Masalta MFG10 Series User manual

INSTRUCTION MANUAL

GREEN CONCRETE SAW

MFG10 SERIES

WARNING

!

To reduce the risk of injury, all operators and maintenance personnel must read and understand these

instructions before operating, changing accessories, or performing maintenance on Masalta power

equipment. All possible situations cannot be covered in these instructions. Care must be exercised

by everyone using, Maintaining or working near this equipment.

RR

1

CONTENTS

RULES FORSAFEOPERATION

GeneralSafety .1-2

Diamond Blade Safety ...2

TransportationSafety .2

Emergencies 3

MaintenanceSafety 3

LabelLocation .3

SafetyLabel .4-5

ⅡOPERATION

Introduction ..5

Determiningthe Right Machine 5

OperatingPrinciple .5

DeliveryChecks ..5

Blade Placement 5-6

Blade Removaland Replacement 6

BeforeStarting .6

Operation ... 6-7

Stoppingthe Engine ...7

Guard, Coversand V-belt ..7

ⅢMAINTENANCE

Troubleshooting 8-10

ⅣSPECIFICATION..11

ⅤWARRANTY ..12

ⅥMAINTENANCERECORD .12

ⅦECDECLARATION .13

RULES FORSAFEOPERATION

WARNING:

Failuretofollowinstructionsinthismanualmaylead to

seriousinjuryoreven death!Thisequipmentistobe

operated bytrained and qualified personnelonly!This

equipment isforindustrialuseonly.

The followingsafetyguidelinesshouldalwaysbeused

when operatingthe MASALTAconcreteCutters:

GENERALSAFETY

DONOT operateorservicethisequipmentbefore

readingthe entiremanual.

Thisequipmentshouldnotbeoperatedbypersons

under18yearsofage.

NEVER operatethisequipmentwithoutproper

protectiveclothing,shatterproofglasses,steel-toed

bootsand otherprotectivedevicesrequired bythe job.

NEVER operatethisequipment when not feelingwell

due tofatigue, illness ortakingmedicine.

■NEVER operatethisequipmentunderthe

influenceordrugsoralcohol.

■NEVER useaccessoriesorattachments,

whicharenotrecommended byMASALTA

forthisequipment. Damagetothe

equipment and/orinjurytousermayresult.

■Themanufacturerdoesnotassume

responsibilityforanyaccidentdueto

equipmentmodifications.

■Whenevernecessary,replacenameplate,

operation and safetydecalswhen they

becomedifficult toread.

■ALWAYS check the machine forloosened

threadsorboltsbeforestarting.

■NEVER touchthe hotexhaustmanifold,

mufflerorcylinder. Allowthesepartstocool

beforeservicingengine orsaw.

■High Temperatures –Allowthe engine to

coolbeforeaddingfuelorperforming

serviceandmaintenancefunctions.

Contactwith hot componentscan cause

serousbums.

■Theenginesectionofthiscutterrequires

an adequatefree flowofcoolingair.

NEVER operatethe cutterinanyenclosed

ornarrowarea wherefree flowofthe airis

restricted.Ifthe airflowisrestricted itwill

causeseriousdamagetothe saworengine

and maycauseinjurytopeople.Remember

the cutter’sengine givesoff DEADLY

carbon monoxide gas.

ALWAYS refuelinawell-ventilated area,

awayfromsparks and open flames.

ALWAYS useextremecaution when

workingwithflammableliquids.When

refueling,stopthe engine and allowitto

cool. DONOT smoke around ornearthe

machine.Fireorexplosion couldresult

fromfuelvapors, oriffuelisspilled on ahot

engine.

NEVER operatethecutterinanexplosive

atmosphereornearcombustiblematerials.

Anexplosion orfirecouldresultcausing

severebodilyharmoreven death.

Topping-off tothe fuel fillerportis

dangerous, asittendstospill fuel.

2

NEVER usefuelasacleaningagent.

ALWAYS read,understand,andfollowproceduresin

operator sManualbeforeattemptingtooperate

equipment.

ALWAYS besuretooperatorisfamiliarwithproper

safetyprecautionsandoperatingtechniquesbefore

usingthe cutter.

Stopthe engine when leavingthe cutterunattended.

Block the unit when leavingorwhen usingon aslope.

Maintainthisequipmentinasafeoperatingcondition

at all times.

ALWAYS stoptheenginebeforeserving,addingfuel

and oil.

NEVER Run engine withoutairfilter.Severeengine

damagemayoccur.

NEVER Run engine withoutairfilter.Severeengine

damagemayoccur.

ALWAYS serviceaircleanerfrequentlytoprevent

carburetormalfunction.

ALWAYS storeequipmentproperlywhen itisnot

beingused.Equipmentshouldbestored inaclean,

drylocationout ofthe reachofchildren.

NEVER operatethiscutterinareasthatcontain

combustiblematerialorfumes.Fireand/orexplosions

mayresult fromerrant sparks fromthe equipment.

WARNING:

DO NOT operatethisequipment unless all guardsand

safetydevicesareattached and inplace.

Caution mustbeexercised whileservicingthis

equipment. Rotatingand movingpartscan cause

injuryifcontacted.

Keepall inexperienced andunauthorized peopleaway

fromthe equipment at all times.

Unauthorized equipmentmodificationswill voidall

warranties.

DIAMOND BLADESAFETY

Useappropriatesteelcentered diamond blades

manufactured foruseon concretecutters.

ALWAYS inspectdiamond bladesbeforeeachuse.

The bladeshouldexhibitno cracks,dings,orflawsin

the steelcenteredcoreand/orrim. Center(arbor)hole

mustbeundamaged and true.

Examine blade flangesfordamage, excessivewear

and cleanliness beforemountingblade.

Blade shouldfitsnuglyon the shaft and

against the inside/outside blade flanges.

Ensurethatthe blade ismarked withan

operatingspeed greaterthan theblade

shaft speed ofthe cutter.

Onlycutthematerialthatisspecified by

the diamond blade.Readthe

specificationsofthe diamond blade to

ensurethepropertoolhasbeenmatched

tothematerialbeingcut.

ALWAYSkeepblade guardsinplace.

Exposureofthe diamond blade mustnot

exceed 180 degrees.

Ensurethatthediamond blade doesnot

comeintocontactwithground orsurface

duringtransportation. DONOT dropthe

diamond blade on ground orsurface.

Theengine governorisdesigned to

permitmaximumengine speed ina

no-load condition.Speedsthatexceed

thislimitmaycausethediamond blade to

exceedthemaximumsafeallowable

speed.

Ensurethatthe bladeismounted for

properoperatingdirection.

CUTTERTRANSPORTATIONSAFETY

Usethe liftingbail and appropriatelifting

equipmenttoensurethe safemovement

ofthe cutter.

DO NOT usethe handlebarsand/orfront

pointerasliftingpoints.

NEVER towthe sawbehind avehicle.

Ensurethatbothpointerbarsare

positioned appropriatelytominimizetheir

exposureduringtransportation.

Safeguardagainstextremecutter

attitudesrelativetolevel.Enginestipped

toextremeanglesmaycauseoil to

gravitateintothe cylinderhead making

the engine difficult tostart.

NEVER transportthe cutterwiththe

blade mounted.

3

EMERGENCIES

ALWAYS knowthe location ofthe nearestfireextinguisherand firstaidkit. Knowthe location of

the nearesttelephone.Alsoknowthe phone numbersofthe nearestambulance,doctorand fire

department. Thisinformation willbeinvaluableinthe caseofan emergency.

MAINTENANCESAFETY

NEVER lubricatecomponentsorattempt serviceon arunningmachine.

ALWAYS allowthe machine aproperamount oftimetocoolbeforeservicing.

Keepthe machineryinrunningcondition.

Fixdamagetothe machine immediatelyand alwaysreplacebroken parts.

Disposeofhazardouswasteproperly.Examplesofpotentiallyhazardouswasteareusedmotoroil,

fueland fuelfilters.

DO NOT usefood orplasticcontainerstodisposeofhazardouswaste.

LABELLOCATION

4

SAFETYLABLES:

MASALTAmachinesuseinternationalpictoriallabelswhereneeded. Theselabelsaredescribed below:

Label Meaning

DANGER!

Enginesemit carbon monoxide; operateonlyin

well-ventilated area. ReadtheOperation Manualfor

machine information. Nosparks, flames, orburningobjects

nearthemachine. Shutoffthe engine beforerefueling. Use

onlyclean, filtered unleadedgasoline.

CAUTION!

Useonlyclean, filtered gasoline fuel.

WARNING!

Hot surface!

WARNING!

Alwayswearhearingand eyeprotection when operating

thismachine.

CAUTION!

Read andunderstand the supplied Operation Manual

beforeoperatingthe machine. Failuretodosoincreasethe

risk ofinjurytoyourselforothers.

WARNING!

Hand injuryifcaught inmovingbelt.

Alwaysreplacebelt guard.

5

Label Meaning

WARNING!

All displacement ofthe machine outside the cuttingarea

shall becarried out withthe toolnot inrotation.

WARNING!

Cuttinghazard.Alwaysreplaceblade guard!

OPERATION

Introduction/DeterminingtheRight

Machine

Congratulationson yourpurchaseofourCutter!

Youvemade anexcellentchoice!OurGreen

Concretecutterhasbeenspecificallydesigned as

the idealmachine forthe professionalcontractor

who isengaged inconcreteandasphaltflat

sawing.

ThisMFG10 Sawisdesigned fordrysawingof

concreteslabsutilizingdiamond blades.The saw

hasbeen engineered forgeneralandindustrialflat

sawingapplicationsthatinclude:JointSawingof

Green Concrete,DecorativeSawing inCured

Concrete,LightDemolition Sawingand “V”Groove

Beveling.The simpleand compactnatureofthe

machine makesitaperfectsawingtoolforone

person tooperateand transport. Thesaw

combinesinnovativefeatures,topquality

components,andacommitted attentionto

state-of-the-art manufacturing.

OPERATING PRINCIPLE

Thefollowinginstructionswerecompiled to

provide you information on howtoobtainlongand

troublefree useofthe unit.Periodicmaintenance

ofthisunitisessential.Readthemanualinits

entiretyandfollowthe instructionscarefully.

Failuretodosomayinjureyourselfora

bystander.

DELIVERYCHECKS

Immediatelyupon takingdeliveryofyournew

equipment and beforeputtingit intoservice:

Read the operation manualcompletely—it

couldsaveagreatdealofunnecessary

expense.

Read the engine manualsupplied.

Check thegeneralcondition ofthe

equipment—hasitbeen damaged during

delivery?

Check engine oil level.

Check fuellevels.

BLADEPLACEMENT

1.Blade Guard –Pivotthe blade guardfront

coverallthe wayback.The guardtension

springwill keepthe front coverinposition.

2. Blade HexNut –Unscrewthe blade shaft

nut(rightsideloosensclockwiseand

tightenscounter-clockwisewhilethe left

side loosenscounter-clockwiseand

tightensclockwise.DONOTovertighten

the nut when finalizingthe assembly.

6

3.OutsideBladeFlange (Collar) Ensurethatthe

outside blade flangeisplaced flushagainstthe

diamond blade.The inside surfaceofthe flangemust

befree ofdebrisand permitatightclosureon the

surfaceofthe blade core.

4.Diamond Blade Ensurethattheproperdiamond

blade hasbeenselectedforthejob.Payclose

attentiontothedirectionalarrowson the blade.The

blade’soperatingdirectionalarrowsmustpointina

“down cutting “directiontoperformcorrectly. When

placing the blade ontothe blade shaft, ensurethe

arborholeoftheblade matchesthediameterofthe

shaft.

5.InnerFlange(Collar) Thisflangeisfixed upon the

blade shaft. Theinside surfaceofthe flangemustbe

free ofdebrisand permit atight closureonthesurface

ofthe blade.

BLADEREMOVALAND REPLACEMENT

1.Ensurethe Engine Shutdownswitchand ON/OFF

switchon theengine areturned tothe “OFF “position.

2.PlacetheMFG10 Sawon astablelevelworking

surface.

3.Ensurethe blade israised and the raise/lowerrod is

locked intoposition.

4.Raisetheblade byapplingadownwardpressureon

the handlebarstoraisetheblade andallowthe

raise/lowerrod todropintothe “raised-position “slot.

5.Lift upthe blade guardcovertogainaccess tothe

diamond blade.

6.Usetheprovided blade nutand bladeshaft

lockingwrenchestoinstall the diamond

blade.

7.Whileholdingthe bladeshaft withthelocking

Wrench,removethe blade hexnut

(clockwisedirection)and outerblade flange.

8.Removethe oldblade and install anew

blade inthesamerotationaldirectionas

marked on theblade.

9. Reinstall theouterblade flangeand hexnut.

Tightenthenutfirmly(counter-clockwise

direction). DO NOTOVERTIGHTEN.

BEFORESTARTING

1.Read safetyinstructionsat the beginningof

manual.

2.Usecorrect blade forcuttingconditions.

3.Clean the saw,removingdirtand dust,

particularlytheengine coolingairinlet,

carburetorand aircleaner.

4.Check the airfilterfordirtand dust. Ifair

filterisdirty,replaceairfilterwithanewone

asrequired.

5.Check carburetorforexternaldirtanddust.

Clean withdrycompressed air.

6.Check fasteningnutsand boltsfor

tightness.

Caution Setunitup inanopenarea.Avoid

close proximitytostructures orother

equipment.Failuretodo somay cause

inadvertentinjurytooperatororother

personsinthearea.

OPERATION

1.Ensuretheengine Shutdownswitchand

the engine ON/OFF switchon the engine

arebothinthe OFF position toavoid

accidentalstarting.

2.Placethe fuelvalvelevertothe

“ON“position.

3.Placethe engine Shutdownswitchand the

engine ON/OFF switchon the engine tothe

“ON “position.

7

4.Placethe Chock Leverinthe CLOSED”

position.

5.Rotatethe throttleleverhalfwaybetween Fast

and Slowforstarting.All sawingisdone at

full throttle.The engine governorspeed is

factorysettoensureoptimumblade operating

speeds.

6.Graspthe startergripand slowlypull itout.

The resistant becomesthe hardest atacertain

position,correspondingtothe compression

point. Pull the startergripbrisklyand smoothly

forstarting.

7.Ifthe engine hasstarted,slowlyreturnthe

chokelevertothe OPEN”position.Ifthe

engine hasnotstarted repeatsteps1through

5.

8.Beforethesawisplaced intooperation,run

the engine forseveralminutes.Check forfuel

leaks,and noisesthatwouldassociatewitha

looseguardsand/orcovers.

9.Rotatethe throttlelevertowardfull throttle.

10.Tobeginsawing,lowerthe rotatingblade

allowingit tocut tothepresent depth.

11.When blade hasreached full cuttingdepth,

slowlywalkbehind the sawataratethatwill

allowthe engine tooperatewithoutlosing

optimumRPM.

12.When the end ofthe cuthasbeen reached,

raisethe bladeoutofthecutbypullingback

on thehandlebars(usingadownward

pressure)until the raise/lowerrod dropsintoits

slot withthe blade inthe raisedposition.

13.Ifcuttingiscomplete, shut thesawdownusing

the following ShutdownProcedures”.

TO STOPTHEENGINE

Tostopthe engine undernormalconditions:

1.Placethe engine throttleleverinthe Slow

position,andlisten fortheengine speedto

decrease.Allowengine torun for2or3

minutesforpropercooldown.

2.Turnthe engine Shutdownswitchtothe OFF”

position.

3.Turnthe engine ON/OFF switchtothe OFF”

position.

4.Placethefuelvalvelevertothe OFF

position.

GUARDS, COVERS&V-BELTS

BladeGuardCheck

CHECKthe followingon the blade guard”

1.Ensurethe capacityofthe blade guard

matchesthe diameterofyourdiamond

blade.

2.Checkthattheguardisboltedfirmlyupon

the sawframe.

3.Check thatthe springtensioned frontcover

ofthe guardisfirmlyseatedwiththe rear

section oftheguard, and therearenogaps.

NEVERlift the blade guardwhilecutting.

V-beltAlignmentand Tensioning

1.Removethe boltsthatsecuretheV-belt

covertothe sawframe.

2.Check uniformparallelismofV-beltand

pulley(sheaves).Useastraight-edgeor

machinist’ssquareagainstbothpulleysand

adjust bothpulleysuntil equallyaligned.

3.DONOToverorundertighten the V-belt.

Severedamagecan occurtothe sawand

engine crankshaft ifthe beltis

over-tensioned.Adecreaseof powertothe

blade and poorperformancewillresultif

the beltisunder-tensioned (looseon

pulleys).

8

MAINTAINENACE-TROUBLESHOOTING

BLADETROUBLESHOOTING

SYMPTOM POSSIBLEPROBLEM SOLUTION

Bladetoohardforthematerial

beingcut?

ConsultDealerforcorrectblade.Try

cuttingverysoftmaterial(sandstone,silica

brick,cinderblock)to"Redress"the blade.

Engine torque diminished

becauseoflooseV-belt? Tighten and/orreplaceV-Belt.

InsufficientEngine power? Checkthrottlesetting. CheckEngine

horsepower.

Improperdircection of

rotation?

Checkthatthe bladeisproperlyoriented

and rotationalarrowpointsina

"Down-Cutting"direction.

Blade slowsor

stopscutting,

still remains

on blade

Bladeisslippingon the blade

shaft? Checkthatthe blade&flangepin

areproperlyinstalled on the bladeshaft.

Blade beingusedon

misaligned saw? Checkbladeshaftbearingsandalignment

integrity.

Blade isexcessivelyhardfor

the materialbeingcut?

Checkspecification of the bladewith

the materialbeingcut. ConsultDealer

forinformation.

Blade beingusedat improper

RPM? Ensurebladesurfacefeetperminute

speed (SFPM) isapproximately6,000.

Blade improperlymounted on

arborshouldersandflanges? Ensurebladeisproperlyaffixed on the

blade shaft.

Blade doesnot

cutstraight

and/ortrue.

Excessiveforceapplied to

blade whilecutting? DONOT forcethe bladeinthecut. Apply

aslowand steadypacewhen sawing.

Bladestoo hardforthe

materialbeingcut?

ConsultDealerforcorrectblade. Try

cuttingverysoftmaterial(sandstone,silica

brick,cinderblock)to"Redress"the blade.

Blade improperlymounted on

arborshouldersandflanges? Ensurebladeisproperlyaffixed ontheblade

shaft.

Blade notreceivingenough

coolingair?

Ensureproperflow&volumeofwateris

provided forwet cuttingblades. Ensure

sufficientcoolingairiscirculated about

adrycuttingblade.

Arborholeout of round? Ensurebladeisproperlyaffixed on the

blade shaft.

Incorrectblade chosenfor

materialbeingcut?

Checkspecification of the bladewith

the materialbeingcut. ConsultDealeror

forinformation.

Blade

discoloring,

cracklingand/or

wearing

excessively.

Excessiveforceapplied to

blade whilecutting? DONOT forcethe bladeinthecut.Apply

aslowand steadypacewhen sawing.

9

MAINTAINENACE-TROUBLESHOOTING

SYMPTOM POSSIBLECAUSE SOLUTION

Sparkplugbridging? Checkgap,insulationorreplace

sparkplug.

Carbon depositon sparkplug? Clean orreplacesparkplug.

Shortcircuitdue todeficient

sparkplug

insulation?

Checksparkpluginsulation,replace

ifworn.

Difficulttostart, "fuelis

available,but no

SPARKat spark

plug".

Impropersparkpluggap? Settopropergap.

ON/OFF switchisshorted? Checkswitchwiring,replaceswitch.

Ignition coil defective? Replaceignition coil.

Impropersparkgap,pointsdirty? Setcorrectsparkgapand clean

points.

Condenserinsulation wornor

shortcircuiting? Replacecondenser.

Difficult tostart,"fuelis

available, and SPARK

ispresentatthe

sparkplug".

Sparkplugwirebroken orshort

circuiting? Replacedefectivesparkplugwiring.

Wrongfueltype? Flushfuelsystem,and replacewith

correcttypeof fuel.

Waterordustinfuelsystem? Flushfuelsystem.

Aircleanerdirty? Clean orreplaceaircleaner.

Difficulttostart,"fuel

isavailable, spark

ispresent and

compression is

normal". ChokeOpen? CloseChoke.

Suction/exhaustvalvestuckor

protruded? Re-seatvalves.

Piston ringand/orcylinderworn? Replacepiston ringsand orpiston.

Cylinderhead and/orsparkplug

nottightened

prope

r

ly?

Torque cylinderheadboltsandspark

plug.

Difficulttostart,"fuel

isavailable, spark

ispresentand

compression islow".

Head gasketand/orsparkplug

gasket

damaged?

Replace head and spark plug

gaskets.

Fuelnot availableinfueltank? Fill withcorrecttypeof fuel.

Fuelfilterclogged? Replacefuelfilter.

Fueltankcapbreatherhole

clogged? Clean orreplacefueltankcap.

Nofuelpresentatthe

carburetor.

Airinfuelline? Bleed fuelline.

10

MAINTAINENACE-TROUBLESHOOTING

TROUBLESHOOTING (ENGINE, CONTINUED)

SYMPTOM POSSIBLECAUSE SOLUTION

Aircleanernotclean? Clean orreplaceaircleaner.

Checkfloatadjustment.

Improperlevelincarburetor? Rebuildcarburetor.

Defectivesparkplug? Clean orreplacesparkplug.

"Weakinpower"

compression is

properand does

notmisfire.

Impropersparkpluggap? Settopropergap.

Waterinfuelsystem? Flushfuelsystemand replacewith

correct typefuel.

Ignition coil defective? Replaceignition coil.

"Weakinpower"

compression is

properbut misfires.

Dirtysparkplug? Clean orreplacesparkplug.

Wrongfueltype? Flushfuelsystem,andreplac

e

withcorrecttypeof fuel.

Sparkplugheatvalue improper? Replacewithcorrecttypeofspark

plug.

Engine overheats.

Coolingfinsdirty? Clean coolingfins.

Governoradjusted correctly? Adjustgovernor.

Governor spring defective or

missing?

Replacegovernorspring.

Rotationalspeed

fluctuates. Fuelflowrestricted? Checkentirefuelsystemforleaks or

clogs.

Recoil mechanismclogged withdust

and dirt? Clean recoil assemblywithsoapand

water.

Recoil starter

malfunction. Spiralspringloose? Replacespiralspring.

11

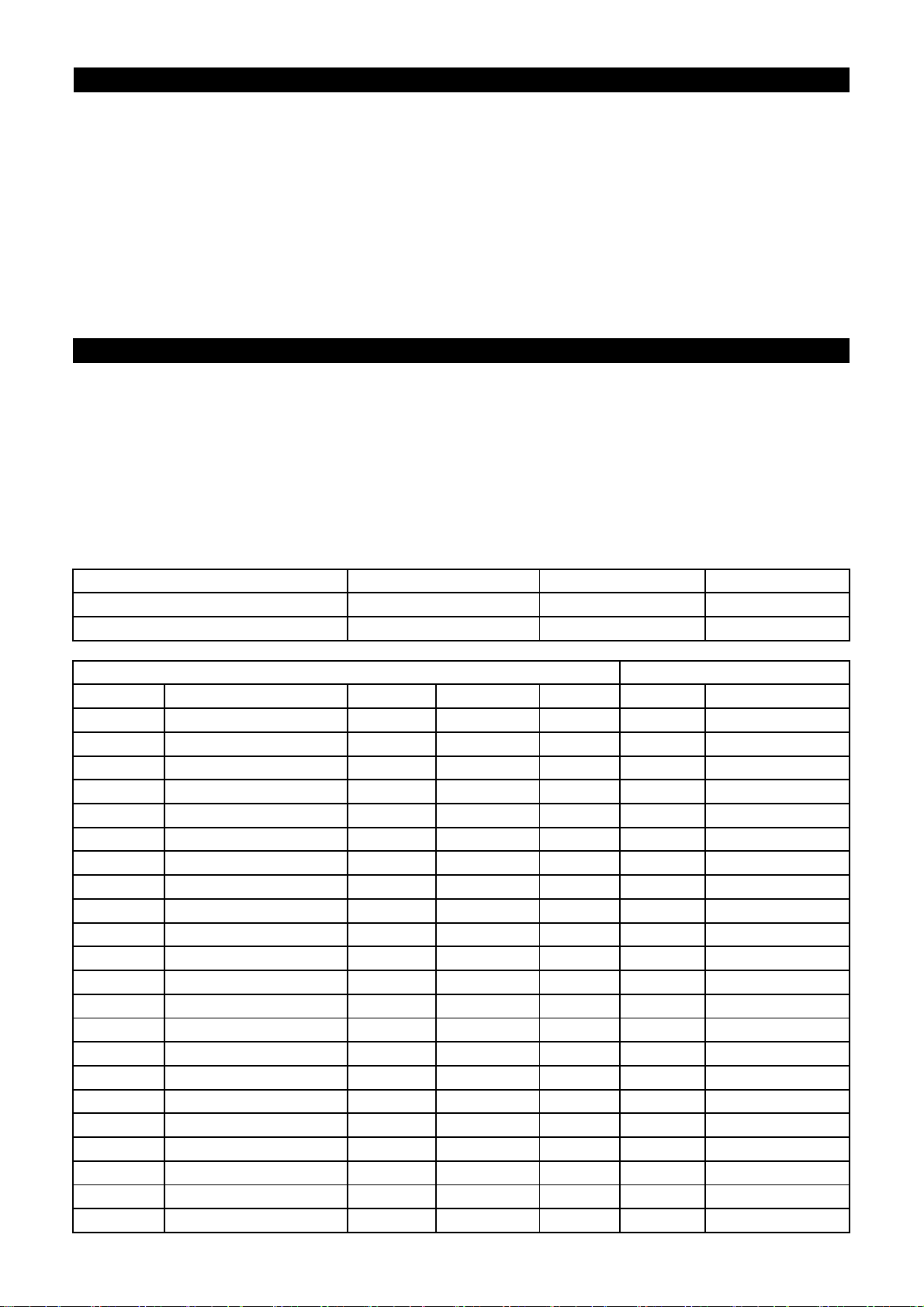

Nameplate:

Acoustic Noise (According to 2000/14/EC)

Hand-Arm vibration Specification (According to ISO 5394, EN 1033 and EN500-4): 5.0m/s2

Working Size (LxWxH): 1665 x 340 x 920 mm

Transporting

1. Shutdown engine for transportation.

2. For transportation, tighten fuel tank cap

securely to prevent fuel from spilling.

3. Use trolley wheel (a) for short distance

transportation.

MFG10-3/4

Measured sound power level

88 dB(A)

Guaranteed sound power

level

110 dB(A)

ⅤSEPECIFICATION

Motor

MFG10-3 Petrol, Robin EX17 4.2kw output

MFG10-4 Petrol, Honda GX160 4.0kw output

Operation Weight

MFG10-3 47kgs

MFG10-4 50kgs

Max. Cutting Depth - - - - - - - - 82.6mm (3.25 in)

Blade size - - - - - - - - - - - - - - - - - 250mm (10in)

Depth Adjustment Mechanism - - Handle Rotation

Driving Mechanism - - - - - - - - - - - - Manual Push T

h

e

s

e

p

r

o

d

u

c

t

s

a

r

e

c

o

v

e

r

e

d

b

y

w

a

r

a

Hasnot been damaged byaccident, misuseorabuse.

PREVENTATIVE MAINTENANCEAND ROUTINESERVICEPLAN

InvoiceNumber: TypeofMachine:

DatePurchased: DealerName:

SerialNumber: DealerPhone:

REPLACEMENTPARTSUSED MAINTENANCELOG

PARTNO. DESCRIPTION QUANTITYCOST DATE DATE OPERATION

MAINTENANCERECORD

ThisGreenConcreteSawhasbeenassembledwithcareandwillprovideyearsofservice.Preventative

maintenanceandroutineserviceareessentialtothelonglifeofyoursaw.Afterreadingthroughthis

manualthoroughly,youwillfindthatyoucandosomeoftheregularmaintenanceyourself.However,when

inneedofpartsormajorservice,besuretoseeyourdealer.Foryourconveniencewehaveprovidedthis

spacetorecordrelevant dataabout yoursaw.

Theseproductsarecoveredbywarrantyforaperiodofsix(6)monthsfromthedateofpurchaseagainst

defectsinmaterialorworkmanshipprovided that:

Hasnot been tampered withorrepaired byanyunauthorized person.

The product concerned hasbeen operated and maintained inaccordancewiththe operatinginstructions.

Theownerisresponsibleforthecostoftransportationtoandfromtheauthorizedrepairerandtheunitisat

the ownersrisk whileintransit toand fromthe repairer.

Impactdamageisnotcoveredunderwarranty.Clutchesarenotcoveredunderanywarranty.

Engines arewarrantedbytheirmanufacturer.

WARRANTYWARRANTYWARRANTYWARRANTY

12

13

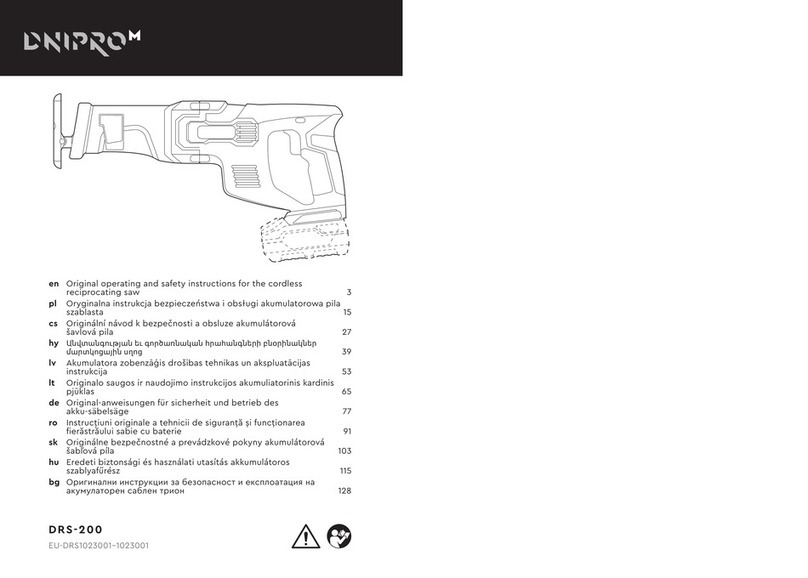

ECDECLARATIONOFCONFORMITY

CE-KONFORMIT TSERKL UNG

DECLARACIÓNDECONFORMIDADDELACE

DÉCLARATIONDECONFORMITÉC.E.

MASALTAENGINEERING CO., LTD

Weisi Road, BaoheIndustrial Estate, HeFei 230051, China

herebycertifiesthattheconstructionequipmentspecifiedhereunder/bescheinigt, da.dasBauger.t /certifica

quelam quinadeconstrucción/ attestequelematériel:

1.Category/ Art/ Categoría/ Catégorie:

GreenConcreteSaw

2. Type/ Typ/Tipo/ Type:

MFG10 SERIES

hasbeenproducedinaccordancewiththefollowing standards:/in übereinstimmungmitfolgendenRichtlinien

hergestelltwordenist:/hasido fabricadoenconformidadcon lassiguientesnormas:/a étéproduit

conformémentauxdispositionsdesdirectiveseuropéennesci-après:

2000/14/ECoutdoor

2006/42/EC

2004/108/EC/EN55012:2007

EN13862/2001

15.02.10 Hermann JosefLensing

--------------------------------------------------- ResearchandDevelopment Manager

Date/ Datum/ Fecha / Date

Table of contents

Other Masalta Saw manuals

Popular Saw manuals by other brands

EINHELL

EINHELL TE-MB 18/127 Li Original operating instructions

Black & Decker

Black & Decker GKC108 Original instructions

DNIPRO M

DNIPRO M DRS-200 Operating and safety instructions

Hitachi

Hitachi CR 13VB Instruction manual and safety instructions

Target

Target MICROCON MCC 75E Operating instructions and parts list

Erbauer

Erbauer ERB2502SE user manual