4

DRYER SAFETY

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of re, electric shock, or injury to persons when using the dryer,

follow basic precautions, including the following:

SAVE THESE INSTRUCTIONS

nRead all instructions before using

the dryer.

nThis dryer is intended only for drying

clothes and textiles that have been

washed in water. Do not use for any other

purpose.

nWARNING: If you smell gas, do not use

the dryer or any electrical equipment

nearby. Warn other people to clear the

area. Contact the dryer owner immediately.

nOil-affected items can ignite

spontaneously, especially when exposed

to heat sources such as a tumble dryer.

The items become warm, causing an

oxidation reaction in the oil. Oxidation

creates heat. If the heat cannot escape,

the items can become hot enough to catch

re. Piling, stacking or storing oil-affected

items can prevent heat from escaping and

so creates a re hazard.

nTo reduce the risk of re due to

contaminated loads, the nal part of a

tumble dryer cycle occurs without heat

4

IMPORTANT SAFETY INSTRUCTIONS

precautions, including the following:

WARNING:

Read all instructions before using the dryer.

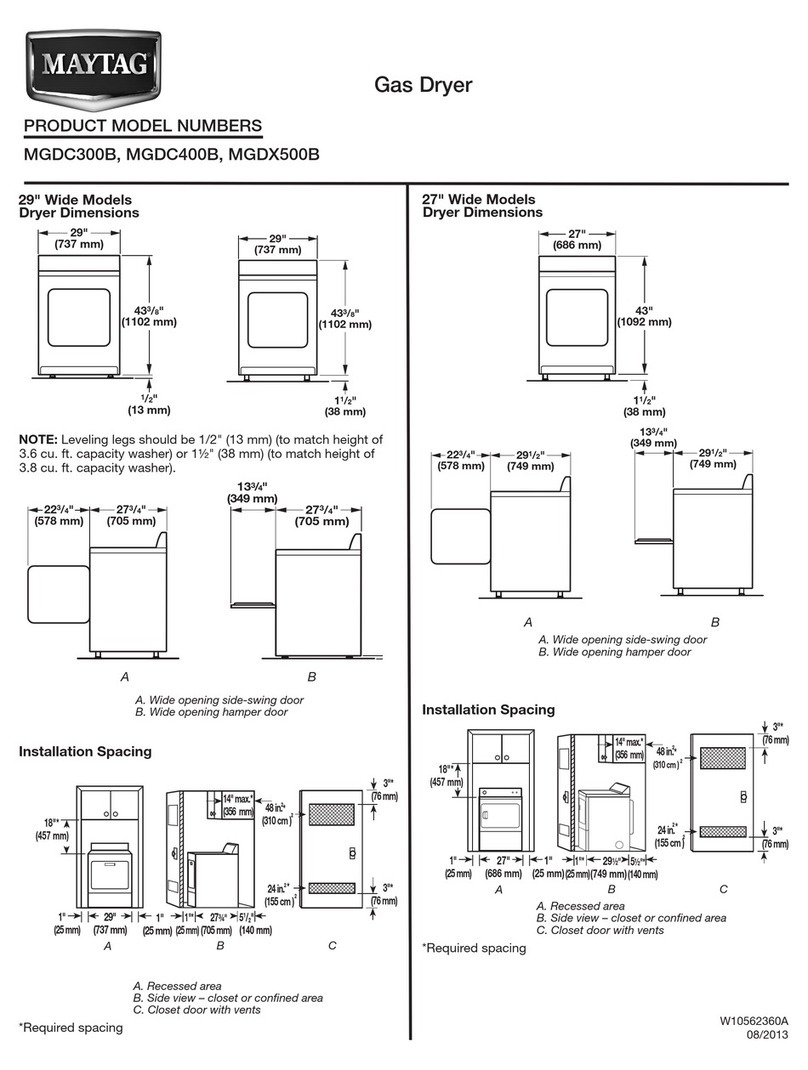

Keep a minimum clearance of 100 mm (4 in.) between the

rear of the dryer and any wall.

The operation of this appliance may affect the operation of

other types of appliances which take their air supply for safe

combustion from the same room. There has to be adequate

ventilation to replace exhausted air and thus avoid the

back-ow of gases into the room from appliances burning

other fuels, including open res, when operating the tumble

dryer. If in doubt, consult the appliance manufacturers.

Do not obstruct the air supply to the dryer (see Installation

Instructions for minimum clearances).

Do not place items exposed to cooking oils in your dryer.

Oil-affected items can ignite spontaneously, especially when

exposed to heat sources such as in a tumble dryer. The

items become warm causing an oxidation reaction in the oil.

Oxidation creates heat. If the heat cannot escape, the items

can become hot enough to catch re. Piling, stacking or

storing oil-affected items can prevent heat from escaping

and so create a re hazard.

If it is unavoidable to dry in the dryer items that have been

soiled with substances such as cooking oil, acetone, alcohol,

petrol, kerosene, spot removers, turpentine, waxes and wax

removers, or that have been contaminated by hair care

products, should be washed in hot water with an extra

amount of detergent before being dried in the dryer. These

items may give off vapours that could ignite or explode. Such

washing will reduce, but not eliminate, the hazard.

This appliance is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless

they have been given supervision or instructions concerning

use of the appliance by persons responsible for their safety.

Children should be supervised to ensure that they do not

play with the appliance.

The dryer should not be used if industrial chemicals have

been used for cleaning.

Before the dryer is removed from service or discarded,

remove the doors to the drying compartment.

Do not reach into the dryer if the drum is moving. A door

switch is tted for your safety.

Do not install or store the dryer where it will be exposed

to the weather.

Do not tamper with controls.

Do not continue to use this appliance if it appears to be

faulty.

Do not repair or replace any part of the dryer or attempt

any maintenance unless specically recommended in this

Use and Care Guide. Repairs and servicing should only

be carried out by competent service personnel.

Do not use fabric softeners or products to eliminate static

unless recommended by the manufacturer of the fabric

softener or product. Follow their instructions.

Clean dryer lint screen before or after each load. Do not

operate dryer without lint screen in place.

Keep area around the exhaust and inlet openings and

adjacent surrounding areas free from the accumulation of

lint, dust, and dirt.

The interior of the dryer and exhaust vent should be

cleaned periodically by qualied service personnel.

See Installation Instructions for earthing instructions.

Do not dry unwashed items in this dryer.

Items such as foam rubber (latex foam), shower caps,

waterproof textiles, rubber backed articles and clothes or

pillows tted with foam rubber pads must only be dried

on a clothesline.

SAVE THESE INSTRUCTIONS

WARNING: Never stop a tumble dryer cycle before the

end of the drying cycle unless all items are quickly removed

and spread out so that the heat is dissipated.

To reduce the risk of re, electric shock, or injury to persons when using the dryer, follow basic

The nal part of a tumble dryer cycle occurs without heat

(cool down cycle) to ensure that the items are left at a

temperature that ensures the items will not be damaged.

If the supply cord is damaged, it must be replaced by the

manufacturer or its service agent or a similarly qualied

person in order to avoid a hazard.

WARNING:

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly could result in serious injury, death or property

damage.

–

–

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

–Installation and service must be performed by a qualified installer, service agency, or

the gas supplier.

•Do not try to light any appliance.

•Do not touch any electrical switch; do not use any phone in your building.

•Clear the room, building, or area of all occupants.

•Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's

instructions.

•If you cannot reach your gas supplier, call the fire department.

(cool down period). Avoid stopping

a tumble dryer before the end of the

drying cycle unless all items are quickly

removed and spread out so that the heat is

dissipated.

nIf it is unavoidable that fabrics that

contain vegetable or cooking oil or that

have been contaminated by hair care

products be placed in a tumble dryer, they

should rst be washed in hot water with

extra detergent – this will reduce, but not

eliminate the hazard.

nDo not dry articles that have been

previously cleaned in, washed in, soaked

in, or spotted with petrol, dry-cleaning

solvents, other ammable, or explosive

substances as they give off vapors that

could ignite or explode.

nItems that have been soiled with

substances such as acetone, alcohol,

petrol, kerosene, spot removers,

turpentine, waxes, and wax removers

should be washed in hot water with extra

detergent before being dried in the dryer.