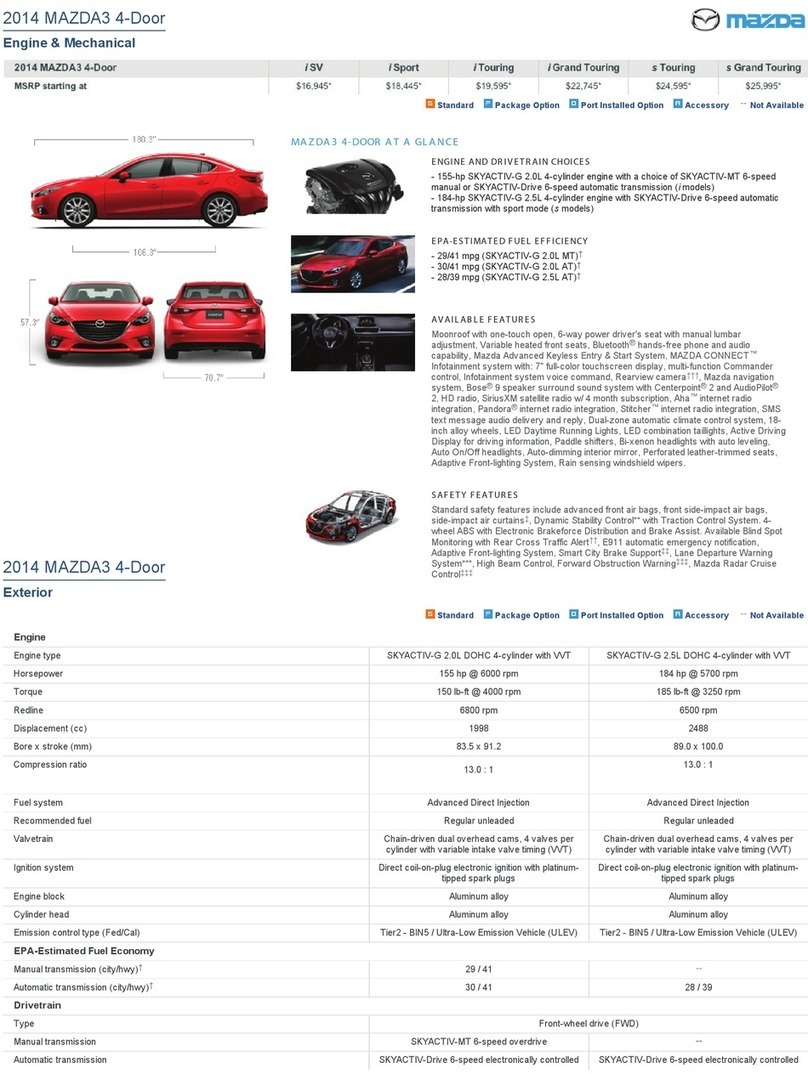

ENGINE

10.Drive

pulley,

435211

601

This

pulley

has

the

followingdif-

ferencesfromthestock

version:

(1)

The

materialis

aluminum

alloy

toreduce

weightand

rotating

inertia.

(2)

Theoilseallip'scontactarea

has

been

treated

forwearre-

sistance.

(3)

Thediameter

is

90

mm.

11. Flywheel,4352

1

1755

Thisflywheelis fabricatedfrom

steelbut is significantlylighter

thanstock

to reducerotating

in-

ertia.

12. Needle

bearing,082278184

Theneedle

bearing

has

a higher

load

capacitytowithstand

severe

clutchengagements.

C. Intake

andexhaust

group.

1. Intake

manifold,

435213100

This

manifoldhas

thefollowing

features:

(1)

ltiscastfromaluminum

alloy.

(2)

lthas

beendesignedtoaccept

and

workwiththeDDW48lDA

carburetor.

andto match

an

engine

installation

angleof

4"40'.

(3)

The

length

of theintake

pas-

sages

has beendetermined

foroptimumtuningandeffi-

ciencyat

the

designedengine

speeds.

2. Gaskets,

rotorhousing

to

intake

manifold:

086278205

intakemanifoldto

carburetor:

. 086278206

3. Carburetorsupport,0862

78240

This

support

reducesthetransfer

of

engine

vibrationstothe

carbur-

etor and thereby

prevents

fuel

surgingandbubbling.

4. Exhaust

header

and

pipe,

header:

435278250

pipe:4352

78260

Someofthe

mainfeaturesof

exhaustsystemare:

(1)

Boththeheaderand

pipe

are

fabricatedfromstainlesssteel.

(2)

Theheader

is

atubulardesign,

andthe

pipe

terminatesin a

megaphone.

(3)

The

header

and

pipe

are

join-

edbya sliding

connectionto

allow

forengine

vibration

and

movement.

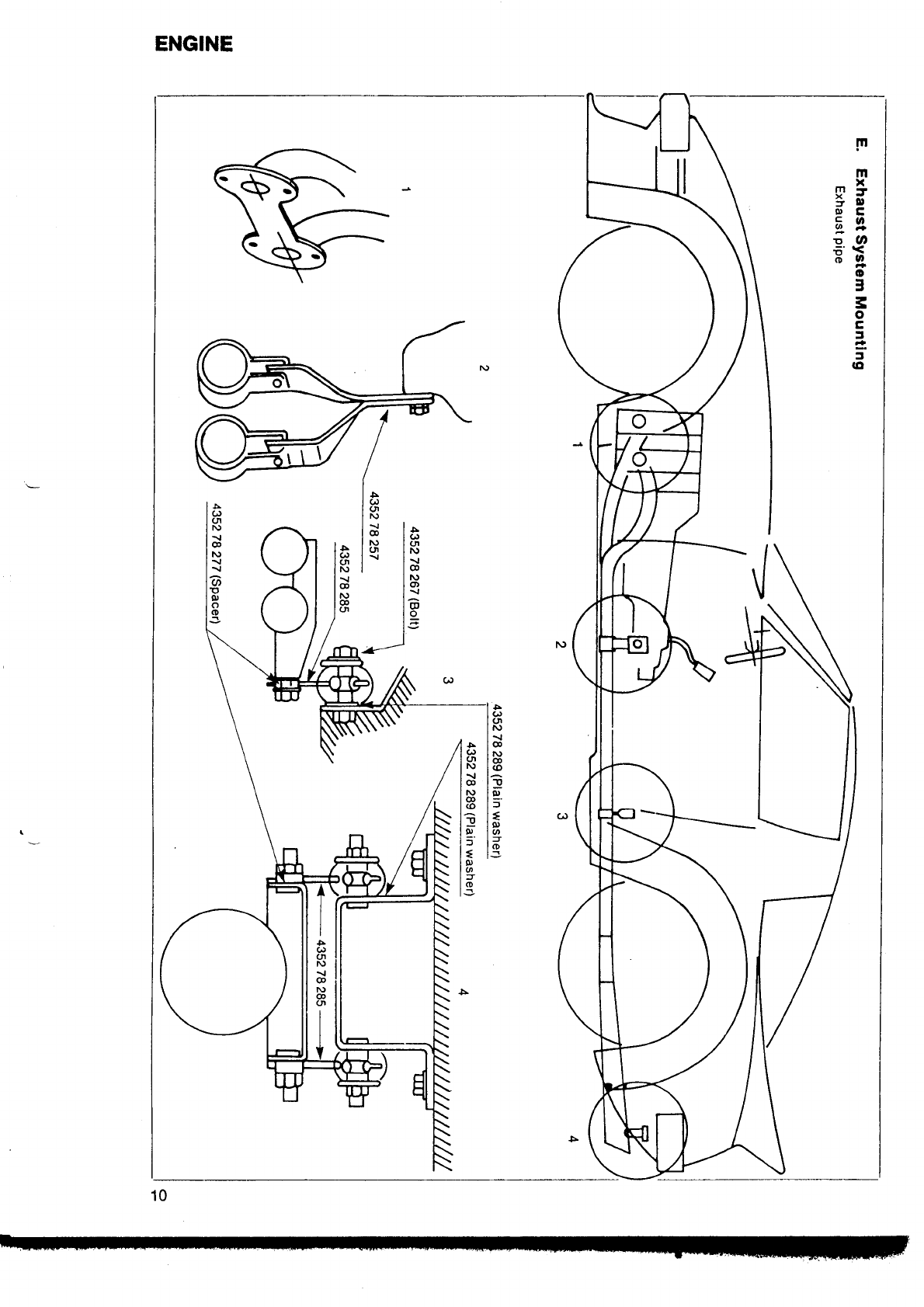

5. Exhaust

system

support

brackets

See

page

10for

details.

D. Lubrication

group.

1. Oil

pump,

105878

220A

Theshaft

and

rotorsin thecom-

petition

oil

pump

aremoreresis-

tanttowearandseizing.

Oil

pressure

regulator

assembly,

435214

250

Thisregulator

will maintain

oil

pressure

at

6.5

-r0.5

kg/cm'.

Engineoil

cooler,105878

180

This

larger-than-stock

coolerwill

increase

coolingcapacity

by 50

percent

over

stock.

E. Cooling

group.

1.Water

pump,4801

15

010

Thecompetitionwater

pump

is

aluminumalloy.

Water

pumppulley,4801

15151

To reduce

weightthis pulley

is

madefrom

aluminumalloy,and

itslarger-than-stock

130mmdia-

meter

will

enhanceV-belt

life

and

reduce

the speedof the water

pump.

Radiator,105878190

The

aluminumalloy

competition

radiator'slarger

corewill

increase

enginecoolingcapacity

by60

per-

cent

overstock.

V-belt,105878154

This

notchedV-beltismoreresis-

tantto

heat.

stretchand

vibration.

F. Electricalsystem.

1. lgnitioncoil,4801

1B100

This higheroutputcoil is exclu-

sively

designedfor use with the

Mazdacompetition

capacitivedis-

charge

ignition

(CDl).

2. Hightensionwires,

coil-to-distributor:43521B110

distributor-to-spark

pl

ugs:

48011B150

These

high

tensionwires

have

a

metalwire

coreto reducevoltage

drop.

3. Distributor,4B0l

1B200

Thesearethe mainfeaturesof the

distributor:

(1)

lt is breakerless,

havinga

magnetic

trigger.

(2)

Thereis no advance

mechan-

ism.

2.

3.

2.

3.