IRRIGAMATIC ASSEMBLING

3.2.2 SENSOR INSTALLATION

•

•

•

•

•

•

Insert the sensor in the arm hole from the magneto

side and fix it with nut and check nut.

Fix the spiralled cable to the roller arm and to the

hose guide by straps or cable holders.

Fix the cable to the irrigator frame, centrally over

the hose guide in such a length as to allow the hose

guide to slide from right to left with the cable still

slightly twisted . Make sure the cable is in such a

position as to avoid any damage during operation.

For heavy duty conditions an optional speed

sensor is available with a Rilsan cable.

Fix the sensor cable to the irrigator frame by

straps or cable holders as far as the electronic

gearcase.

The speed sensor cable bears a ring with

number 2 and should be connected to gearcase

connector 2.

4. INSTALLATION OF THE

ADJUSTING VALVE

4.1 INSTALLATION OF THE BY-PASS

VALVE

4.1.1 BY-PASS VALVE INFORMATION

•

•

•

The by-pass valve is used to send more or less

water to the turbine, thus allowing to adjust the

trolley return speed.

The valve is sized according to the irrigator

characteristics.

The following table shows the size of the valve

generally used according to the irrigation hose

diameter:

irrigation hose by-pass valve

50 - 100 mm 2”

80 - 110 mm 2” ½

100 - 125 mm 3”

130 - 140 mm 4”

When the by-pass valve is fully open, the hose

rewinding speed is zero even when the hose is

partially rewound. For this reason, under specific

conditions, it may be useful to install valves in a

size different from standard ones.

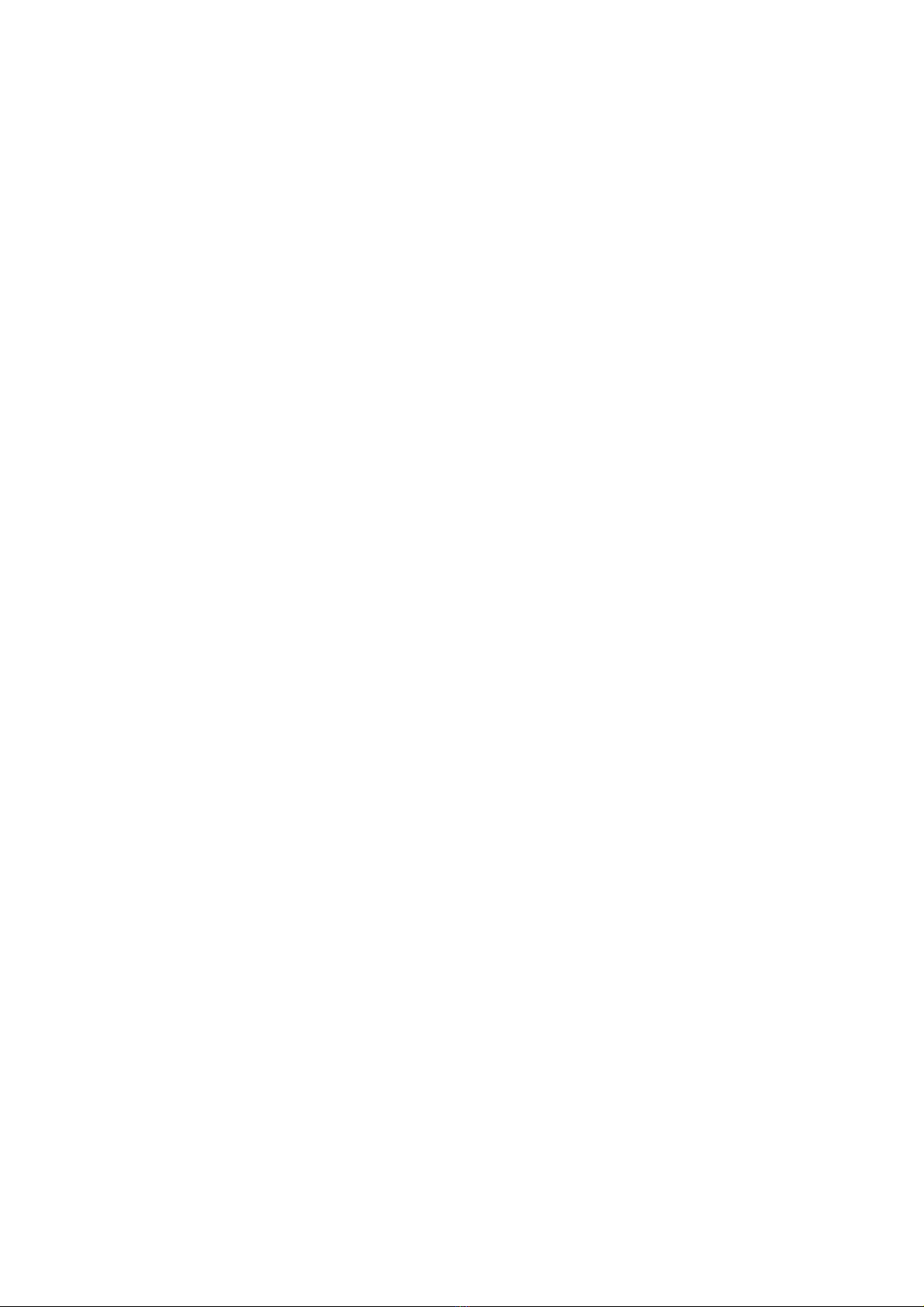

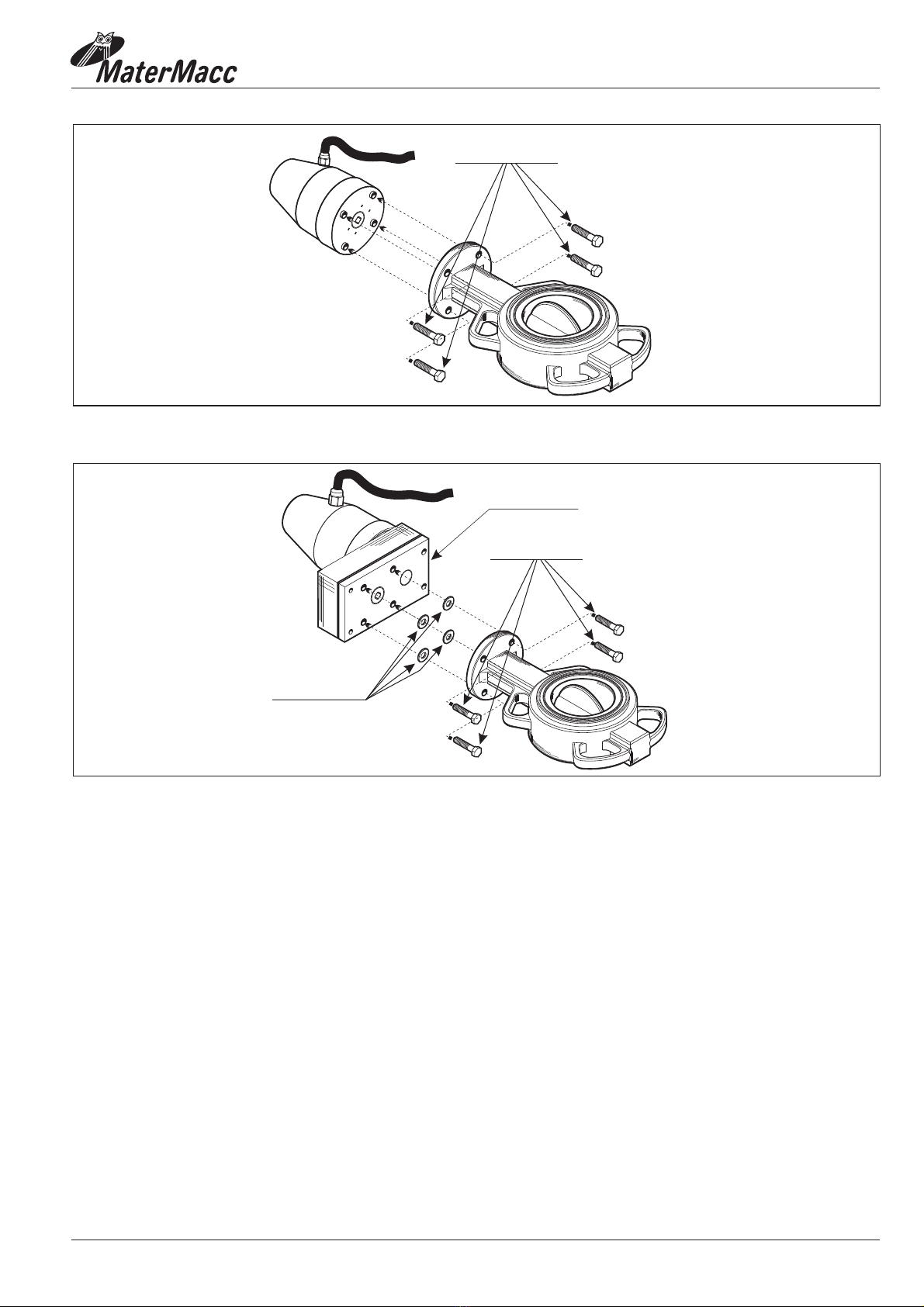

By-pass valves consist of a 100 mm long body with

female gas threading at the ends and a head gasket

for wafer mounting. A butterfly valve with an

elastic rim is mounted inside The motor reduction

gear is fitted on the valve shaft. The motor

reduction gear is controlled by the gearcase for

speed adjustment.

4.1.2 HOW TO MOUNT THE BY-PASS VALVE

Fit the by-pass valve in the by-pass duct of the

turbine in such a position as to prevent the motor

reduction gear from getting upside down to

prevent water seepage . The duct with the by-pass

valve should not be rigid, but at least with a section

of rubber or plastic hose to prevent any damage to

the valve.

Page 03