Masalta MSP Series User manual

WARNING

!

R

INSTRUCTION MANUAL

SUBMERSIBLE PUMP

(FLEXIBLE SHAFT PUMP)

MSP SERIES

1

CONTENTS

SAFETY INSTRUCTIONS …………………1

HEALTH & SAFETY…………….…..………2

TRANSPORTATION……………….….…….3

LABELS………………….….……….….……4

FUNCTIONAL DESCRIPTION……………5-6

OPERATION …...………...………...……6-7

SAFETY INSTRUCTIONS

For your own personal protection and for the safety of those around you, please read and ensure you

fully understand the following safety information. It is the responsibility of the operator to ensure that

he/she fully understands how to operate this equipment safely. If you are unsure about the safe and

correct use of our MSP, consult your supervisor.

CAUTION: Improper maintenance can be hazardous. Read and Understand

this section before you perform any maintenance, service or repairs.

Ensure, that all symbols on the machine, can always be clearly read.

Do not leave any tools or parts lying around on the work floor, as this can cause accidents.

Stationary power units and drives must have a distance of at least one metre from equipment,

buildings or other units.

Protect the unit against rain, snow or any other forms of moisture. This could cause damage or

malfunctions.

Only operate the unit on a dry surface. If water accumulates under the unit, you must switch off the

unit and let it dry properly.

When cleaning the machine, ensure that no water or cleaning detergents get into the engine.

When the machine is not being used for longer periods of time, then it must be stored in a dry and

clean area.

Make sure that the flexible shaft is not bent too severely and does not run over sharp edges.

Otherwise move the hose protection to the kink for protection.

Open flames and smoking are strictly prohibited in the immediate vicinity of the unit.

Make sure that waste, such as paper, dry leaves or grass do not accumulate around the

exhaust muffler. They can easily ignite.

Pay attention to your own safety and the safety of your colleagues.

Regular maintenance of the machine promotes safe operation.

The following safety-aspects specifically apply to those machines equipped with a petrol engine:

Do not use an MSP, fitted with a petrol engine, indoors or in poorly ventilated places, such as pits

etc. Make sure that there is sufficient ventilation in spaces which are surrounded by walls. Do not

inhale exhaust fumes. They contain toxic carbon monoxide that can lead to unconsciousness

or death.

Prior to starting the engine, the flexible shaft must be disconnected from the drive unit.

SERVICE & MAINTENANCE…..………7-8

TECHNICAL DATA …..………..…………8-9

TROUBLESHOOTING.………..…………9-10

WARRANTY ……..…………..……..……10

MAINTENANCE RECORD……..…………11

EC DECLARATION…………….…………..12

2

Do not change the preset engine speed. This could cause engine damage.

Check for fuel leaks before running the machine.

Do wear working-gloves, safety glasses and protecting clothing during refueling.

Make sure that there is sufficient ventilation during refueling.

Refueling is only allowed after the engine has been cooled off sufficiently.

Refueling, while the engine is hot, might lead to a very dangerous situation. It is strictly forbidden to

refuel:

·In the direct vicinity of open fire or other flammable materials,

·While smoking cigarettes etc.

·In explosion endangered spaces.

HEALTH & SAFETYS

Working Area

KEEP your working area clean and well lit. Cluttered benches and dark areas invite accidents.

DO NOT OPERATE the equipment in explosive atmospheres, such as in the presence of

flammable liquids, gases, or dust.

KEEP AWAY from standers, children, and visitors while operating a power tool. Distractions can

cause to loose control.

Specific Safety Rules

For your own safety, as well as for the others one, and in order not to cause any damage to this

equipment, please read carefully the instructions that are explained as follows:

1.- For the proper use of this device, please assure that the operator has been correctly informed

of the content of this manual before using it.

2.- This equipment must be used only under the applications for which it has been designed and only

according to these safety instructions.

3.- Do not touch any hot parts such as the engine block or exhaust muffler during operation or directly

afterwards. These parts can become very hot and cause severe burns.

4.- Do not work in an area exposed to flammable liquids or gases.

5.- Do not allow inexperienced or not trained personnel to use the equipment alone.

6.- Always keep the operating controls dry, clean and free of oil or grease.

7.- When working with a petrol engine:

- Read the engine manufacturer's manual before working.

- Do not work in closed rooms, the exhaust fumes may be toxic.

- Wait 2 minutes for the petrol refill until the motor gets cold.

PPE (Personal Protective Equipment).

Suitable PPE must be worn when using this equipment i.e. Hardhat, Safety Goggles, Ear

Defenders, Work gloves and Non-skid, hard-toed shoes. Clothing should be appropriate, i.e. should

be close-fitting but not restrict your movement. Wear personal protective gear can avoid injuries or

health hazards:

3

TRANSPORTATION

Switching off the unit

Before you transport the unit, it must be switched off, and the engine must be given sufficient

time to cool down.

Lifting

When lifting the unit, observe the following instructions:

Designate a skilled person to guide you for the lifting procedure.

You must be able to see or hear this person.

Use only suitable and certified hoisting gear, lifting tackle and load-bearing equipment with

sufficient lifting capacities.

Only use the attachment points described in the operation manual.

Attach the unit securely to the hoisting gear.

Ensure that no one is nearby prior to lifting the unit.

Do not climb onto the unit.

Make sure that no one walks under or stands beneath the suspended unit.

Remove (loose) components before lifting.

Loading

Loading ramps must be able to bear the load and be in a stable position.

Make sure that no one can be endangered if the unit slips away or tips over or if parts suddenly

move upward or downward.

Put the operating controls and moving parts in their transport position.

Secure the unit with load-securing straps so that it cannot roll or slide away or tip over. Only use the

attachment points described in the operation manual.

Transport vehicle

Use only suitable transport vehicles with sufficient load-carrying capacities.

Restarting

Parts, accessories or tools that have been detached for transport purposes must

be carefully re-mounted and fastened before you restart the unit.

When you restart the unit, only proceed as described in the operation manual.

4

LABELS

Your unit has adhesive labels containing the most important instructions and safety information.

Make sure that all the labels are kept legible.

Replace any missing or illegible labels.

Label

Meaning

DANGER!

Engines emit carbon monoxide; operate only in

well-ventilated area. Read the Operation Manual for

machine information. No sparks, flames, or burning

objects near the machine. Shut off the engine before

refueling. Use only clean, filtered unleaded gasoline.

WARNING!

Hot surface!

CAUTION!

Read and understand the supplied Operation Manual

before operating the machine. Failure to do so

increase the risk of injury to yourself or others.

5

FUNCTIONAL DESCRIPTION

The submersible pump consists of the components

Drive unit

Pump head

Flexible shaft

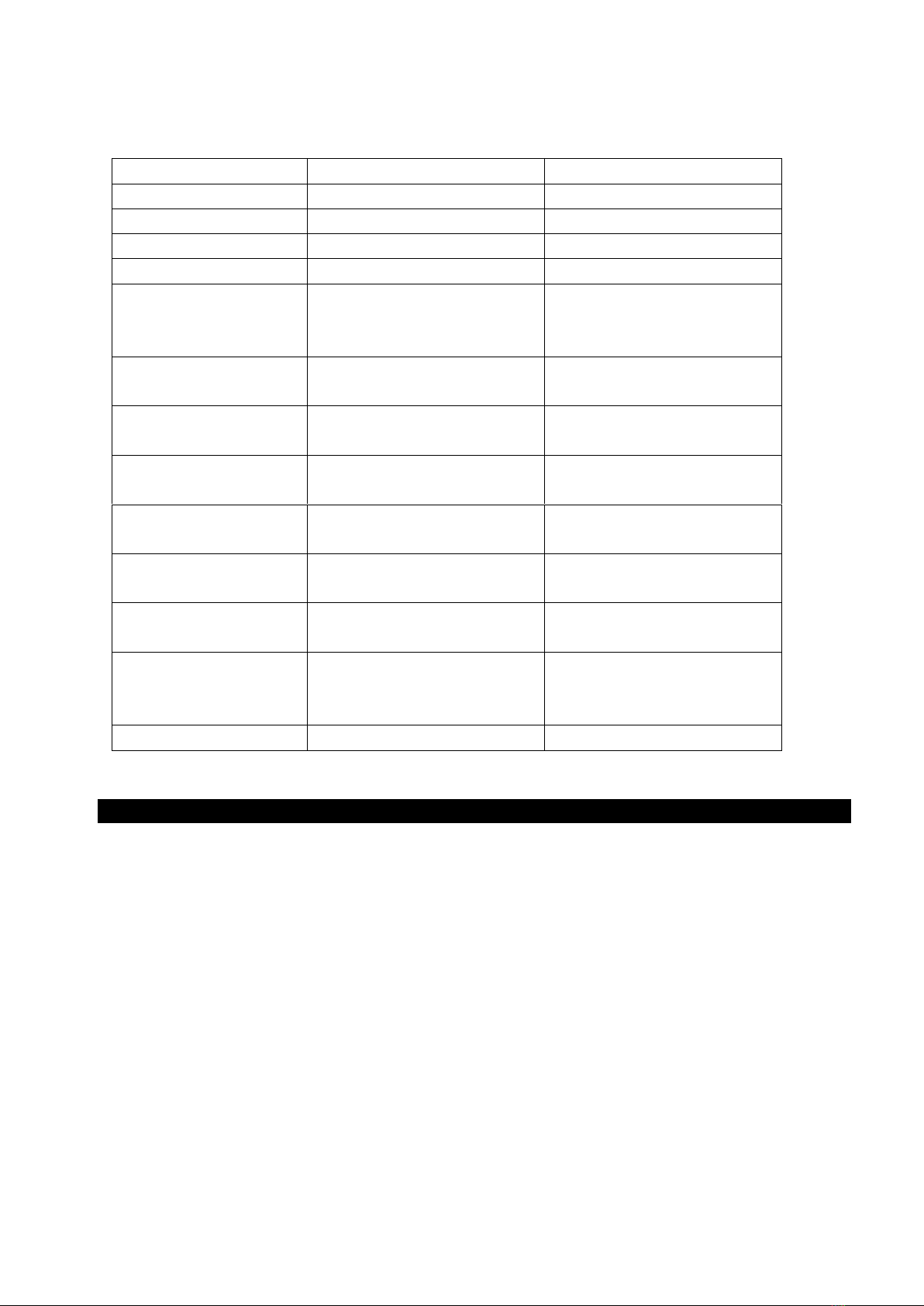

Item

Description

Item

Description

1

Drive Unit MVDR

5

Pressure Connection

2

Connection to Drive Unit

6

Suction Strainer

3

Flexible Shaft

7

Flexible Shaft Connection

4

Spring protection

8

Connection to Pump Head

Optional Drive Unit --- MVDS & MVE

1

2

3

4

5

6

7

8

MVE

MVDS

6

Functionality (schematic diagram)

Item

Description

Item

Description

1

Drive

4

Pump Head

2

Hose protection

5

Hose Clamp (optional)

3

Protective hose with flexibleshaft

6

Pressure hose (optional)

The drive drives the pump head by means of a flexible shaft.

The pump head sucks water through the suction strainer and pumps it through

the pressure hose.

OPERATION

Read and follow all the safety instructions at the beginning of this operation

manual. Improper use can result in injury or serious material damage.

Submersible pump connections

Make sure that all components are connected firmly:

Flexible shaft to drive unit.

Flexible shaft to pump.

Pressure hose to pump.

Otherwise this could result in damage to or malfunction of the submersible pump.

Checking before starting

Before you start the engine, check the following:

!

WARNING

7

Fuel level –the tank should be at least half full.

Oil level –the oil level must be between the lower and upper marks.

Air filter –replace any damaged parts.

Starting up

Prior to operating the submersible pump, the drive engine should have the correct operating

temperature (warm up for 2-3 minutes). Then switch the engine back off again.

Open the fuel tap by moving the fuel ON/OFF lever fully to the right.

If starting the engine from cold, set the choke ON by moving the choke lever fully to the left. If

restarting a warm engine, the choke is usually not required. However, if the engine has cooled to a

degree, partial choke may be required.

Turn the engine ON/OFF switch clockwise to the “1”position.

Set the throttle to the idle position by moving the throttle lever fully to the right.

Do not start the engine on full throttle, as the compactor will

vibrate as soon as the engine starts.

Taking a firm hold of the control handle with one hand, grasp the

recoil starter handle with the other. Pull the recoil starter until

engine resistance is felt, then let starter return.

Taking care not to pull the starter’s cope fully out, pull the starter

handle briskly.

Repeat until the engine fires.

Once the engine fires gradually, set the choke lever to the OFF position by moving it to the right.

To stop

Set the throttle to idle and turn the engine ON /OFF switch anticlockwise to the “0” position to stop

the engine. Then turn the fuel off.

SERVICE & MAINTENANCE

Maintenance and repair work must be carried out only to the extent described in this manual.

Before carrying out maintenance or repair work, switch off the engine and allow it to cool down. For

petrol-powered engines, you must pull off the spark plug connector.

Cleaning

Always keep the unit clean and be sure to clean it each time you have finished

using it. Clean the engine cooling fins when the engine has cooled down. Do not

use gasoline or solvents. Danger of explosion!

The air filter element should be cleaned because a clogged air cleaner can

cause poor engine starting, lack of power and shorten engine life substantially.

To clean or replace air filter loosen the wing nut on the air filter housing (Figure 1),

remove the cover and take out air filter cartridge. If only cleaning of the air filter

is desired blow through the air filter cartridge from the inside, moving a jet of dry

compressed air up and down until all dust is removed.

8

Maintenance schedule

Daily

before

operation

After the

first

20 hours

Weekly or

every

25 hours

Monthly

or every

100 hours

Annually

or every

300 hours

Check the fuel:

- fuel level of tank

- tank for leaks

- lines for leaks

Check the oil level of the

drive

Check the pump head:

- for loose parts

- housing, impeller, main

shaft and oil seal for wear

and cracks

Check the flexible shaft:

- the coupling for wear

- the protective hose for

wear and cracks

- grease must be free of

dirt and metal chips

It must be possible to

easily turn the main shafts

of pump head,

flexible shaft and

connections to the drive

Check the pressure hose

for wear and cracks

Check the unit for

abnormal operating noise

Clean air filter

Change the engine oil

Clean fuel filter

Check and clean the spark

plug

Replace the spark plug

Grease the flexible shaft

Have worn or damaged components replaced immediately!

Malfunction of the oil seal in the pump!

Water could penetrate the engine via the flexible shaft.

Stop the engine immediately and eliminate the problem.

!

CAUTION

9

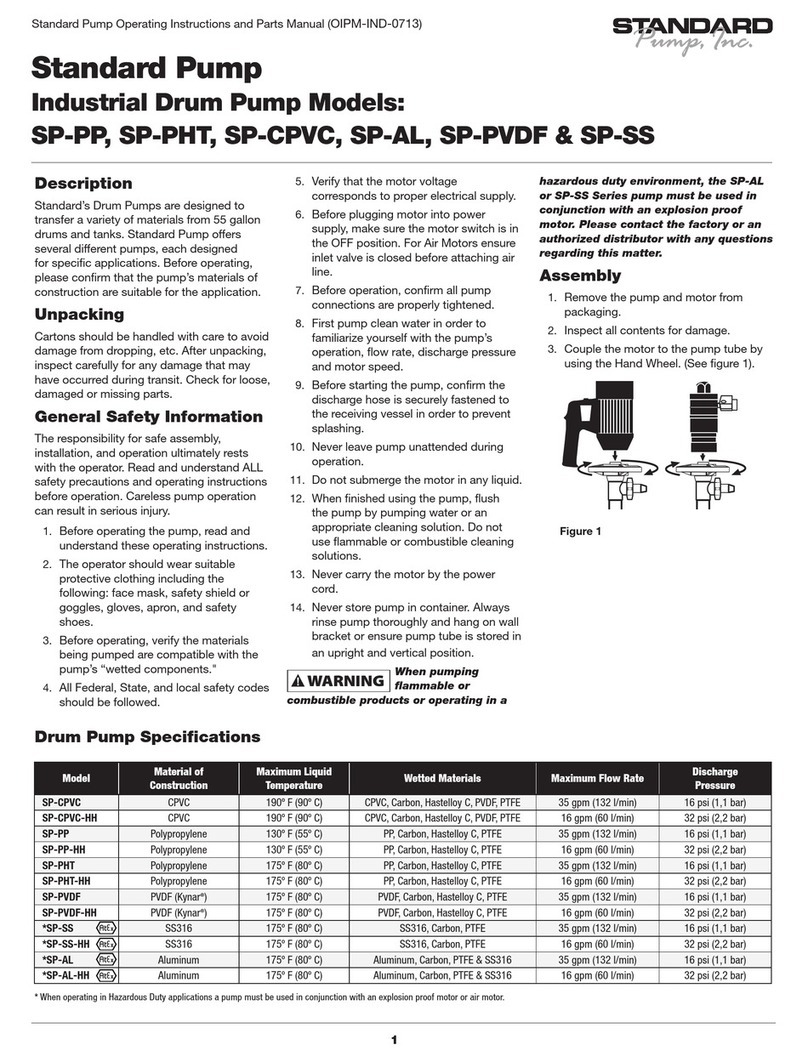

TECHNICAL DATA

Drive Unit

Model

MVDR-1

MVDS-1

MVDR-3

MVDS-3

MVDR-4

MVDS-4

MVE

Engine Type

Diesel, 170

Petrol, Robin

EX17

Petrol, Honda

GX160

Electric

Motor

Power kw

3.1

4.2

4.0

1.1/1.5

Weight kg (lb)

31 (68)

21 (46)

21 (46)

Pump Head with Flexible Shaft

Model

MSP2

MSP3

Discharge Dia mm (in)

50 (2)

75 (3)

Max. Lift m

15

18

Max. Capacity L/min

1000

1300

Revolution rpm

3000-3600

Length of Hose m

*5

Weight kg (lb)

21 (46)

22 (49)

* Our standard length of flexible hose for the pump is 5m, 4m-9m length is avaible.

TROUBLESHOOTING

Drive

Malfunction

Cause

Remedy

No delivery

Connection damaged

Have the part replaced

Engine does not start

Fuel tank empty

Top up with fuel

Fuel tap closed

Open the fuel tap

Oil level “too low”because the

drive is leaning (automatic oil

shut off)

Position the drive horizontally

Oil level too low (automatic oil

shut off)

Top up with engine oil

Spark plug

Clean, set electrode gap, or

replace

Engine does not turn

Engine damage

Repair engine or have it

replaced

Engine not running

smoothly

Air filter dirty

Clean air filter

Spark plug

Clean, set electrode gap, or

replace

10

Pump head

Malfunction

Cause

Remedy

Abnormal noises

Grease used up

Replace grease

Ball bearing defective

Have the ball bearing replaced

Flexible shaft damaged

Replace the flexible shaft

Protective hose damaged

Replace the protective hose

Low delivery volume

Pump housing, impeller, main

shaft or oil seal damaged or

worn

Have the part replaced

Pump housing or pressure

hose blocked

Clean the component

thoroughly

Pressure hose damaged or

disconnected

Have pressure hose replaced

or repaired

No delivery, but rotation

sound can be heard

Flexible shaft coupling

damaged

Replace the flexible shaft

Pressure hose disconnected

Have pressure hose replaced

or repaired

Impeller, housing, drive shaft

or oil seal damaged

Have the part replaced

Housing or pressure hose

blocked

Clean the component

thoroughly

No delivery,

no rotation sound to be

heard

Ball bearing defective

Have the ball bearing replaced

Flexible shaft broken

Replace the flexible shaft

WARRANTY

These products are covered by warranty for a period of six (6) months from the date of purchase

against defects in material or workmanship provided that:

·The product concerned has been operated and maintained in accordance with the operating

instructions.

·Has not been damaged by accident, misuse or abuse.

·Has not been tampered with or repaired by any unauthorized person.

The owner is responsible for the cost of transportation to and from the authorized repairer and the unit

is at the owners risk while in transit to and from the repairer.

Impact damage is not covered under warranty. Clutches are not covered under any warranty.

Engines are warranted by their manufacturer.

11

MAINTENANCE RECORD

Preventative Maintenance and Routine Service Plan

This Vibrating Screed Screed has been assembled with care and will provide years of service.

Preventative maintenance and routine service are essential to the long life of your Vibrating Screed.

After reading through this manual thoroughly, you will find that you can do some of the regular

maintenance yourself. However, when in need of parts or major service, be sure to see your dealer. For

your convenience we have provided this space to record relevant data about your Vibrating Screed.

Invoice Number:

Type of Machine:

Date Purchased:

Dealer Name:

Serial Number:

Dealer Phone:

REPLACEMENT PARTS USED

MAINTENANCE LOG

PART NO.

DESCRIPTION

QUANTITY

COST

DATE

DATE

OPERATION

12

EC DECLARATION OF CONFORMITY

CE-KONFORMIT.TSERKL.RUNG

DECLARACIÓN DE CONFORMIDAD DE LA CE

DÉCLARATION DE CONFORMITÉC.E.

MASALTA ENGINEERING CO., LTD

Weisi Road, Baohe Industrial Estate, HeFei 230051, China

hereby certifies that the construction equipment specified hereunder / bescheinigt, da. das Bauger.t / certifica que la

máquina de construcción / atteste que le matériel :

MSP2 / MSP3

has been produced in accordance with the following standards:/in übereinstimmung mit folgenden Richtlinien hergestellt

worden ist:/ha sido fabricado en conformidad con las siguientes normas: / a étéproduit conforme aux dispositions des

directives européennes ci-après :

2000/14/EC

98/37/EC

89/336/EC

EN500-1

EN500-4

20.06.09 Hermann Josef Lensing

--------------------------------------------------- Research and Development Manager

Date / Datum / Fecha / Date

13

Distributed By

MASALTA ENGINEERING CO., LTD

Add: Weisi Road, Baohe Industrial Estate, Hefei, China

Tel: 86-551-4846600, 4846601 Fax: 86-551-4846616

E-mail: sales@masalta.com.cn, masalt[email protected].cn,

Http://www.masalta.com.cn

Version: 01/12/01

This manual suits for next models

9

Table of contents

Popular Water Pump manuals by other brands

DYI SHENG

DYI SHENG DS20-A-01 operating manual

Becker

Becker KVT 3.100 operating instructions

Standard Pump

Standard Pump SP-CPVC operating instructions

Xylem

Xylem Flygt 3127 Installation, operation and maintenance manual

Clarke

Clarke CM1 Operating & maintenance instructions

Pentair

Pentair SUPERFLO VST Installation and user guide

Grundfos

Grundfos PHP A-1 4.0 instruction manual

vacuubrand

vacuubrand MV 10C VARIO select Instructions for use

Homa

Homa TGR series Original instruction manual

Hydromatic

Hydromatic SKV50M1 Installation and service manual

Grundfos

Grundfos DMH 28X Installation and operating instructions

VADA

VADA V30-RC instruction manual