Page 2

Table of contents

1About this operating manual....................................................................................3

2Safety.........................................................................................................................4

2.1 Intended use...............................................................................................................4

2.2 Qualifications of personnel..........................................................................................4

2.3 General safetynotices .................................................................................................5

2.4 Special safety notices .................................................................................................6

2.5 Basic rules..................................................................................................................7

3Task and use.............................................................................................................7

4Delivery and transport..............................................................................................7

5Installation.................................................................................................................8

5.1 Mounting the snow blower on the tractor.....................................................................8

5.1.1 Mounting snow blower SBL - M 12-40 QH an JD X700...............................................8

5.1.2 Mount snow blower SBL - M 12-40 C and SBL - M 12-40 C on tractor........................9

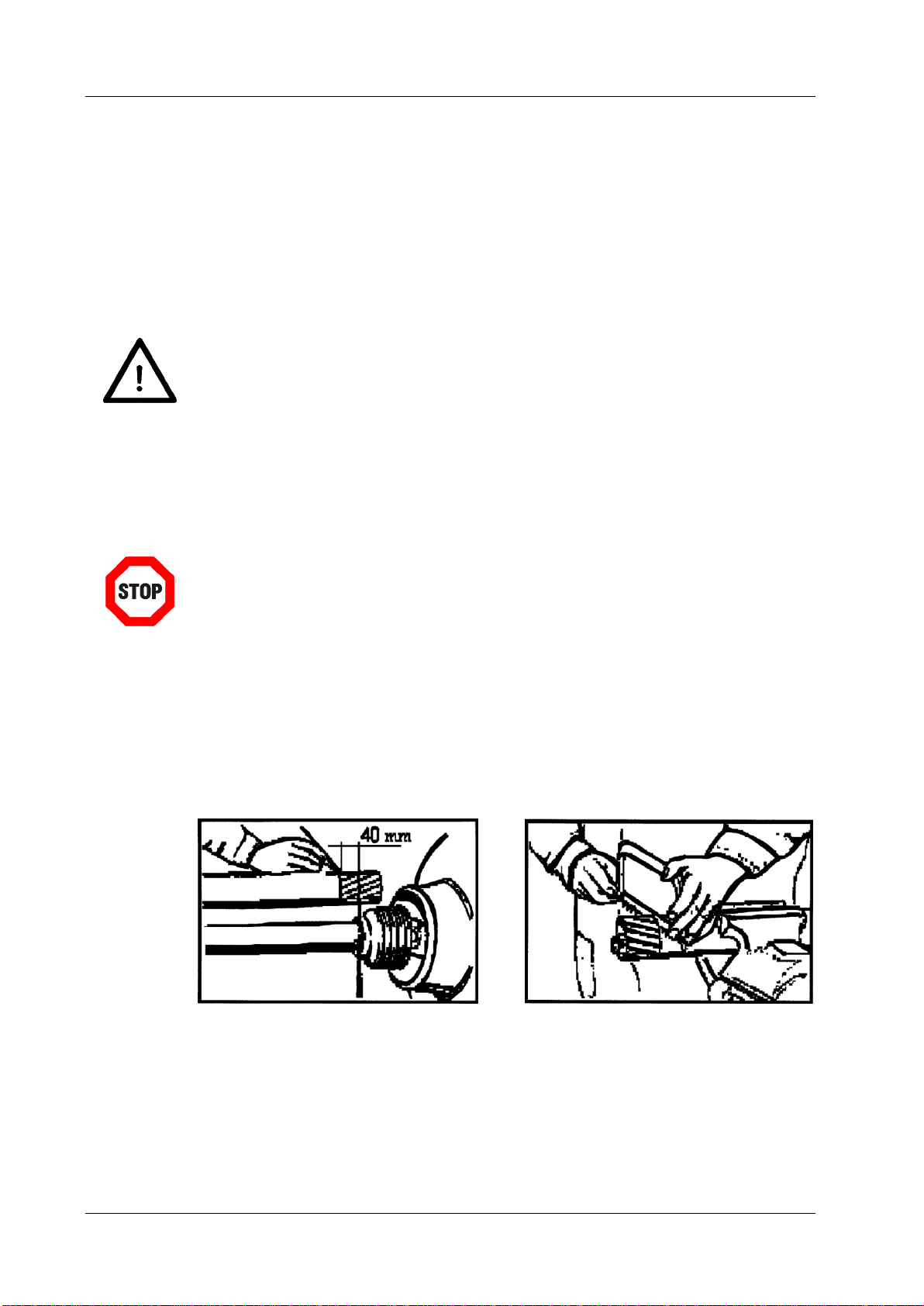

5.2 Installation of the universal joint shaft........................................................................10

5.2.1 Adaptation of the universal joint shaft........................................................................10

5.2.2 Mounting the universal joint shaft..............................................................................11

6Operation.................................................................................................................12

6.1 Working with the snow blower...................................................................................12

6.2 Adjusting the work height of the machine..................................................................13

7Maintenance............................................................................................................13

7.1 General information...................................................................................................13

7.2 Maintenance .............................................................................................................14

7.2.1 Front auger and deflector group................................................................................14

7.2.2 Safety screw.............................................................................................................15

7.2.3 Throw-out tower........................................................................................................15

7.2.4 Gearbox....................................................................................................................16

7.2.5 Lubricating the universal joint shaft...........................................................................17

7.3 Faults........................................................................................................................17

7.4 Repair.......................................................................................................................18

8Disposal...................................................................................................................18

9Guarantee................................................................................................................18

10 Technical data, implements and optional equipment...........................................19

11 List of illustrations..................................................................................................20

12 EC Declaration of Conformity ................................................................................21