Copyright © Matrix Technology Solutions Ltd.4

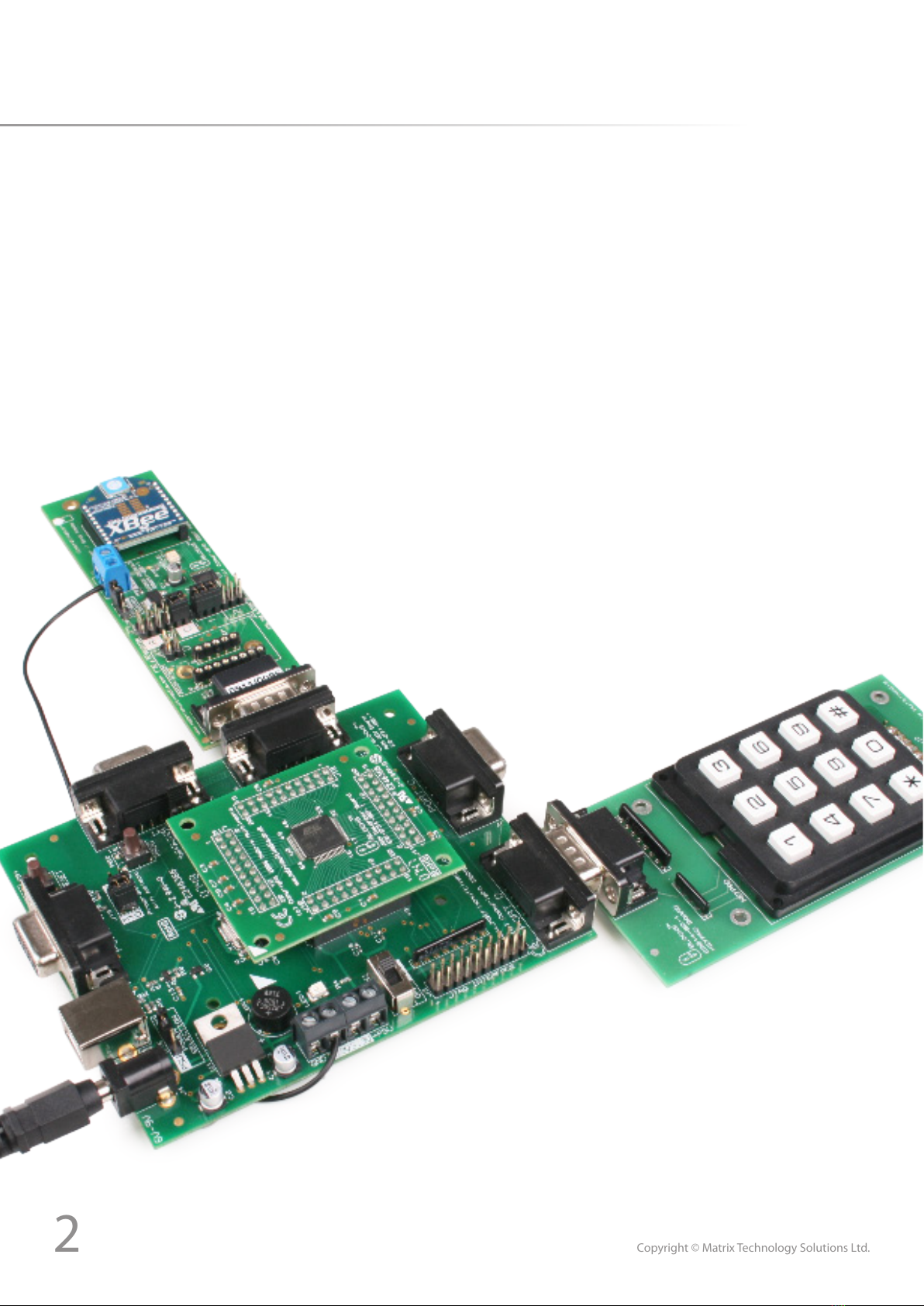

General information

This E-block board is a development tool for the powerful

AT91 SAM 7 microcontroller from Atmel. The SAM 7 is

a 32 bit RISC device running at an interval frequency of

36MHz, and having 128k ROM and 32K static RAM as

well as 2 USARTs, 4 x 10 bit A/D converters and a native

USB bus. This incredibly powerful microcontroller can

be used for a range of advanced E-blocks projects. The

board has ve E-blocks ports and the processor itself

is housed on a removable daughter board (Atmel ARM

processors are only available in SMD technology) so that

the ARM can be incorporated into custom PCBs.

1. Features

• 32 bit RISC processor with 128K ROM and 32K SRAM

• USB programmable with boot loader

• 5 x E-blocks ports, 32 I/O lines

• Compatible with most downstream boards

• Native USB and SPI buses

• Removable crystal

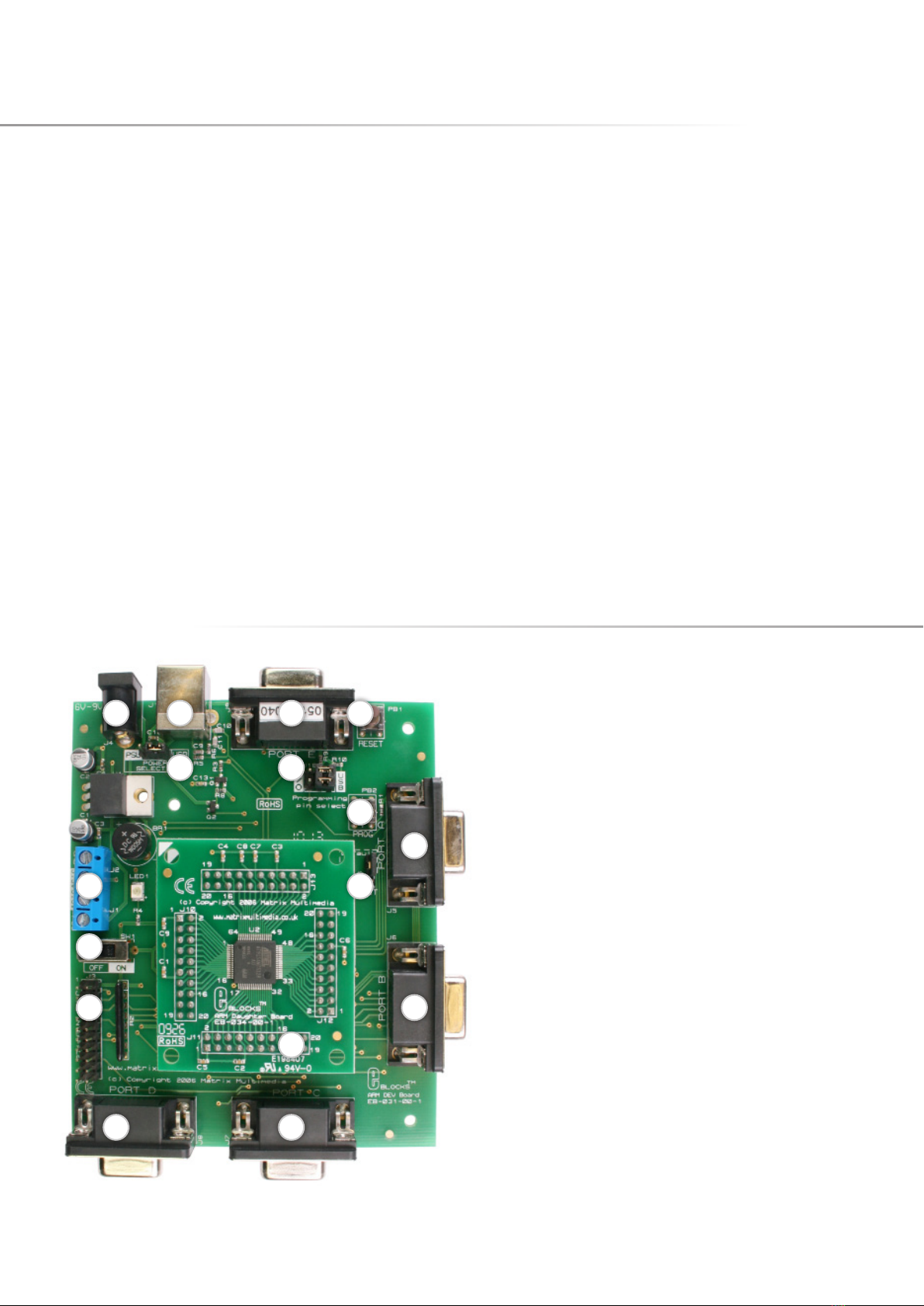

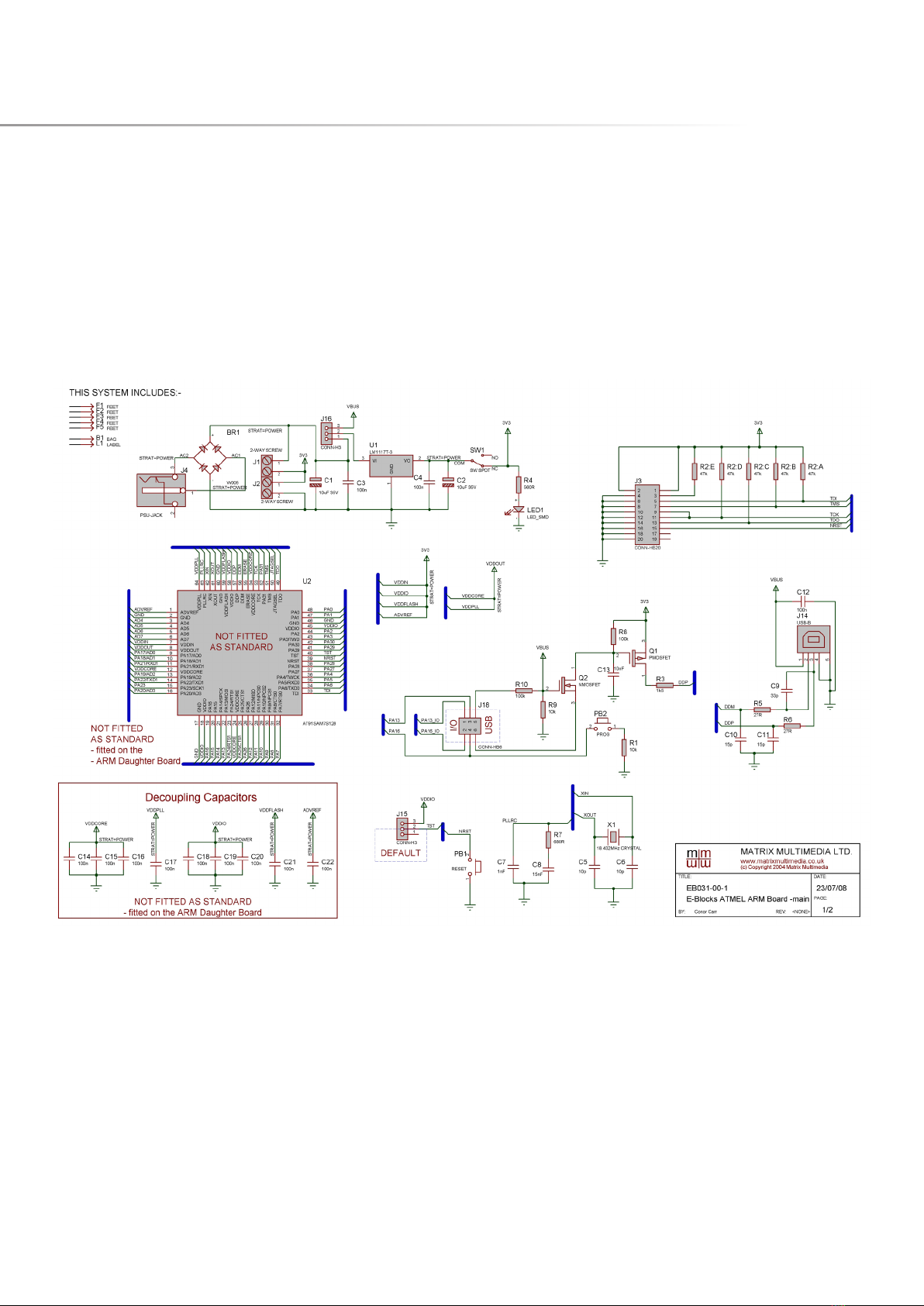

Circuit description

The ARM board solution is made up of two parts:

• A mother board (ARM board EB031) that allows ARM

devices to be programmed and the program to be

executed ‘seamlessly’.

• The ARM daughter board (EB034) that houses the

ARM device on a simple to use board. This allow the

user to program the device using the ARM board

(EB031) and then either use this daughter board in

either the ARM board (EB031) for development, or

to easily use the ARM daughter board in another

project.

1. Power supply

The board is normally operated from an external

regulated DC power supply of 6V - 9V. This allows full

operation including programming.

The board has two modes of power supply; either from

an external regulated DC power supply or powered

using the computer via the USB port. The external

power supply is specied as 6-9V regulated DC power

supply. When using the USB port to power the board,

the user must be aware of the limitations for the use of

this USB port - for example the limited current that can

be supplied via USB (approx. 100mA).

The jumper link system, J16, allows the user to decide

on the source of the power supply. If using an external

power supply the jumper should be positioned to the

left hand side of the jumper system labelled ‘PSU’. If

using USB power place the jumper on the right hand

side of the jumper system. LED1 indicates that power

is supplied to the board from either the external power

supply or the USB cable.

Please note that both USB and the PSU cables should

be removed for the ARM board before changing the

position of this jumper.

Remember that other E-blocks will have to receive 3.3V by

placing a connecting wire from the +V screw terminal of

the ARM board to the +V screw terminal of each E-block

that requires a voltage. Also the user should ensure that

all the E-blocks that they are using are 3.3V compatible.

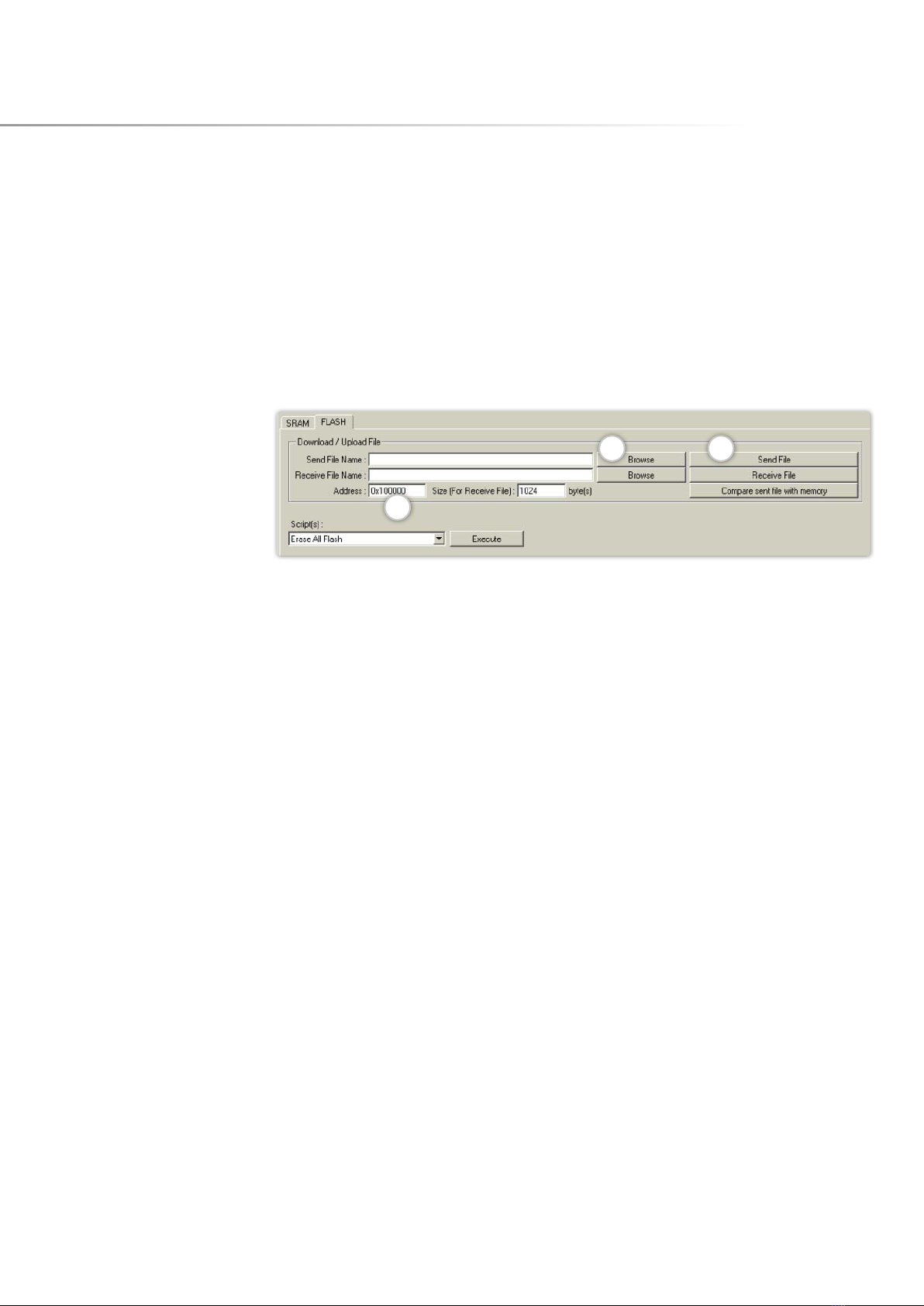

2. Programming (hardware)

The ARM board connects to a personal computer via

the USC socket. Any USB socket on the PC can be used.

The host ARM device is set-up to communicate with the

USB bus and the programming circuitry. The board uses

MOSFET transistors to detect the USB bus, which allows

the board to be programmed.

The board has a connection (10 +10 DIL PCB header pins)

that allows the ARM device to be programmed via an

external programmer using the JTAG pins available on

the ARM device. This is a standard JTAG connection.

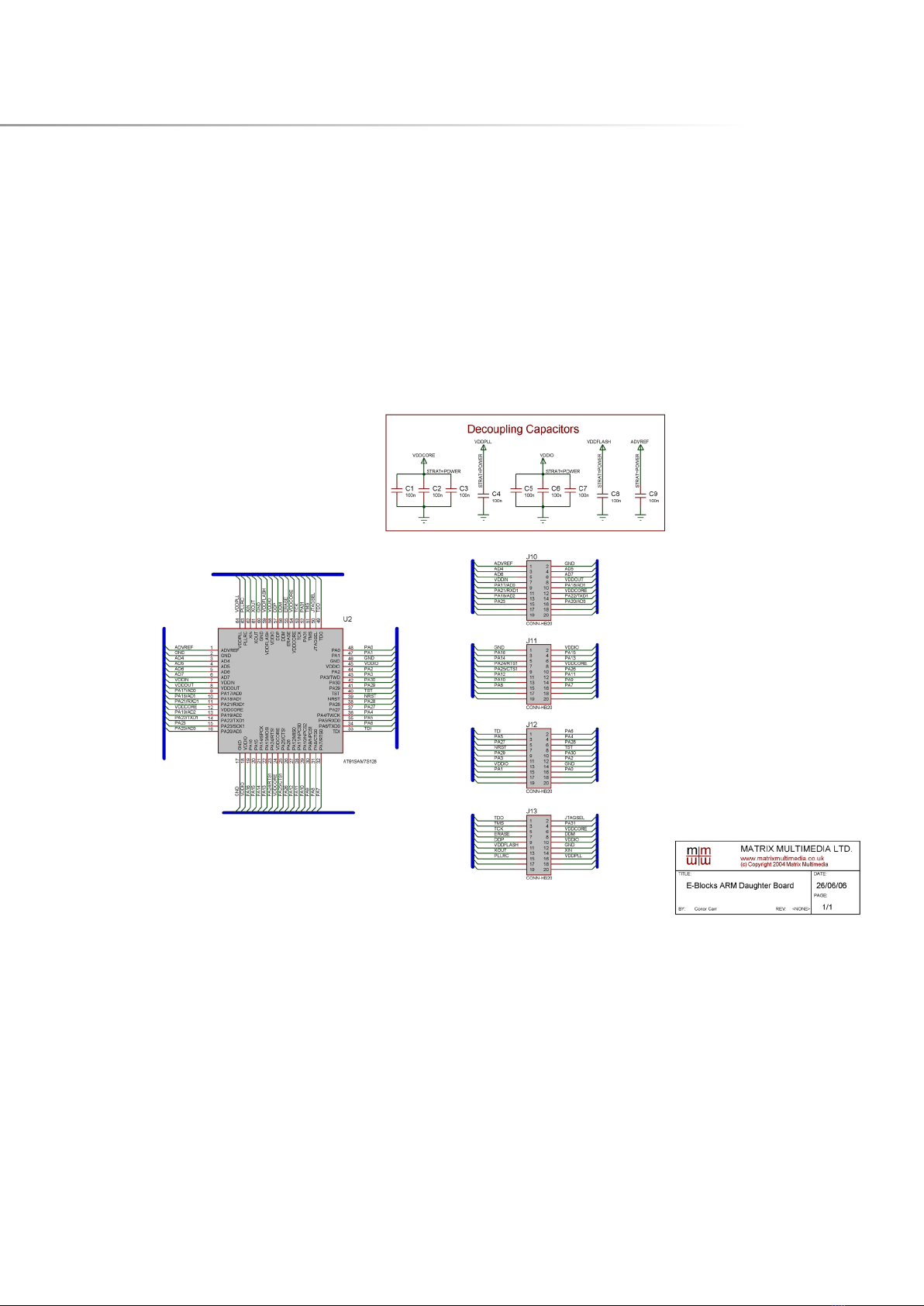

DIL sockets and I/O ports

The ARM board uses an external ARM daughter board.

This daughter board enables the ARM board to be both

a development board and a programmer. This means