Masalta MFS 14 User manual

OPERATION MANUAL

FLOOR SAW MFS 14

WARNING

!

To reduce the risk of injury, all operators and maintenance personnel must read and understand these

instructions before operating, changing accessories, or performing maintenance on Masalta power

equipment. All possible situations cannot be covered in these instructions. Care must be exercised

by everyone using, Maintaining or working near this equipment.

R

1

Table of Contents

1. SAFETY INFORMATION.....2

1.1 Safety Precautions .. . 2

1.2 Operating Safety . . .3

1.3 Blade Safety .. .. ..4

1.4 Transportation Safety 4

1.5 Service Safety .. . 4

1.6 Safety Labels .. .....5-6

2. OPERATION ....... 7

2.1 Controls & Components ... 7

2.2 Application ... .8

2.3 Operating Principle .8

2.4 Assembling the blade . .... .. ....8

2.5 To Start ... ... 8-9

2.6 Cutting . ... .. 9

2.7To Stop .. ....9

3. MAINTENANCE .. .. .. . 10

3.1 Blade Removal and Replacement ... ... 10

3.2 Blade Guard Check. .. 10

3.3 Poly V-belt Alignment and Tensioning .. .. ....10

3.4 Troubleshooting .. .. ... .11

3.4.1 Blade Troubleshooting .. 11

3.4.2 Engine Troubleshooting ......... 12-13

3.5 Transporting .. ... .. ...... .14

4. TECHNICAL DATA ... ..... .. .. .15

WARRANTY ...... .. .. ..16

MAINTENANCE RECORD ..... ...17

.

EC DECLARATION .... ..18

2

SAFETY INFORMATON

1.1 Safety Precautions

Before using this equipment, study the entire owner s manual to become familiar

with its operation. Do not allow untrained or unauthorized personnel, especially

children, to operate this equipment. Use only factory authorized parts for service.

This manual contains DANGER, WARNING, CAUTION callouts

which must be followed to reduce the possibility of personal injury,

damage to the equipment, or improper service.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

!

!

DANGER

!

WARNING

!

CAUTION

3

SAFETY INFORMATON

1.2 Operating Safety

Failure to follow instructions in this manual may lead to serious injury or even death! This

equipment is to be operated by trained and qualified personnel only! This equipment is for

industrial use only.

The following safety guidelines should always be used when operating the concrete saw:

DO NOT operates or services this equipment before reading the entire manual. Always read,

understand, and follow procedures in operator’s Manual before attempting to operate

equipment.

ALWAYS be sure to operator is familiar with proper safety precautions and operating

techniques before using the saw. This equipment should not be operated by persons under 18

years of age.

NEVER operate this equipment without proper protective clothing, shatterproof glasses,

steel-toed boots and other protective devices required by the job.

NEVER operate this equipment when not feeling well due to fatigue, illness or under the

influence of drugs or alcohol.

NEVER use accessories or attachments, which are not recommended by MASALTA for this

equipment. Damage to the equipment and/or injury to user may result.

The manufacturer does not assume responsibility for any accident due to equipment

modifications.

Whenever necessary, replace nameplate, operation and safety decals when they become

difficult to read.

ALWAYS check the machine for loosened threads or bolts before starting.

NEVER touch the hot exhaust manifold, muffler or cylinder. Allow these parts to cool before

servicing engine or saw.

High Temperatures – Allow the engine to cool before adding fuel or performing service and

maintenance functions. Contact with hot components can cause serious bums.

NEVER operate the saw in any enclosed or narrow area where free flow of the air is restricted.

There is a risk of carbon monoxide poisoning. It could cause serious damage to the saw or

engine and may cause injury to people.

ALWAYS use extreme caution when working with flammable liquids. When refueling, stop the

engine and allow it to cool. Do not smoke around or near the machine.

NEVER operate the saw in an explosive atmosphere or near combustible materials. Fire

and/or explosions may result from errant sparks from the equipment.

Stop the engine when leaving the saw unattended. Block the unit when leaving or when using

on a slope.

Maintain this equipment in a safe operating condition at all times. Never use fuel as a cleaning

agent.

ALWAYS store equipment properly when it is not being used. Equipment should be stored in a

clean, dry location out of the reach of children.

4

SAFETY INFORMATON

1.3 Blade Safety

Use appropriate steel centered diamond blades manufactured for use on concrete saws.

ALWAYS inspect diamond blades before each use. The blade should exhibit no cracks, dings,

or flaws in the steel centered core and/or rim. Center (arbor) hole must be undamaged and

true. Examine blade flanges for damage, excessive wear and cleanliness before mounting

blade. Blade should fit snugly on the shaft and against the inside/outside blade flanges.

Ensure that the blade is marked with an operating speed greater than the blade shaft speed of

the saw.

Only cut the material that is specified by the diamond blade. Read the specifications of the

diamond blade to ensure the proper tool has been matched to the material being cut.

ALWAYS keep blade guards in place. Exposure of the diamond blade must not exceed 180

degrees.

Ensure that the diamond blade does not come into contact with ground or surface during

transportation. DO NOT drop the diamond blade on ground or surface.

The engine governor is designed to permit maximum engine speed in a no-load condition.

Speeds that exceed this limit may cause the diamond blade to exceed the maximum safe

allowable speed.

Ensure that the blade is mounted for proper operating direction.

1.4 Transportation Safety

Use the lifting bail and appropriate lifting equipment to ensure the safe movement of the saw.

DO NOT use the handle bars and/or front pointer as lifting points.

NEVER tow the saw behind a vehicle.

Ensure that both pointer bars are positioned appropriately to minimize their exposure during

transportation.

Safeguard against extreme saw attitudes relative to level. Engines tipped to extreme angles

may cause oil to gravitate into the cylinder head making the engine difficult to start.

NEVER transport the saw with the blade mounted.

1.5 Service Safety

NEVER lubricate components or attempt service on a running machine.

ALWAYS allow the machine a proper amount of time to cool before servicing.

Keep the machinery in running condition.

Fix damage to the machine immediately and always replace broken parts.

Dispose of hazardous waste properly. Examples of potentially hazardous waste are used

motor oil, fuel and fuel filters.

DO NOT use food or plastic containers to dispose of hazardous waste.

5

SAFETY INFORMATON

1.6 Safety Labels

MASALTA machines use international pictorial labels where needed. These labels are described

below:

Label Meaning

DANGER!

Engines emit carbon monoxide; operate only

in well-ventilated area. Read the Operation

Manual for machine information. No sparks,

flames, or burning objects near the machine.

Shut off the engine before refueling. Use

only clean, filtered unleaded gasoline.

WARNING!

Read and understand the supplied

Operation Manual before operating the

machine. Failure to do so increase the risk of

injury to yourself or others.

WARNING!

Always wear hearing and eye protection

when operating the machine.

CAUTION!

Lifting point.

6

SAFETY INFORMATION

Label Meaning

WARNING!

Hot surface!

WARNING!

WARNING!

Be care of your hand and foot when cutting.

WARNING!

A nameplate listing the model number and

serial number is attached to each unit. Please

record the information found on this plate so it

will be available if the nameplate lost or

damaged. When requesting service

information, the serial number should be

specified of the unit.

7

OPERATION

2. OPERATION

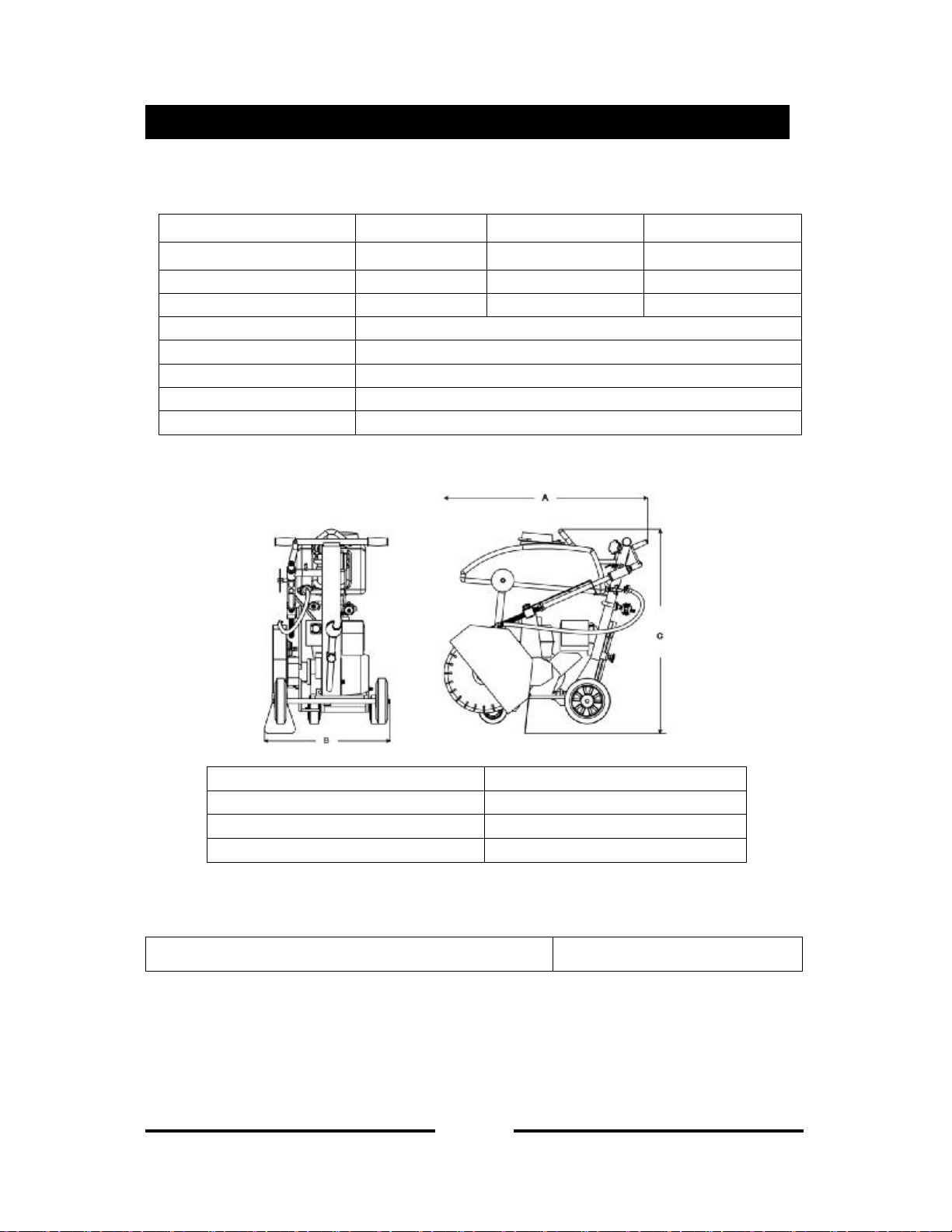

2.1 Controls & Components

Ref. Description Ref. Description

1 Refueling 6 Trolley wheel

2 Handle for Blade high Adjustment 7 Splash Guard

3 Throttle Control 8 Blade Guard

4 Water Tank Filling 9 Diamond Blade

5 Handle for Operating 10 Pointer Wheel

1

5 4

5

6

8

9

7

10

3

8

OPERATION

2.2 Application

Floor saw has been specifically designed as the ideal machine for the professional contractor

who is engaged in concrete and asphalt flat cutting. It is the most common type of diamond blade

cutting. it is possible to cut both concrete (green or cured, with or without rebar) or asphalt with a

floor saw. Our saw utilized for jobs requiring precision cutting including floors, pavements,

walkways, ramps and other flat sawing applications. This type of cutting is described as “flat”

because the pavement is cut somewhere close to a horizontal plane.

2.3 Operating Principle

The following instructions were compiled to provide you information on how to obtain long and

trouble free use of the unit. Periodic maintenance of this unit is essential. Read the manual in

its entirety and follow the instructions carefully. Failure to do so may injure yourself or a

bystander.

2.4 Assembling the Blade

1. Water hose coupler – Disconnect the water hose coupler.

2. Inner Flange (Collar) – This flange is fixed upon the blade shaft. The inside surface of the

flange must be free of debris and permit a tight closure on the surface of the blade.

3. Diamond Blade – Ensure that the proper diamond blade has been selected for the job.

Pay close attention to the directional arrows on the blade. The blade’s operating

directional arrows must point in a “ down – cutting “ direction to perform correctly. When

placing the blade onto the blade shaft, ensure the arbor hole of the blade matches the

diameter of the shaft.

4. Outside Blade Flange (Collar) – Ensure that the outside blade flange is placed flush

against the diamond blade. The inside surface of the flange must be free of debris and

permit a tight closure on the surface of the blade core.

5. Blade Hex Nut – Unscrew the blade shaft nut, DO NOT overtighten the nut when finalizing

the assembly.

6. Blade Guard – Pull the cover on, tighten the screw beside the blade guard cover

2.5 To Start

1. Turn the throttle control level to the middle position.

2. Set the engine ON/OFF switch to the “ON” position.

3. If it is cold start, turn the choke lever to close position.

4. Grip the recoil starter handle and pull it until you feel slight resistance. Then pull sharply

and quickly. Return the recoil starter handle to the starter case before releasing.

5. Grip the recoil starter handle and pull it a little to feel a slight resistance. Then pull it

powerfully from there. To release the handle do not release it at the position where it has

been pulled to, but release it after returning closely to the starter case.

9

OPERATION

6. If the engine has started, while listening to explosion sounds, return the choke lever slowly

to full-open position. Be sure to perform a warm-up run for the period 3 to 5 minutes at low

speed, while paying careful attention to gasoline leakage or abnormal sound.

7. If it is difficult to start the engine by repeatedly pulling the starter rope, pull off the spark

plug and check the sparking performance. If the plug is wet due to excessive fuel intake or

soiled, replace the coil or clean sufficiently to its internals. With the ignition plug removed,

pull the recoil starter handle 2-3 times to discharge excessive blended gas.

2.6 Cutting

1. Before the saw is placed into operation, run the engine for several minutes. Check for fuel

leaks, and noises that would associate with a loose blade guard covers.

2. Rotate the throttle lever to “rabbit” position.

3. To begin sawing, lower the rotating blade allowing it to cut to the present depth.

4. When blade has reached full cutting depth, slowly walk behind the saw at a rate that will

allow the engine to operate without losing optimum RPM.

5. When the end of the cut has been reached, raise the blade out of the cut by pulling back

on the handlebars (using a downward pressure) until the raise/lower rod drops into its slot

with the blade in the raised position.

6. If cutting is complete, shut the saw down using the following “ To Stop Procedures”.

2.7 To Stop

Stop the engine under normal conditions:

1. Place the engine throttle lever in the slow position, and listen for the engine speed to

decrease. Allow engine to run for 2 or 3 minutes for proper cool down.

2. Turn the engine ON/OFF switch to the “OFF” position.

3. Place the fuel valve lever to the “tortoise” position.

10

MAINTENANCE

3. MAINTENANCE

3.1 Blade Removal and Replacement

1. Disconnect the water hose coupler.

2. Ensure the Engine ON/OFF switch on the engine are turned to the “OFF“ position.

3. Place the PMF14 Saw on a stable level working surface.

4. Ensure the blade is raised and the raise/lower rod is locked into position.

5. Raise the blade by rotating the handlebars

6. Loose the screw, lifting up the blade guard cover to gain access to the diamond blade.

7. Use the provided blade nut and blade shaft locking wrenches to replace the diamond

blade.

8. While holding the blade shaft with the locking Wrench, remove the blade hex nut

(counter-clockwise direction) and outer blade flange.

9. Remove the old blade and install a new blade in the same rotational direction as marked

on the blade.

10. Reinstall the outer blade flange and hex nut. Tighten the nut firmly (clockwise direction).

DO NOT OVER TIGHTEN.

3.2 Blade Guard Check

1. Ensure the capacity of the blade guard matches the diameter of your diamond blade.

2. Check that the guard is bolted firmly upon the saw frame.

3.3 V-belt Alignment and Tension

1. Remove the bolts that secure the V-belt cover to the saw frame.

2. Check uniform parallelism of V-belt and pulley (sheaves). Use a straight-edge or

machinist’s square against both pulleys and adjust both pulleys until equally aligned.

3. DO NOT over or under tighten the V-belt. Severe damage can occur to the saw and engine

crank shaft if the belt is over-tensioned. A decrease of power to the blade and poor

performance will result if the belt is under-tensioned (loose on pulleys).

11

MAINTENANCE

4.

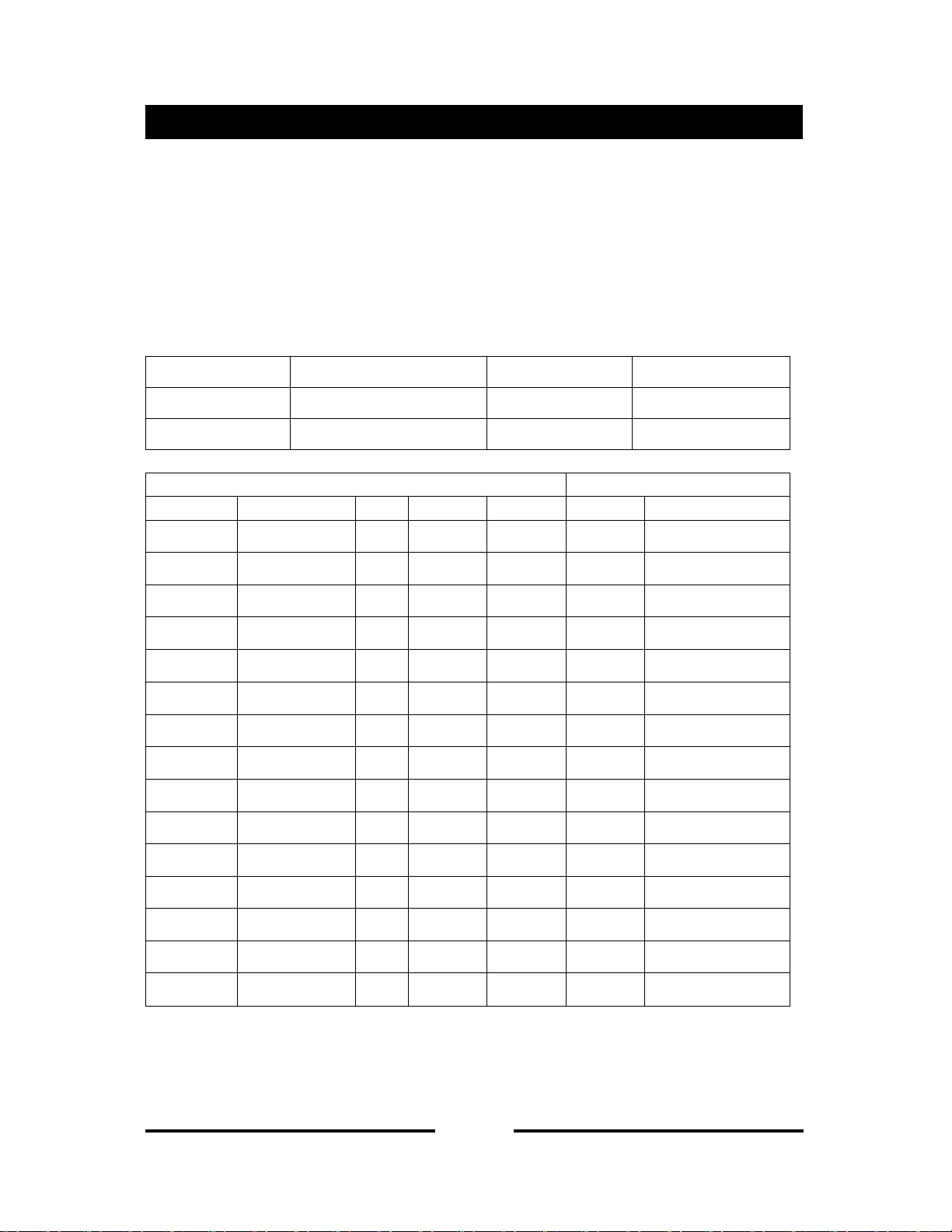

3.4 Troubleshooting

3.4.1 Blade Troubleshooting

SYMPTOM POSSIBLE PROBLEM SOLUTION

Blade too hard for the

material being cut?

Consult Dealer for correct blade. Try

cutting very soft material (sandstone, silica

brick, cinder block) to "Redress" the blade.

Engine torque diminished

because of loose V-belt? Tighten and/or replace V-Belt.

Insufficient Engine power? Check throttle setting. Check Engine

horsepower.

Improper dircection of

rotation?

Check that the blade is properly

oriented and rotational arrow points in a

"D

o

wn

-

Cutting"

direction.

Blade slows

or stops

cutting, still

remains on

blade

Blade is slipping on the blade

shaft?

Check that the blade & flange pin are

properly installed on the blade shaft.

Blade being used on

misaligned saw?

Check blade shaft bearings and

alignment integrity.

Blade is excessively hard for

the material being cut?

Check specification of the blade with the

material being cut. Consult Dealer for

information.

Blade being used at improper

RPM?

Ensure blade surface feet per minute

speed (SFPM) is approximately 6,000.

Blade improperly mounted on

arbor shoulders and flanges?

Ensure blade is properly affixed on the

blade shaft.

Blade does

not cut

straight

and/or true.

Excessive force applied to

blade while cutting?

DO NOT force the blade in the cut. Apply

a slow and steady pace when sawing.

Blades too hard for the

material being cut?

Consult Dealer for correct blade. Try

cutting very soft material (sandstone, silica

brick, cinder block) to "Redress" the blade.

Blade improperly mounted on

arbor shoulders and flanges?

Ensure blade is properly affixed on the

blade shaft.

Blade not receiving enough

cooling air?

Ensure proper flow & volume of water is

provided for wet cutting blades. Ensure

sufficient cooling air is circulated about a

dry cutting blade.

Arbor hole out of round? Ensure blade is properly affixed on the blade

shaft.

Incorrect blade chosen for

material being cut?

Check specification of the blade with the

material being cut. Consult Dealer or for

information.

Blade

discoloring,

crackling

and/or

wearing

excessively.

Excessive force applied to

blade while

cutting?

DO NOT force the blade in the cut. Apply

a slow and steady pace when sawing.

12

MAINTENANCE

3.4.2 Engine Troubleshooting

SYMPTOM POSSIBLE CAUSE SOLUTION

Spark plug bridging? Check gap, insulation or replace

spark plug.

Carbon deposit on spark

plug? Clean or replace spark plug.

Short circuit due to deficient

spark plug insulation?

Check spark plug insulation, replace

if worn.

Difficult to start,

"fuel is

available, but no

SPARK at spark

plug".

Improper spark plug gap? Set to proper gap.

ON/OFF switch is shorted? Check switch wiring, replace switch.

Ignition coil defective? Replace ignition coil.

Improper spark gap, points

dirty? Set correct spark gap and clean points.

Condenser insulation worn or

short circuiting? Replace condenser.

Difficult to start,

"fuel is

available, and

SPARK is

present at the

spark plug".

Spark plug wire broken or

short circuiting? Replace defective spark plug wiring.

Wrong fuel type? Flush fuel system, and replace

with correct type of fuel.

Water or dust in fuel system? Flush fuel system.

Air cleaner dirty? Clean or replace air cleaner.

Difficult to start,

"fuel is vailable,

spark is present

and ompression

is normal".

Choke Open? Close Choke.

Suction/exhaust valve stuck or

protruded? Re-seat valves.

Piston ring and/or cylinder

worn? Replace piston rings and or piston.

Cylinder head and/or spark

plug not tightened properly?

Torque cylinder head bolts and

spark plug.

Difficult to start,

"fuel is

available, spark

is present and

compression is

low".

Head gasket and/or spark

plug gasket damaged? Replace head and spark plug gaskets.

13

MAINTENANCE

SYMPTOM POSSIBLE CAUSE SOLUTION

Fuel not available in fuel

tank? Fill with correct type of fuel.

Fuel filter clogged? Replace fuel filter.

Fuel tank cap breather hole

clogged? Clean or replace fuel tank cap.

No fuel present

at the

carburetor.

Air in fuel line? Bleed fuel line.

Air cleaner not clean? Clean or replace air cleaner.

Check float adjustment.

Improper level in carburetor?

Rebuild carburetor.

Defective spark plug? Clean or replace spark plug.

"Weak in power"

compression is

proper and does

not misfire.

Improper spark plug gap? Set to proper gap.

Water in fuel system? Flush fuel system and replace with

correct type fuel.

Ignition coil defective? Replace ignition coil.

"Weak in power"

compression is

proper but

misfires. Dirty spark plug? Clean or replace spark plug.

Wrong fuel type? Flush fuel system, and replace with

correct type of fuel.

Spark plug heat value

improper? Replace with correct type of spark plug.

Engine

overheats.

Cooling fins dirty? Clean cooling fins.

Governor adjusted

correctly? Adjust governor.

Governor spring defective or

missing? Replace governor spring.

Rotational

speed

fluctuates.

Fuel flow restricted? Check entire fuel system for leaks or

clogs.

Recoil mechanism clogged

with dust and dirt?

Clean recoil assembly with soap and

water.

Recoil starter

malfunction.

Spiral spring loose? Replace spiral spring.

14

MAINTENANCE

3.5 Transporting

1. Shutdown engine for transportation.

2. The blade must be removed from the saw during all transport and lifting.

3. For transportation, tighten fuel tank cap securely to prevent fuel from spilling.

4. Use the parking brake during transportation

5. Use lifting point when lifting machine

6. Make sure lifting device has enough capacity to hold machine

15

TECHNICAL DATA

4. TECHNICAL DATA

Model MFS14-1 MFS14-3 MFS14-4

Engine type Kipor170 Robin EX17 Lombardini LD225

Power kw(hp) 3.1(4.2) 4.2(5.7) 4.0(5.5)

Weight kg(lb) 83(183) 70(154) 70(154)

Max cutting depth cm(in) 18.5(7.2)

Blade size cm(in) 30-35(12-14)

Depth adjustment Handle rotation

Driving Manual push

Water tank capacity (L) 28

Dimension:

Sound Specification (According to 2000/14/EC)

Guaranteed sound power level 108 dB(A)

Hand-Arm vibration Specification (According to ISO 5394, EN 1033 and EN500-4): 5.0m/s2

Ref. Dimension (MM)

A 1050

B 910

C 480

16

WARRANTY

MASALTA products are covered by warranty for a period of twelve (12) months from the date

of purchase against defects in material or workmanship provided that:

l The product concerned has been operated and maintained in accordance with the

operating instructions.

l Has not been damaged by accident, misuse or abuse.

l Has not been tampered with or repaired by any unauthorized person.

The owner is responsible for the cost of transportation to and from the authorized repairer and

the unit is at the owners risk while in transit to and from the repairer.

Impact damage is not covered under warranty. Clutches are not covered under any

warranty.

Engines are officially guaranteed by Honda, Robin, Kipor manufacturer. Please refer to

the annex for engine warranty.

17

MAINTENANCE RECORD

PREVENTATIVE MAINTENANCE AND ROUTINE SERVICE PLAN

MASTERPAC green concrete saw has been assembled with care and will provide years of

service. Preventative maintenance and routine service are essential to the long life of your

saw. After reading through this manual thoroughly, you will find that you can do some of the

regular maintenance yourself. However, when in need of parts or major service, be sure to

see your dealer. For your convenience we have provided this space to record relevant data

about your saw.

Invoice Number: Type of Machine:

Date Purchased: Dealer Name:

Serial Number: Dealer Phone:

REPLACEMENT PARTS USED MAINTENANCE LOG

PART NO. DESCRIPTION

QTY COST DATE DATE OPERATION

18

EC DECLARATION OF CONFORMITY

CE-KONFORMIT TSERKL UNG

DECLARACIÓN DE CONFORMIDAD DE LA CE

DÉCLARATION DE CONFORMITÉ C.E.

MASALTA ENGINEERING CO., LTD

Weisi Road, Baohe Industrial Estate, HeFei 230051, China

hereby certifies that the construction equipment specified hereunder / bescheinigt, da. das Bauger.t / certifica

que la m quina de construcción / atteste que le matériel :

1. Category / Art / Categoría / Catégorie:

Floor Saw

2. Type / Typ / Tipo / Type:

MFS 14

has been produced in accordance with the following standards:/in übereinstimmung mit folgenden Richtlinien

hergestellt worden ist:/ha sido fabricado en conformidad con las siguientes normas: / a été produit

conformément aux dispositions des directives européennes ci-après :

2000/14/EC outdoor

2006/42/EC

2004/108/EC/EN55012:2007

EN13862/2001

15.02.10 Hermann Josef Lensing

--------------------------------------------------- Research and Development Manager

Date / Datum / Fecha / Date

Table of contents

Other Masalta Saw manuals

Popular Saw manuals by other brands

Craftsman

Craftsman 10 IN. TABLE SAW 315.22811 owner's manual

Wen

Wen BA4664 instruction manual

Barranca Diamond

Barranca Diamond BD10 Owner's Manual and Operating Instructions

HURRY UP

HURRY UP HUCRS-200 instruction manual

Wellsaw

Wellsaw 1016 operating & maintenance manual

DeWalt

DeWalt DCS727-XE Original instructions