HOPPER SWITCH

The vacuum is equipped with a safety

switch to prevent the machine from being

switched on when the hopper cover is

open.

0

PERATI

N

G

MAXI

MATlC VACUUM

The vacuum is designed for use on large

carpeted areas such as airport concourses,

hotel ballrooms/meeting rooms, etc.

1.

Large debris such as paper cups,

plates, etc., should be picked up before

starting the cleaning process.

2.

Planyour cleaning route towork away

from the electrical source. Move ma

-

chine forward at a steady pace.

WARNING:

Do not push vacuum

over power cord while machine is run

-

ning. Always lift cord over vacuum.

WARNING:

Before opening hopper

cover switch off machine and watt

until fan rotation stops to prevent

dust and debris from being ejected.

3.

To

keep the vacuum operating at max

-

imum efficiency: Periodically switch off

the machine, shake vacuum bag to

allow the finer dirt and dust

to

settle

into the hopper. Open hopper cover,

lift out dust bin and empty.

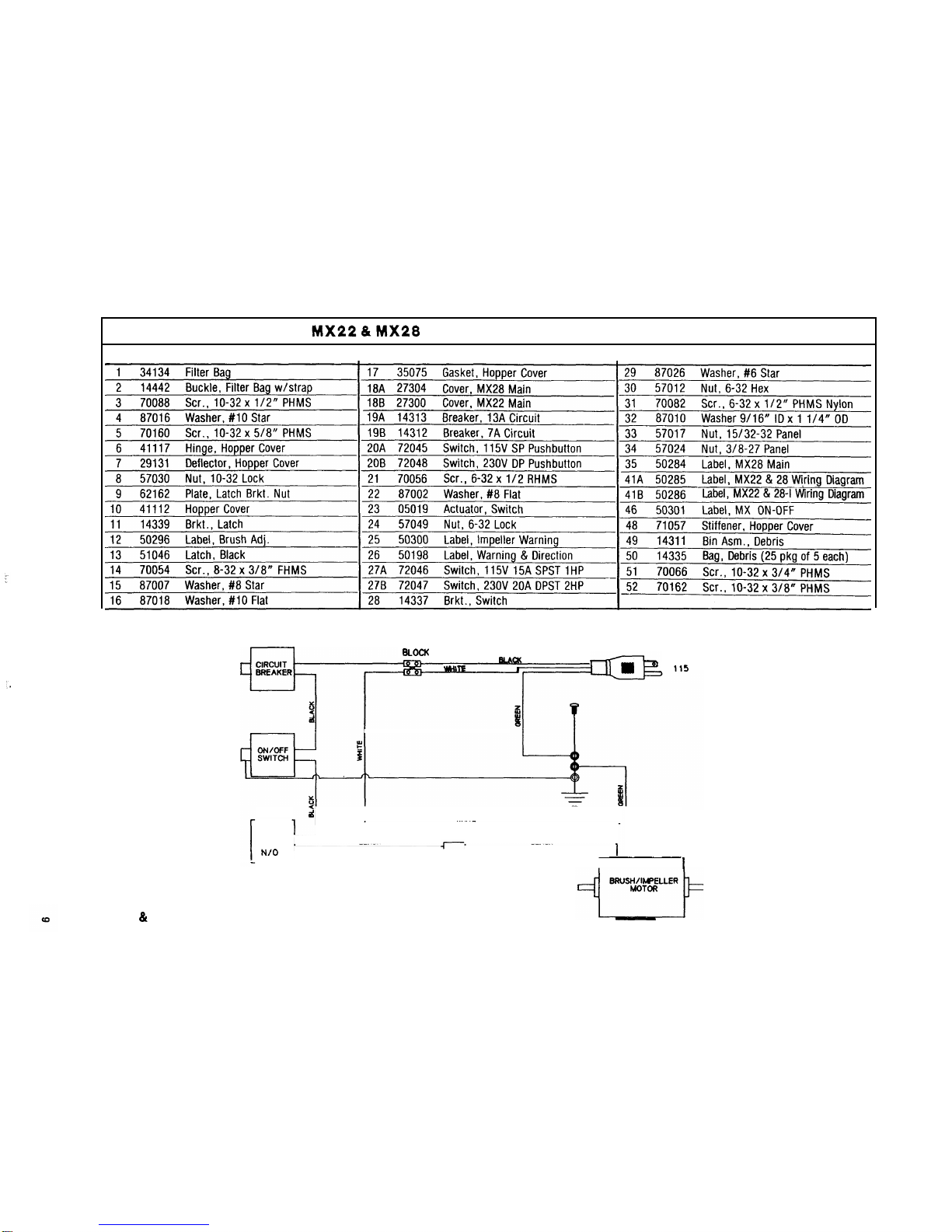

CIRCUIT BREAKER

The vacuum is equipped with a circuit

breaker to protect the motor in the event

an excessive overload condition occurs.

If the breaker trips, wait 2 minutes before

resettlng. If the breaker trips immediately

after resetting, check for probable cause

such as:

A.

Brushadjustment set too low.

B.

Obstructions in brush roller or impeller.

REGULAR MAINTENANCE

1.

Shake down bag and empty debris bin,

daily.

2.

Check power cord for damaged or fray

-

ed insulation.

3.

Return brush adjustment lever to

“store” position when machine is not

Inuse.

4.

Every

4

to 6 months remove wheels,

clean axles, and apply a thin coating

of silicone lubricant to axles.

5.

The filter bagcan be washed twice be

-

fore losing the filtering ability. This

should be done using a mild deter ent

incool water and hung up to dripjry.

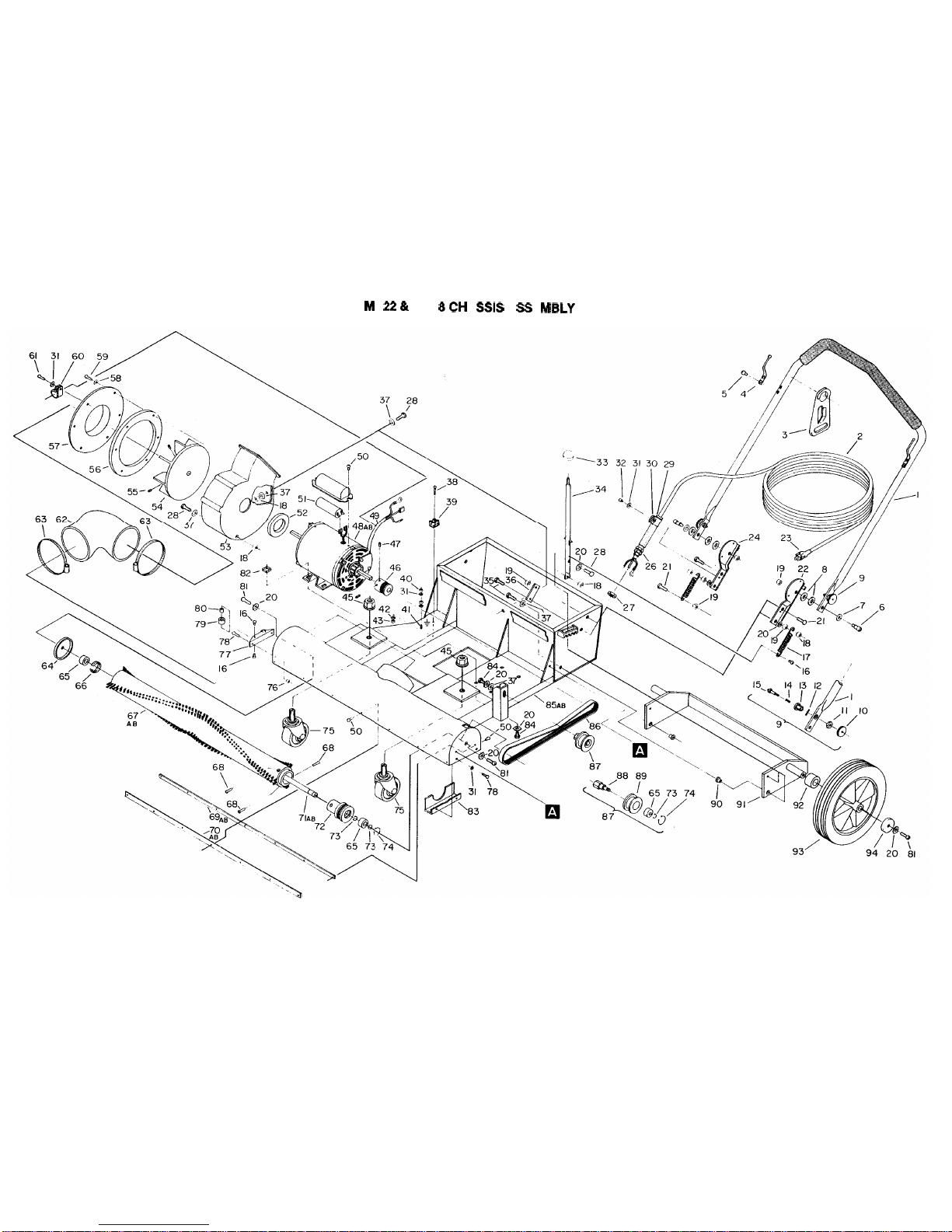

SERVICING THE MAXIMATIC

WARNING:

Remove machine power

cord from electrical source before making

any repairs of adjustments to the machine.

I

M

P

E

LL

ER ASSEMB

LY

/

B

R

USH

DRIVE MOTOR IMPELLER

1.

Removeintake duct.

2.

Removeimpeller housing cover.

,3.

Loosen (2) screws in impeller and

remove from motor shaft.

MOTOR

1.

Loosen idler and roll belt off motor

pulley.

2.

Remove intake duct, impeller and

housing.

3.

Disconnect motor leads from terminal

block.

4.

Remove

(4)

bolts holding motor to

chassis.

NOTE:

When re

-

installing motor use a

straight edge to check pulley alignment

betweenbrush and motor pulleys.

To access impeller assembly/belt and

motor.

1.

Release hopper cover latches and tilt

cover back.

2.

Remove

(4)

screws holdin main cover

to chassis. (2) located at Bront corners

and

(2)

at front inside of rear wheels.

Lift up

RIGHT

side of cover and slide

to left to remove.

BELT/B

R

U

S

H

1.

Loosen idler pulley and roll belt off

motor pulley.

2.

Removebelt/brush pulley guard.

3.

Removescrew from each end of brush

shaft and remove brushassembly.

NOTE:

When installing a new belt or

motor, centerline distance between

motor shaft and brush shaft should be

set at

12

318 Inches.

10

I1

A.

Terminal

Block

0.

Cover

B.

Intake

Duct

C.

Impeller

Housing

F.

Belt

E.

ImpellerlBrush Motor

CASTERS/BRUSH HOUSING

SHOES

NOTE

When replacing casters

or

shoes

the dimensions shown in Drawing 12 must

be made to maintain efficiency of the

vacuum.

NOTE:

Make adjustments with the ma

-

chine instore position setting on a

LEVEL

surface andwith the casters pointing rear

-

ward.

1.

The distance between surface and

bottom of rear brush housing should

be 9/16 in. Check both right and left

side of housing.

2.

When replacing shoes install a screw

at each end of shoe first. Using a

straight edge install balance of screws

keeping shoe straight.

,

..

.

-.

.

-

-

STRAIGHT

EDGE

MACHINEMUST

BE

IN

STORE

POSITION

\

I

’

’j4”

’

MAKE ADJUSTMENTS

REAR SHOE WITH CASTERS

POINTING REARWARD

FRON~

SHOE

BRUS~HOUSING

5