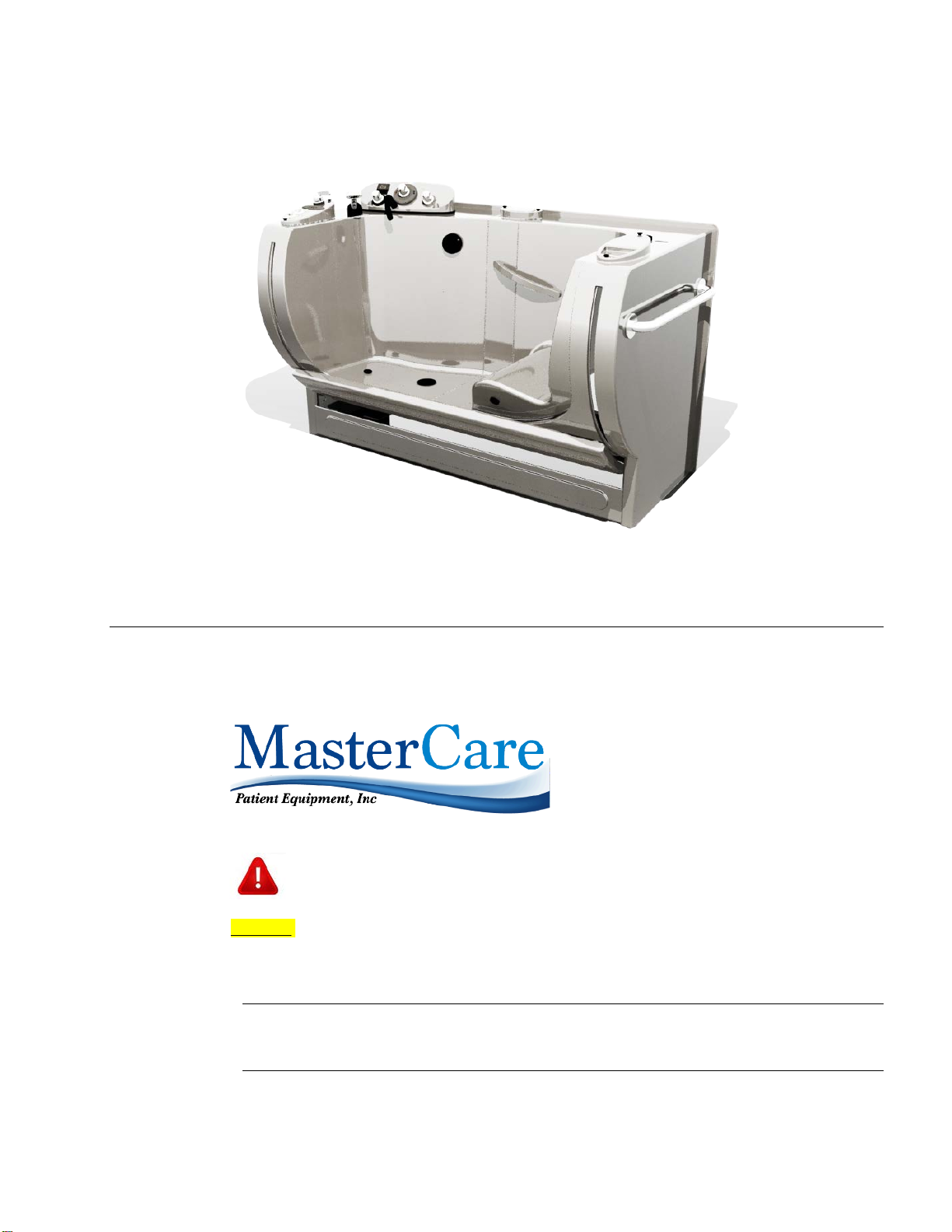

Generation II Entree Bath –All Models

INSTALLATION MANUAL

2071 14th Ave – Columbus, NE 68601

800-798-5867 FAX: 402-563-9102

INSTALLATION CHECK LIST

1. Upon Receipt:

Immediately upon receipt, check for visible freight damage. If damage is found, it must be reported,

communicated and documented immediately to the freight company and MasterCare 1-800-798-5867. Proceed to

inspect the tub for hidden and concealed damage. Leave the tub on the pallet until ready for installation. If the tub

is going to be stored for a period of time before installation, cover it with a tarp to protect it from dust and

construction debris.

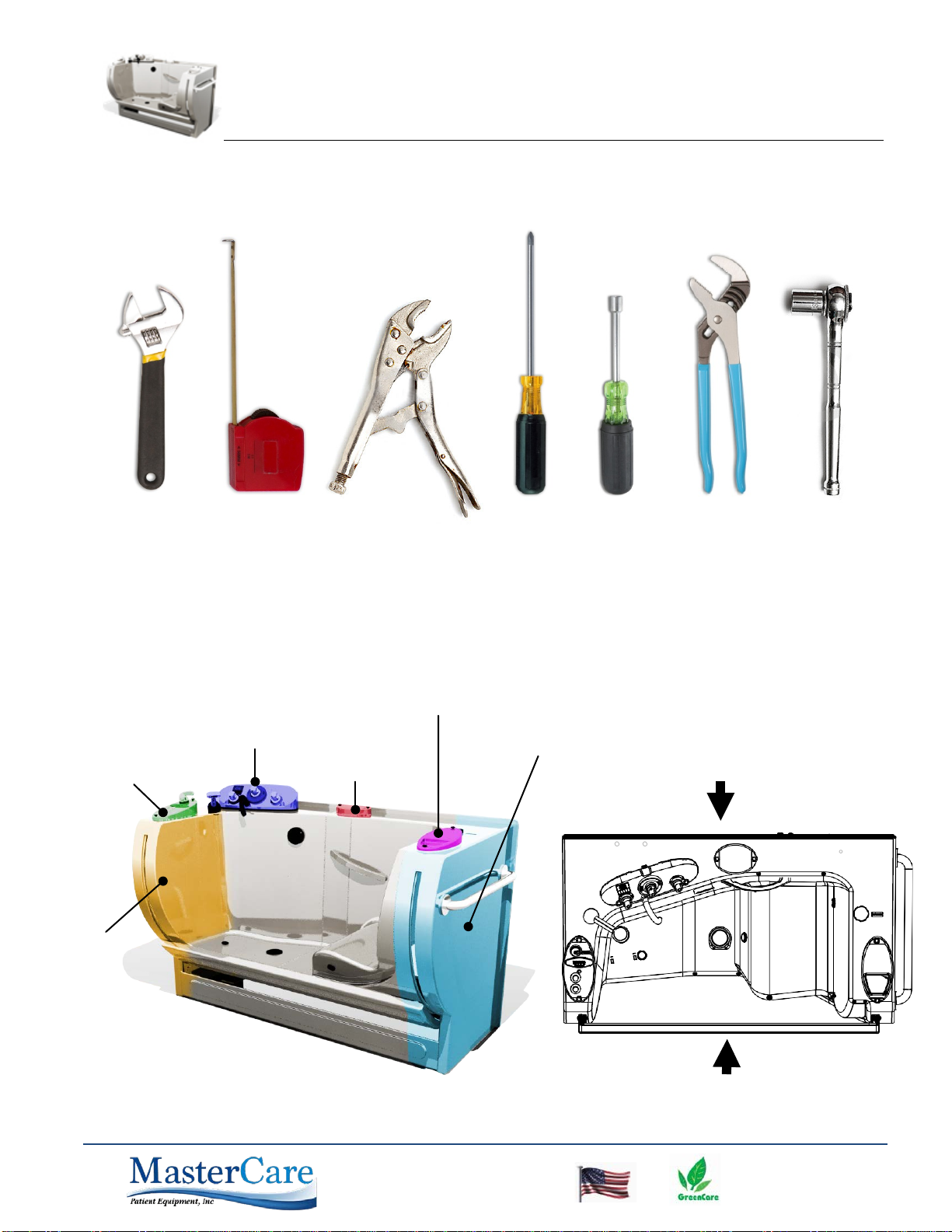

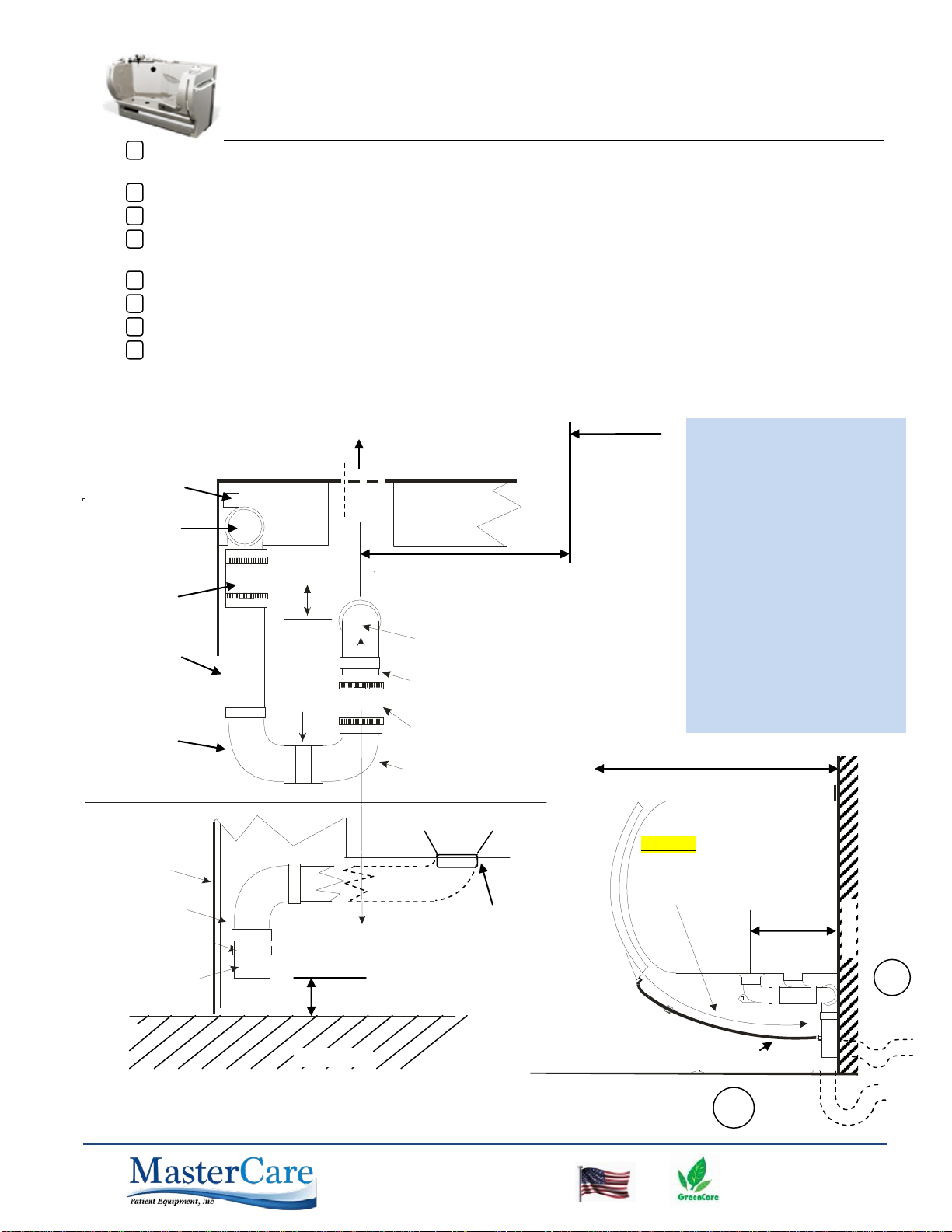

2. Entree Bath Uncrating Instructions: (Note: Read and follow instructions thoroughly.

Refer to the drawing on following page to reference details.)

a. Remove the stretch wrap (plastic) from the outside of the crate.

b. Remove the ten (10) lag screws from the bottom of the crate (Detail 1).

c. Two people will now be required to lift the crate over the top of the Entree

Bath.

d. Set aside the

Entree Gen II Starter Kit box and the Combo Case

from the

pallet. It is recommended to leave the stretch wrap (plastic) on the Entree

Bath until the tub is in its final location.

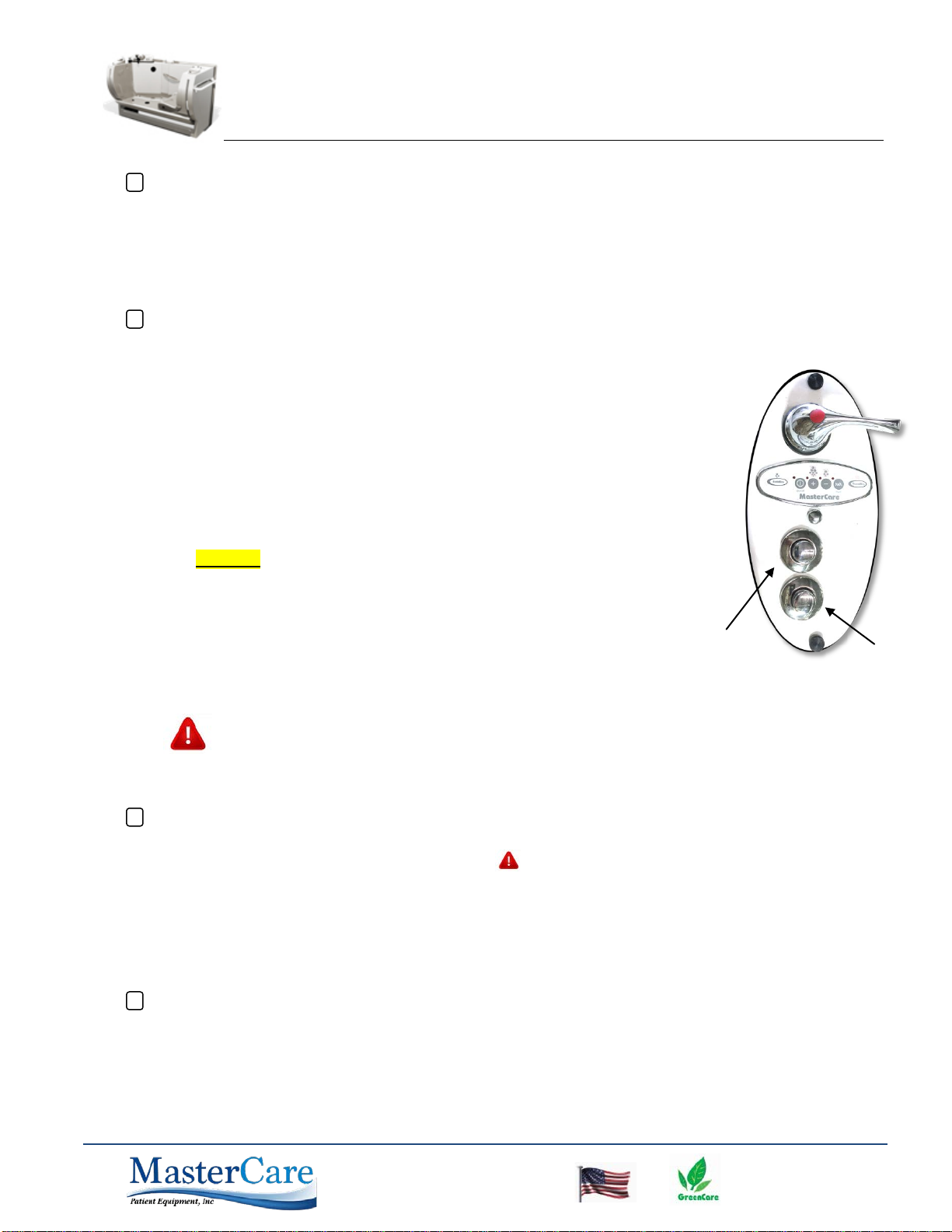

e. Remove the two (2) 10-32 x ¾” thumbscrews from the Entree cover panel

(Detail 4). Gently remove the cover panel from the tub.

CAUTION: Remove the cover panel before removing the tub from the crate.

f. Locate the Tub Power Cord, center rear back of tub, then plug in the tub and

close the door halfway by depressing the Door Close button located on the

Foot End Control Panel. Locate the two lag screws by looking through the

service hole located on the backside of the tub (Detail 3). Proceed to

remove the two lag screws; discarding board.

g. Remove the four (4) screws from each of the anchoring plates (Detail 2).

h. The Entree Bath can now be lifted off of the pallet.

The Entree Bath is VERY HEAVY. Two people (Minimum) are required to move the Entree Bath.

i. Position the cover panel onto the front of the Entree Bath and line up the screw holes (Detail 4). Place one

of the 10-32 x ¾” thumbscrews into each hole on the cover panel and tighten accordingly.

3. Transfer and Positioning: The tub is shipped with the door in the open position. To transfer, plug the tub into

an

extension cord and rotate the door to a nearly closed position, by pushing on the Door Close button until the door

rotates all the way up and it just starts to cam in. Do not close the door all the way so that the seal is

compressed. Leaving the door closed with the seal compressed over a long period of time can damage the seal.

The tub may have to be in an open position to get through some doors. After the tub is on-site, leave the special

packing around the

tub door on until after the tub is installed and ready for its test operation. Check again to make

sure the door is not

fully closed and compressing the seal.

4. Connect the electrical service to the tub. The tub comes with a cord with a plug, or it can be hard wired with flex

watertight conduit by an electrician. (Verify that the tub is properly grounded if rewired).

button

button