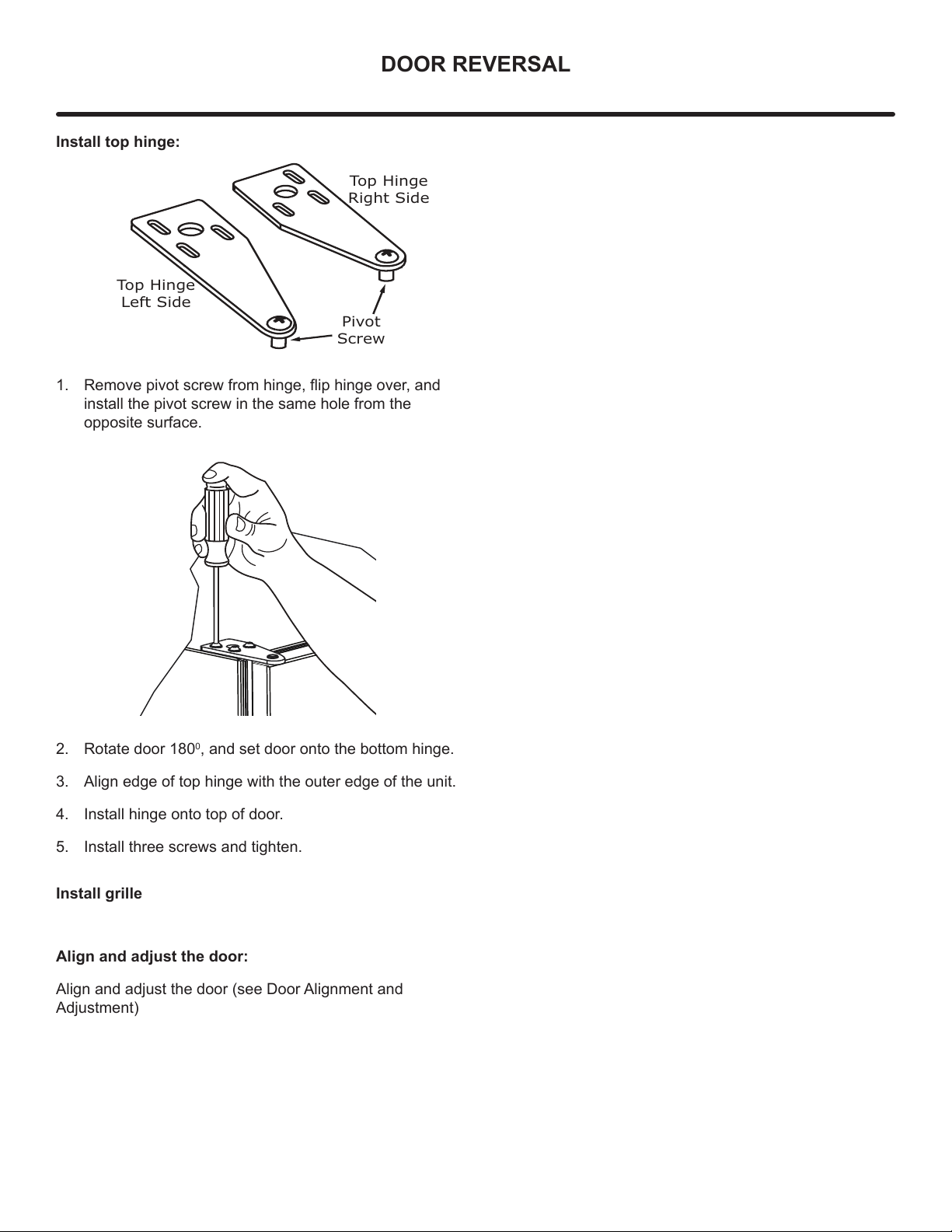

3. Turn the adjusting screw toward the minus (-) sign

(clockwise) for smaller cubes or toward the plus (+)

sign (counterclockwise) for larger cubes.

4. Install the ice maker assembly cover.

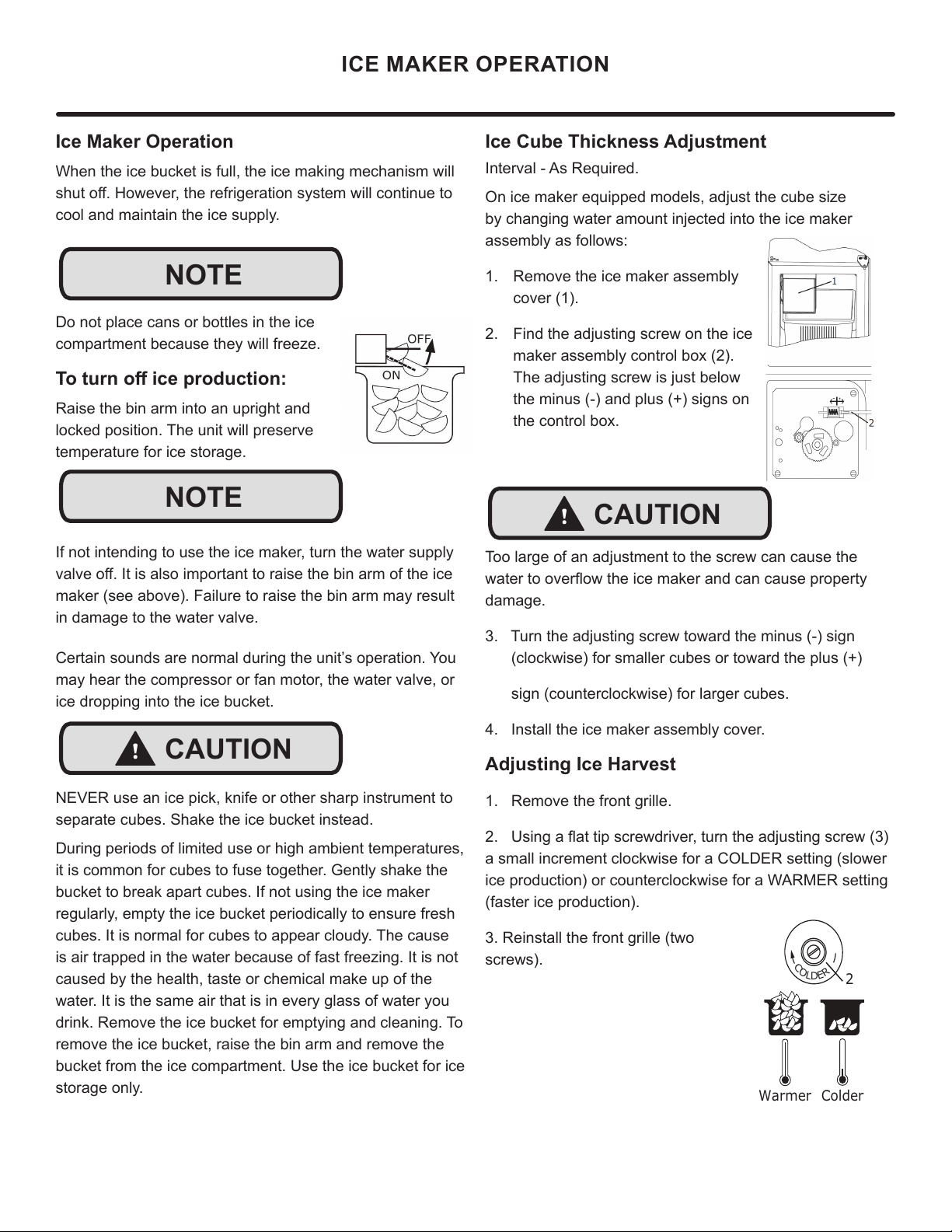

Adjusting Ice Harvest

1. Remove the front grille.

8VLQJDÀDWWLSVFUHZGULYHUWXUQWKHDGMXVWLQJVFUHZ

a small increment clockwise for a COLDER setting (slower

ice production) or counterclockwise for a WARMER setting

(faster ice production).

3. Reinstall the front grille (two

screws).

Ice Maker Operation

When the ice bucket is full, the ice making mechanism will

VKXWRႇ+RZHYHUWKHUHIULJHUDWLRQV\VWHPZLOOFRQWLQXHWR

cool and maintain the ice supply.

Do not place cans or bottles in the ice

compartment because they will freeze.

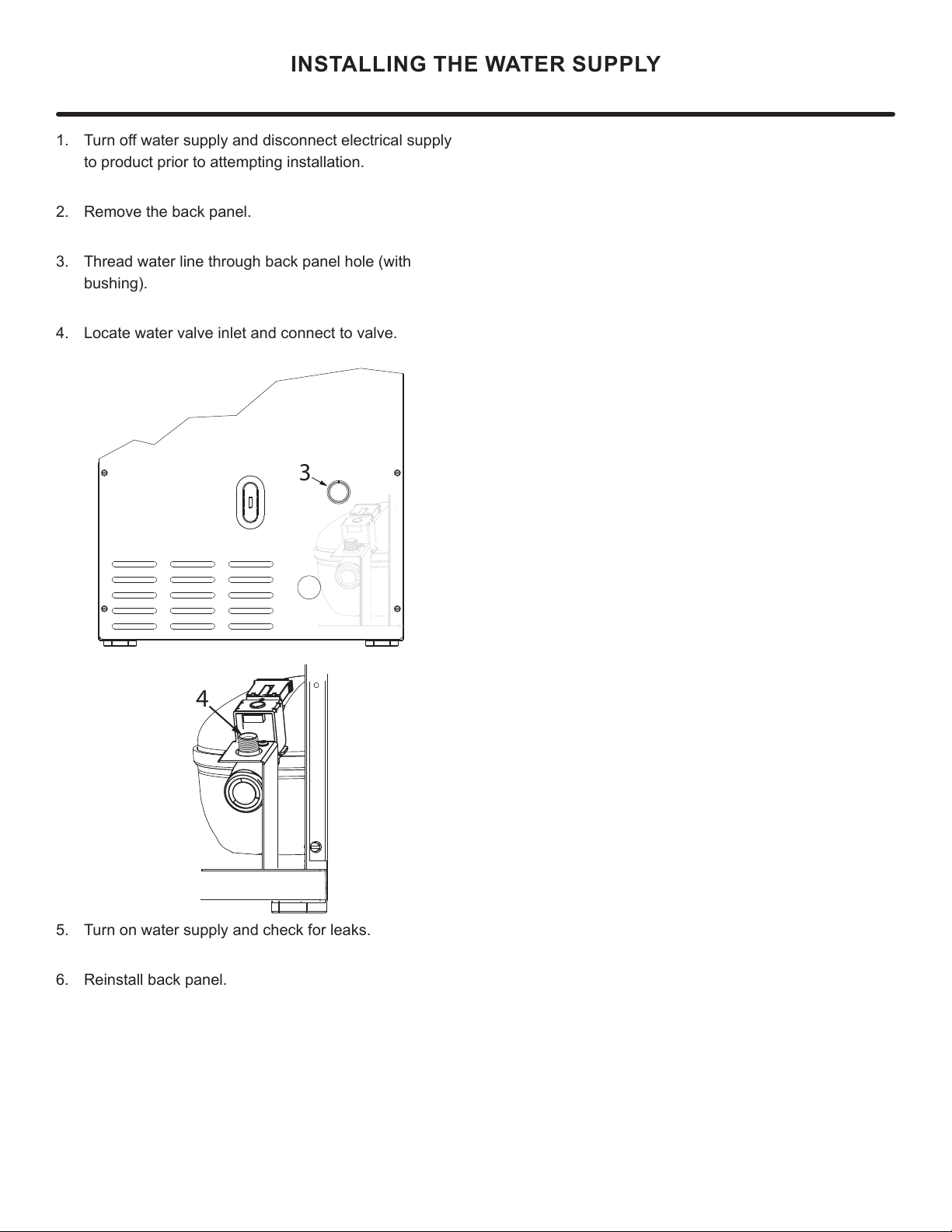

7RWXUQRႇLFHSURGXFWLRQ

Raise the bin arm into an upright and

locked position. The unit will preserve

temperature for ice storage.

If not intending to use the ice maker, turn the water supply

YDOYHRႇ,WLVDOVRLPSRUWDQWWRUDLVHWKHELQDUPRIWKHLFH

maker (see above). Failure to raise the bin arm may result

in damage to the water valve.

Certain sounds are normal during the unit’s operation. You

may hear the compressor or fan motor, the water valve, or

ice dropping into the ice bucket.

NEVER use an ice pick, knife or other sharp instrument to

separate cubes. Shake the ice bucket instead.

During periods of limited use or high ambient temperatures,

it is common for cubes to fuse together. Gently shake the

bucket to break apart cubes. If not using the ice maker

regularly, empty the ice bucket periodically to ensure fresh

cubes. It is normal for cubes to appear cloudy. The cause

is air trapped in the water because of fast freezing. It is not

caused by the health, taste or chemical make up of the

water. It is the same air that is in every glass of water you

drink. Remove the ice bucket for emptying and cleaning. To

remove the ice bucket, raise the bin arm and remove the

bucket from the ice compartment. Use the ice bucket for ice

storage only.

ICE MAKER OPERATION

NOTE

NOTE

!CAUTION

!CAUTION

C

O

L

D

E

R

Warmer Colder

13