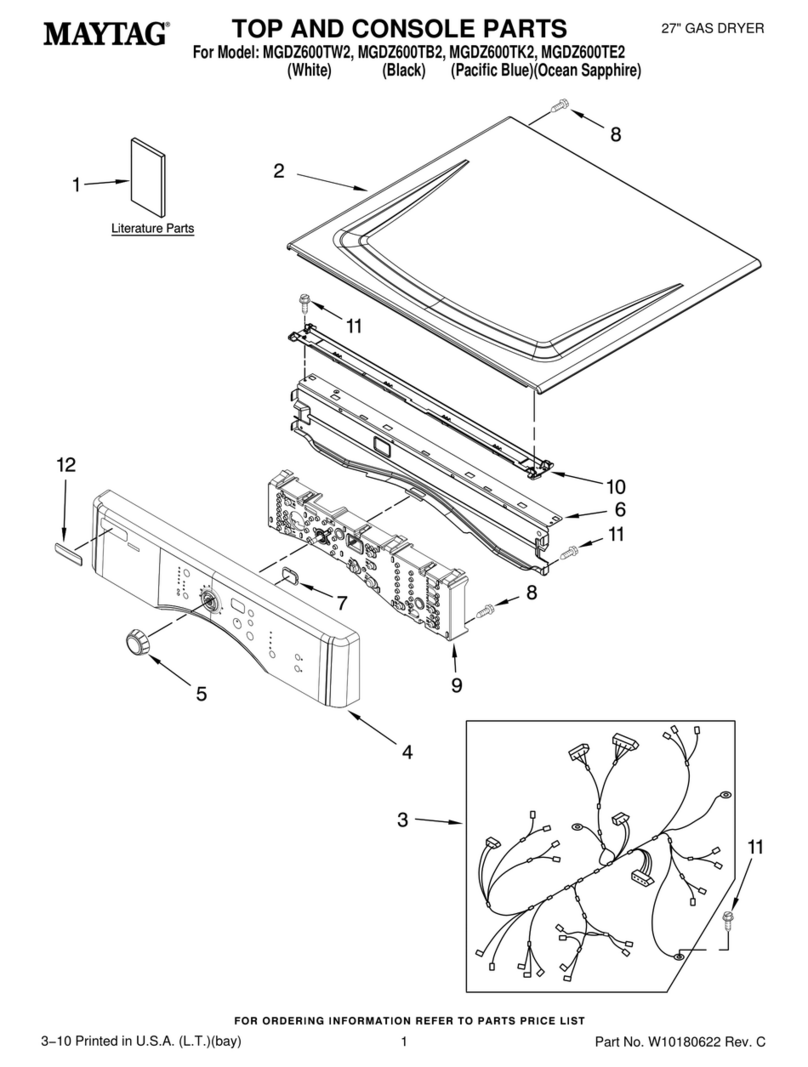

Table of Contents

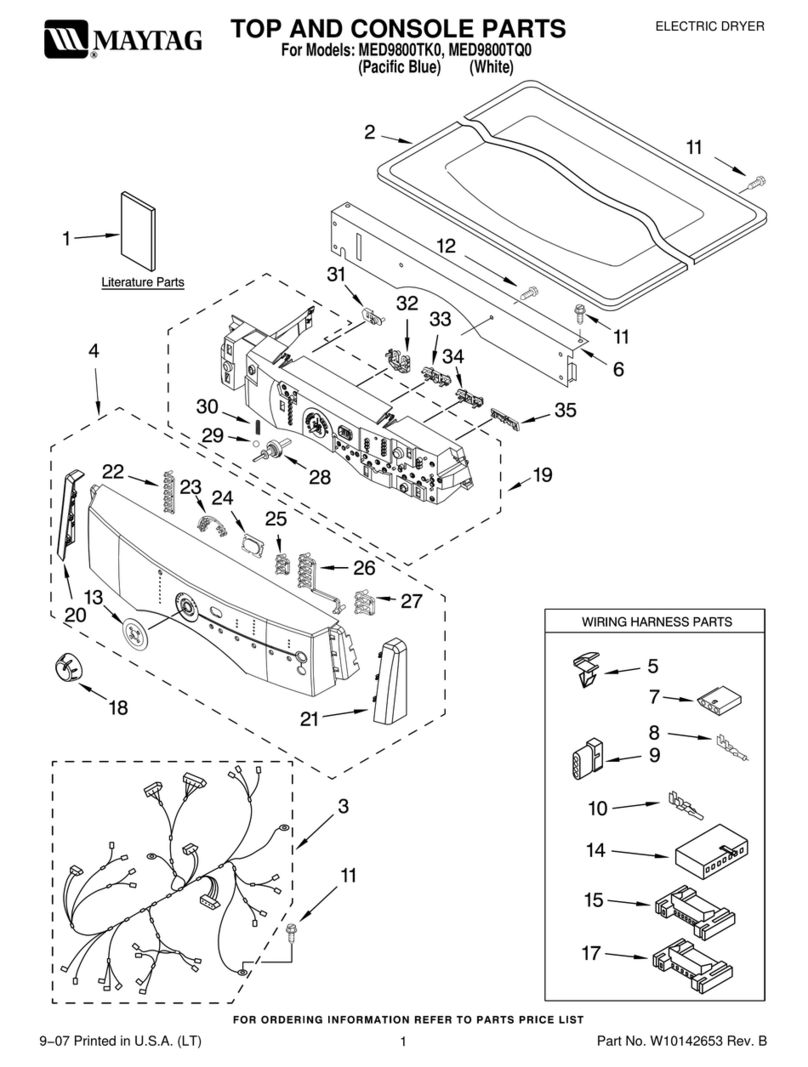

Part Locations and Removal ................4

LowerFrontPanel Removal ......................................... 4

UpperFrontPanel Removal ......................................... 4

TopCoverRemoval....................................................... 4

MiddlePanelRemoval.................................................. 4

LintBox/BlowerAssemblyRemoval............................. 5

GasValve/Ignition SystemRemoval............................. 5

OvenChamberRemoval ............................................... 6

GasValve/Ignition System Components ...................... 6

OvenHousing Components.......................................... 6

TumblerSupport

WheelAssembly Replacement .................................... 6

TumblerAlignment ....................................................... 7

BeltReplacement ........................................................ 8

Placing the Belt Back on the Motor Sheave................. 8

Electrical Component Locations..........9

Electrical Panel ........................................................... 9

Sail Switch andAxial ProbeAssembly ........................ 9

Exhaust Probe, Exhaust Hi-limit,

andLintDrawerSwitch ................................................ 9

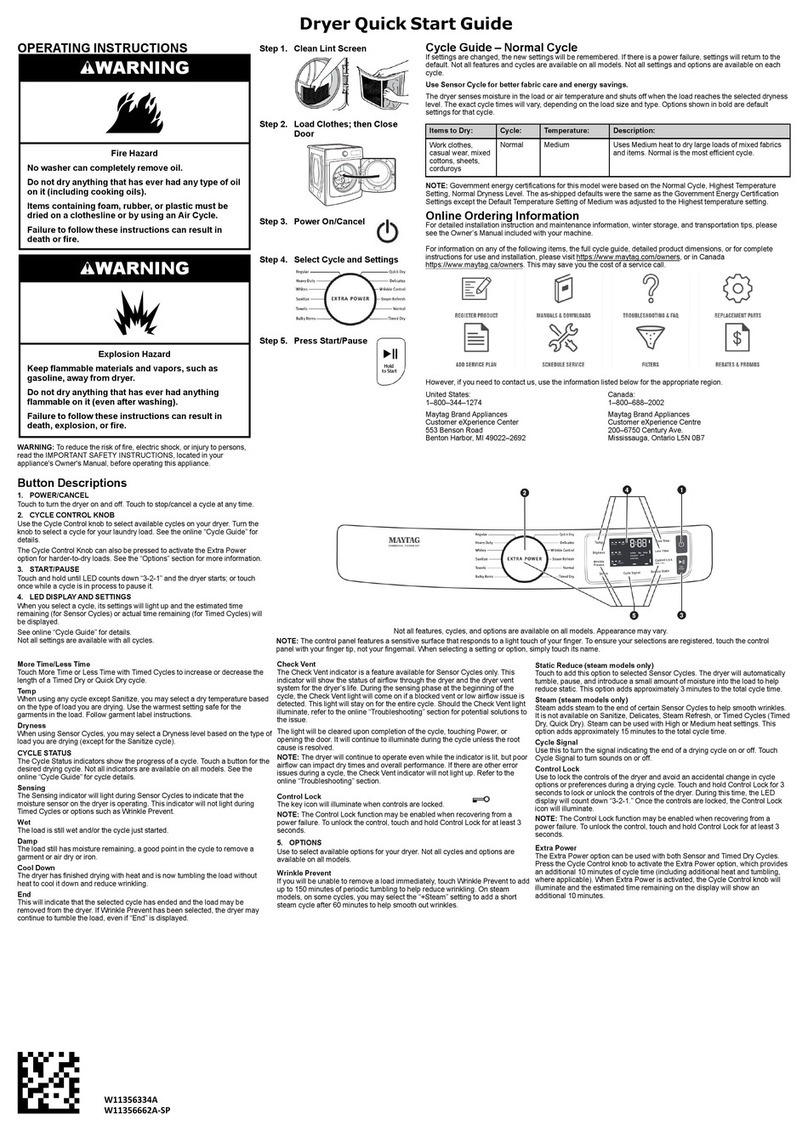

IMPORTANT

You must disconnect and lockout the electric

supply and the gas supply or the steam supply

before any covers or guards are removed from

the machine to allow access for cleaning,

adjusting,installation,ortestingofanyequipment

per OSHA (Occupational Safety and Health

Administration)standards.

Please observe all safety precautions

displayed on the equipment and/or specified in

theinstallationmanualincluded with thedryer.

CAUTION

Dryer(s)should never beleftunattendedwhilein

operation.

“Caution: Label all wires prior to disconnection

whenservicingcontrols. Wiringerrorscancause

improperoperation.”

«Attention: Lor des opérations d’entretien des

commandes étiqueter tous fils avant de les

déconnecter. Toute erreur de câblage peut étre

unesourcede danger et de panne.»

WARNING

Childrenshould notbeallowedto playonornear

thedryer(s). Childrenshouldbesupervisedifnear

dryer(s)inoperation.

Under no circumstances should the dryer door

switch(es), lint door/drawer switch(es), or heat

safetycircuit(s)ever be disabled.

Thedryermustnever beoperatedwithanyofthe

back guards, outer tops, or service panels

removed. Personalinjury or fire could result.

Thedryermustnever beoperatedwithoutthelint

filter/screen in place, even if an external lint

collectionsystemisused.

FOR YOUR SAFETY

Donotdrymopheadsinthedryer. Donotuse

dryerinthepresenceofdrycleaningfumes.

The dryers must not be installed or stored in

an area where it will be exposed to water

and/orweather.

The wiring diagram for the dryer is located in

thefront electrical control box area.