1

[,

16. Remove the keys on the eccentric shaft and

oil pump shaft.

17. Slide the balance

weight,thrust washerandneedle

bearingoff the shaft.

18. Removethe bolts attaching

the bearinghousing,

and slide the bearing

housing,needle

bearing,

spacer

and thrust plate off the shaft.

29. Turn the engineon the work stand so that the

top of the engine

is up.

30. To removethe flywheel in case

of engine

mounted

with manual transmission,

proceedas follows:

1) Removethe clutch pressure

plateassemblyattaching

bolts, and remove the pressure

plate assembly

and

clutch disk.

2) Straightenthe tab of the lock washerand remove

the flywheel nut using the specialwrench (49 0820

03s).

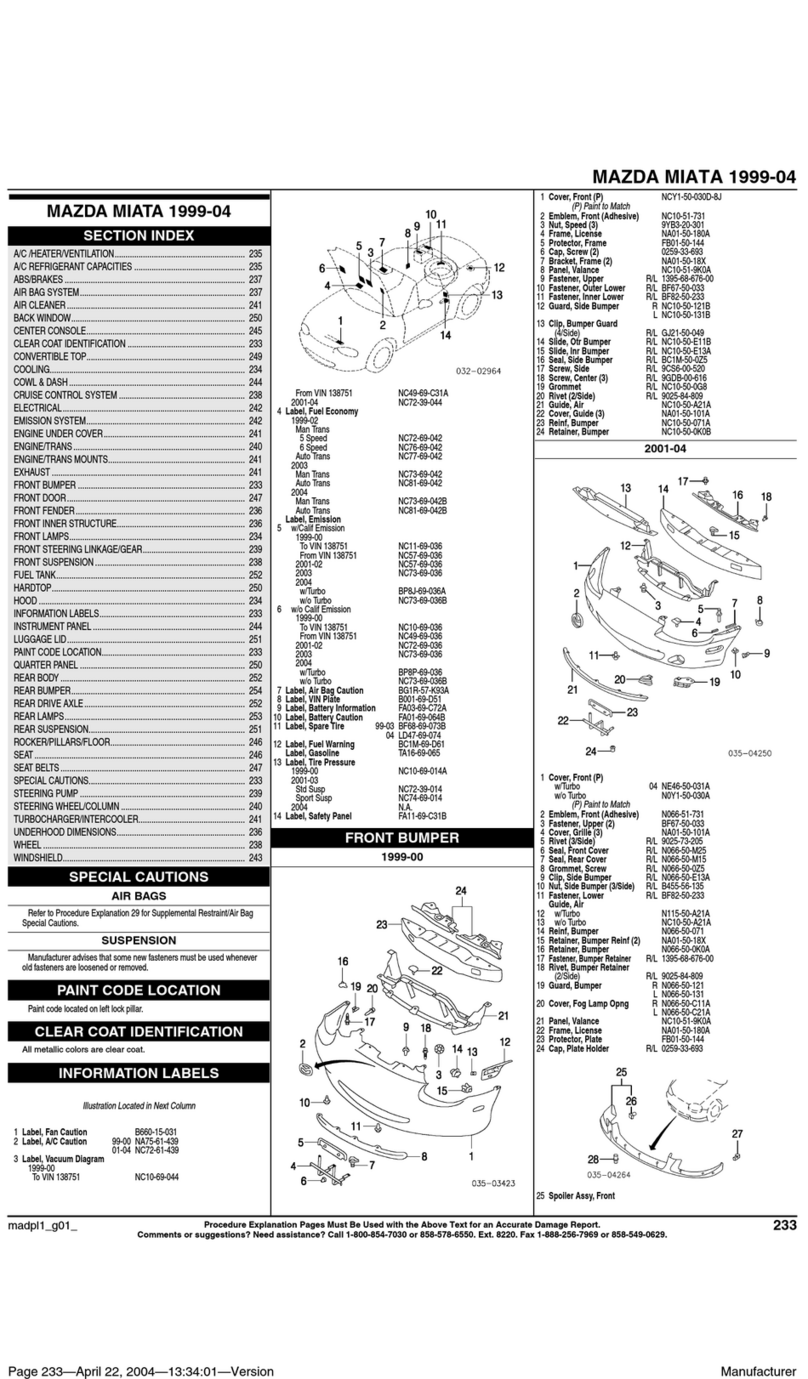

Fig. 1-15 Removing flywheel nut

3) Remove

the flywheel by usingthe flywheel puller

(49 0823 3004), turning the handle of the puller and

lightly hitting the head of the puller.

Fig. 1-16 Removing flywheel

3l . To remove

the counter weight in caseof engine

mounted with automatic transmission,

proceed as

follows.

I) Removethe drive plate, and then remove

the ring

sear

brake

(49 1881060).

l) Attach the counterweight brake(49 l88l 055).

Thenstraiehten

the tab of thelock washer

andremove

the counter weight nut using the specialwrench (49

082003s).

3) Remove the counter weight by using the counter

weight puller (49 0839 3054), turning the handle

of the puller and lightly hitting the head of the

puller.

32. Remove the key on the eccentric shaft and turn

the engineon the work standso that the rear of the

engineis up.

33. Loosen the tension bolts in the sequence

shown

in Fig. I-17, and removethe tensionbolts.

Fis.1-17 loosening order

Note:

Do not loosen

the tension

boltsat onetime. Perform

the removalin two or three procedures.

34. Llft the rear housing off the shaft.

Fig. 1-18 Removing rear housing

35. Remove

anysealsstuckto the rotor sliding

surface

of the rear housing and placethem back into their

respective

originalpositions.

36. Removethe all corner seals,

corner sealsprings.

side seals,side seal springsand side piecesfrom the

rearside

of the rotor, and place

them in the sealcase

(49 0813 250), in accordance

with the numbers

near

eachrespectivegroove

on the faceof the rotor. These

marks are made in order to prevent

eachsealfrom

Tensionbolts