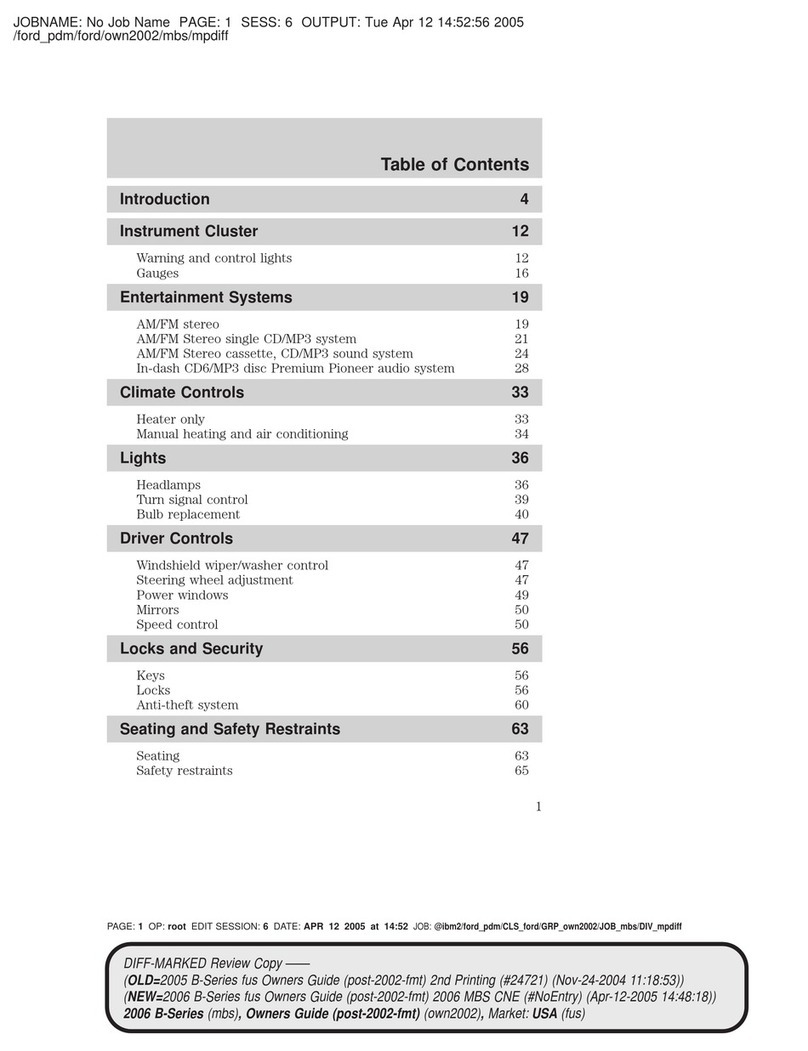

GENERAL INFORMATION

IMPORTANT INFORMATION ..................... GI- 2

BASIC ASSUMPTtONS ............................ a- 2

SAFETY RlSK

........................................

GI- 2

POSSBLE LOSS OF WARRANTY ............. GI- 2

WARNiNF ON LUBRICANTS

AND GREASES .................................... GI- 2

HOW TO USE THIS MANUAL.. .................. Gl- 3

PREPARATION ...................................... Gl- 3

REPAIR PROCEDURE ............................. Gl- 3

SYMBOLS

.............................................

a- 4

NOTES, CAUTIONS, AND WARNINGS ....... Gl- 4

FUNDAMENTAL PROCEDURES ................. Gl- 4

PROTECTION OF THE VEHICLE .............. Gi- 4

A WORD ABOUT SAFETY ....................... Gl- 5

PREPARATION OF TOOLS

AND MEASURING EQUIPMENT ............. GI- 5

SPECIAL TOOLS

....................................

Gt- 5

REMOVAL OF PARTS

............................. GI- 5

DISASSEMBLY ...................................... Gi- 5

REASSEMBLY ....................................... Gl- 6

ADJUSTMENTS

.....................................

GC- 7

RUBBER PARTS AND TUBING ................ Gl- 7

JACK AN5 SAFETY STAN5 POSITDNS .... Gl- 8

VEHICLE LIFT (Z-SUPPORT TYPE)

POSITIONS ............................................ GI- 8

TOWING .................................................. GL 9

IDENTIFICATION NUMBER LOCATIONS ..... GI-10

UNITS

..................................................... GI-I 0

ABBREVIATIONS ..................................... Gl-I 0

CAUTION ................................................ Gl-I 1

1NSTALLATtON OF A MOBlLE

TWO-WAY RADIO SYSTEM .................... GI-II

REMOVAL OF tGNIT1ON KEY ON

AUTOMATIC TRANSAXLE MODEL .......... Gl-11

ELECTRICAL TROUBLESHOOTlNG TOOLS GI-12

CAUTION WITH ELECTRICAL PARTS ........ Gl-13

03UGIX-001