Component Testing Procedures

!WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to oven before servicing, unless

testing requires power.

16026270 June 2005

©2005 Maytag Services

2

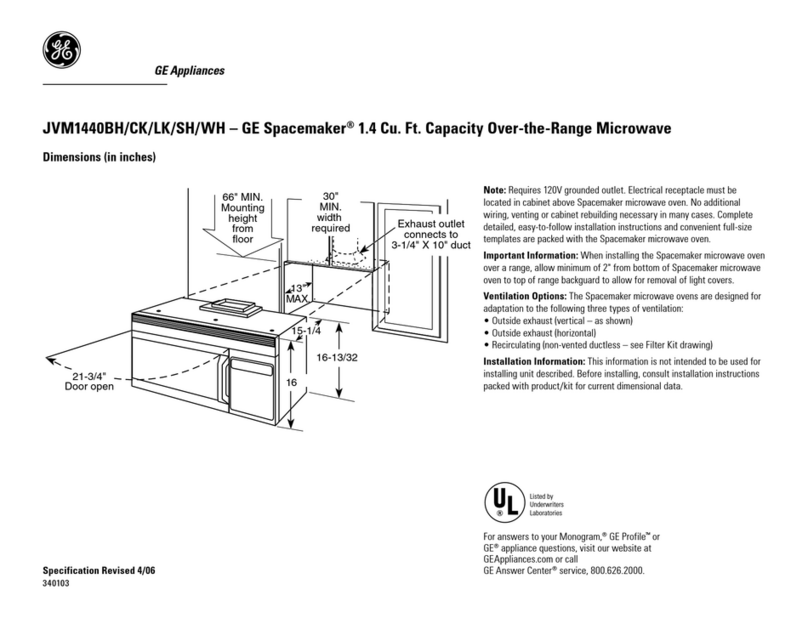

Illustration Component Test Procedure Results

High voltage

transformer

Primary

Secondary

Filament

0 V

120 V

Discharge Capacitor

Disconnect connector and measure

continuity with meter on R x 1 scale:

Secondary ......................................

Filament..........................................

Primary (High & Low)......................

(Measure at room temperature, or 70° F/

22°C)

Measure continuity with meter on “High”

scale: Primary winding to ground ..............

Filament winding to ground.............

Approximately 50-120 Ω

Less than 1 Ω

Less than 1 Ω

Infinite Ω

Infinite Ω

Magnetron Discharge Capacitor

Remove wires from magnetron and

connect ohmmeter to terminals. Also

check between each terminal and ground.

Between Terminals: Less than 1 Ω

Each terminal to ground: Infinite

resistance.

Note: This test is not conclusive. If

oven does not heat and all other

components test good replace the

magnetron and retest.

High Voltage

Capacitor

Discharge Capacitor

Remove wires from capacitor terminals

and connect ohmmeter, set on highest

resistance scale to terminals.

Also check between each terminal and

capacitor case.

Between Terminals: Meter should

momentarily indicate several ohms,

then return to infinity. If no deflection

occurs, or if continuous deflection

occurs, replace capacitor.

Terminal to Case: Infinite resistance

High Voltage Diode Discharge Capacitor

Remove diode lead from capacitor and

connect ohmmeter.

Reverse leads for second test.

Infinite resistance should be measured

in one direction and continuity in the

opposite direction.

NOTE: Ohmmeter must contain a

battery of 6 volts minimum.

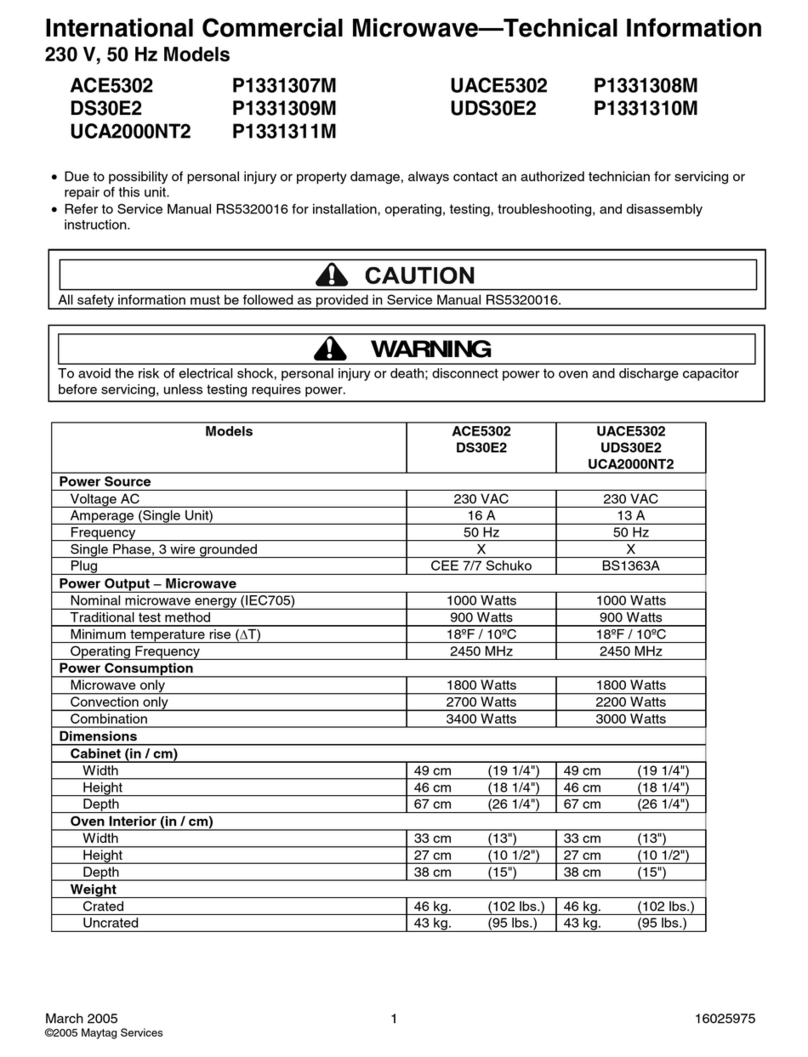

Power Level Cycle On

(Continuity)

Cycle Off

(Open)

1 4 sec 18 sec

2 6 sec 16 sec

3 8 sec 14 sec

4 10 sec 12 sec

5 12 sec 10 sec

6 14 sec 8 sec

7 16 sec 6 sec

8 18 sec 4 sec

9 20 sec 2 sec

Relay 7

Disconnect the leads. Place water in the

oven and select power levels 1 through

10. Check continuity between the

terminals of the relays.

10 22 sec 0 sec