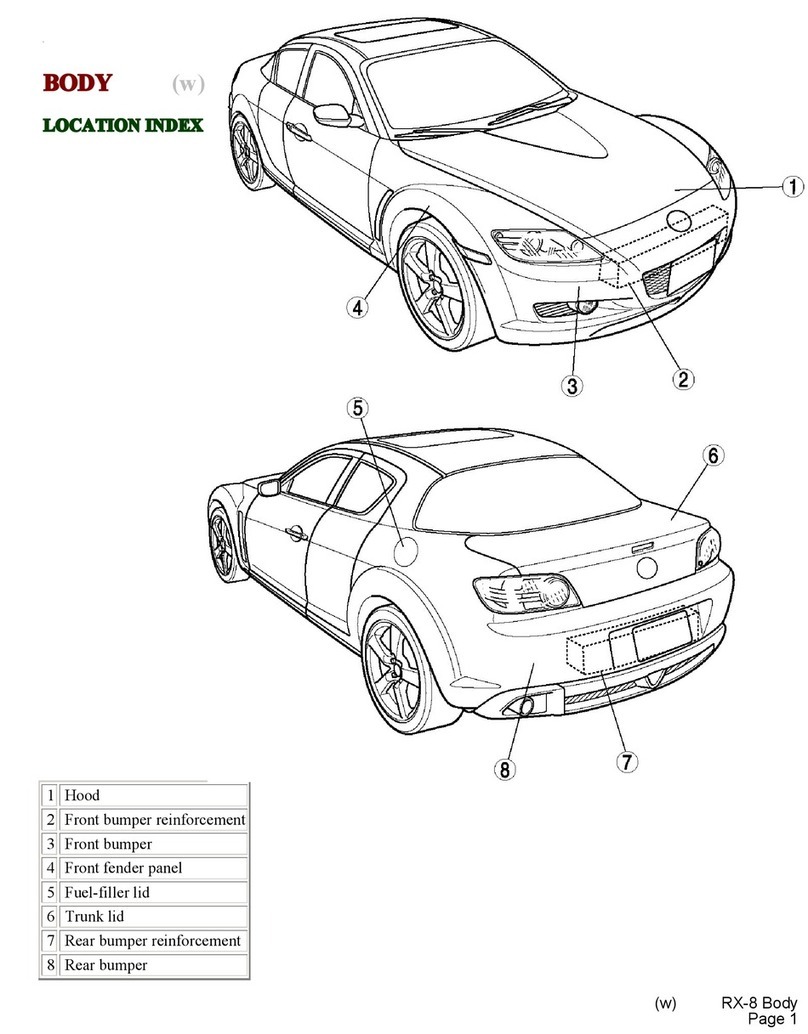

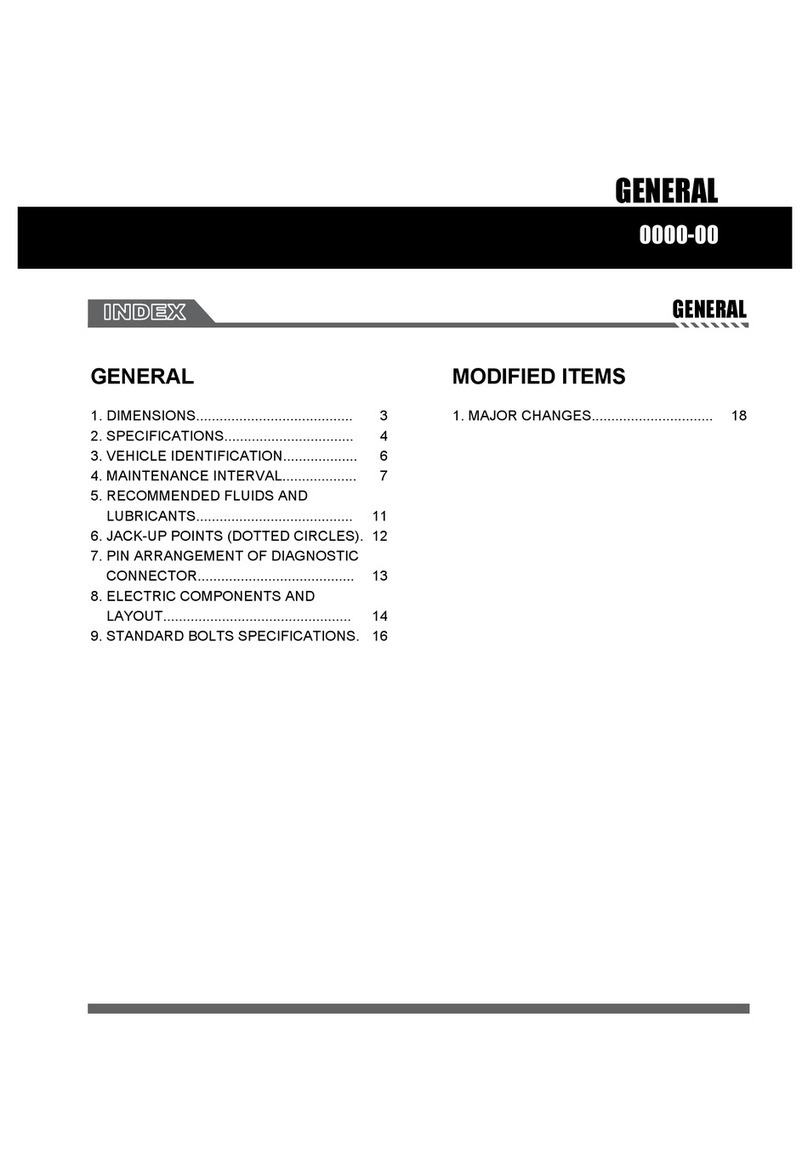

GENERAL INFORMATION

IMPORTANTINFORMATION

......................

GI- 2

.............................

BASIC ASSUMPTIONS GI- 2

SAFETY RISK

............................................

GI- 2

POSSIBLE LOSSOF WARRANTY

...........

GI- 2

WARNING ON LUBRICANTSAND

GREASES

................................................

GI- 2

HOWTO1 USETHIS MANUAL

.....................

GI- 3

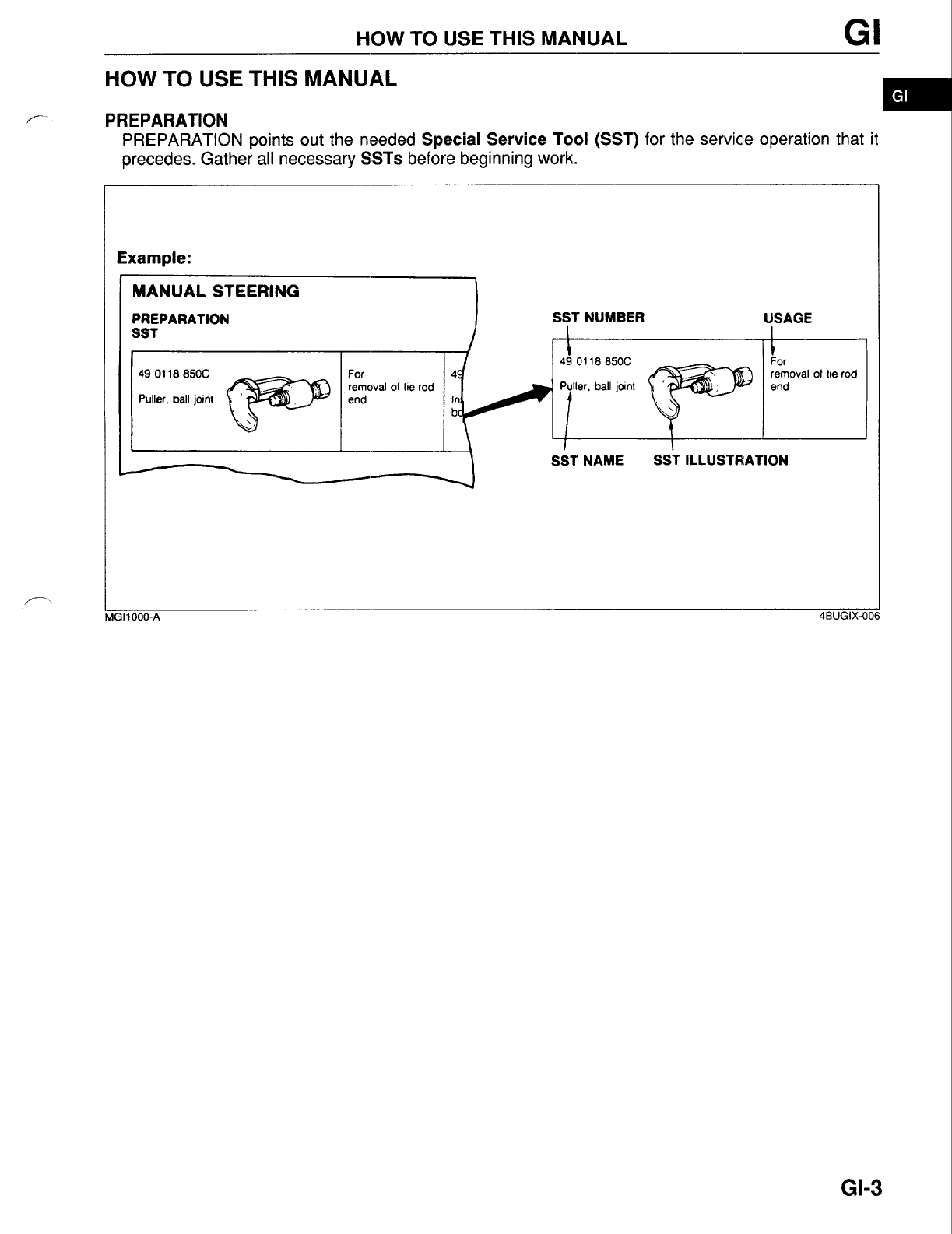

PREPARATION

.........................................

GI- 3

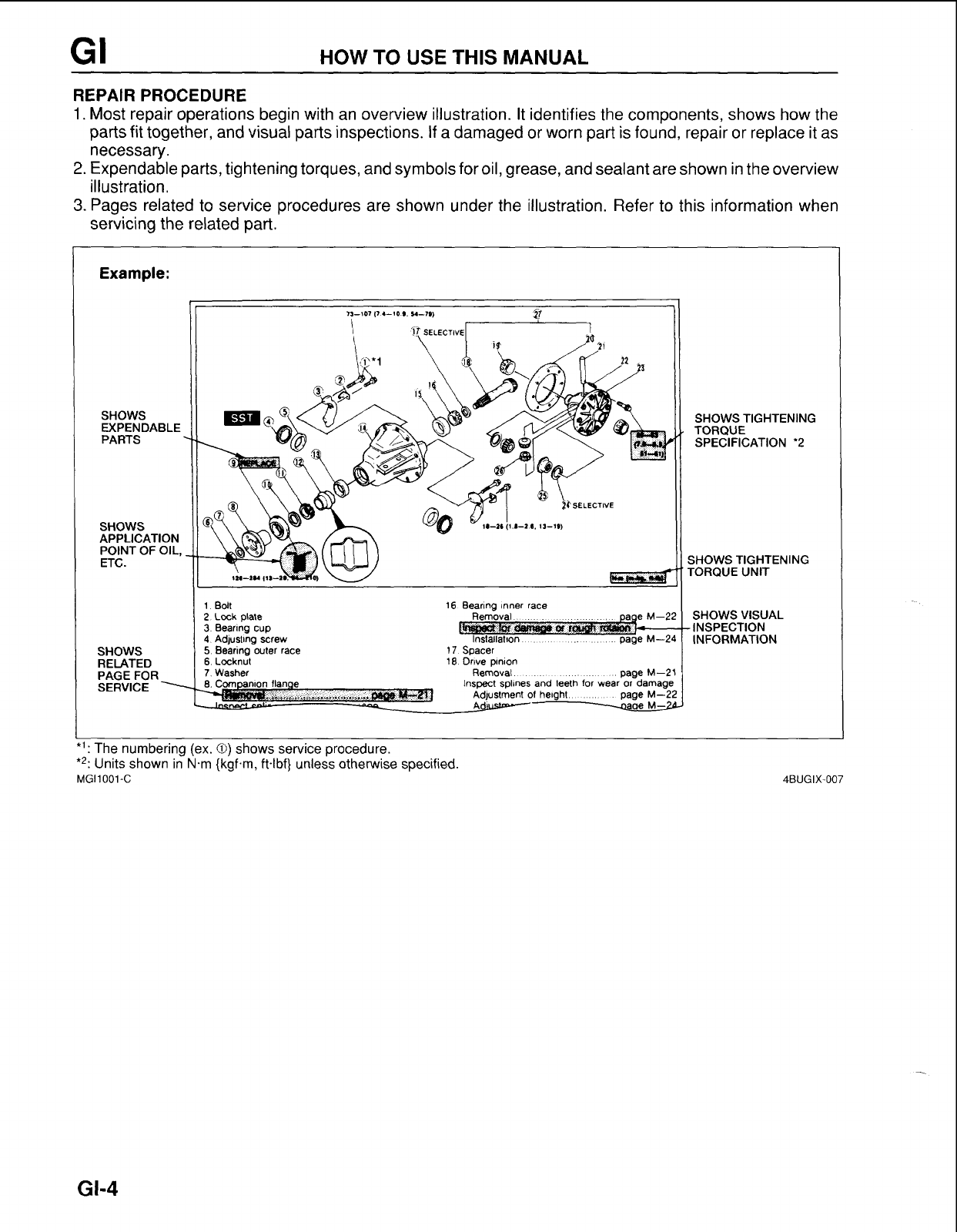

REPAIR PROCEDURE

..............................

GI- 4

SYMBOLS

..................................................

GI- 5

NOTES. CAUTIONS. AND WARNINGS

....

GI-

5

................

FUNDAMENTALPROCEDURES GI-

5

PROTECTIONOF THE VEHICLE

.............

GI- 5

........................

A WORD ABOUT SAFETY GI- 6

PREPARATIONOFTOOLSAND

MEASURING EQUIPMENT

.....................

GI- 6

.......................................

SPECIALTOOLS GI- 6

REMOVALOF PARTS

...............................

GI-

6

DISASSEMBLY

..........................................

GI- 6

ASSEMBLY

................................................

GI-

7

ADJUSTMENTS

.........................................

GI-

8

RUBBER PARTSAND TUBING

................

GI-

8

JACK AND SAFETY STAND(RIGID RACK)

POSITIONS

.................................................

GI-

9

..............................................

FRONT END GI-10

REAR END

.................................................

GI-10

VEHICLE LIFT(2-SUPPORTTYPE)

.................................................

POSITIONS GI-1

1

FRONT END

..............................................

GI-12

REAR END

...............................................

GI-12

.......................................................

TOWING GI-13

GENERAL TOWING PROCEDURE

PREPARATORYSTEPS

.........................

GI-13

TOWllVG TWO-WHEELDRIVE

...............................................

VEHICLES GI-13

TOWllVG FOUR-WHEEL DRIVE

VEHICLES

...............................................

GI-14

TOWllVG EQUIPMENT

..............................

GI-15

TOWllVG CONNECTIONS

.........................

GI-1

6

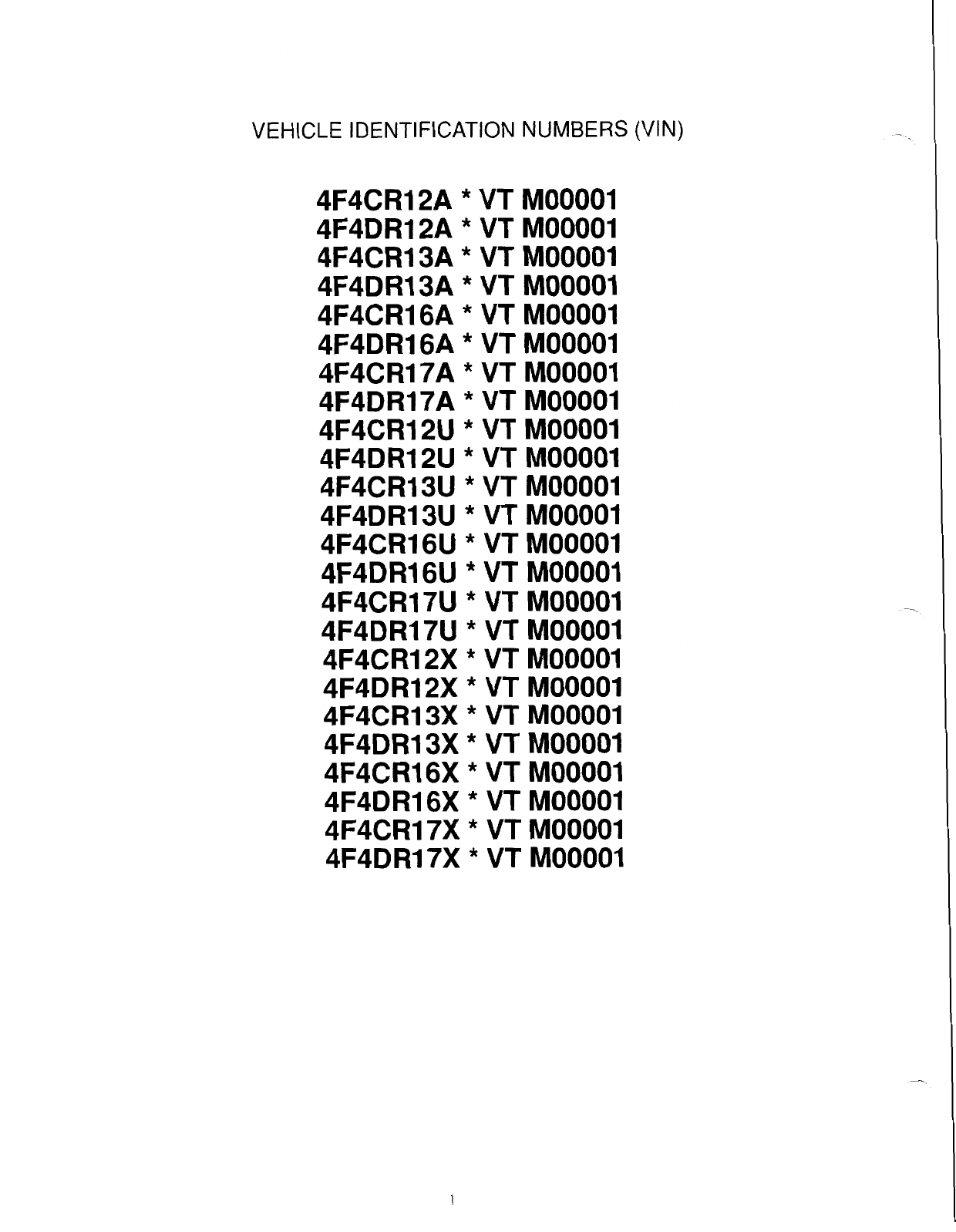

VEHICLE IDENTIFICATIONNUMBER

........

GI-17

SAFETY COMPLIANCECERTIFICATION

......................................................

LABELS GI-1

9

...........................................................

UNITS GI-23

ABBREVIATIONS

........................................

GI-23

SAE STANDARDNAME

..............................

GI-24

......................................................

CAUTION GI-26

ELECTRICALTROUBLESHOOTING

TOOLS

.....................................................

GI-26

.....

CAUTION WITH ELECTRICAL PARTS GI-27

4BUGIX-001