OPERATION

!! IMPORTANT !! –It’s important to test the sprayer with plain water after assembly and any extended

period of storage. This will allow you to check for leaks without wasting expensive chemical or damaging

an area that you’re trying to spray.

Attach the sprayer to a tractor, then fill the tank approximately ½ full with water and connect the wiring harness

to a 12VDC source.

Ensure the boom valve is in the closed position, then turn the wiring harness switch to the ON position. The

pump should run for a short period of time until the pump is primed then automatically turn off. KEEP THE

SWITCH ON TO PERFROM THE FOLLOWING TESTS. Check for any leaks and make repairs if necessary.

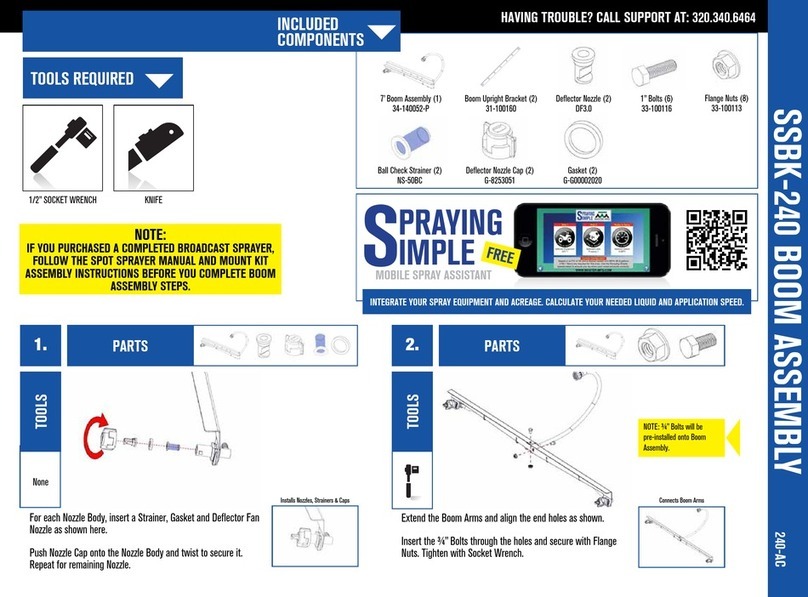

Using the spray wand, ensure the nozzle is pointed down and away from yourself or others, then cycle the

trigger on the spray gun a few times until water sprays out from the nozzle consistently. Release the trigger and

confirm the pump comes up to pressure and stops. Locate the spray boom valve and turn the valve to the open

position. Confirm the booms spray pattern is facing down and even from side to side. Adjust nozzle position as

necessary. Turn off the spray boom valve. Once again, the pump should come up to pressure and shut off.

Check the entire system for leaks and make any necessary adjustments. Turn the power switch to the off

position.

Your sprayer is equipped with an inline switch located in the wiring harness. This switch is used to operate the

pump on or off.

There is also a secondary switch located in the pump. This switch is designed to turn the pump off when it

reaches 40 psi. This switch is calibrated at the factory and should not be tampered with.

Ensure the basket strainer is in place and fill the tank with the desired amount of water based on the amount of

solution needed. Measure out the chemical required for the amount of fresh water in the tank as specified by the

chemical label. Slowly pour the chemical into the tank while mixing. Initially you can remove the basket

strainer and use the spray gun to spray back into the tank to help the mixing process and purge mixed solution

through the pump and spray wand hose. Make sure you replace the basket strainer when done.

Using the handgun

-Ensure the power switch is in the on position.

-Begin spraying by pointing the spray nozzle toward the ground and squeezing the handle lever. The

pump will turn on automatically.

-The spray pattern exiting the nozzle can be adjusted from a straight stream to a cone pattern by rotating

the nozzle.

Using the spray boom

-Ensure the power switch is in the off position.

-Pull the sprayer to the location you would like to spray and turn the boom valve to the on position.

-Begin pulling the sprayer at the desired MPH (See calibration section) and turn the power switch to the

on position. The pump will start to run and the boom will begin spraying.

-Use the power switch to cycle the pump between spraying and stopping.

-When spraying in rows it is common practice to overlap your spray pattern by 50% to ensure

consistent chemical delivery.