HYDRAULIC VARIABLE DISPLACEMENT PUMP

INSTALLATION GUIDE

Dynaset

O

y

|

Menotie

3,

FI-33470

Y

löjär

vi,

Finland

|

tel:

+358

3

3488

200

|

[email protected] |

ww

w

.dynaset.com

6

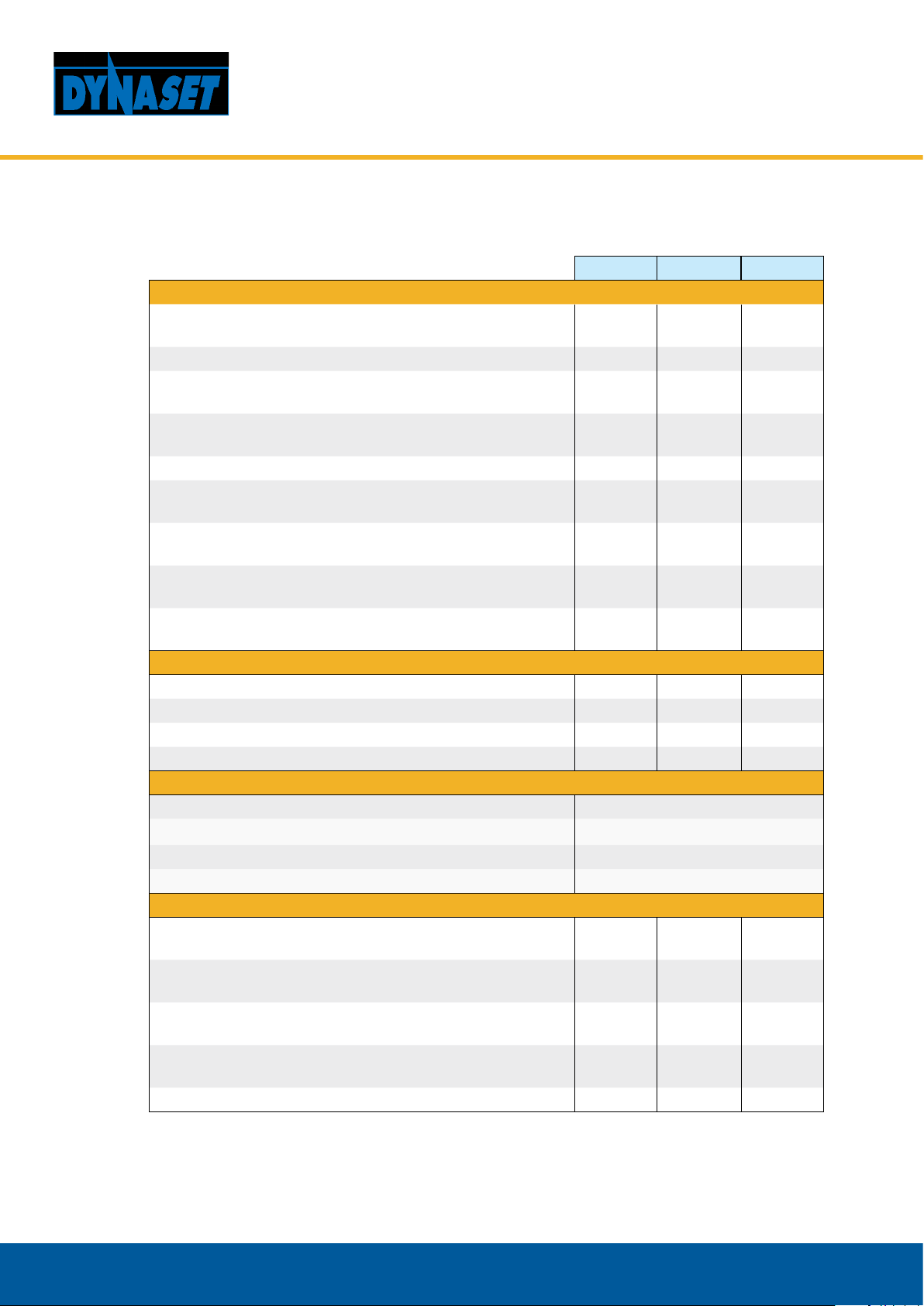

4. INSTALLATION MEASUREMENTS

60 90 110

Flange DIN ISO 7653 DIN ISO 7653 DIN ISO 7653

Axle DIN ISO 14 B8x32x35 DIN ISO 14 B8x32x35 DIN ISO 14 B8x32x35

amm (in) 50 (1.97) 50 (1.97) 50 (1.97)

bmm (in) 25 (0.98) 28 (1.10) 27,5 (1.08)

cmm (in) 32 (1.26) 32 (1.26) 32 (1.26)

dmm (in) 18 (0.71) 18 (0.71) 18 (0.71)

emm (in) 55 (2.17) 55 (2.17) 54,85 (2.16)

fmm (in) 9 (0.35) 9 (0.35) 9 (0.35)

gmm (in) 15 (0.59) 15 (0.59) 15 (0.59)

hmm (in) 100 (3.94) 106 (4.17) 112 (4.41)

imm (in) 253,5 (9.94) 277.5(10.93) 279,5 (13.07)

jmm (in) 95,25 (3.75) 95,25 (3.75) 45,1 (1.77)

kmm (in) 91,25 (3.59) 94 (3,7) 91 (3,58)

lmm (in) 86 (3.39) 89,5 (3.52) 95 (3.74)

mmm (in) 98,5 (3.88) 106 (4.17) 111 (4.37)

nmm (in) 102 (4.02) 101 (3.98) 106 (4.17)

omm (in) 80 (3.15) 80 (3.15) 80 (3.15)

pmm (in) 98,5 (3.88) 106 (4.17) 111 (4.37)

qmm (in) 115 (4.53) 120 (4.72) 127 (5.00)

r Ømm 80 -0,03

-0,06 80 -0,03

-0,08 80 -0,03

-0,08

s - M8 M8 M8

t Ømm (in) 13 (0.5) 13 (0.5) 13 (0.5)

umm(in) 65 - 109 (2.56 - 4.29)*

vmm(in) 38mm(1 1/2"), 42 mm, 50mm(2"), 64mm(2 1/2"), 76(3")*

*Dierent ange size options available depending on the required ow rate.

Measurements may vary if pump is equipped with additional options, suchs as valves or different flanges.