Contents

Page 2

Table of contents

1About this operating manual....................................................................................3

2Safety.........................................................................................................................4

2.1 Intended use...............................................................................................................4

2.2 Qualification of personnel............................................................................................4

2.3 Safety instructions.......................................................................................................4

3Attachment and start up...........................................................................................6

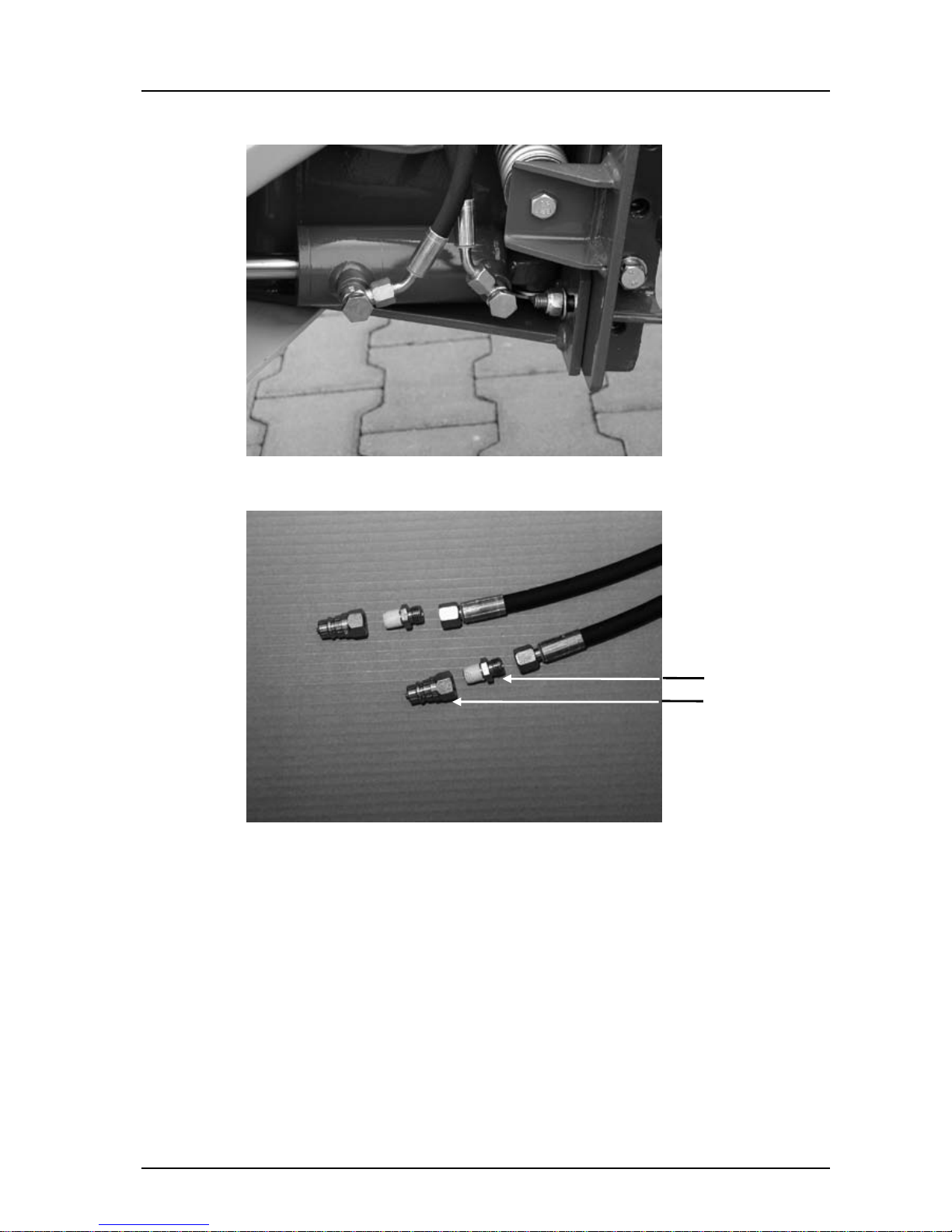

3.1 Preparations on the snow blade..................................................................................6

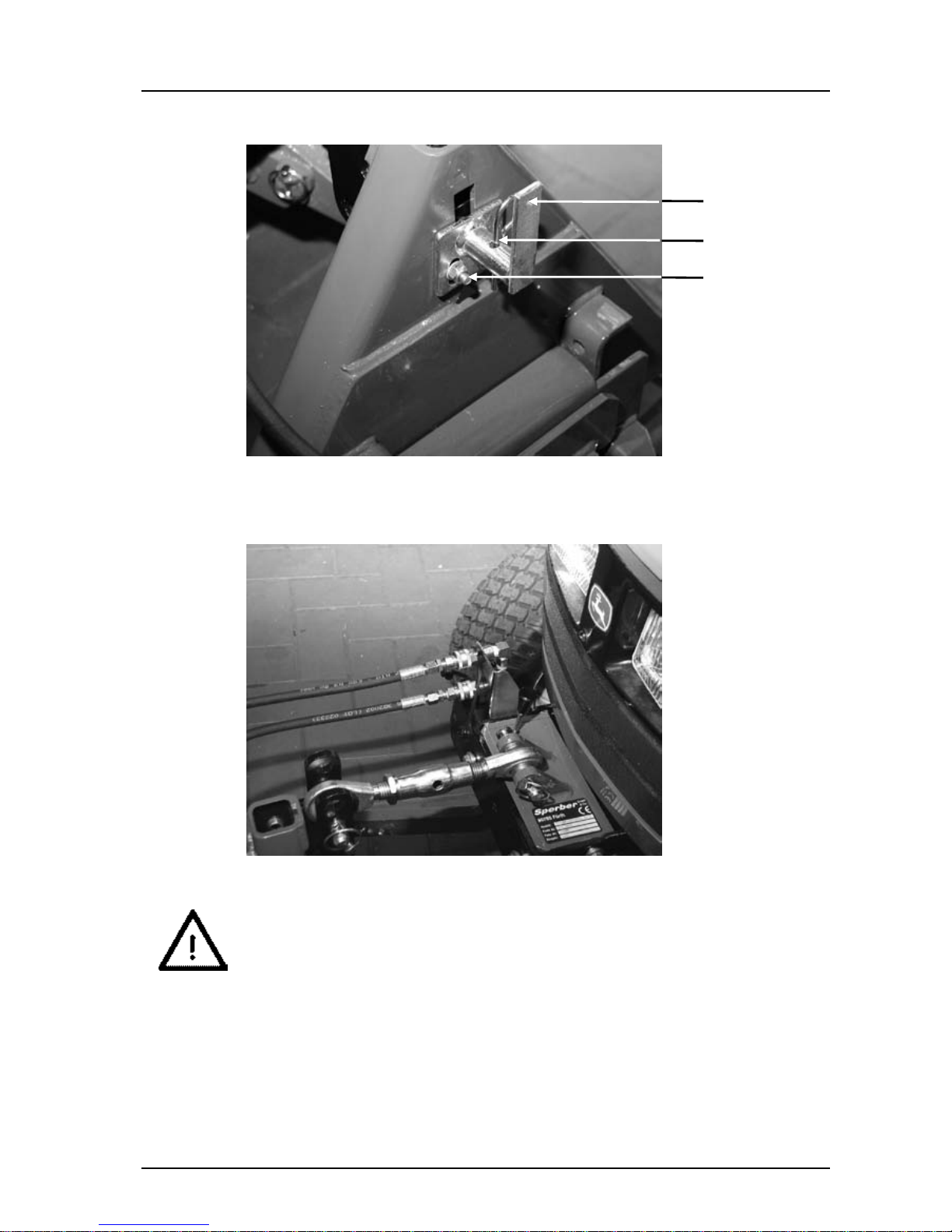

3.2 Attaching the snow blade on the tractor......................................................................8

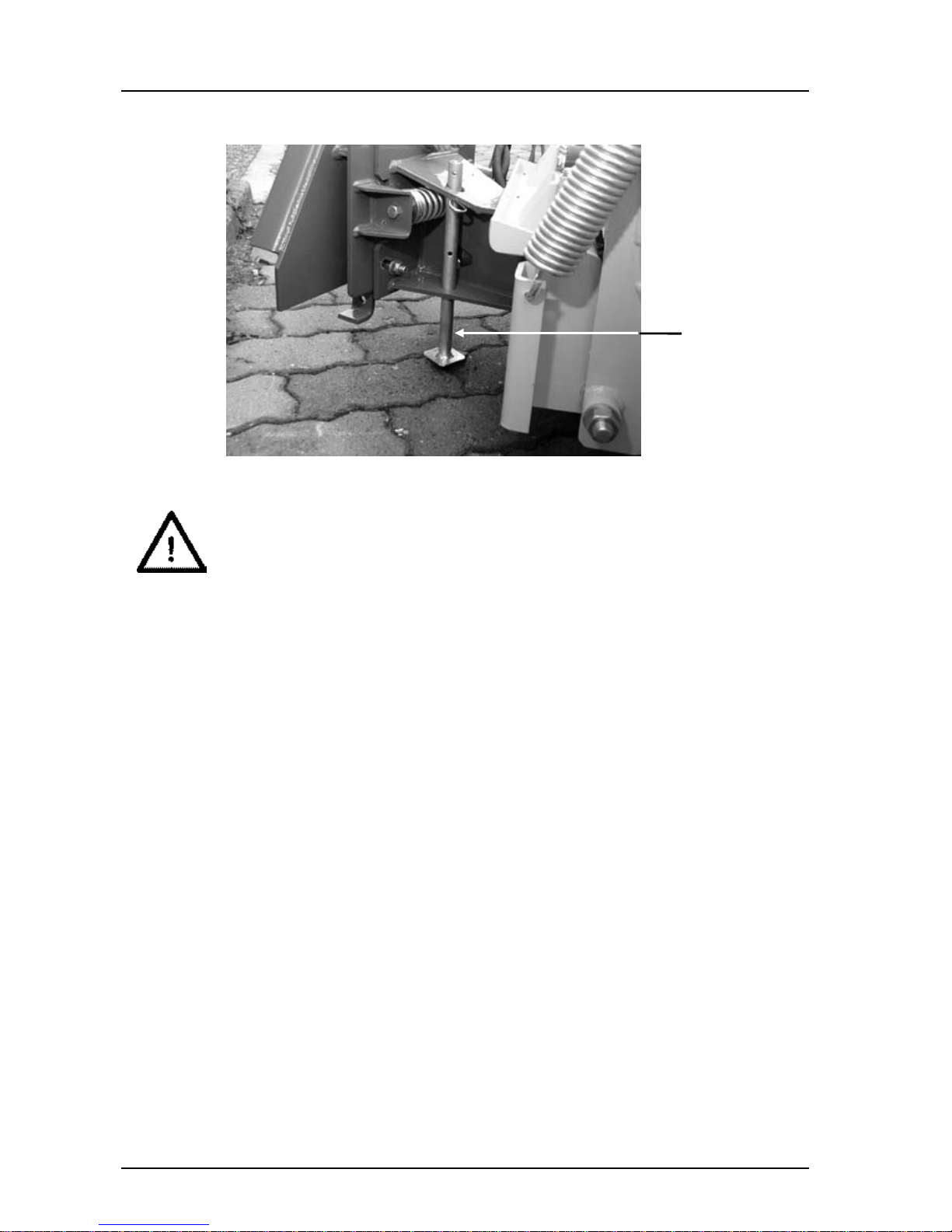

3.3 Adjustments on the snow blade: ...............................................................................12

4Operation and fault correction...............................................................................15

4.1 Operation..................................................................................................................15

4.2 Fault correction.........................................................................................................15

4.3 Contact.....................................................................................................................16

5Service.....................................................................................................................17

6Disposal...................................................................................................................19

7Warranty..................................................................................................................19

8Technical data and accessories.............................................................................20

8.1 Technical data...........................................................................................................20

8.2 Accessories ..............................................................................................................20

9List of illustrations..................................................................................................21

10 EC Declaration of Conformity ................................................................................22