CONTROLS

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

Throttletwistgrip.Twistinwardstoopen.Whenfullyclosedengineshould

justidlewhenhot.

Aircontrollever.Pullinwardstoincreaseairsupply.Onceset,whenengine

haswarmedup,requiresnoalterationfordifferentroadspeeds.Shouldbefully

closedtostartenginefromcold.

Ignitioncontrol.Advancesandretardsignitionpoint.Pullinwardstoadvance.

Retardtwo-fifthsoftotalmovementforstarting.

Valvelifterlever.Smallleverclosetoclutchlever.Liftsexhaustvalvefrom

seat,releasingcompressionincombustionchamber,enablingenginetobeeasily

rotatedforstarting.Alsousedforstoppingengineifthrottlestopisset

asadvisedinPara.(1)above.AlsoseePara.6.

Clutchlever.Largeleverinfrontoflefthand.Griptoreleaseclutchsothat

drivetorearwheelisdisconnected.Usedwhenmovingawayfromstandstill

andwhenchanginggear.

Frontbrakelever.Largeleverinfrontofrighthand.Griptooperatefront

wheelbrakeand,fornormalbraking,useinconjunctionwithrearbrakeappli-

cation.SeePara.9.

Rearbrakepedal.Depresswithleftfoottoapplyrearbrake.Applygently

anduseincreasingpressureasroadspeeddecreases.

Gearchangepedal.Controlsselectionofthefourspeeds,orratios,between

engineandrearwheelrevolutions,witha " free,"orneutral,position.See

Para.7 andIllustration3.

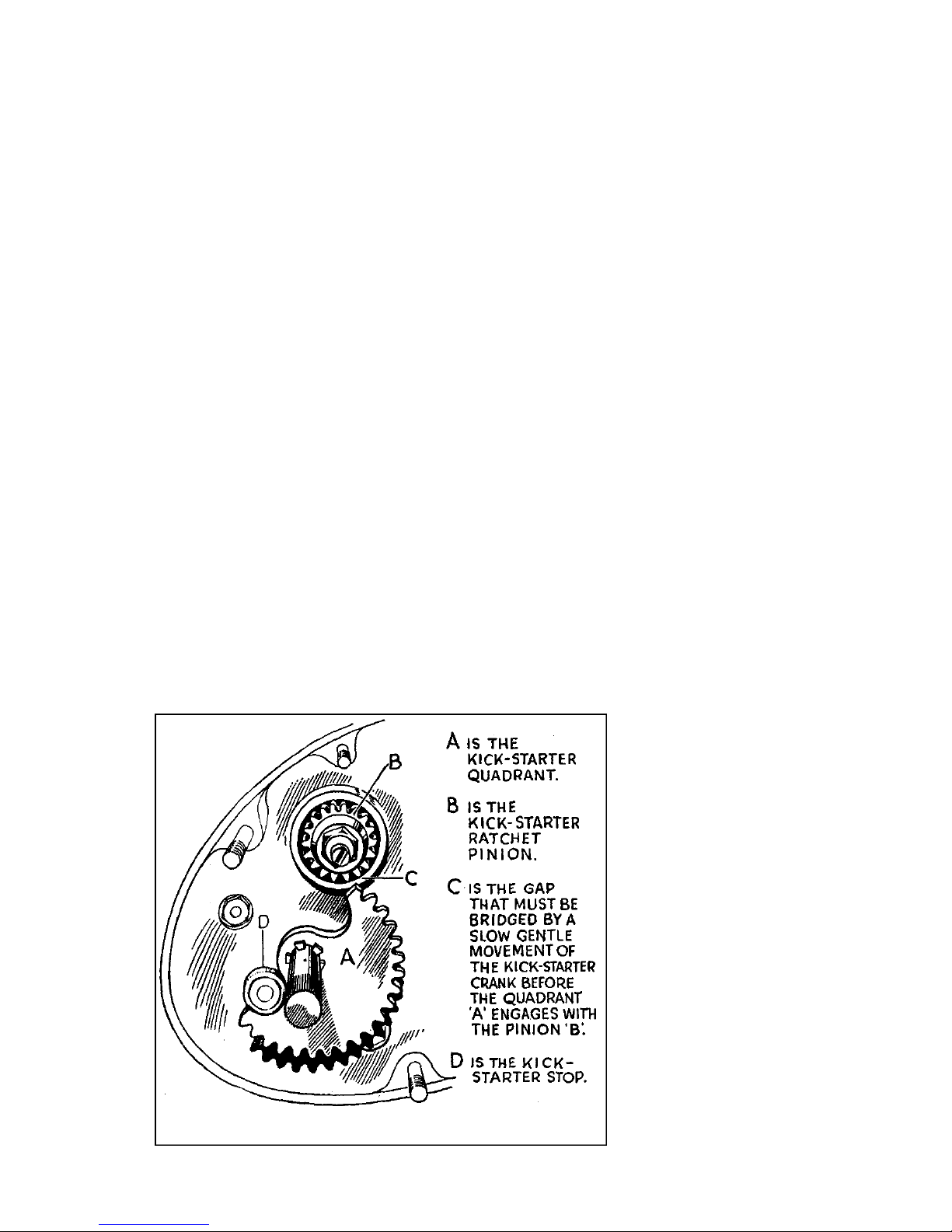

Kick-starterpedal.Thealmostverticalpedalonrighthandsideofgearbox.

FordetailsofuseseePara.5 andIllustration2.

Lightingswitch.Intopofheadlamp.Controlslampsbyrotatingleverwhich

hasthreepositions:—

(1)" OFF."Lampsnoton.

(2)" L."Pilotbulbinheadlampandrearlampon.

(3)" H."Headandrearlampson.Headlamphasa doublefilament.See

Item(17)below.

Ammeter.Intopofheadlamp.Indicatesflowofelectriccurrentin,orout,

ofbattery.("Charge" or" Discharge.")

Hornpushswitch.Depressbuttontosoundhorn.

Gearboxfillercap.SeeParas.23and66.

Footrest.Forrider.

Petroltankfillercap.Torelease,slightlydepress,turn,andthenliftaway.

Oiltankfillercap.OperatedasPetroltankfillercap(15).

Dippingswitch.Triggerswitchonlefthandlebar.Usedtoselectnormalor

"dipped" beamofheadlampwhenmainlightingswitchleverisinthe" H "

position.

2CONTROLS