Maytag MDG-170 Administrator Guide

Other Maytag Dryer manuals

Maytag

Maytag MEDB800VB - Bravos Steam Electric Dryer User manual

Maytag

Maytag MGD4200BG0 User manual

Maytag

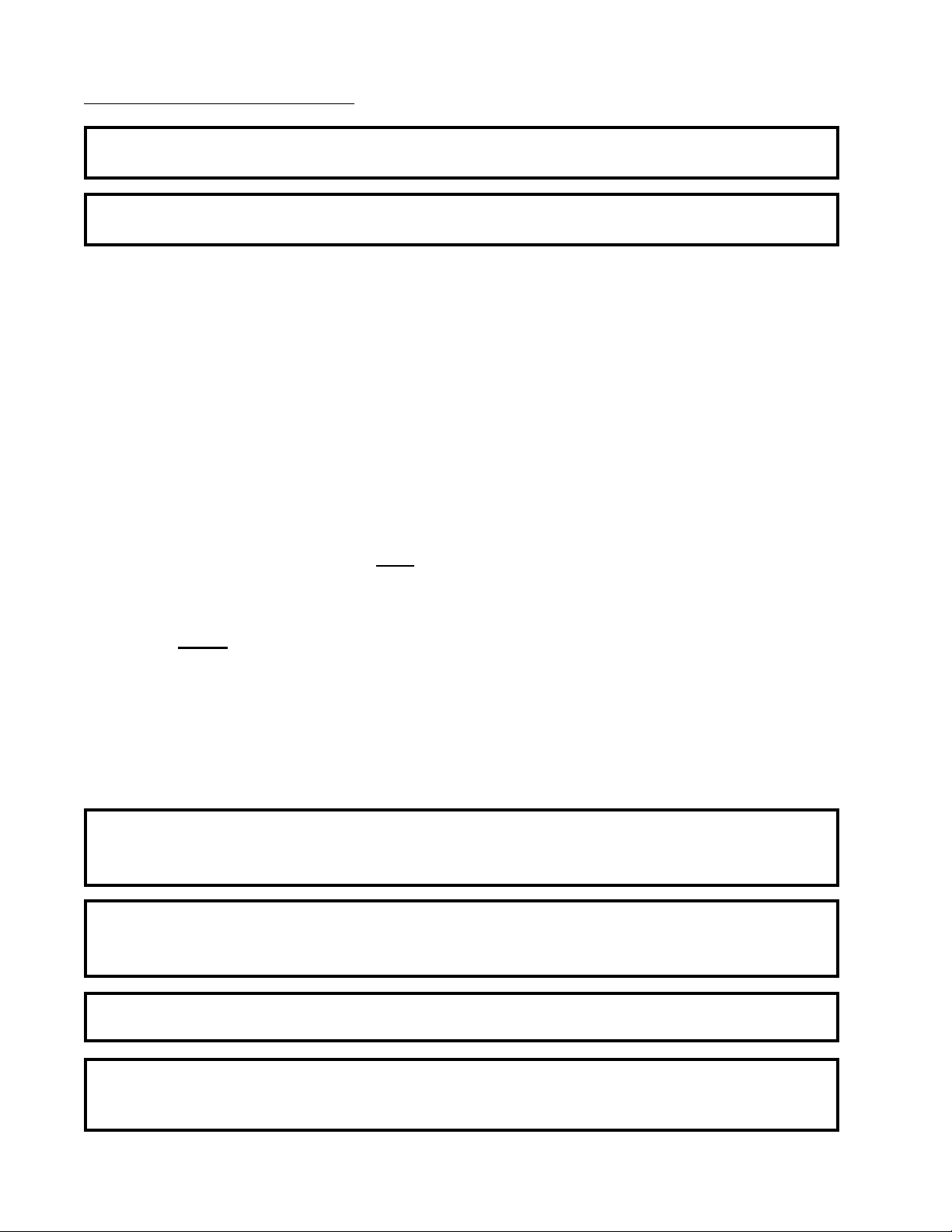

Maytag MEDC400V Manual

Maytag

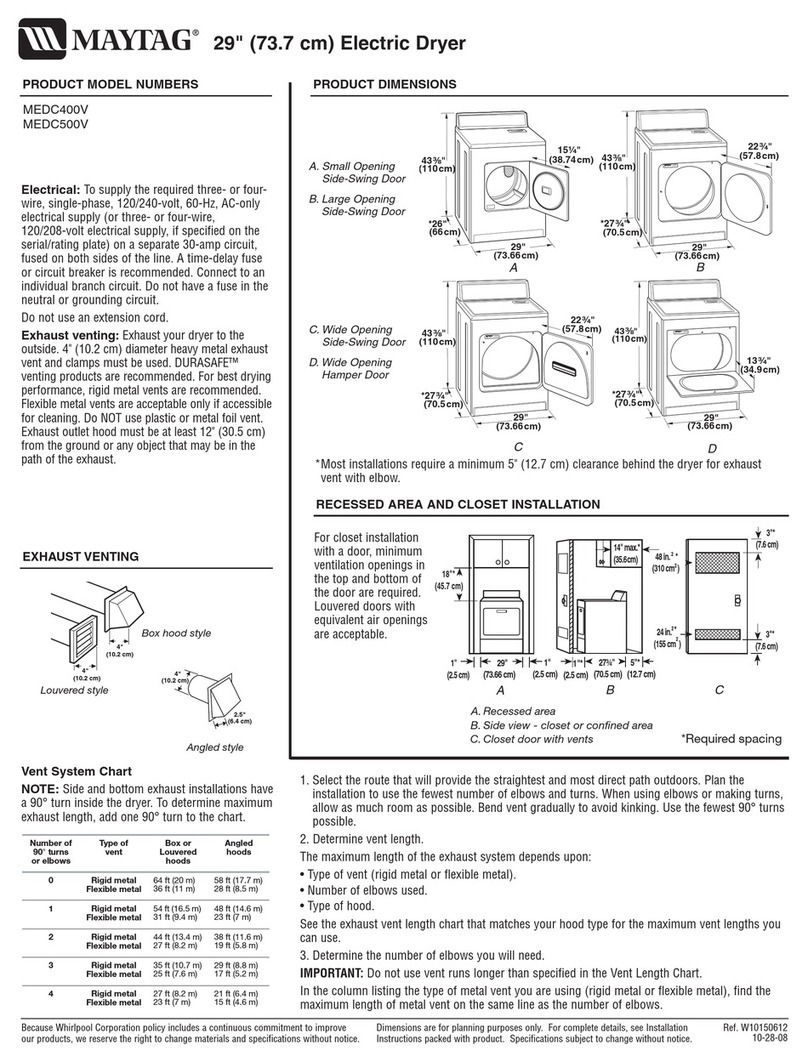

Maytag MGD7100D User manual

Maytag

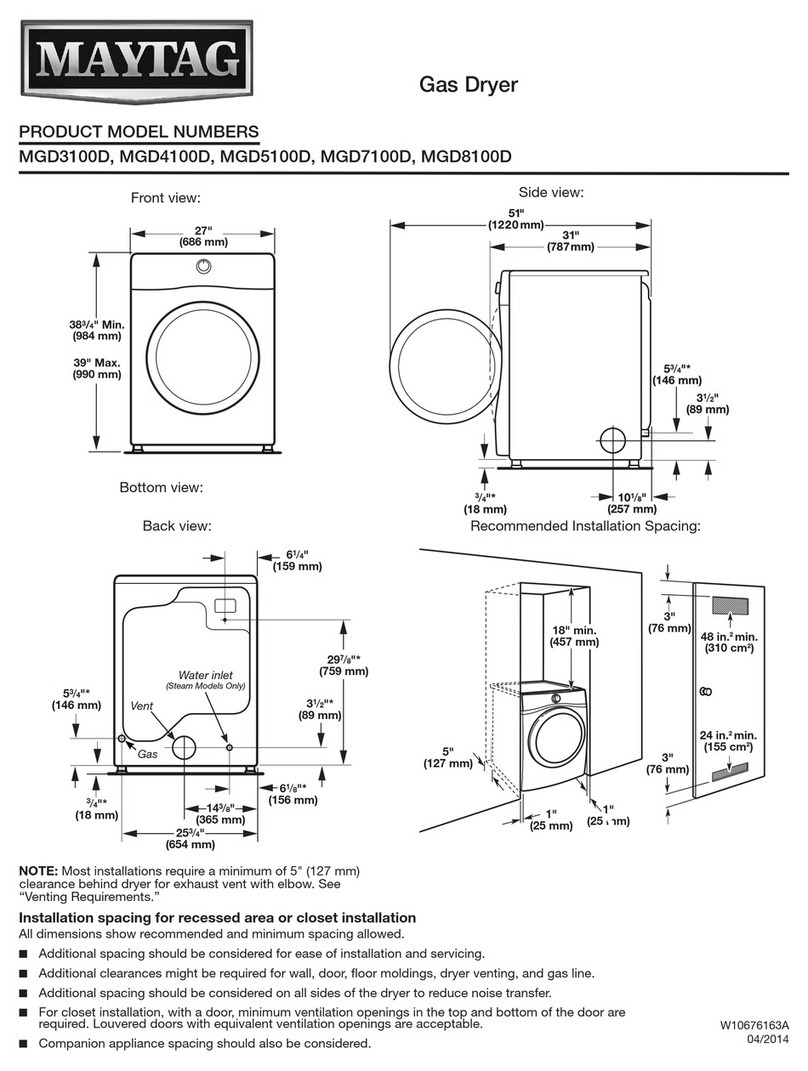

Maytag BRAVOS XL User manual

Maytag

Maytag MLG35PD User manual

Maytag

Maytag MED5707TQ0 User manual

Maytag

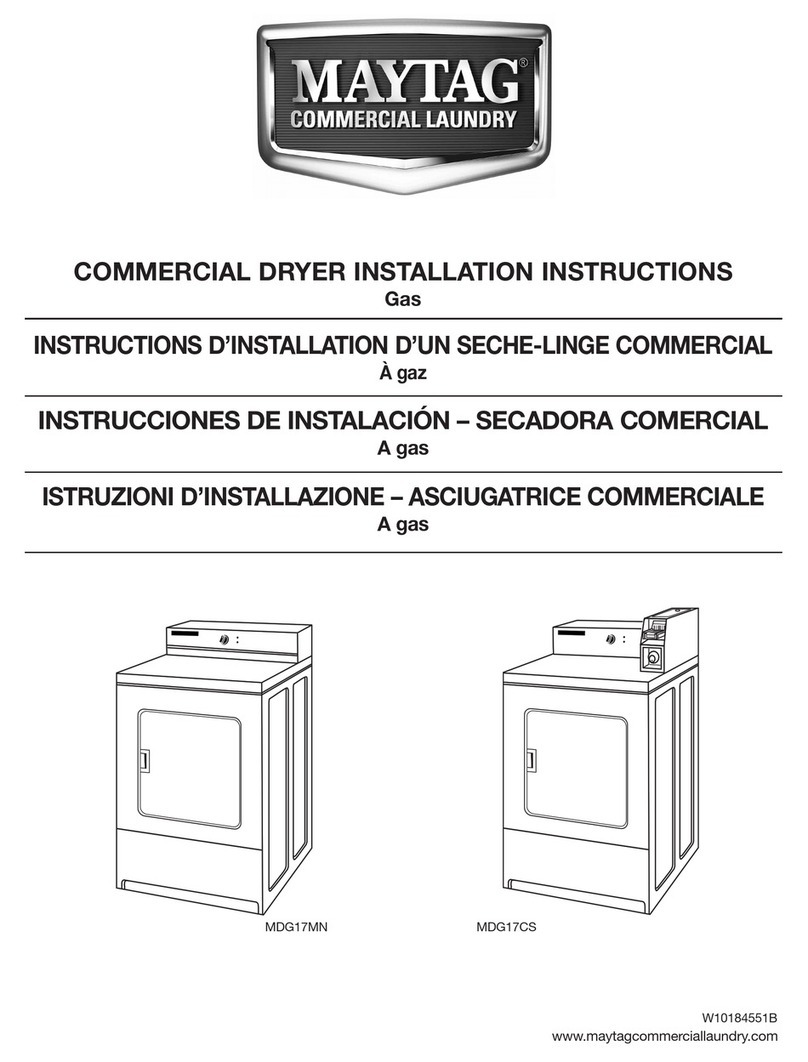

Maytag MDG17MN User manual

Maytag

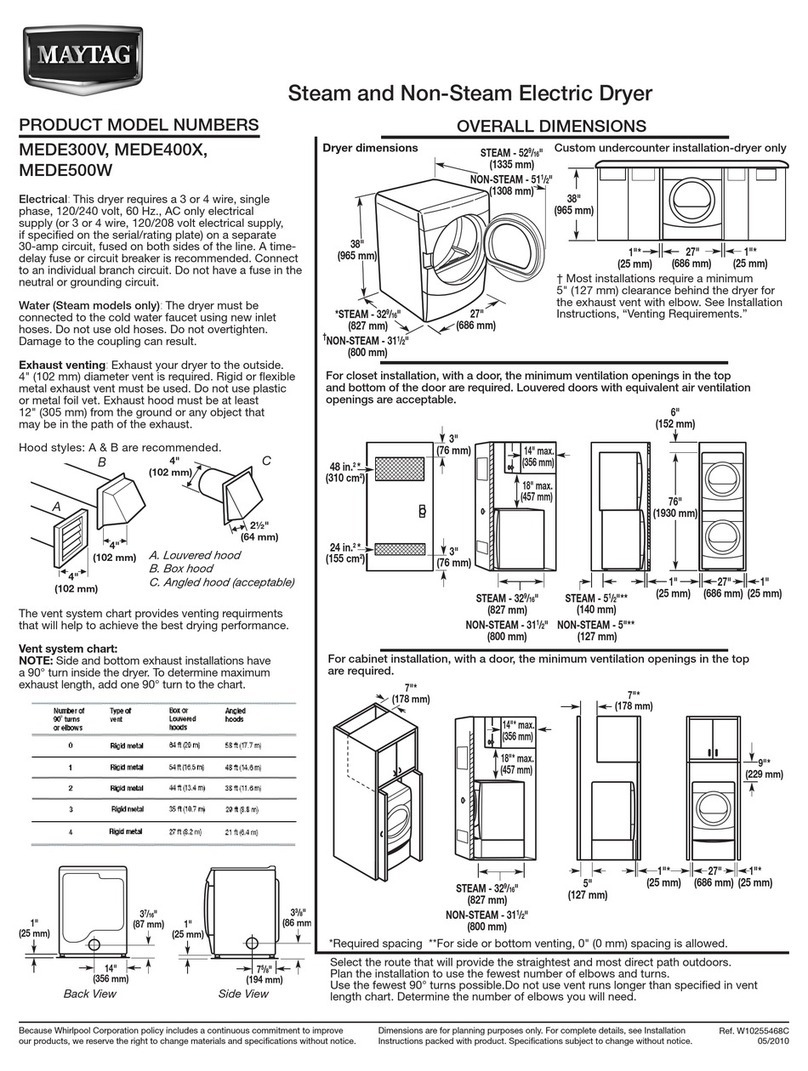

Maytag MEDE300V Parts list manual

Maytag

Maytag ELECTRIC DYER User manual

Maytag

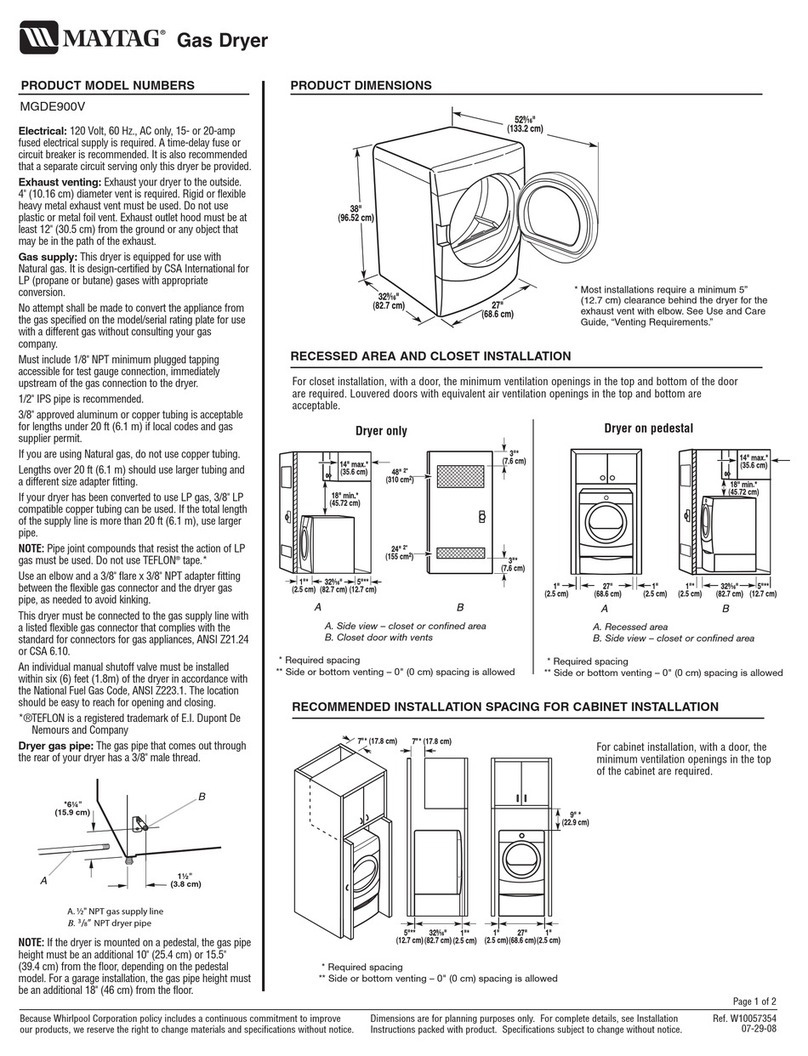

Maytag MGDE900V User instructions

Maytag

Maytag MDG21PD Installation and operation manual

Maytag

Maytag 8TMGD6630HW User manual

Maytag

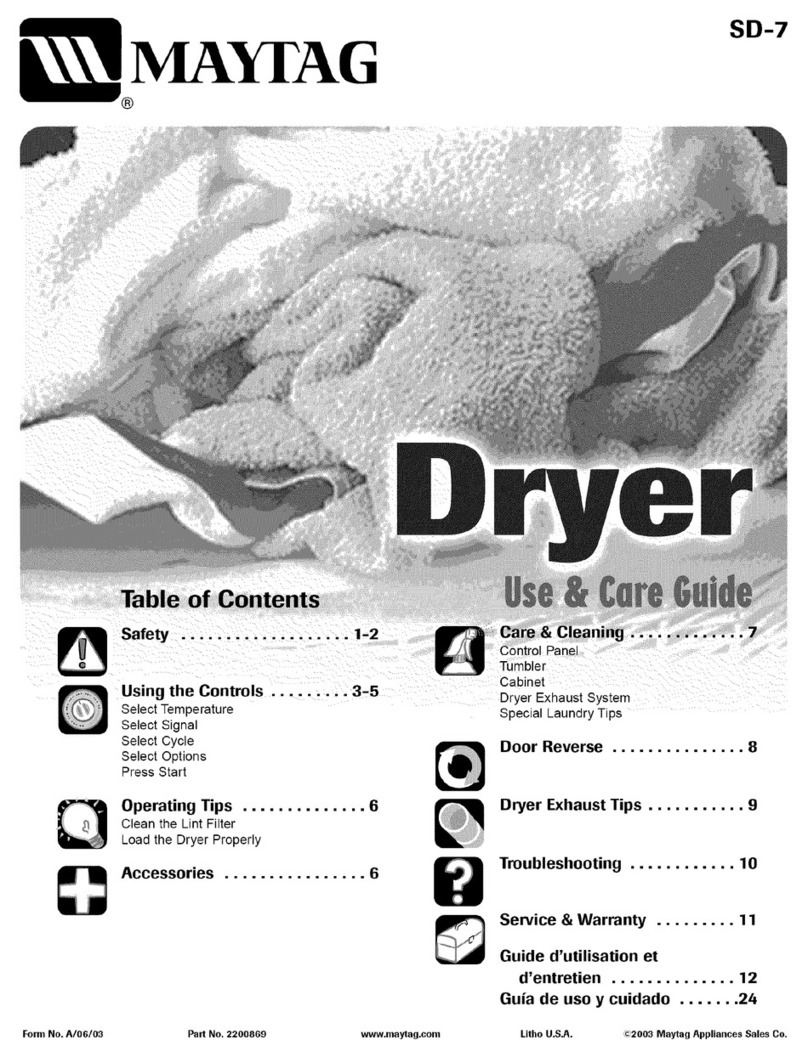

Maytag SD-7 User manual

Maytag

Maytag CD-3 User manual

Maytag

Maytag MDE2600AYW User manual

Maytag

Maytag W10557651B User manual

Maytag

Maytag MEDE201Y User manual

Maytag

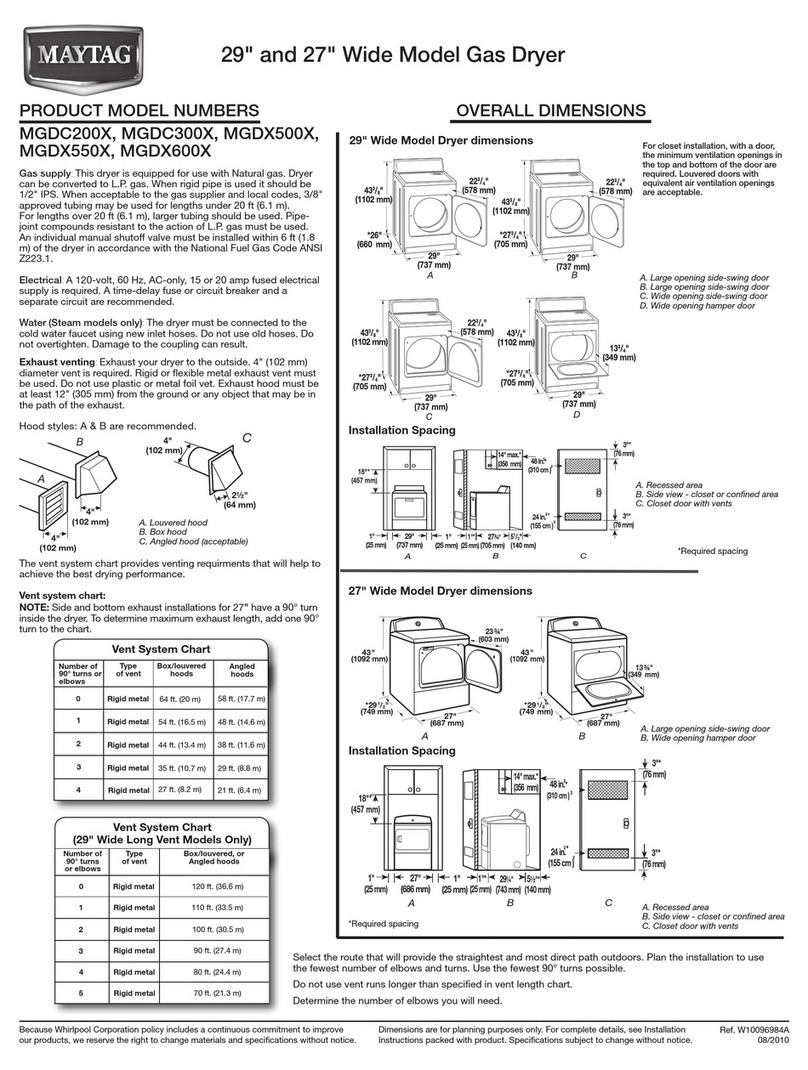

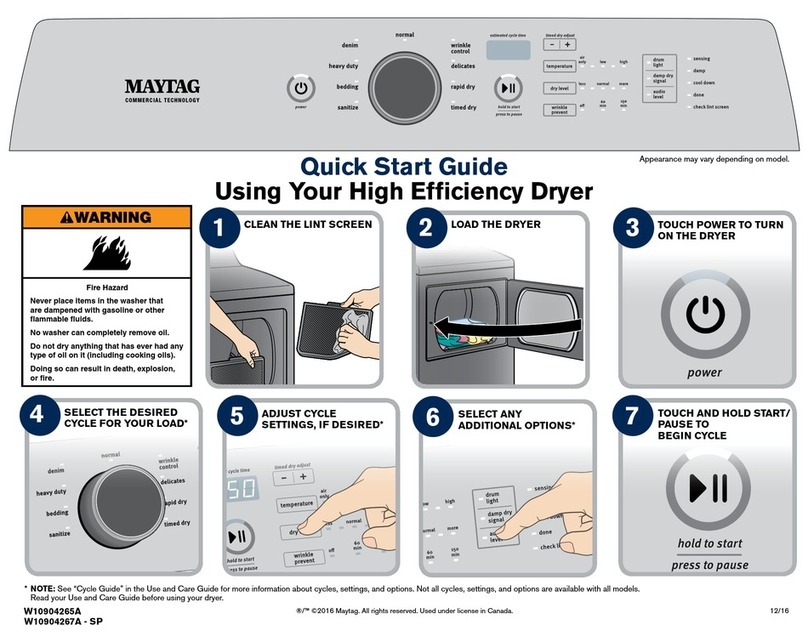

Maytag MGDC200X User instructions

Maytag

Maytag YMEDB765FC User manual

Popular Dryer manuals by other brands

Alliance Laundry Systems

Alliance Laundry Systems TMB795C Installation

Asko

Asko T793C operating instructions

Kenmore

Kenmore 8041 - 5.8 cu. Ft. Capacity Electric Dryer installation instructions

Frigidaire

Frigidaire CAQE7077KW0 use & care

Bosch

Bosch WTX8HKM9SN User manual and installation instructions

Sharp

Sharp KD-NHH9S7GW2-PL user manual