17

1

2

3

6

9

12

13

14

15

16

Non‐continuousduty‐donotuseonairstoragecylinders

Usetwistlock

lu

rated

@15am

sfor230v

@30am

sfor120v

minimum

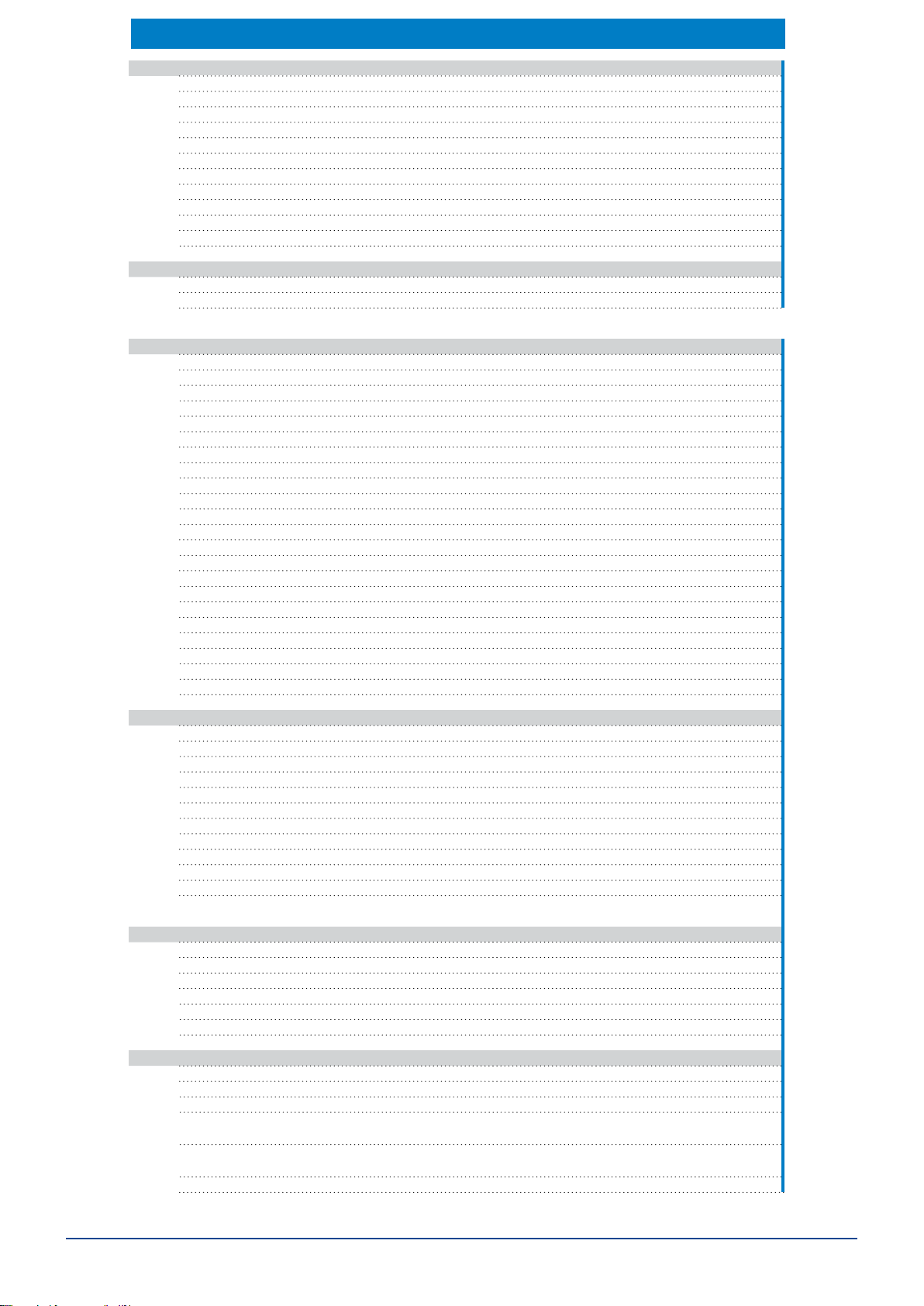

1. 3 HP electric motor, single phase with On/Off switch (full load amps – 230 volt 15 amps – 120 volt 30 amps @ 3000psi)

2. Compressor heads, air cooled, 4 stages of compression

3. Purification chamber

4. Purification cap, unscrew counterclockwise for filter removal – Make sure power is off and #5 and #6 are open prior to attempting to

remove cap – use LF-1001 purification disposable cartridge only – read instructions on cartridge

5. Purification drain tap – slowly open to drain every 20 minutes – if you get moisture you are not draining #6 sufficiently.

6. Moisture oil/vapor separator, drain every 10 minutes or more often if in hot and humid climate.

7. Separator

8. Purified air outlet – screw on fill hose assy (not shown) snuggly (NO TEFLON TAPE NEEDED) will accept

SCUBA and SCBA fill hose assy with On/Off bleed valve

9. Pressure maintaining valve to assure proper filtration and air quality. Will not open until compressor reaches 1600/1800 psi

10. Final pressure gauge – oil bubble is for contraction and expansion of shock dampening oil.

DO NOT OPERATE COMPRESSOR WITHOUT IT.

12. Final safety relief valve, factory preset to 3300 psi for SCUBA – 10% above the average scuba cylinder, cylinder or compressor must

be turned off at rated pressure - 3000psi for SCUBA to avoid overworking relief valve.

DO NOT ATTEMPT RE-ADJUSTING.

13. Oil drain – not shown on side of crankcase – run unit 2 minutes and elevate opposite end for quicker drainage

14. Oil fill and dip stick – simply pull up, pour oil in slowly (capacity 12 oz) - use MaxLube 501 synthetic breathing compressor oil only.

Change out break in oil after 15 hours – replace with MaxLube 501 provided, then every 50 hours thereafter.

15. Crankcase vent, remove cap prior to refilling oil & replace prior to start after oil changes

16. Fan guard – DO NOT REMOVE

17. Belt guard – DO NOT OPERATE WITHOUT (see manual for belt tension)

18. Retractable handle – can be removed for storage by loosening (2) retaining screws on retainer

NOTES: (the below rating A & B is based on a 80cft cylinder @ 3000 psi)

A. The LF-1001 filter is rated for 2,440 cft of grade “E” air @ 72

o

F intake temperature, draining the condensate

often = prox. 30 cylinders. For hot and humid climates you must de-rate by 10% for every 5

o

above 72

o

F.

B.

In order to keep the amps draw at a minimum the fill time is approx 15% longer than gas driven units.

Date:

Max‐Air

2807PeddlerLane

Kerrville,Texas78028

830‐955‐8188/830‐257‐3720Fax

E‐mail:sales@max‐air.com

www.max‐air.com

Finalsafetyreliefvalve

presetfor:_________psi

Serial#:

__________

10

11

5

18

4

8

11. Intake air filter behind pressure gauge.

7

MA 35 ELEC 1PHASE 3PHASE 120 VAC 230 VAC 60 HZ 50 HZ

MA 35 Gas Honda MA 35 Gas Subaru

P

ersonal,portable,highpressurebreathingaircompressor