TEXEL MEP User manual

Texel

Magnetic Drive Pump

Operation

Manual

Thank you for purchasing Texel Corrosion Resistant Pump.

Although the pump is designed and manufactured for applications in which corrosion resistance is a priority, modifications

in operating conditions or improper operations may result in unexpected incidents.

It is requested that the user read this operation manual thoroughly and use the product in a proper manner.

Contents

1.

Things to be confirmed upon arrival................................ 6

2.

For the safety ..................................................................... 6

2.1.

Transportation ................................................................ 6

2.2.

Confirmation................................................................... 6

2.3.

Application...................................................................... 6

3.

Storage ............................................................................... 6

3.1.

Short-term storage (less than three months).................. 6

3.2.

Long-term storage (more than three months)................. 6

4.

Installation and piping....................................................... 7

4.1.

Installation ...................................................................... 7

4.2.

Piping ......................................................................... 7

4.2.1.

Piping load (common for all models) ................ 7

4.2.2.

Suction piping (other than MES type) (Fig.

4-4)................................................................... 7

4.2.3.

Discharge piping (other than MES type)........... 8

4.2.4.

Suction piping (MES type) (Fig. 4-4)................. 8

4.2.5.

Discharge piping (MES type) (Fig. 4-3) ............ 8

4.2.6

Motor wiring...................................................... 8

5.

Notes on handling............................................................ 11

5.1.

Notes on the start-up.................................................... 11

5.2.

Notes on the operation................................................. 11

5.3.

Notes on stopping ........................................................ 12

5.4.

Notes operational interruption ...................................... 12

5.5.

Notes on the motor....................................................... 12

5.6.

Notes on the ambient temperature............................... 12

5.7.

Notes on the fluid ......................................................... 12

5.8.

Others .......................................................................... 12

5.9.

Ordering spare parts .................................................... 12

6.

MER type .......................................................................... 13

6.1.

Construction and parts name ....................................... 13

6.2.

Maintenance and inspection......................................... 14

6.2.1.

Routine inspection.......................................... 14

6.2.2.

Regular inspection.......................................... 14

6.2.3.

Abrasive limit of the bearing ........................... 14

6.3.

Disassembling & assembling ....................................... 15

6.3.1.

Notes on disassembling ................................. 15

6.3.2.

Preparation for disassembling ........................ 15

6.3.3.

Disassembling ................................................ 15

6.3.4.

Assembling..................................................... 16

6.3.5.

Replacement of the motor and outer magnet . 16

6.3.6.

Replacement of the main shaft and front

thrust .............................................................. 17

6.3.7.

Replacement of the front bearing ................... 17

6.3.8.

Replacement of the rear bearing and the

rear thrust....................................................... 17

6.3.9.

Replacement of the casing and casing cover . 18

7.

MEH-040 type ................................................................... 19

7.1.

Construction and parts name ....................................... 19

7.2.

Maintenance and inspection......................................... 20

7.2.1.

Routine inspection.......................................... 20

7.2.2.

Regular inspection.......................................... 20

7.2.3.

Abrasive limit of the bearing ........................... 20

7.3.

Disassembling & assembling ....................................... 21

7.3.1.

Notes on disassembling ................................. 21

7.3.2.

Preparation for disassembling ........................ 21

7.3.3.

Disassembling ................................................ 22

7.3.4.

Assembling..................................................... 22

7.3.5.

Replacement of the motor and outer magnet . 23

7.3.6.

Removing and replacing the main shaft ......... 23

7.3.7.

Replacement of bearing ................................. 24

7.3.8.

Replacement of the mouth ring and

front/rear thrust rings...................................... 24

7.3.9.

Replacement of the casing and casing cover. 24

8.

MTA-040/080/100 type...................................................... 25

8.1.

Construction and parts name ....................................... 25

8.2.

Maintenance and inspection ........................................ 26

8.2.1.

Routine inspection.......................................... 26

8.2.2.

Regular inspection.......................................... 26

8.2.3.

Abrasive limit of the bearing ........................... 26

8.3.

Disassembling & assembling ....................................... 27

8.3.1.

Notes on disassembling ................................. 27

8.3.2.

Preparation for disassembling ........................ 27

8.3.3.

Disassembling ................................................ 28

8.3.4.

Assembling..................................................... 29

8.3.5.

Replacement of the motor and outer magnet . 29

8.3.6.

Removing and replacing the main shaft ......... 29

8.3.7.

Replacement of bearing ................................. 30

8.3.8.

Replacement of the mouth ring and the

front/rear thrust rings...................................... 30

8.3.9.

Replacement of the shaft support................... 30

9.

MTA-101/125/150 type...................................................... 31

9.1.

Construction and parts name ....................................... 31

9.2.

Maintenance and inspection ........................................ 32

9.2.1.

Routine inspection.......................................... 32

9.2.2.

Regular inspection.......................................... 32

9.2.3.

Abrasive limit of the bearing ........................... 32

9.3.

Disassembling & assembling ....................................... 33

9.3.1.

Notes on disassembling ................................. 33

9.3.2.

Preparation for disassembling ........................ 33

9.3.3.

Disassembling ................................................ 34

9.3.4.

Assembling..................................................... 35

9.3.5.

Replacement of the motor and outer magnet . 35

9.3.6.

Removing and replacing the main shaft ......... 36

9.3.7.

Replacement of bearing ................................. 36

9.3.8.

Replacement of the mouth ring and the

front/rear thrust rings...................................... 36

9.3.9.

Replacement of the shaft support................... 36

10.

MTA-200 type.................................................................... 37

10.1.

Construction and parts name ....................................... 37

10.2.

Maintenance and inspection ........................................ 38

10.2.1.

Routine inspection.......................................... 38

10.2.2.

Regular inspection.......................................... 38

10.2.3.

Abrasive limit of the bearing ........................... 38

10.3.

Disassembling & assembling ....................................... 39

10.3.1.

Notes on disassembling ................................. 39

10.3.2.

Preparation for disassembling ........................ 39

10.3.3.

Disassembling ................................................ 40

10.3.4.

Assembling..................................................... 41

10.3.5.

Replacement of the motor and outer magnet . 41

10.3.6.

Removing and replacing the main shaft ......... 41

10.3.7.

Replacement of bearing ................................. 41

10.3.8.

Removing and replacing the impeller ............. 42

10.3.9.

Replacement of the mouth ring and the

front/rear thrust............................................... 42

11.

MSX-100/125/150 type...................................................... 43

11.1.

Construction and parts name ....................................... 43

11.2.

Maintenance and inspection......................................... 44

11.2.1.

Routine inspection.......................................... 44

11.2.2.

Regular inspection.......................................... 44

11.2.3.

Abrasive limit of the bearing ........................... 44

11.3.

Disassembling & assembling ....................................... 45

11.3.1.

Notes on disassembling ................................. 45

11.3.2.

Preparation for disassembling ........................ 45

11.3.3.

Disassembling ................................................ 46

11.3.4.

Assembling..................................................... 47

11.3.5.

Replacement of the motor and outer magnet . 48

11.3.6.

Replacement of the front thrust ring and

mouth ring ...................................................... 49

11.3.7.

Replacement of the bearing ........................... 49

11.3.8.

Replacement of the main shaft....................... 49

12.

MET-040 type.................................................................... 50

12.1.

Construction and parts name ....................................... 50

12.2.

Maintenance and inspection......................................... 51

12.2.1.

Routine inspection.......................................... 51

12.2.2.

Regular inspection.......................................... 51

12.2.3.

Abrasive limit of the bearing ........................... 51

12.3.

Disassembling & assembling ....................................... 52

12.3.1.

Notes on disassembling ................................. 52

12.3.2.

Preparation for disassembling ........................ 52

12.3.3.

Disassembling ................................................ 53

12.3.4.

Assembling..................................................... 54

12.3.5.

Replacement of the motor and outer magnet . 54

12.3.6.

Removing and replacing the main shaft ......... 54

12.3.7.

Replacement of bearing ................................. 54

12.3.8.

Replacement of the mouth ring and the

front/rear thrust............................................... 55

13.

MET-050/080 type............................................................. 56

13.1

Construction and parts name ....................................... 56

13.1.1

MET-050 type ................................................. 56

13.1.2

MET-080 type ................................................. 57

13.2.

Maintenance and inspection......................................... 58

13.2.1.

Routine inspection.......................................... 58

13.2.2.

Regular inspection.......................................... 58

13.2.3.

Abrasive limit of the bearing ........................... 58

13.3.

Disassembling & assembling ....................................... 59

13.3.1.

Notes on disassembling ................................. 59

13.3.2.

Preparation for disassembling ........................ 59

13.3.3.

Disassembling ................................................ 60

13.3.4.

Assembling..................................................... 61

13.3.5.

Replacement of the motor and outer magnet . 61

13.3.6.

Removing and replacing the main shaft ......... 61

13.3.7.

Replacement of the front bearing (MET-050

type)............................................................... 61

13.3.8.

Replacement of the rear bearing (MET-050

type)............................................................... 62

13.3.9.

Replacement of the front bearing (MET-080

type)............................................................... 62

13.3.10.

Replacement of the rear bearing (MET-080

type)............................................................... 62

13.3.11.

Replacement of the rear thrust ring ................ 62

14.

MST-050 type.................................................................... 63

14.1.

Construction and parts name ....................................... 63

14.2.

Maintenance and inspection ........................................ 64

14.2.1.

Routine inspection.......................................... 64

14.2.2.

Regular inspection.......................................... 64

14.2.3.

Abrasive limit of the bearing ........................... 64

14.3.

Disassembling & assembling ....................................... 65

14.3.1.

Notes on disassembling ................................. 65

14.3.2.

Preparation for disassembling ........................ 65

14.3.3.

Disassembling ................................................ 65

14.3.4.

Assembling..................................................... 66

14.3.5.

Replacement of the motor and outer magnet . 67

14.3.6.

Removing and replacing the main shaft ......... 67

14.3.7.

Replacement of the bushing........................... 67

14.3.8.

Replacement of the thrust ring ....................... 67

15.

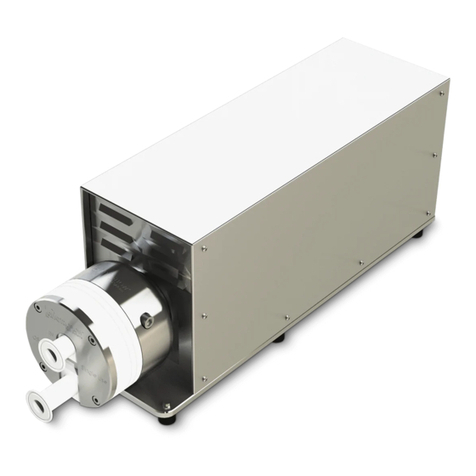

MEP-040/050 type ............................................................ 68

15.1.

Construction and parts name ....................................... 68

15.2.

Maintenance and inspection ........................................ 69

15.2.1.

Routine inspection.......................................... 69

15.2.2.

Regular inspection.......................................... 69

15.2.3.

Abrasive limit of the bearing ........................... 69

15.3.

Disassembling & assembling ....................................... 70

15.3.1.

Notes on disassembling ................................. 70

15.3.2.

Preparation for disassembling ........................ 70

15.3.3

Disassembling ................................................ 71

15.3.4.

Assembling..................................................... 71

15.3.5.

Replacement of the motor and outer magnet . 71

15.3.6

Installing and removing the impeller and

inner magnet .................................................. 72

15.3.7.

Replacement of bearing ................................. 72

15.3.8.

Replacement of the mouth ring and the

front/rear thrust rings...................................... 72

6.

MEP-080 type ................................................................... 73

16.1.

Construction and parts name ....................................... 73

16.2.

Maintenance and inspection ........................................ 74

16.2.1.

Routine inspection.......................................... 74

16.2.2.

Regular inspection.......................................... 74

16.2.3.

Abrasive limit of the bearing ........................... 74

16.3.

Disassembling & assembling ....................................... 75

16.3.1.

Notes on disassembling ................................. 75

16.3.2.

Preparation for disassembling ........................ 75

16.3.3.

Disassembling ................................................ 76

16.3.4.

Assembling..................................................... 77

16.3.5.

Installing and removing the impeller and

inner magnet .................................................. 77

16.3.6.

Replacement of bearing ................................. 77

16.3.7.

Replacement of the mouth ring and the

front/rear thrust rings...................................... 77

17.

MES-040 type ................................................................... 78

17.1.

Construction and parts name ....................................... 78

17.2.

Maintenance and inspection ........................................ 79

17.2.1.

Routine inspection.......................................... 79

17.2.2.

Regular inspection.......................................... 79

17.2.3.

Abrasive limit of the bearing ........................... 79

17.3.

Disassembling & assembling ....................................... 80

17.3.1.

Notes on disassembling ................................. 80

17.3.2.

Preparation for disassembling ........................ 80

17.3.3.

Disassembling ................................................ 81

17.3.4.

Assembling..................................................... 82

17.3.5.

Replacement of the motor and outer magnet . 82

17.3.6.

Installing and removing the impeller and

inner magnet .................................................. 82

17.3.7.

Replacement of bearing ................................. 82

17.3.8.

Replacement of the mouth ring and the

front/rear thrust rings...................................... 83

18.

MES-050 type ................................................................... 84

18.1.

Construction and parts name ....................................... 84

18.2.

Maintenance and inspection......................................... 85

18.2.1.

Routine inspection.......................................... 85

18.2.2.

Regular inspection.......................................... 85

18.2.3.

Abrasive limit of the bearing ........................... 85

18.3.

Disassembling & assembling ....................................... 86

18.3.1.

Notes on disassembling ................................. 86

18.3.2.

Preparation for disassembling ........................ 86

18.3.3.

Disassembling ................................................ 87

18.3.4.

Assembling..................................................... 88

18.3.5.

Replacement of the motor and outer magnet . 88

18.3.6.

Removing and replacing the main shaft ......... 89

18.3.7.

Replacement of the bearing ........................... 89

18.3.8.

Replacement of the mouth ring and

front/rear thrust rings...................................... 89

19.

MES-080 type ................................................................... 90

19.1.

Construction and parts name ....................................... 90

19.2.

Maintenance and inspection......................................... 91

19.2.1.

Routine inspection.......................................... 91

19.2.2.

Regular inspection.......................................... 91

19.2.3.

Abrasive limit of the bearing ........................... 91

19.3.

Disassembling & assembling ....................................... 92

19.3.1.

Notes on disassembling ................................. 92

19.3.2.

Preparation for disassembling ........................ 92

19.3.3.

Disassembling ................................................ 93

19.3.4.

Assembling..................................................... 94

19.3.5.

Replacement of the motor and outer magnet . 94

19.3.6.

Removing and replacing the main shaft ......... 94

19.3.7.

Replacement of bearing ................................. 95

19.3.8.

Replacement of the mouth ring and the

front/rear thrust rings...................................... 95

20.

Allowable piping load...................................................... 96

21.

Failure modes and their causes ..................................... 97

21.1.

Insufficient flow/pressure.............................................. 97

21.2.

Inability to hoist ............................................................ 98

21.3.

Vibration/noise ............................................................. 99

21.4.

Overcurrent ................................................................ 100

22.

References ..................................................................... 101

22.1.

Possible temperature classes of the pump................. 101

22.2.

Maximum allowable temperature ............................... 101

22.3.

Gap between the bracket and the outer magnet ........ 101

22.4.

Tightening torque for the outer magnet fastening

screws 102

22.5.

Priming time for the self-priming pumps..................... 103

22.5.1.

MES-040/050 type........................................ 103

22.5.2.

MES-080 type............................................... 104

23.

Pump label.................................................................... 1055

24. Corrrosion resistance chart…………………………….. 106

25. Contact lis………………………………………………….. 108

Indication What it means

Warning

A procedure that may

result in a death or a

serious injury if the

instruction is not

followed.

Caution

A procedure that is

expected to result in a

minor to moderate injury

or property

damage if the

instruction is not

followed.

Possible

Explosion

Indicates a danger if

used in an explosive

atmosphere.

i

Information

A procedure that is

strongly recommended

to use the product more

safely.

1. Things to be confirmed upon

arrival

Upon arrival of the pump, please check and confirm

followings.

(1) The specifications on the label on the pump match the order

specifications.

(2) All accessories are in place.

(3) All bolts and screws are securely fastened.

(4) The pump appears normal without a trace of damage during

the transportation.

(5) Remove the external fan cover and check that the external

fan could be turned easily by hand. If the fan seems heavy

or does not turn at all, there is a possibility that the pump

had suffered internal damage during transportation.

If a fault is found, please contact the supplier or Seikow

Chemical Engineering & Machinery immediately.

2. For the safety

Like other high-speed or high-pressure machinery, a magnetic

drive pump can be very dangerous if it is not used properly.

Special attention is required if a corrosive or hazardous chemical

is used.

The "warnings" in this manual must be heeded to avoid dangers

to the property and human life.

To use the product in a potentially explosive atmosphere subject

to EC Directive 94/9, the product must bear the CE marking on its

label. Check the marking before use. In addition, cautions under

the "Ex" mark should be observed if the product is to be used in

an explosive atmosphere. [Refer to 23. Pump Label.]

2.1. Transportation

Although the entire pump can be lifted using the eye-bolt

provided on the pump, ensure to secure the motor part with a

suspension rope (nylon sling) prior to the operation to ensure the

safety.

Warning

(1) An eye-bolt or a hooking hole provided

on the motor is

rated only for the motor weight and, thus, it must be

prohibited to suspend the entire pump using it.

(2) If a special base (outside the contract/standard) is set

on the pump, do not suspend the pump using the

eye-bolt.

2.2. Confirmation

Pump installation and/or a test run after a maintenance work

should be performed after confirming that all bolts, including the

drain bolts and casing bolts, are securely fastened.

2.3. Application

The pump is designed and manufactured for the specific

application and specifications designated in the contract. Should

it be necessary to use the pump for any other application, please

consult the supplier or Seikow Chemical Engineering &

Machinery prior to doing so.

This pump is classified under Explosion Proof Group II and

Equipment Category 2G. For the temperature classification, refer

to [22.1. Possible Temperature Classes of the Pump] and, for the

temperature limits, refer to [22.2. Maximum Allowable

Temperature].

3. Storage

The pump should be maintained and inspected according to the

following instructions during the storage period prior to the start of

operation.

3.1. Short-term storage (less than three

months)

(1) Do not remove the bore seal.

(2) Store the pump indoors choosing a well ventilated location

without humidity. Also ensure to avoid wind-blown rainwater,

leak from the roof, pool of water, etc.

(3) Protect the cable holes on the motor terminal box with a

duct tape to close the gap and prevent dusts from entering

the box.

(4) Avoid a location where there is a possibility of the pump

suffering damage due to a fall of other object or a contact

with other devices being transported. If it is not possible to

avoid such a location, provide a sufficient protection to the

pump.

(5) Do not place heavy objects on the pump.

(6) In winter, there is a possibility of dew condensation and the

dew being frozen inside the pump. Drain the pump to avoid

this.

(7) Should it be necessary to store a pump that had been used,

do the followings.

Clean the interior of the pump with fresh water.

Provide protections to the pump inlet and outlet to

prevent infiltration of foreign materials.

If the sum of initial operation period and the storage

period becomes longer than one year, replace the

gasket or the O-ring and inspect the interior of the pump

before running it again.

3.2. Long-term storage (more than three

months)

(1) Instructions (1) through (7) for the short-term storage stated

above.

(2) Measure and record the insulation resistance at the time of

acceptance and check it regularly as the insulator of the

motor may absorb moisture and the insulation resistance

may drop.

If the insulation resistance has dropped, dry the insulator

following instructions from the manufacturer and provide

protection against moisture.

(Refer to attached instruction manual for the motor.)

Warning

If the pump is run with degraded insulation of the motor, a

leak of electricity or other accident may occur. Ensure to

check the insulation resistance regularly.

10~30mm

金楔

基礎ボルト

ベッド/ブラケット

金楔

(3) Remove the external fan cover once a month and turn the

external fan manually.

(4) If the pump is run after a period of one year or longer,

ensure to replace the gasket with a new one.

4. Installation and piping

Possible Explosion

In order to protect the health of employees who may be

exposed to a danger in an explosive atmosphere and

enhance the safety, observe EC Directive 1999/92 as a

minimum standard. Check the standards under EN 1127-1.

4.1. Installation

(1) In principle, the pump should be installed on a concrete

foundation. If it is not possible, the pump may be installed

on a steel structure provided that the vibration during

operation is prevented.

(2) Insert the foundation bolt into a bolt hole on the bed, attach

a nut tightly to the bolt head, and suspend it inside the

foundation bolt hole.

(3) In case of a concrete foundation, insert a wedge in between

the concrete and bed surfaces at four locations and keep

the pump level.

(4) To check the levelness, use a level gauge on the upper

surface of the pump outlet flange and check in all directions.

(5) After checking the levelness, fill the gaps between the

concrete foundation and the bed or the main unit with a fine

mortar, as well as gaps in the foundation bolt holes. Ensure

that everything is evenly bonded. (See Fig. 4-1.)

(6) Leave the pump as is for several days to let the mortar

harden. Then tighten the nut on the foundation bolt.

(7) In case the pump is installed on a steel structure, bolts and

nuts may be used but ensure to fasten them tightly in a

similar manner.

Fig. 4-1

Possible Explosion

In order to prevent the built-

up static electricity, pump has to

be grounded to a secure grounded point..

4.2. Piping

Prior to connecting piping, confirm that the bore seal has been

removed.

4.2.1. Piping load (common for all models)

(1) Support and secure pipes connected to the pump inlet and

outlet at a location close to the pump to avoid undue load on

the pump.

(2) In case metal pipes are used or the pipe length is long, use

flexible joints instead of connecting pipes directly.

(3) Limit the piping load on the pump to the max. allowable load

specified in 20. Allowable Piping Load.

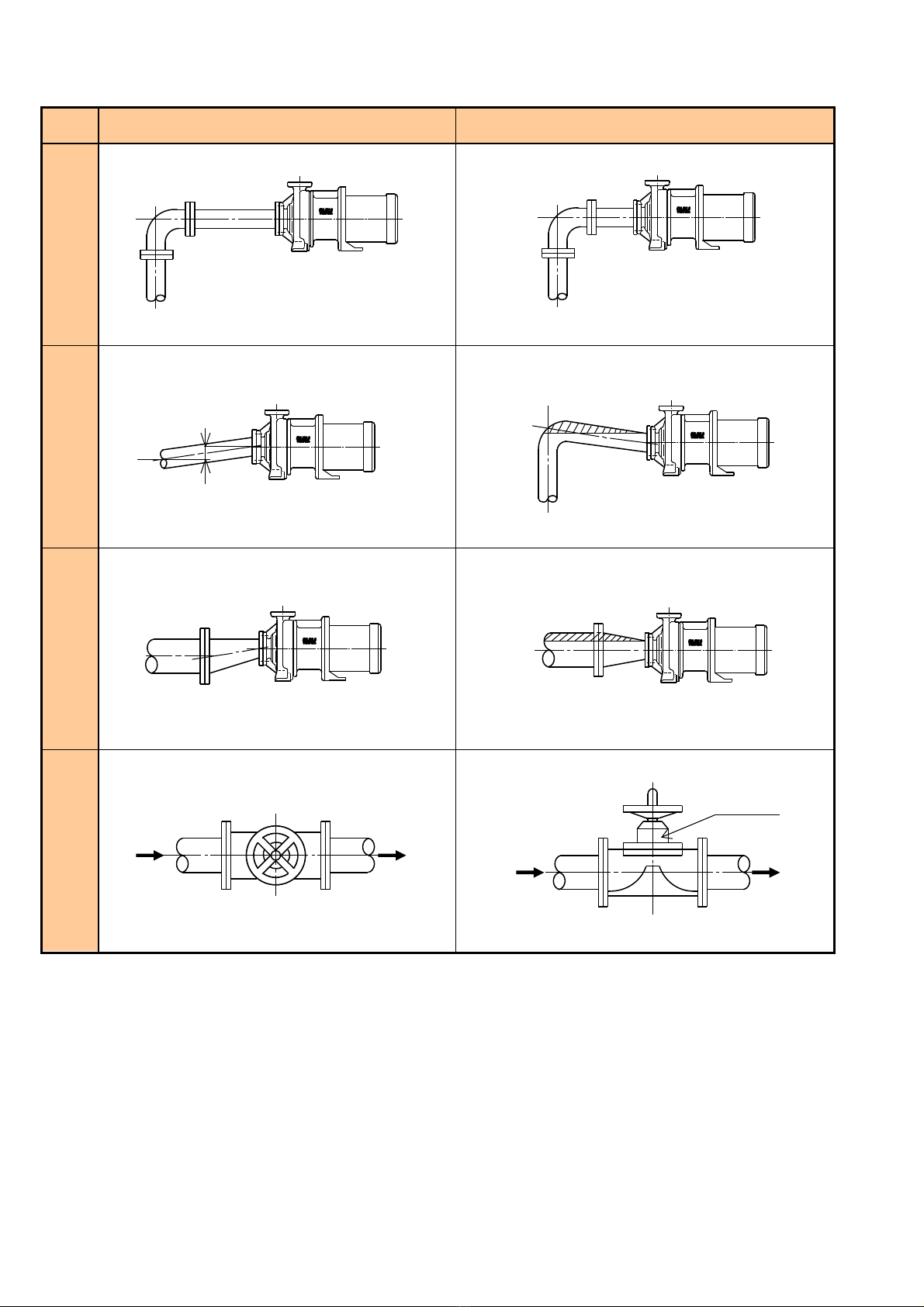

4.2.2. Suction piping (other than MES type) (Fig.

4-4)

(1) Make the suction piping as short as possible. However, note

that a valve and a short pipe (about 0.3m) must be attached

to facilitate disassembling of the pump.

(2) Make the flange joint portion of the suction piping as short

as possible.

(3) Since the suction piping will have a significant effect on

NPSH

AV

, give a thorough consideration on the pipe

diameter, length and attachments.

(4) Provide an upward gradient (approx. 1/50) on the piping

from the supply surface of fluid to the pump to avoid

entrapment of air. However, if the fluid is forced into the

pump, the gradient on the piping should be downward

toward the pump.

(5) Provide a dust screen on the supply tank.

(6) Ensure that the tip of the suction pipe is dipped sufficiently

deep into the fluid to avoid air to be sucked in during the

operation.

(7) Install the valve on the suction side with its handle

positioned horizontally as entrapped air may be formed

while priming the pump.

(8) Limit the number of bends as small as possible and avoid

providing a bend close to the pump inlet.

(9) If a reducer is used, use an eccentric type to avoid the

entrapment of air.

(10) If a concentric reducer is used, provide an air release on the

larger bore side. If multiple pumps are installed for the same

tank, provide an independent suction piping for each pump.

10−30 mm

Metal wedge

Foundation bolt

Bed/b

rac

ket

Metal wedge

4.2.3. Discharge piping (other than MES type)

(1) Always provide a valve for the discharge piping.

(2) Since entrapped air in the discharge piping can also cause

unwanted effect, provide an air release whenever

necessary.

(3) Even if the discharge piping is in the form of a siphon,

ensure to place the highest position below the no-discharge

water head.

(4) A check valve may be provided to prevent a back flow at the

time of stopping the pump or, when the actual water head is

very high, to prevent a water hammer. However, since air

can be entrapped below the check valve at the start of the

pump, provide an air release. (Fig. 4-2)

Fig. 4-2

4.2.4. Suction piping (MES type) (Fig. 4-4)

(1) A self-priming pump would not function properly if any air is

sucked in, no matter how little it is. Pay special attention to

the suction piping to prevent the air from being sucked in.

(2) Ensure that no air is sucked in at joints. Especially, for a

flanged joint, pay special attention to uneven tightening of

bolts and twist of packings.

(3) In case of PVC piping, apply welding, in addition to an

adhesive, to connect joints. Use of an adhesive only may

cause an engulfment of air, if the adhesion is incomplete,

and may degrade the self-priming performance.

(4) Position the pump as close to the fluid surface as possible

and make the horizontal distance of suction piping short and

limit the number of bends as small as possible. However,

note that a short pipe (approx. 0.3m) should be attached to

facilitate disassembling of the pump.

(5) Provide an upward gradient (approx. 1/50) on the piping

from the supply surface of fluid to the pump to avoid

entrapment of air. However, if the fluid is forced into the

pump, the gradient on the piping should be downward

toward the pump.

(6) Always provide a strainer if an infiltration of foreign matter is

expected. In providing a strainer, pay attention to cavitation

due to the increase in the suction piping resistance.

(7) Place the tip of pump inlet at least 2D (D: the bore diameter

of suction piping) away from the tank bottom and, at the

same time, at least 2D below the fluid surface.

(8) If the pump inlet is located near the fluid feeding point of the

tank, bubbles caused by the inflow of fluid may cause the air

to be mixed in. Ensure to place the inlet at a location where

bubbles would not reach.

(9) If multiple pumps are installed for the same tank, provide an

independent suction piping for each pump.

4.2.5. Discharge piping (MES type) (Fig. 4-3)

(1) Install the discharge piping with as few bends as possible

and provide an upward gradient.

Always provide a discharge adjustment valve on the

discharge piping system.

(2) A check valve may be provided to prevent a back flow at the

time of stopping the pump or, when the actual water head is

very high, to prevent a water hammer. However, since

self-priming operation may not produce enough power to lift

the check valve at the start of the pump, provide an air

release.

(3) Design the discharge piping so that the siphon

phenomenon can be prevented. The occurrence of a siphon

phenomenon will discharge all fluid inside the pump and

prevent self-priming operation when resuming the

operation.

Fig. 4-3

4.2.6 Motor wiring

It is recommended that the motor wiring to be done by a person

with appropriate expertise and skill. Also read the user's manual

for the motor thoroughly and perform the work properly.

Air release

Check valve

Pressure

gauge

Compound

gauge

Check valve

Discharge pipe

support

Discharge

valve

Flexible joint

Bypass pipe

valve

Bypass pipe support

Air release bypass pipe

Flexible joint

Suction pipe

support

Possible Explosion

Confirm requirements on the motor label as there is a

danger of motor explosion due to improper wiring. Refer to

DIN EN 60079-14.

Fig. 4-4

Good Bad

Bend

Gradient piping

Piping with a reducer

Direction of gate valve

installation

L < 4D

Entrapped air

Entrapped air

L

≥

4D

Entrapped air

D: Pipe diameter

1/50

5. Notes on handling

5.1. Notes on the start-up

(1) Remove the external fan cover of the motor and confirm

that the external fan can be turned easily.

(2) Clean the supply tank and suction pipes as trash and/or

scales that have entered the suction pipes during the pipe

installation can cause a fatal damage.

(3) Confirm the rotational direction of the motor. (The direction

is indicated on the casing cover and the motor.)

Caution

If the bearing material is SiC, confirm the rotational direction

either after the priming or after removing the motor. Even an

instantaneous operation can cause damage.

(4) Completely open the valve on the suction piping.

(5) Perform priming to fill the pump with the fluid completely.

Discharge air using the discharge piping, etc. to perform

priming. If it is difficult to discharge air, turn the external fan

of the motor in the reverse direction manually three to four

times.

(6) Start the pump with the discharge valve completely closed.

(7) If the pump is fully primed, the discharge pressure will rise

immediately. Then open the discharge valve slowly and set

the operational pressure or discharge rate at a desired

level.

Caution

Possible Explosion

Pay extra attention to the priming operation because a

no-load operation or an operation with insufficient priming

can cause a fatal fault. In addition, note that there is a

possibility of explosion due to a rise in temperature in an

explosive atmosphere.

If the discharge pressure drops, stop the pump and find the

cause of insufficient priming.

Possible Explosion

A prolonged no-discharge operation will lead to a rise in

fluid temperature ultimately causing a danger of explosion.

Ensure to open the discharge valve as soon as possible.

Although the preferred time depends on the conditions of

the fluid and facility, it is recommended to open the valve

within one minute as a guideline. (SS-EN 13463-1)

i

Information

Sometimes, one priming operation is not sufficient to secure

enough initial fluid volume. Either repeat inching operation

and priming several times or release air from the suction

piping to amass sufficient initial fluid volume.

5.2. Notes on the operation

(1) Checking the sound

Sucking in air or objects from the suction pipe often cause

an abnormal sound with a vibration. A fluctuation of the

needle on the suction gauge is often caused by infiltration of

air.

(2) Inspection of vibration

A precaution is necessary for cavitation or vibration due to

faulty installation. Always adjust the discharge rate using

the discharge valve. Do not close the valve on the suction

piping.

(3) Others

Pay attention to the discharge pressure, suction, flow rate,

electric current value, etc. An abnormal fluctuation and/or a

drop in these values often is a result of a solid matter being

stuck or air being sucked in on the suction side.

Possible Explosion

In a self-priming pump, the fluid will be agitated by the

self-priming operation. Check the possibility of explosion if

the fluid is a flammable one listed in Dangerous Goods

Ordinance, Article 4 Dangerousness Characteristics.

Possible Explosion

Since the portion of the pump interfacing with the fluid is

made of a plastic material, the portion may become

electrically charged if it is used with a highly insulating fluid.

5.3. Notes on stopping

(1) Normally, the pump should be stopped after completely

closing the discharge valve. Closing the suction valve first

will cause cavitation and may result in a seizure.

(2) If the pump is run with the fluid forced in, close the suction

valve after stopping the pump.

(3) If the pump stops as a result of a power outage during an

operation, first turn off the power switch and, at the same

time, close the discharge valve manually.

5.4. Notes operational interruption

If the operation is interrupted for a prolonged period, drain the

pump. This is especially important in winter, when the fluid inside

the pump could freeze and the resulting expansion in the volume

could cause a crack or breakage of the piping.

5.5. Notes on the motor

(1) For the purpose of the operation in areas with a risk of

explosion, the maximum allowable temperature of the pump

fluid also depends on the motor like the pump's temperature

classification. In case of a flange motor, prohibit running the

motor exceeding the maximum allowable temperature

specified by the supplier for the shaft and the flange.

(2) The outer magnet is set on the motor shaft. In case of

disassembling/assembling, ensure to tighten the fastening

bolts for the motor shaft and outer magnet at our specified

standard torque. [Refer to 22.4 Tightening Torque for the

Outer Magnet Fastening Screws.]

Possible Explosion

If the motor is not set properly on the bracket or the outer

magnet is not secured properly with the fastening bolts,

there is a possibility that sparks will be generated during the

operation due to contacts between the outer magnet and

the bracket. (SS-EN 13463-5)

[Refer to 22.3. Gap between the Bracket and Outer

Magnet.]

5.6. Notes on the ambient temperature

The allowable ambient temperature range is from −10°C to 40°C.

(However, use the product under the normal room temperature

whenever possible.)

The symbol "X" is indicated on the pump label as the allowable

ambient temperature in compliance with EC Directive 94/9/EG.

(Refer to Chapter 22.)

5.7. Notes on the fluid

(1) Pay attention not to let bubbles being formed in the fluid.

(2) Ensure to keep the slurry density below 5% and the particle

diameter below 200 μm.

* The above conditions may differ depending on the type of

fluid and operational conditions. Use them as a reference.

5.8. Others

(1) Run the auxiliary pump attached to the piping once in a

while to confirm its readiness for operation.

(2) A no-load operation of the pump will cause a seizure of the

bearing and may result in a fatal accident and, thus, should

be avoided at all times.

(3) Use the pump at a designated discharge rate and water

head. Do not attempt to run it at an extremely high or low

discharge rate.

5.9. Ordering spare parts

For ordering spare parts, confirm the construction and the parts

name and inform them together with the type, parts name and

serial number to the supplier or Seikow Chemical Engineering &

Machinery. Note that the label is on the side of bracket.

6. MER type

6.

1

.

C

onstruction and parts name

No. Parts name Material Q’ty Remarks

No. Parts name Material Q’ty Remarks

001 Casing PVDF / ETFE 1

059 Magnet lining PVDF 1

002 Casing cover FC200 1

060 Rear casing C-PVDF 1 C-ETFE

013 Impeller PVDF / ETFE 1

096 Bracket ring SS400 1

018 Main shaft Al

2

O

3

/ SiC 1

102-01 O-ring (casing) FPM / EPDM 1 G-190

028 Bracket FC200 1

102-12 O-ring (drain plug) FPM / EPDM 1 P-9

038 Drain plug PVDF / ETFE 1

104-03 Casing bolt SUS304 6

051 Front bearing C/G-PTFE 1 Carbon/SiC

104-23 Motor bolt SUS304 4

052 Rear bearing C/G-PTFE 1 Carbon/SiC

104-31 Suction pipe cover bolt SUS304 6

053 Suction pipe cover FC200 1

104-42 Discharge pipe cover bolt SUS304 3

054 Front thrust Al

2

O

3

/ SiC 1

104-46 Outer magnet fastening screw

SNCM 2

055 Discharge pipe cover FC200 1

104-54 Rear casing bolt SUS304 2

056 Rear thrust Al

2

O

3

/ SiC 1

901 Motor 1

057 Outer magnet Rare earth 1

912 Adaptor ring SS400 1

058 Inner magnet Rare earth 1

(902) (Motor liner) SS400 1 *1

*1: When installing a 2.2kW-eG3/3.7kW general purpose motor, mount the 902 motor liner instead of an adaptor ring.

6.2. Maintenance and inspection

6.2.1. Routine inspection

Perform the following inspection and record the results.

(1) The fluid level of the supply tank

(2) The suction and discharge pressure

(3) The current of the motor and the bearing temperature

(4) Abnormal noise and abnormal vibration

(5) Leaks on flanges and O-ring

6.2.2. Regular inspection

Be careful in handling metals not to squeeze hands or finegers

since the outer and inner magnets are very strong (magnetic

force).

Also, be extra careful in handling the main shaft, bearings, and

thrust rings as they have the potential of break and may cause

serious injuries.

6.2.3. Abrasive limit of the bearing

A [mm] φB [mm] C [mm]

At the time of

delivery 6.0 20.5 5.0

At the time of

replacement 5.0 21.5 4.0

Fig. 6-1

A

φ

B

C

Front bearing Rear bearing

Components Inspection item Action/replacement timing

Casing

Accretion on the interface with the fluid Washing

Corrosion and swelling on the O-ring Replace if faulty

Presence of cracks Check the cause if present

Presence of wears, rubbing, or cracks on the front thrust Check the cause if present

Impellers

Accretion on the blades, presence of foreign matters Washing

Contact of entrance Check the cause if present

Inner magnet

Rubbing against the rear casing Check the cause if present

Presence of cracks on the edge and cylinder inner surfaces Check the cause if present

Accretion on the interface with the fluid Washing

Wear on the front bearing Check the cause if abnormal

Clogged cooling path on the front bearing Washing

Wear on the rear bearing Check the cause if abnormal

Rear casing

Rubbing against the inner magnet Check the cause if present

Accretion on the interface with the fluid Washing

Presence of wears, rubbing, or cracks on the rear thrust Check the cause if present

Main shaft

Presence of cracks Check the cause if present

Wear on the bearing Check the cause if abnormal

Outer magnet

Rubbing against the rear casing Check the cause if present

Connection condition of the outer yoke and the motor shaft, loose

screws

Redo tightening at the

proper position

Motor bearing Presence of abnormal noise Once in two years

(guideline)

6.3. Disassembling & assembling

6.3.1. Notes on disassembling

(1) Wear appropriate protective gear (rubber gloves, protective

goggles) before disassembling the pump.

Warning

There is a danger of injury resulting from the human body

getting in contact with the chemical during or after the

disassembling operation.

(2) Be careful in handling the main shaft and bearings as they

are vulnerable to physical damage.

(3) Since the inner and outer magnets are strongly magnetized,

pay attention to attraction of metallic dusts and metallic

items.

Warning

If a finger gets caught in between the inner or outer magnet

and a metal when they attract each other, a serious injury

can be expected.

6.3.2. Preparation for disassembling

(1) Ensure the safety of operation, for example securing the

footing.

(2) Turn OFF the main power to prevent an accidental operation

of the motor and indicate a maintenance work is in progress

with a sign so that nobody would turn on the power.

Warning

Possible Explosion

The worker may suffer a serious injury if the power is turned

on inadvertently during a disassembly operation. In

addition, it may cause an explosion in an explosive

atmosphere.

(3) Close the valves on the suction/discharge piping completely

and indicate that a maintenance work is in progress with a

sign so that nobody would release the valves.

(4) Before loosening flange bolts, wear a pair of rubber gloves,

protective goggles, etc. and drain the pump and piping from

the drain provided on the pump.

Warning

If the chemical splashes outside the pump and attaches to

the human body, it may results in a burn or a serious injury.

(5) As for the procedures for draining, refer to the common

example explained below and give a thorough

consideration to the fluid and working environment involved.

1) Release the pump drain.

2) Loosen the bolts on the discharge side drain connection

slowly and evenly. If the fluid leaks from the drain during

this operation, wait for the fluid to stop and retreat to a

safe position until the fluid comes to a complete stop.

Warning

(1) If the bolts on the pump flange on the discharge side

were loosened quickly, the fluid may scatter from the

drain and cause a serious injury to the worker.

(2) It is dangerous to stand in front of the drain during the

draining operation. Always check the standing position

while proceeding with the operation.

(6) Repeat the step 2) described above and confirm that the

drain operation is complete by lifting the piping with a

screwdriver or a similar tool when the bolts are removed.

6.3.3. Disassembling

(1) Remove the casing bolts (104-03), pull the casing cover

(002) and casing (001) towards the front and detach them

from the bracket (028). In doing this, the rear casing (060)

will be drawn out at the same time.

Photo 6-1

Photo 6-2

(2) Put down the pump with the suction flange facing down.

Photo 6-3

(3) Remove the rear casing bolts (104-54) and remove the rear

casing (060).

Photo 6-4

(4) Draw out the inner magnet (058+059) and the impeller

(013).

Photo 6-5

Photo 6-6

6.3.4. Assembling

For assembling the pump, follow the disassembling procedure in

reverse order.

(1) With the suction flange facing down, set the casing O-ring

(102-01) on the casing (001).

(2) Insert the inner magnet (058+059) and the impeller (013)

from above.

(3) Fit in the rear casing (060) from above, set the rear casing

bolts (104-54) and tighten them.

(Hold the tightening torque to the level of manual

tightening.)

(4) Hold the casing over (002), set it on the bracket (028), and

tighten the casing bolts (104-03) with a tightening torque of

21.5 N/m (2.2 kgf/m). In doing so, tighten the bolts in

diagonal order to avoid uneven clamping.

Warning

Since the inner and outer magnets attract each other, be

careful to avoid fingers being caught.

(5) Upon completion of assembling, remove the external fan

cover of the motor and confirm that the external fan can be

turned easily by hand.

6.3.5. Replacement of the motor and outer magnet

(1) Suspend the motor with a nylon sling, remove the motor

bolts (104-23), draw out the motor and outer magnet from

the bracket, and put down the motor with the external fan

facing down.

(2) Loosen the outer magnet fastening screws (104-46) and

draw out the outer magnet (057) from the main shaft of the

motor.

(3) To install, insert the outer magnet (057) into the main shaft

of the motor and tighten the outer magnet fastening screws

(104-46) observing the torque specified in 22.4 Tightening

Torque for the Outer Magnet Fastening Screws. In doing so,

align the bottom of outer magnet and the top of the motor

shaft. (Fig. 6-2)

Fig. 6-2

Motor shaft

Outer magnet

Same

surface

0.5mm以下

主軸

フロントスラスト

ケーシング

主軸挿入部

6.3.6. Replacement of the main shaft and front

thrust

(1) To remove, put a Phillips driver through the hole on the

casing support and tap on the driver head lightly with a

hammer with the tip in contact with the main shaft.

Photo 6-7

(2) To install, align the cuts on the main shaft (018), the front

thrust (054) and the shaft support portion of the casing

(001) and then tap on the rear end of the main shaft with a

plastic hammer until they are firmly in place.

Photo 6-8

Fig. 6-3

6.3.7. Replacement of the front bearing

(1) To remove, hold a round rod (24mm diameter) against the

bearing from the back of inner magnet (058+059) (from the

rear bearing (052) side) and tap on it with a plastic hammer.

Photo 6-9

(2) To install, align the cuts from the impeller side and press fit

the front bearing by tapping it lightly with a plastic hammer

by covering the rubbing surface with the front thrust (054)

with a cloth to avoid damaging the surface.

Photo 6-10

6.3.8. Replacement of the rear bearing and the rear

thrust

(1) To remove, lift the rear thrust with a sharp edge, such as an

edge of a cutting knife, after melting the melting teeth with a

hot-air welder.

Photo 6-11

(2) To install, align the cuts, melt the melting teeth at two

locations with a hot-air welder, and then crush them with a

round rod (4mm diameter).

0.5 mm or less

Inserted portion of

the casing main

shaft Front thrust

Main shaft

6.3.9. Replacement of the casing and casing cover

(1) Remove the discharge pipe cover bolts (104-42) and

remove the discharge pipe cover (055).

Photo 6-12

(2) Remove the suction pipe cover bolts (104-42) and remove

the suction pipe cover (053). Although the top cover can be

drawn out directly, remove the bottom cover by turning it so

that it won't hit the drain. If it is difficult to pull it apart due to

rust and/or stains, tap on it lightly with a plastic hammer.

Photo 6-13

(3) Remove the casing (001) from the casing cover (002) by

pushing the surface of the suction flange with a hand or by

tapping it lightly with a plastic hammer.

Photo 6-14

(4) To install, set the casing on the casing cover and hammer it

in lightly with a plastic hammer.

(5) Next, attach the bottom part of the suction pipe cover. In

doing this, insert the cover from the side avoiding the cover

hitting the drain. If the insertion is difficult, tap on it lightly

with a plastic hammer.

(6) Set the suction pipe cover bolts and tighten them.

(7) Set the discharge pipe cover bolts and tighten them.

7. MEH-040 type

7.

1

.

C

onstruction and parts name

No. Parts name Material Q’ty Remarks

No. Parts name Material Q’ty Remarks

001 Casing PVDF / ETFE 1

060 Rear casing C-PVDF 1 C-ETFE

002 Casing cover FC200 1

096 Bracket ring SS400 1

013 Impeller PVDF / ETFE 1

102-01 O-ring (casing) FPM / EPDM 1 G-190

018 Main shaft Al

2

O

3

/ SiC 1

102-12 O-ring (drain plug) FPM / EPDM 1 P-9

028 Bracket FC200 1

104-03 Casing bolt SUS304 6

038 Drain plug PVDF / ETFE 1

104-23 Motor bolt SUS304 4

051 Bearing C/G-PTFE 1 Carbon/SiC

104-31 Suction pipe cover bolt SUS304 6

053 Suction pipe cover FC200 1

104-42 Discharge pipe cover bolt SUS304 3

054 Front thrust Al

2

O

3

/ SiC 1

104-46 Outer magnet fastening screw

SNCM 2

055 Discharge pipe cover FC200 1

104-54 Rear casing bolt SUS304 2

056 Rear thrust Al

2

O

3

/ SiC 1

105 Mouth ring C/G-PTFE 1 Carbon/SiC

057 Outer magnet Rare earth 1

901 Motor 1

058 Inner magnet Rare earth 1

912 Adaptor ring SS400 1

059 Magnet lining PVDF 1

(902) (Motor liner) SS400 1 *1

*1: When installing a 2.2kW-eG3/3.7kW general purpose motor, mount the 902 motor liner instead of an adaptor ring.

7.2. Maintenance and inspection

In order to operate the pump in an orderly manner, it is

recommended to implement a regular inspection program and

keep the record. Shown below are common points of

maintenance.

7.2.1. Routine inspection

Perform the following inspection and record the results.

(1) The fluid level of the supply tank

(2) The suction and discharge pressure

(3) The current of the motor and the bearing temperature

(4) Abnormal noise and abnormal vibration

(5) Leaks on flanges and O-ring

7.2.2. Regular inspection

Be careful in handling metals not to squeeze hands or fingers

since the outer and inner magnets are very strong (magnetic

force).

Also, be extra careful in handling the main shaft, bearings, and

thrust rings as they have the potential of break and may cause

serious injuries.

7.2.3. Abrasive limit of the bearing

A [mm] B [mm] φC [mm]

At the time of

delivery 8.0 5.0 20.5

At the time of

replacement 7.0 4.0 21.5

Fig. 7-1

Mouth ring Bearing

Components Inspection item Action/replacement timing

Casing

Accretion on the interface with the fluid Washing

Corrosion and swelling on the O-ring Replace if faulty

Presence of cracks Check the cause if present

Presence of wears, rubbing, or cracks on the front thrust Check the cause if present

Impellers

Accretion on the blades, presence of foreign matters Washing

Contact of entrance Check the cause if present

Wear on the mouth ring Check the cause if present

Inner magnet

Rubbing against the rear casing Check the cause if present

Presence of cracks on the edge and cylinder inner surfaces Check the cause if present

Accretion on the interface with the fluid Washing

Wear on the bearing Check the cause if abnormal

Clogged cooling path on the bearing Washing

Rear casing

Rubbing against the inner magnet Check the cause if present

Accretion on the interface with the fluid Washing

Presence of wears, rubbing, or cracks on the rear thrust Check the cause if present

Main shaft

Presence of cracks Check the cause if present

Wear on the bearing Check the cause if abnormal

Outer magnet

Rubbing against the rear casing Check the cause if present

Connection condition of the outer yoke and the motor shaft, loose

screws

Redo tightening at the

proper position

Motor bearing Presence of abnormal noise Once in two years

(guideline)

This manual suits for next models

9

Table of contents

Other TEXEL Water Pump manuals

Popular Water Pump manuals by other brands

Zoeller

Zoeller 1461-0006 manual

AST

AST SOC GMP-050 Series instruction manual

Bestway

Bestway Built-in Sidewinder P3150 owner's manual

Homa

Homa Saniboy G 180-16W Original instruction manual

Gardena

Gardena PTU 3700/4 Operator's manual

GORMAN-RUPP

GORMAN-RUPP 02F1-GL Application, Installation, Operation, and Maintenance Manual

Ebsray

Ebsray RC SERIES Installation, operation & maintenance instructions

IWAKI AMERICA

IWAKI AMERICA MD SERIES instruction manual

Advantage Controls

Advantage Controls MicroTron O Series manual

Waspper

Waspper WP20CH/P instruction manual

Kremlin-Rexson

Kremlin-Rexson AIRMIX 08-120 Disassembly/Reassembly

Nakayama

Nakayama PRO NP1070 manual