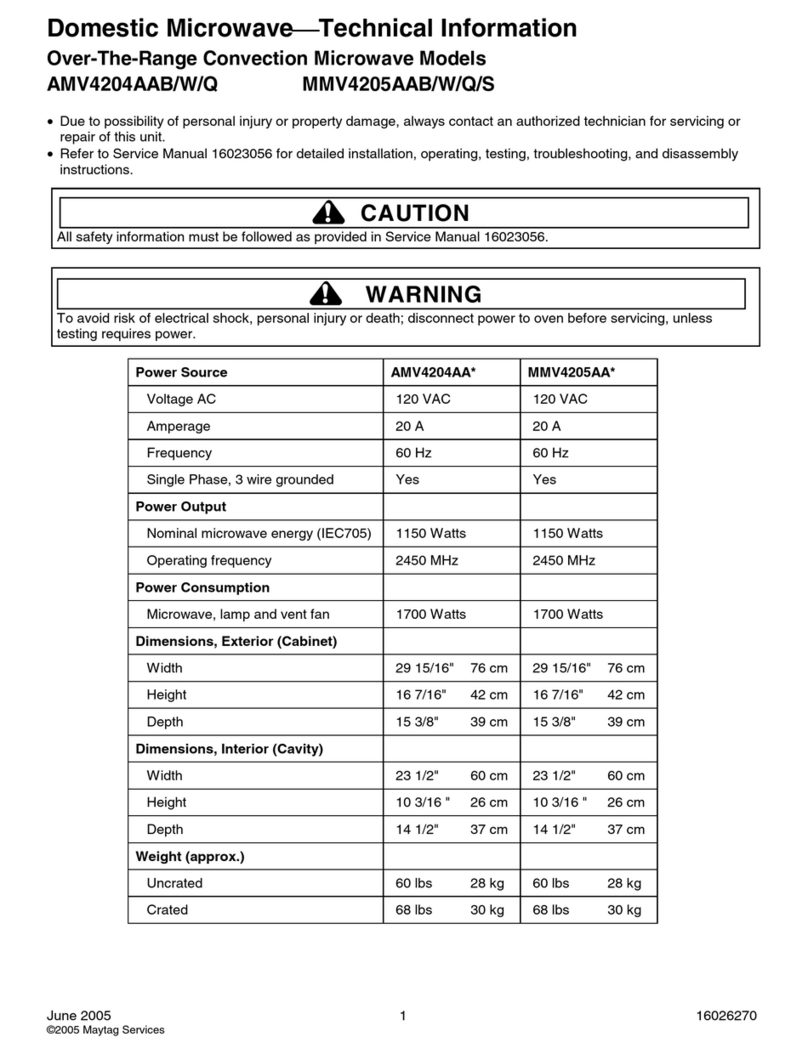

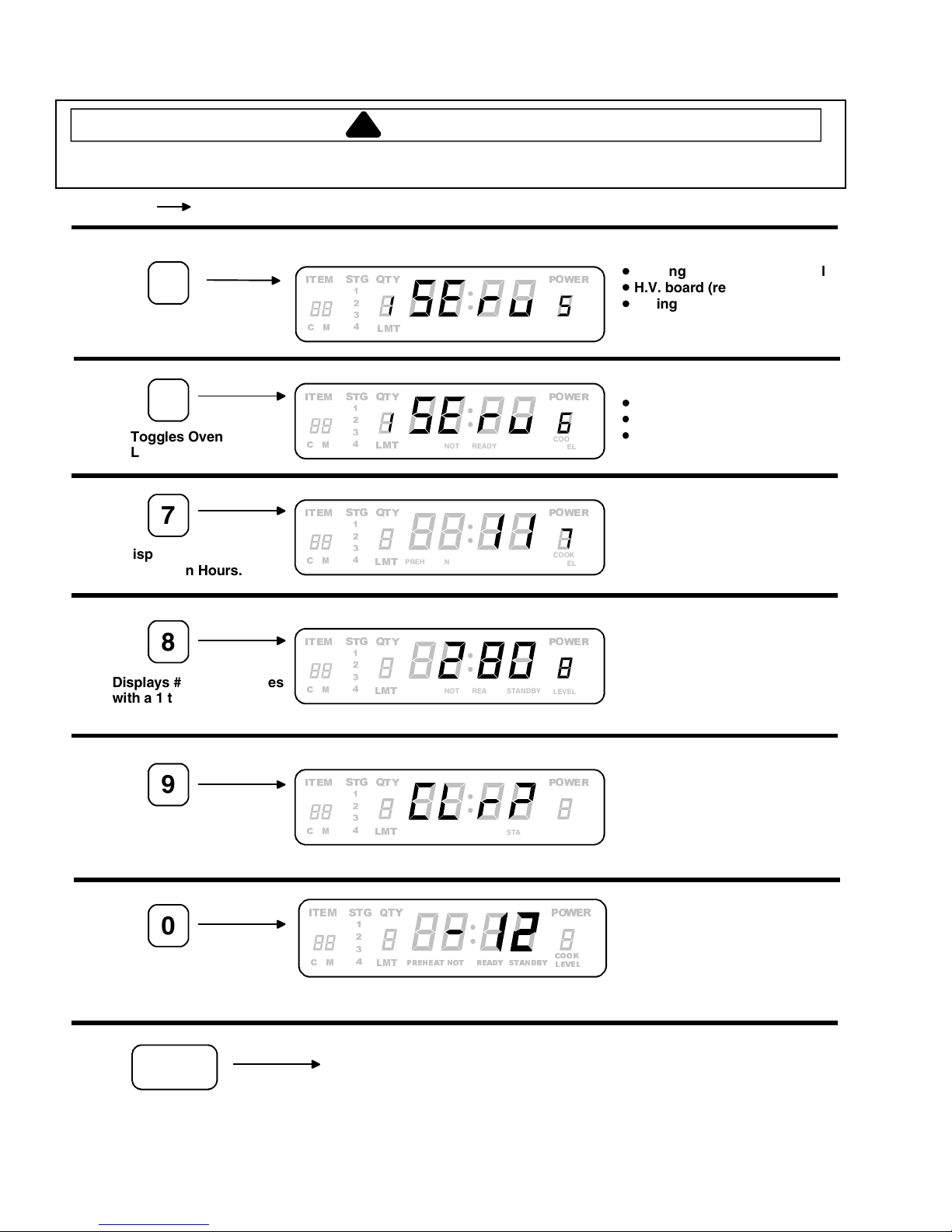

Component Testing Procedures

!

WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven and discharge capacitor

before servicing, unless testing requires power.

16025975 March 2005

©2005 Maytag Services

2

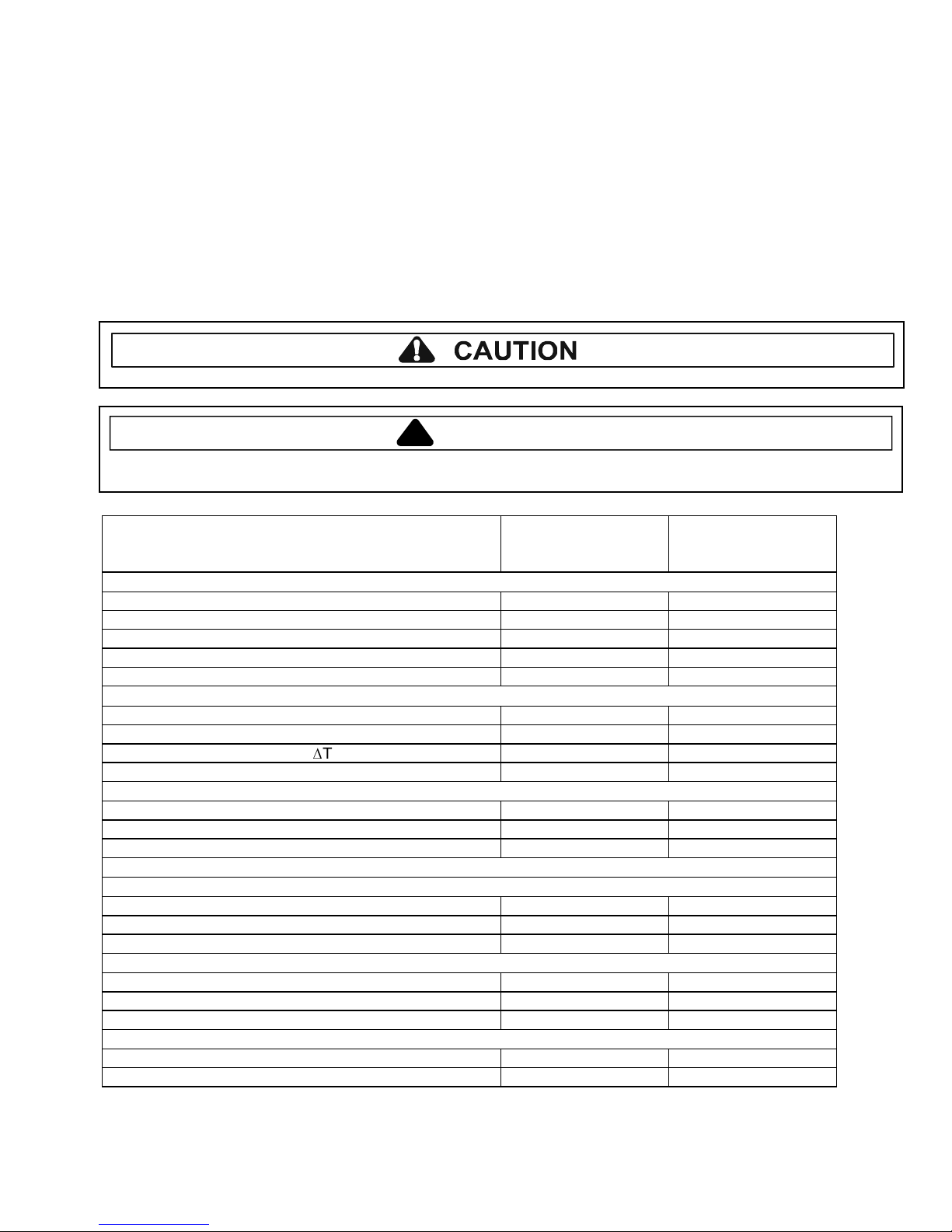

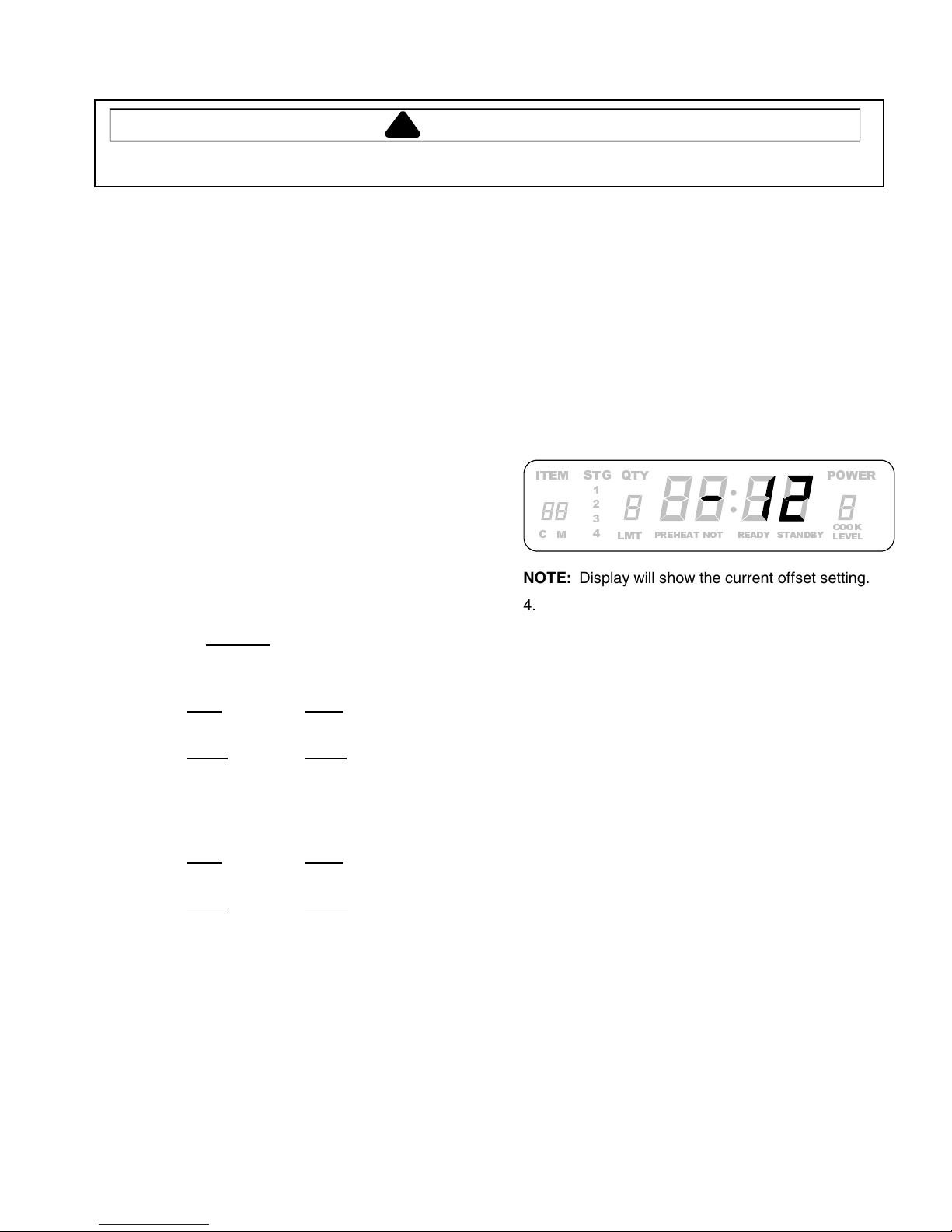

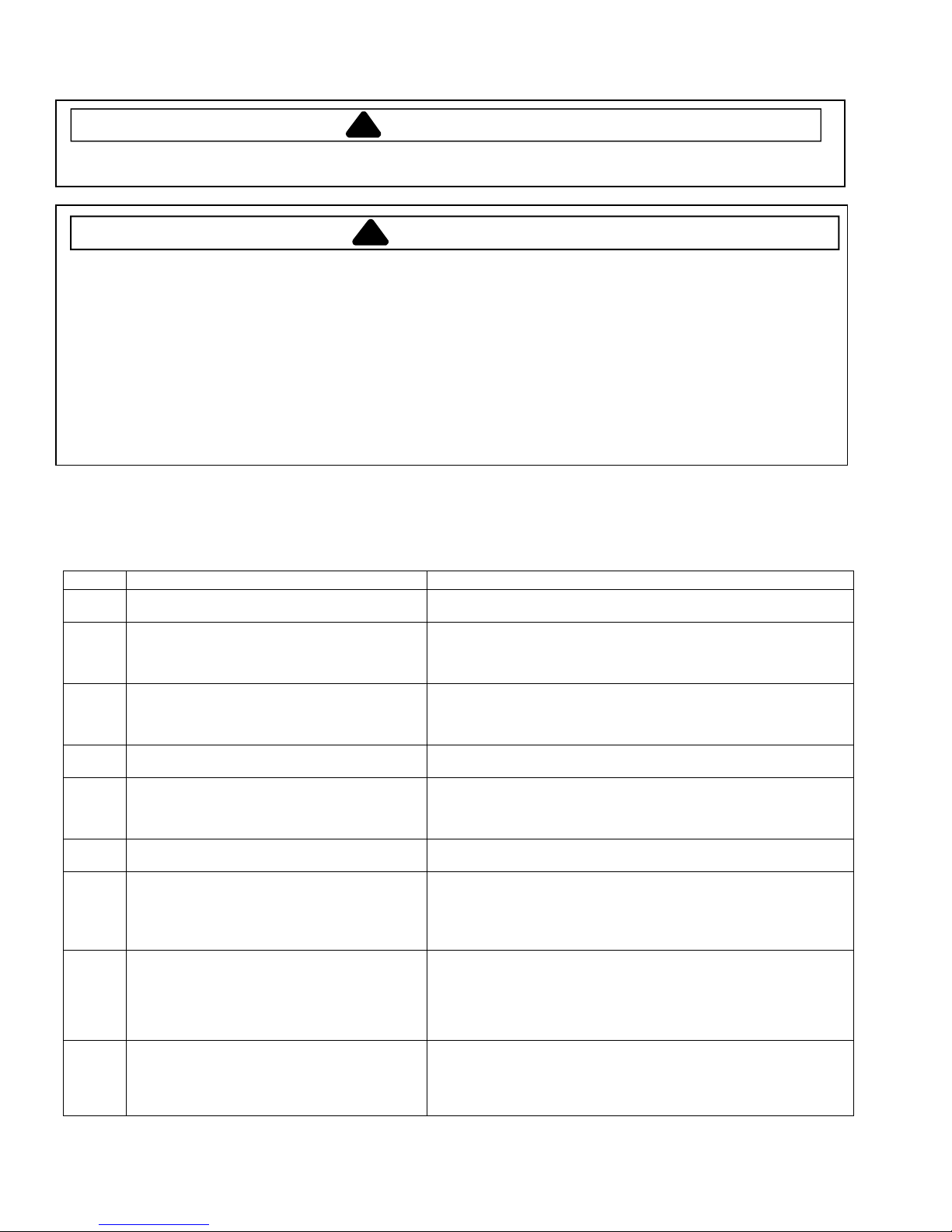

Illustration Component Test Results

Thermal cutout Disconnect all wires from TCO.

Measure resistance across terminals.

Control TCO..........................................

Fan TCO...............................................

Magnetron TCO ....................................

Heater Box Limiter ................................

Open at 300°F (149°C) and

closed at 257°F (125°C)

Open at 125°F (52°C) and

closed at 160°F (71°C )

Open at 235°F (113°C) and

closed at 150°F (66°C)

Open at 351°F (177°C) and

closed at or below 18°F (-8°C)

Diode Discharge Capacitor

Remove diode lead from capacitor and

connect ohmmeter.

Reverse leads for second test.

Infinite resistance should be measured

in one direction and 50KΩor more in

the opposite direction.

NOTE: Ohmmeter must contain a

battery of 6 volts minimum.

MT2

MT1 GATE

Triac Disconnect wires to triac.

Measure resistance from:

MT1 to MT2 ..........................................

MT1 to Gate..........................................

MT2 to Gate..........................................

All terminals to ground ..........................

Caution - Do not operate oven with

wire to terminal MT2 removed.

Infinite

Approximately 15 Ω, then reverse

meter leads 30 Ω

Infinite

Infinite

Triac 1 (top) is for front element

Triac 2 (middle) is for rear element

Triac 3 (bottom) is for microwave

Measure voltage from:

MT1 to Gate

0.8 VAC when energized. If no

voltage, check H.V. board and wiring.

Capacitor Discharge Capacitor

Remove wires from capacitor terminals and

connect ohmmeter, set on highest

resistance scale to terminals.

Also check between each terminal and

capacitor case.

Between Terminals: Meter should

momentarily deflect towards zero then

return to over 5 MΩ. If no deflection

occurs, or if continuous deflection

occurs, replace capacitor.

Terminal to Case: Infinite resistance

Snubber assembly Disconnect wires to snubber.

Measure resistance across terminals.

Infinite

Magnetron Discharge Capacitor

Remove wires from magnetron and connect

ohmmeter to terminals. Also check

between each terminal and ground.

Between Terminals: Less than 1 Ω

Each terminal to ground measures

Infinite resistance.

Note: This test is not conclusive. If

oven does not heat and all other

components test good replace the

magnetron and retest.

Microwave blower

motor

Remove all wires from motor.

Measure resistance across coil.

Approximately 30 Ω