Form No.3351-1A-01A

GI

GI-3

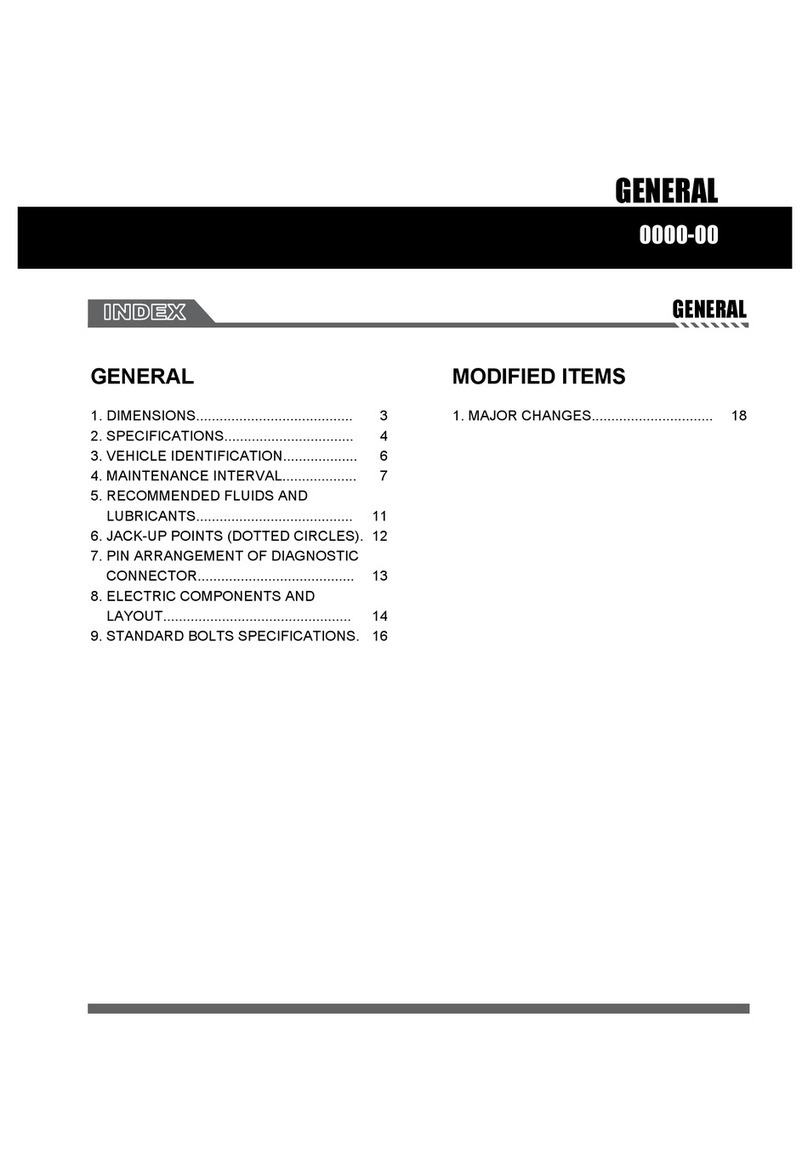

NEW STANDARDS

DFollowing is a comparison of the previous standard and the new standard.

N w Standard Pr vious Standard

Abbr viĆ

ation Nam Abbr viĆ

ation Nam R mark

AP Accelerator Pedal Ċ Accelerator Pedal

ACL Air Cleaner Ċ Air Cleaner

A/C Air Conditioning Ċ Air Conditioning

BARO Barometric Pressure Ċ Atmospheric Pressure

B)Battery Positive Voltage VBBattery Voltage

Ċ Brake Switch Ċ Stoplight Switch

Ċ Calibration Resistor Ċ Corrected Resistance #6

CMP

sensor Camshaft Position Sensor Ċ Crank Angle Sensor

CAC Charge Air Cooler Ċ Intercooler

CLS Closed Loop System Ċ Feedback System

CTP Closed Throttle Position Ċ Fully Closed

Ċ Closed Throttle Position Switch Ċ Idle Switch

CPP Clutch Pedal Position Ċ Clutch Position

CIS Continuous Fuel Injection System GI lectronic Gasoline Injection System

CS sensor Control Sleeve Sensor CSP

sensor Control Sleeve Position Sensor #6

CKP

sensor Crankshaft Position Sensor Ċ Crank Angle Sensor 2

DLC Data Link Connector Ċ Diagnosis Connector

DTM Diagnostic Test Mode Ċ Test Mode #1

DTC Diagnostic Trouble Code(s) Ċ Service Code(s)

DI Distributor Ignition Ċ Spark Ignition

DLI Distributorless Ignition Ċ Direct Ignition

I lectronic Ignition Ċ lectronic Spark Ignition #2

CT ngine Coolant Temperature Ċ Water Thermo

M ngine Modification Ċ ngine Modification

Ċ ngine Speed Input Signal Ċ ngine RPM Signal

VAP vaporative mission Ċ vaporative mission

GR xhaust Gas Recirculation Ċ xhaust Gas Recirculation

FC Fan Control Ċ Fan Control

FF Flexible Fuel Ċ Flexible Fuel

4GR Fourth Gear Ċ Overdrive

Ċ Fuel Pump Relay Ċ Circuit Opening Relay #3

FSO

solenoid Fuel Shut Off Solenoid FCV Fuel Cut Valve #6

G N Generator Ċ Alternator

GND Ground Ċ Ground/ arth

HO2S Heated Oxygen Sensor Ċ Oxygen Sensor With heater

IAC Idle Air Control Ċ Idle Speed Control

Ċ Incorrect Gear Ratio Ċ Ċ

#1: Diagnostic trouble codes depend on the diagnostic test mode

#2: Controlled by the PCM

#3: In some models, there is a fuel pump relay that controls pump speed. That relay is now called the fuel pump

relay (speed).

#6: Part name of diesel engine