TABLE OF CONTENTS

3

cod. G19503950 3

Operating

How to choose between sickle bars...............30

Service Machine Safely

Practice safe maintenance.............................31

Wear appropriate clothing ..............................31

Stay clear of rotating drivelines ......................31

Maintenance...................................................31

Hazard bar......................................................32

Service

/XEUL¿FDWLRQ ....................................................33

Routine maintenance......................................33

Every 2 work hours.........................................33

Wear-proof skids (optional) ............................33

Every 8 work hours.........................................33

Every 50 work hours.......................................33

Periodically (6 months)...................................34

After each mowing .........................................34

Cleaning and oiling the sickle bar..................35

Storage ..........................................................35

Checking the clearance tolerance..................36

Extra maintenance..........................................38

Replacement of section-holding bar...............38

Replacement of sections................................38

Replacement of tooth-holding bar (riveted)....39

Replacement of tooth (riveted).......................39

Replacement of bar holding removable tooth 39

Replacement of removable tooth....................39

Replacing the anti-vibration yokes..................40

Replacement of belts......................................40

Replacement of pulleys..................................40

Transport on road

Transport on road ..........................................41

Demolition and disposal

Demolition and disposal ................................42

Assembly

Assembly........................................................43

Spare parts

Spare parts.....................................................51

Warranty

Warranty.........................................................68

Warranty for replacement parts......................69

Description

Description of the sickle bar mower.................5

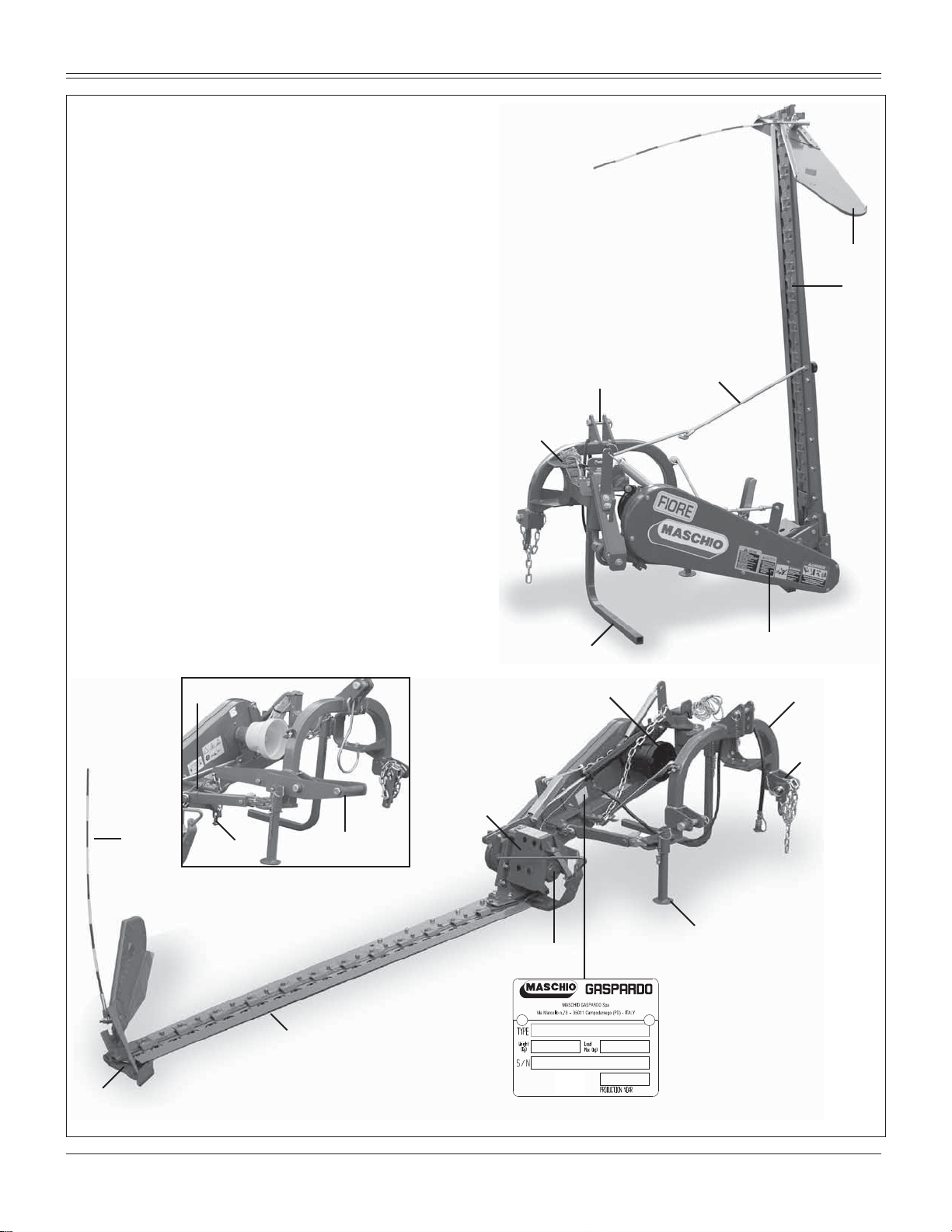

Assembly drawing ............................................6

7HFKQLFDOVSHFL¿FDWLRQ

7HFKQLFDOVSHFL¿FDWLRQ......................................7

Handling ...........................................................7

Safety lables

Safety-Alert lables ............................................8

,GHQWL¿FDWLRQPDFKLQH.......................................8

Machine safety labels.......................................8

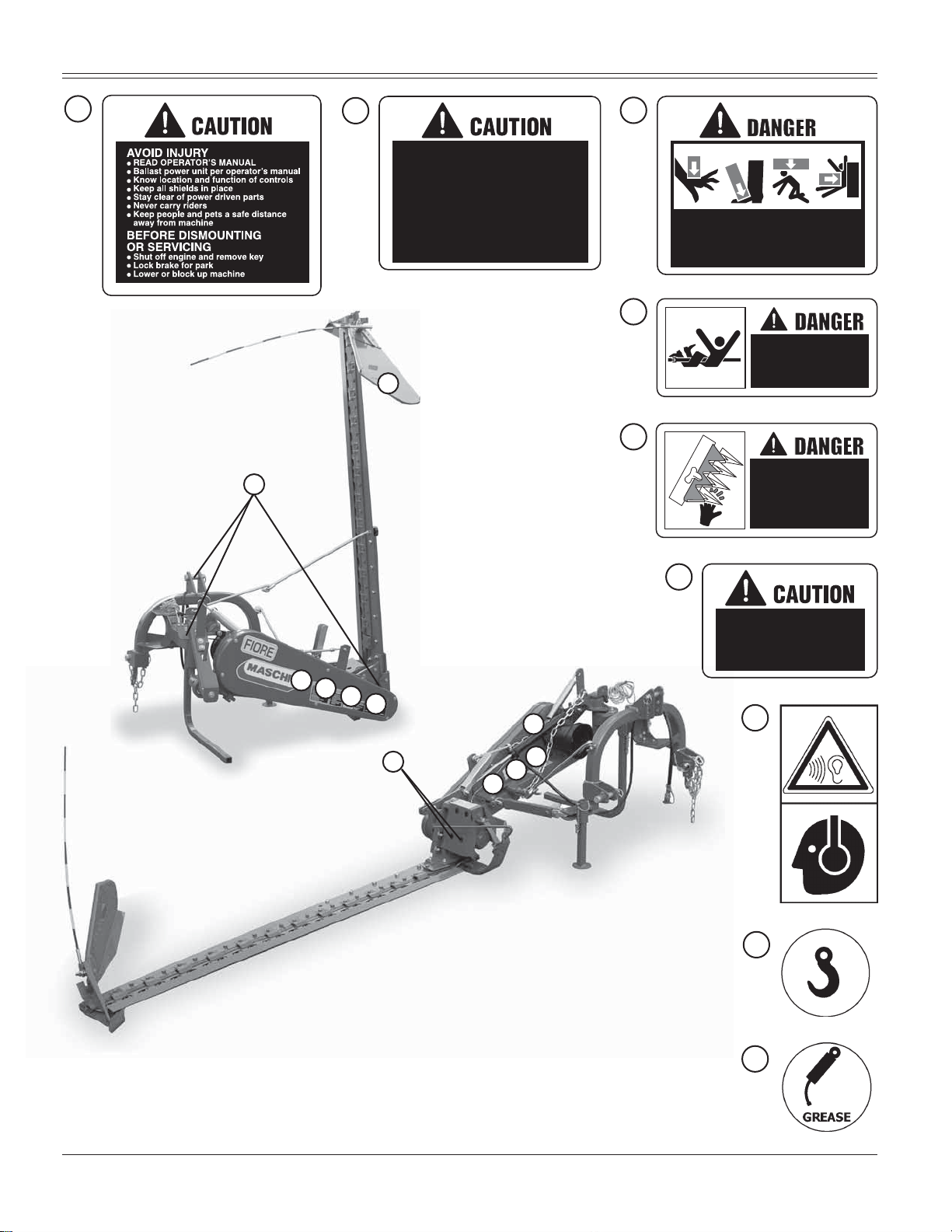

Machine safety lables and position

Machine safety lables and position..................9

Preparing the tractor

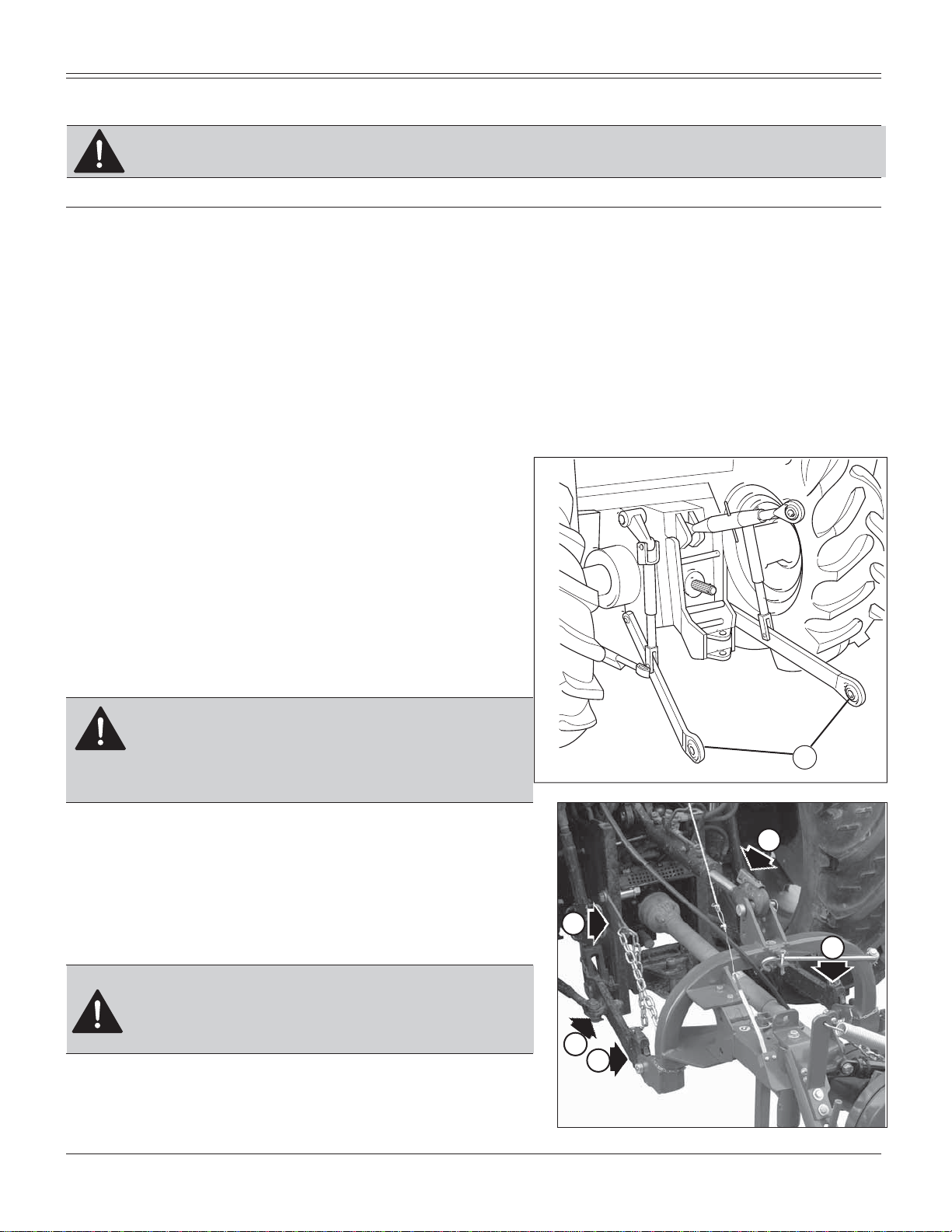

Preparing the tractor.......................................10

Parking instruction..........................................10

Stay clear of rotating drivelines ......................10

Installing

Installing sickle bar mower on tractor ............10

PTO shaft adaptation......................................12

Stability of sickle bar and tractor during

transport .........................................................13

Parking instruction..........................................14

Stay clear of rotating drivelines ......................14

Removing

Removing sickle bar mower ...........................15

Operating

Operate safetly...............................................16

Wear appropriate clothing ..............................17

Stay clear of rotating drivelines .....................17

Operating - Mechanical Lifting System

Use of Mechanical lifting system ..................18

Adapting the sickle bar mower .......................18

Adjustment .....................................................18

Mowing...........................................................20

Operating - Hydraulic Lifting System

Use of Hydraulic lifting system ......................22

Adapting the sickle bar mower .......................24

Adjustment......................................................25

Using the lifting device....................................26

Operation of lifting device...............................26

0RZLQJRQÀDWJURXQG ....................................27

Mowing on slopes...........................................28

Operating - Quick Coupler

Quick Coupler.................................................29

Removing sickle bar mower with

Quick Coupler.................................................29