2. After removing an electrical assembly equipped with ES devices, place

the assembly on a conductive surface such as alminum foil, to prevent

electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static solder removal device. Some solder removal

devices not classified as "anti-static (ESD protected)" can generate

electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical

charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package

until immediately before you are ready to install it. (Most replacement

ES devices are packaged with leads electrically shorted together by

conductive foam, alminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a

replacement ES device, touch the protective material to the chassis or

circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all

other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES

devices. (Otherwise hamless motion such as the brushing together of

your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity (ESD) sufficient to damage an ES device).

3. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

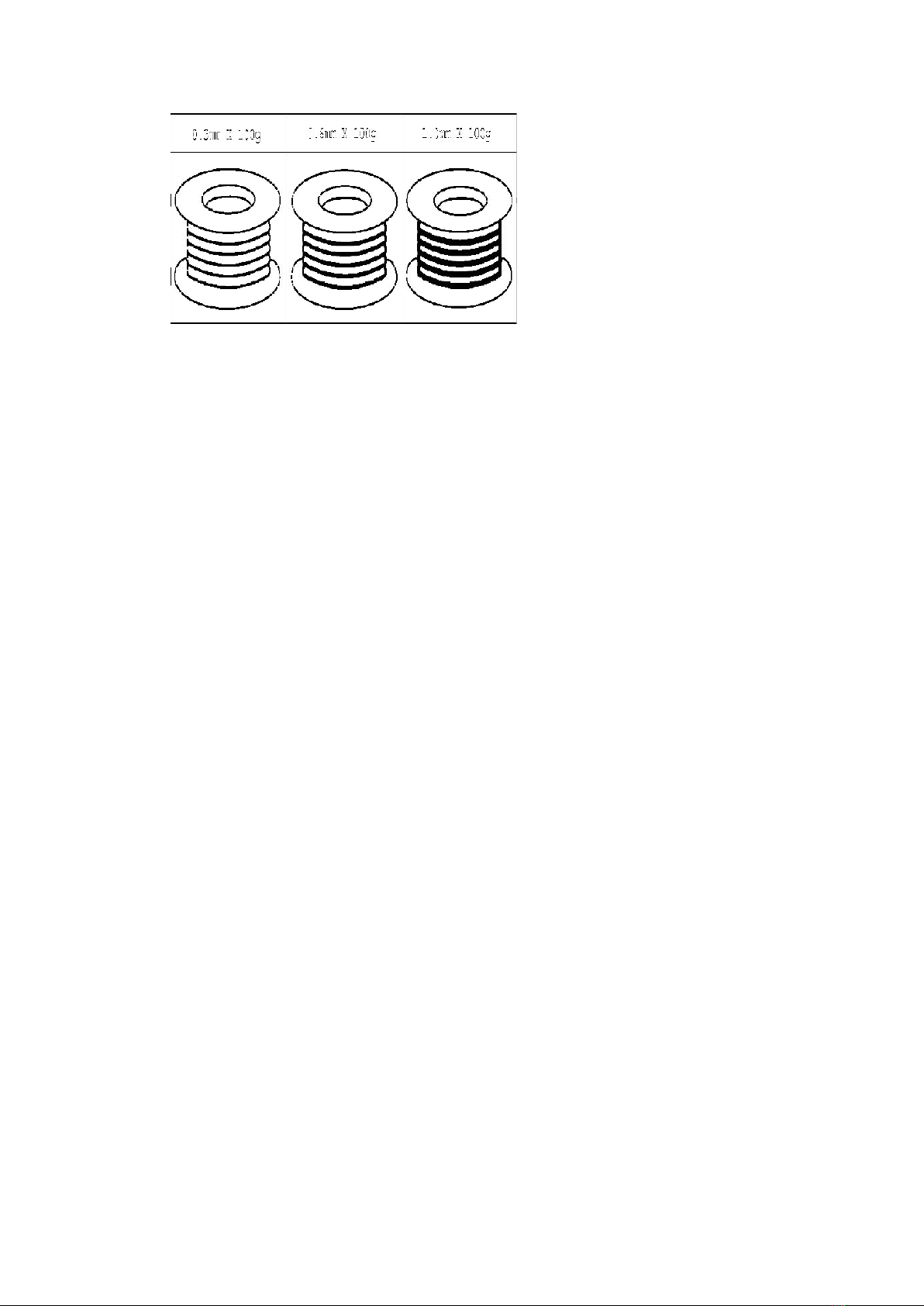

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For

service and repair work, we’d suggest the use of Pb free solder as well, although Pb solder may be

used.

4