MATSUYA

- 3 -

CONTENT PAGE

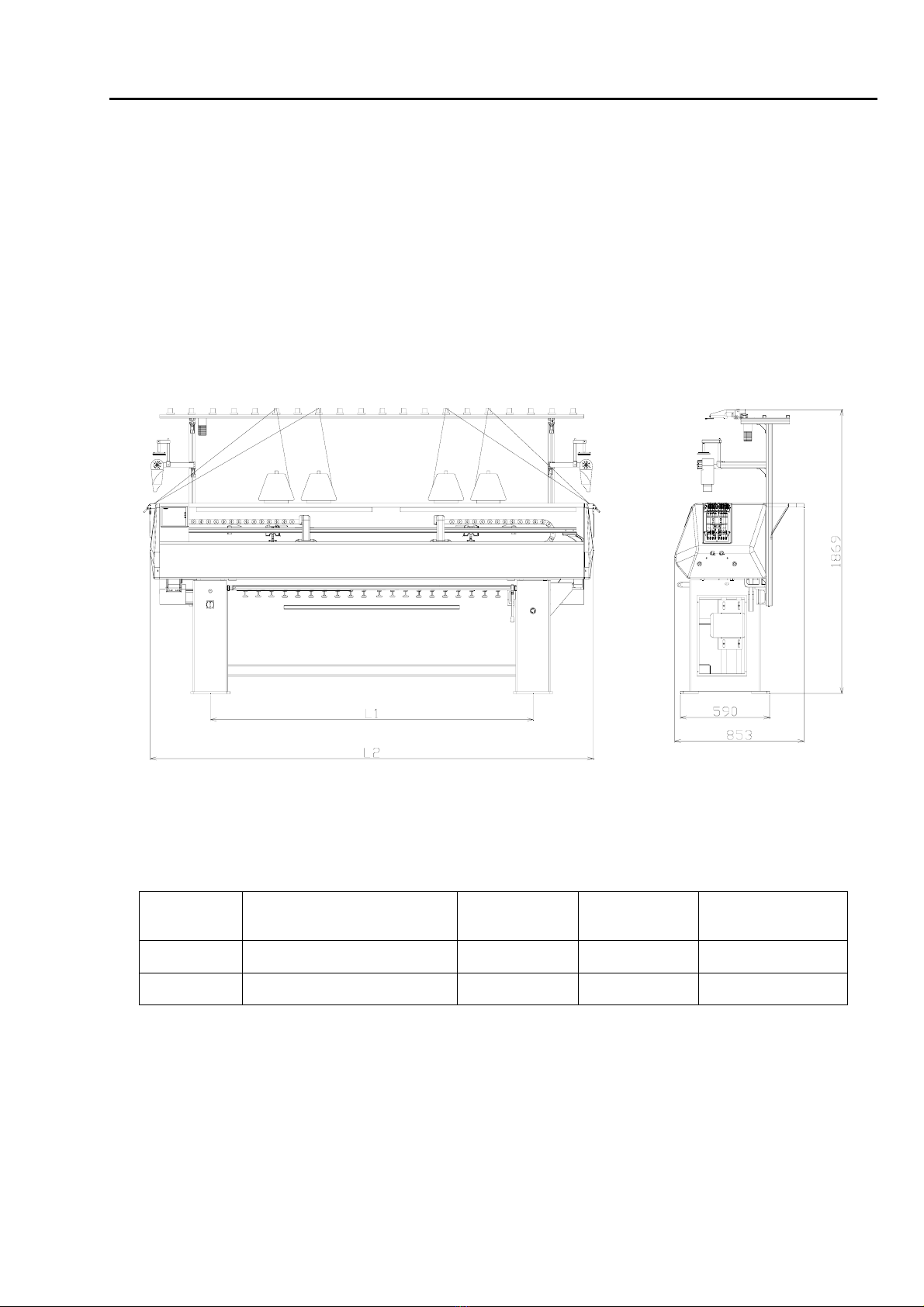

1 INSTALLATION -------------------------------------------------------- 05

2 NAME OF EACH PARTS --------------------------------------------------- 06

3 SAFETY REGULATIONS --------------------------------------------------- 07

4 MACHINE OPERATION AND ADJUSTMENT-------------------------------------- 08

4.1 MACHINE POWER ----------------------------------------------------- 08

4.2 SWITCH BAR & CARRIAGE MOVEMENT ------------------------------------ 08-09

4.3 DRIVE MECHANISM --------------------------------------------------- 09

4.3.1 ADJUSTMENT OF MOTOR TIMING BELT -------------------------------------------- 09

4.3.2 ADJUSTMENT OF CARRIAGE TIMING BELT ----------------------------------------- 10

4.4 CARRIAGE --------------------------------------------------------- 10

4.4.1 CARRIAGE CONNECTION -------------------------------------------------------- 10

4.4.2 ENCODER --------------------------------------------------------------------- 11

4.4.3 YARN FEEDER ADJUSTMENT -------------------------------------------- 11

4.4.4 BRUSH ADJUSTMENT ----------------------------------------------------------- 11

4.4.5 NEEDLE DETECTOR ADJUSTMENT -------------------------------------------------- 12

4.4.6 ADJUSTMENT OF CARRIAGE STOPPER ---------------------------------------------- 12

4.4.7 BEARING ADJUSTMENT --------------------------------------------------------- 13

4.4.8 CARRIAGE NO. ----------------------------------------------------------------13

4.4.9 YARN CHANGE DEVICE ---------------------------------------------------------- 14

4.5 NEEDLE BEDS -------------------------------------------------------- 15

4.5.1 TYPES OF NEEDLES ------------------------------------------------------------ 15

4.5.2 BRIEF DRAWING OF REST NEEDLE ------------------------------------------------ 15

4.6 TAKE-DOWN DEVICE -------------------------------------------------- 16

4.6.1 TAKE-DOWN MOTOR --------------------------------------------------- 16

4.6.2 AUX. TAKE-DOWN ROLLER ---------------------------------------------- 16

4.6.3 FABRIC DROP DETECTOR、FABRIC ROLL-IN DETECTOR----------------------------- 17

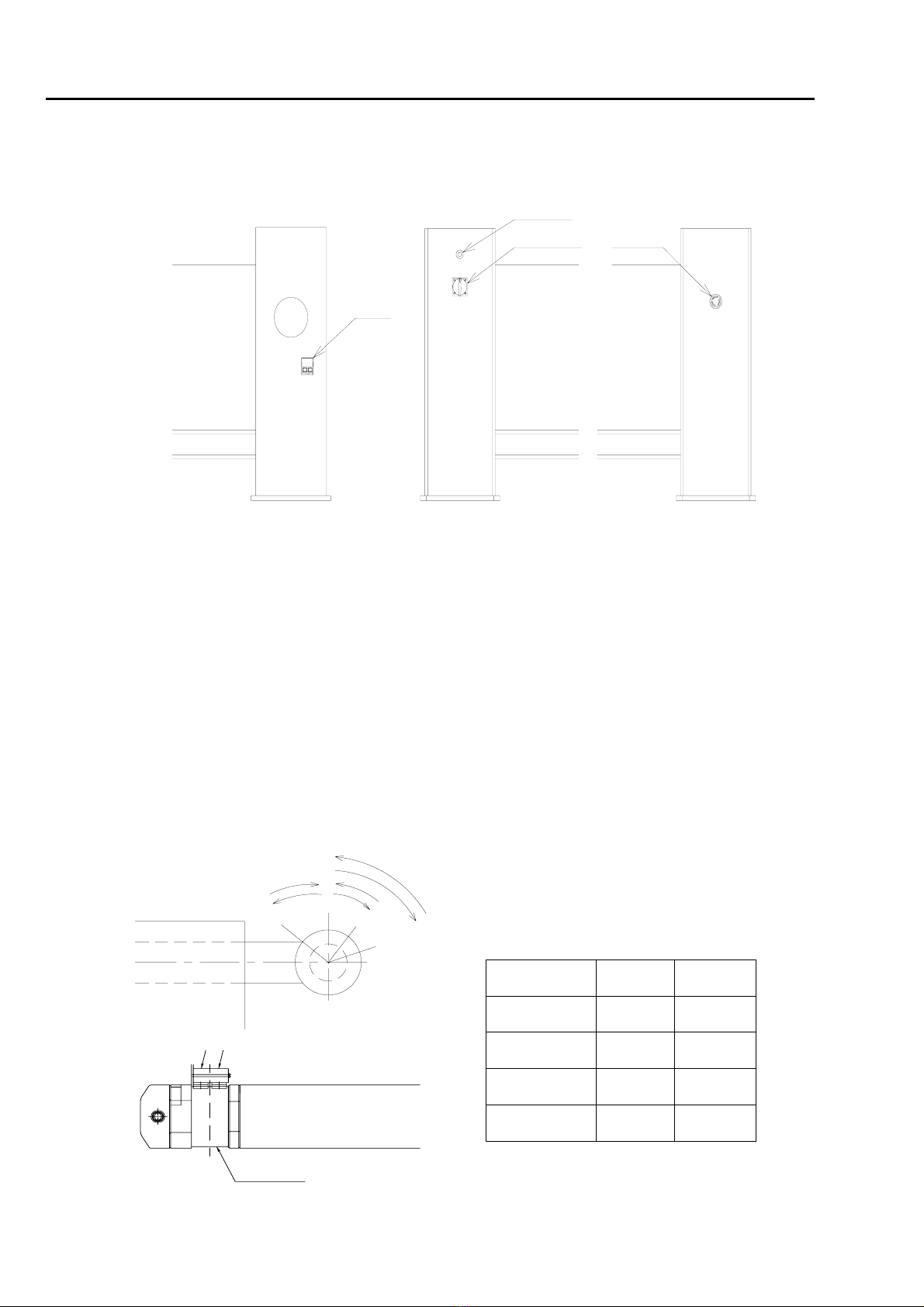

4.7 RACKING DEVICE ---------------------------------------------------- 17

4.7.1 RACKING MECHANISM ------------------------------------------------- 17

4.7.2 ADJUSTMENT OF RACKING ORIGIN SENSOR ---------------------------------- 18

4.8 ADJUSTMENT OF YARN TENSIONER -------------------------------------- 18

4.8.1 MAIN TENSIONER ---------------------------------------------------- 18

4.8.2 SIDE TENSIONER --------------------------------------------------- 19

4.8.3 PILOT LAMP ------------------------------------------------------ 19

5 MACHINE MAINTENANCE--------------------------------------------------- 20

5.1 CLEANING ----------------------------------------------------------- 20

5.2 OILING ------------------------------------------------------------ 20

6 PATTERN DESIGN-------------------------------------------------------- 21

6.1 EXPLANATION OF CAM DATA ---------------------------------------------- 21

6.2 CAM DRAWINGS INDICATING THEIR POSITIONS ---------------------------------- 22-24

6.3 PATTERN SAMPLES ----------------------------------------------------- 25-26