McCormick-Deering Farmall F-14 User manual

Farmall

F-14

Tractor

I.

Before starting

a

new

engine, remove

the

spark

plu

rr

and

put

abut

OW

ounct

of

gas

engine lubricating oil into

each

cylinder;

replace

the

spark

dugs

and mnk

the

engine

to

distribute

the

ail

over

the

cylinder

walfs.

2.

During

the

first

one

hundred hours

of

o

ration,

mix

one

pint

d

engine

oil

with

every

Sive

gallons

of

fd.

table

for

"running

in"

a

new engine.

B

in#

66

drained

cempletefg

undJillEd

with

oil

as

the

4.

Tmctm

IOI

United

5.

CsmgJete instructions

for

oilin

are

showrr

on

"Lubrication

Chart."

6.

Do

nd

&or

i

be

Imded

t

ntif

it

Do

not owrlez%d

the

Tril6tor

at

any

time

or

when

new

lugs

are

wt

intends

in

order

ve

the right

to

make

changttg

in

a

cr

add

any

impvemults without

incurring

the

obligation

to

instdl

such

ch

an

Tractors

prcGclusly

purchased.

This

book

contains, addition

to

instructions

for

iffusitrntions pertainin

to

certain

simple

adjustmen

can readily

be

made.

owever,

the

owner

&auld

am

endoverhauling

or

ry

equipment fof

doin

Avoid

Accidents

Most accidents, whether they occur in industry, on the farm,

at home, or on the highway, are caused

by

the failure of some

individual to follow simple and fundamental safety rules or

precautions. For this reason most accidents can

be

prevented

by recognizing the real cause and doing something about it before

the accident occurs.

Regardless of the care used in the design and construction of

any type of equipment, there are many conditions that cannot

be

completely safeguarded against without interfering with reasonable

accessibility and efficient operation.

A

careful operator is the best insurance against an

accident.

The complete observance of onc?simple rule would pre-

vent many thousand serious injuries each year. That rule

is: C'Nenerattempt to clean,oil, or adjust a machine while

it is

in

motion."

NATIONAL

SAFETY

COUNCIL

INDEX

Description

................

Anti-Freezing Solutions

.................

Carburetor ~asoline)

................

Carburetor [Distillate)

................

Cold Weather Operation

....................

Cooling system

.................

Distillate Operation

.......................

Draw Bar

.................

Engine speed control

..................

Gasoline Operation

.....................

Gear shifting

..............

Lincoln Lubricating System

Lubrication

.....................

.................

Operating Precautions

Preparing Tractor for starting (Gasoline Operation)

.

.

Preparing Tractor for starting (Distillate Operation)

.

Radiator shutter

(

Distillate Operation)

..

.....................

Rear Wheels

.........

Starting Engine Gasoline operation)

........

Starting Engine Distillate Operation)

..................

Steering and Brakes

....................

Stopping Engine

...................

Stopping Tractor

................

Tractor Specifications

TRACTOR

INTENANCE

......................

Air

Cleaner

..................

Corrective Measures

Engine Ignition

....................

Fuel Pump

.......................

.....................

Fuel Strainer

Fuel Tanks

......................

Magneto

........................

....................

Oil

Filter Care

Overhauling

......................

................

Spark plugs and Cables

Storing Tractor

....................

Wiring

........................

NOTE.--

Pages

11

to

15

are for Gasol lne Operat ion

.

Pages

5

to

10

are for Distillate O~eration

.

Page No

.

16

Inside back cover

page

6

is for both'~aso1tneand ~isti~~ateOperations

.

The balance of the book is for both Gasoline and Dlstillate

Operat ion. except as noted

.

TO

OWNERS:

This Tractor

is

designed and built to give good performance and maximum

Service

.

Quality materials and good workmanship are employed throcgh-

out the entire unit

.

The suggestions and requirements for operating outlined in this book

are essential to maintain satisfactory performance and economical

service

.

The care and daily attention given the Tractor

will

largely

.

determine

its

maintenance cost and success of operation

.

Tractor Owners should use the extensive facilities offered by McCormick-

Deering and International dealers when service

is

needed that requires

the knowledge of

an

experienced service man

.

This

is

advisable as

Dealers are kept informed on the best methods of servicing Tractors and

are in a position to give satisfactory service

.

LUBRICATION

S.

1.

1.

Numbers or weights of oil and lubricants recommended.

I

I

Engine

Crankcase

Summer

Magneto

&

Very Light,

Cream Sep.

or Sewing

Machine

Oil

Lubricating

Fittings

Approved

Lubricant

SAE-160

Cleaner

SAE-20

Lighter

Winter SAE-10-W

SAE-20-W

Very Light,

cream sep.

1

ipproiedpFSAE-20

-1

or Sewing Lubricant

Machine SAE-90 Lighter

Oil*

*

Use kerosene in magneto coupling during cold weather.

CautionC Be sure to use a mineral oil for lubrtcating the gng.tne.

Do

not use top cylinder or valve oils.

Note: Engine lubricating oil shall be of well refined oils, free

from water, sediment, acid, resin or any other substance not

derived from petroleum.

Oil

shall not corrode any metal used in

engine construction.

Never check ott level whtle engine is running.

Proper lubrication is very important and instructions should be followed

closely. (See llLubrication Chart").

(See Special Instructions for Cold Feather Operation on pages

17

and

181.

TRANSMISSION, STEERING

GEAR

CASE,

FRONT AND

REAR

WHEELS, ETC.

Transmission Steering Gear Front and Rear

I

Case

I

Case Wheels, ~tc.

I

Summer Approved

Lubricant

SAE-160

See Instructions on page

20

for filllnl Rand-Lubrlcator.

Winter

The lubricant used for Transmissions, etc., Alemtte, Lincoln or Zerk

System should be a good grade of oil and conform to the fo2Zowlng

-

Approved

Lubricant

SAE-160

SAE-160 should be used when minimum temperature is above 40' F.

SAE-90 should be used when minimum temperature

is

below 40° F.

Approved

Lubricant

SAE-160

Approved

Lubricant

SAE-SO

The preferred lubricant should be made from mineral oil and should be

free from solid materials, which are undesirable

for

ball or roller bear-

ing lubrication.

Approved

Lubricant

SAE-90

Approved

Lubricant

SAE-90

3

OPERATING PRECAUTIONS

Read Instruction Book carefully.

Follow 'Lubricatton,Chart.

"

Before cranking tractor engine, be sure:-

I.

Gear shift lever is in neutral position.

2.

Radiator is filled with water.

3.

Englne has sufficient oil in crankcase pan.

When cranking the engine, retard spark control. Operator

should take his position so as to avotd being struck by starttng crank

if there is a reversal of the direct ion of the engine from any cause

whatsoever.

Khen starting the Tractor always engage clutch gradually. so engtne will

pick up the load slowl~.This is parttcularly necessary when going up

a steep hill, cl imbtng out of ditches or when hitched to a heavy or

difficult lood. Never hitch to a stump or other object by means of a

lbnC chain or rope with slack so that when Tractor moves forward it will

jerk into the lood.

Never operate engtne at more than the regu

speeds are dangerous.

Warning:-

Do not hitch to the tractor at any poin

Do not attempt to vull when draw bar is

Always use draw bar and braces.

1

ar governed speed. Excess ive

t except to the draw bar.

removed.

Drawbar and braces must be kept tight.

Never

funnel

avoid

carefu

radius

f

t11 pasol ine

t

ank when near an open

f

1

one or engtne is running. Beep

in contact with metal of fuel tank when pourlnp tn fuel, to

posstbtllty of an electric spark tgnltlng the gas. Be very

1

about lighting matches near gasoline, as the air within the

of several feet 1s permeated with a highly

explosive

vapor.

Cars should be exercised when Tractor is in motlon to prevent accidents

and personal tnjurles,

Do not use the clutch pedal as a foot rest; this causes undue wear on

clutch parts.

Never pour cold water into radiator if engine is hot.

Do not overload the Tractor at any t tme.

When pneumat ic tires are used, keep correct air pressure in

t

tres.

Clean breather in right hand side of value housing every week as

instructed.

IOTB:

Be sure to read instructlons on "SPGCIAL PRECAUTIONS KITE

A

XEY

TRACTOR" gives on back of front cover.

9

GASOLINE

OR

DISTILLATE

OPERATION

Paratraphs are numbered to correspond with numbers on

the

tllustratlons.

PREPARATIONS FOR START

I

NG

LUBRICATION

/See "Lubrlcat ton Chart').

Oil

magneto.

Check oil level of air cleaner.

Check oil level of engine crankcase.

Check oil level of transmission case.

Check oil level of steering gear case.

Check Tractor carefully with "Lubrication Chart1'.

If any lubrication connections are missing, replace

before starting.

Lubricate each place throughout entire Tractor as

instructed on "Lubrication Chartn.

ENGINE COOLING

SYSTEM

-

(Hater capoclty

3&

U.S.

gallons Approximately).

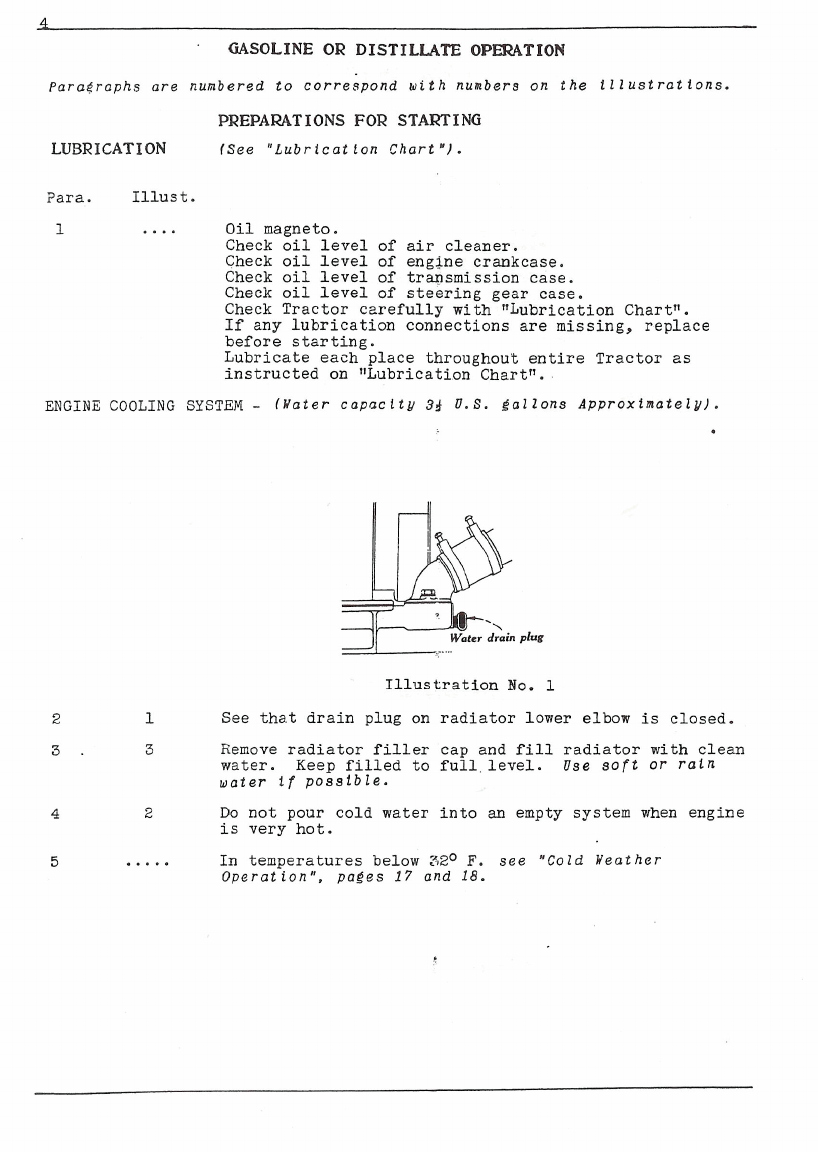

Illustration

No.

1

See that drain plug on radiator lower elbow

is

closed.

Remove radiator filler cap and

fill

radiator with clean

water. Keep filled to full level.

Use soft or rain

water

tf

possible.

Do not pour cold water into

an

empty system when engine

is very hot.

In

temperatures below

320

F.

see "Cold Weather

Operat ion". pages

17

and

18.

DISTILLATE OPERATION

Paragruphs

ore

numbered

to

correspond

aith

numbers

on

the tilustrations.

PREPARATIOHS

FOR

STARTING

-

Clntinved

P~r6.

Ill~~t.

6

..

...

NOTE:

Provision is made in the design of this engine to

use gasoline

as

fuel

and

can be operated on distillate

ty

applicetion of specis1 equipment listed for Pistillate

overation (See Psrts List.).

Ec~nomicelusc

of

distillate Tequires different operating

care

of

the engine. Folloa instructions to obtain best

results.

Before

ch&ngine

to distillate, SIloW encine to thorouehly

warm up. Five to eight minutes

ar

more

are

usuillj

ceress~ry

depending

an

itmospheric t,emperature.

WllTERFPGHT

Grrrn

2

%

2A

To

assist in warming up a

cold engine quickly, close

the winterfront (shutter)

completely (by turning

control handle all the

way

to the left

-

counter-

clockwise).

When heat indicator begins

to show "Hot", Own shutter

just enough

56

a;

to main-

tain the operating temper-

ature on the high side of

the working range

(on

neat

indicator).

Illustration

No.2

Heat Indicptor

2A

Adjustment of winterfront

rill

vary according to tractor

load, long periods

af

idling,

or

atmospheric temperature.

XOTB:

Distillate fuels are heavier than gasoline and

require more heat for proper vaporization.

Illustration

120.

7A

0

iA

Iaportont:

Do not start the engine in freezing reather

Without first closing the winterfront com2letely.

10 If engins

misses

ar

in

slow to accelerste

when

strrting,

it

1s

likely

not

hot enough to run on distillate.

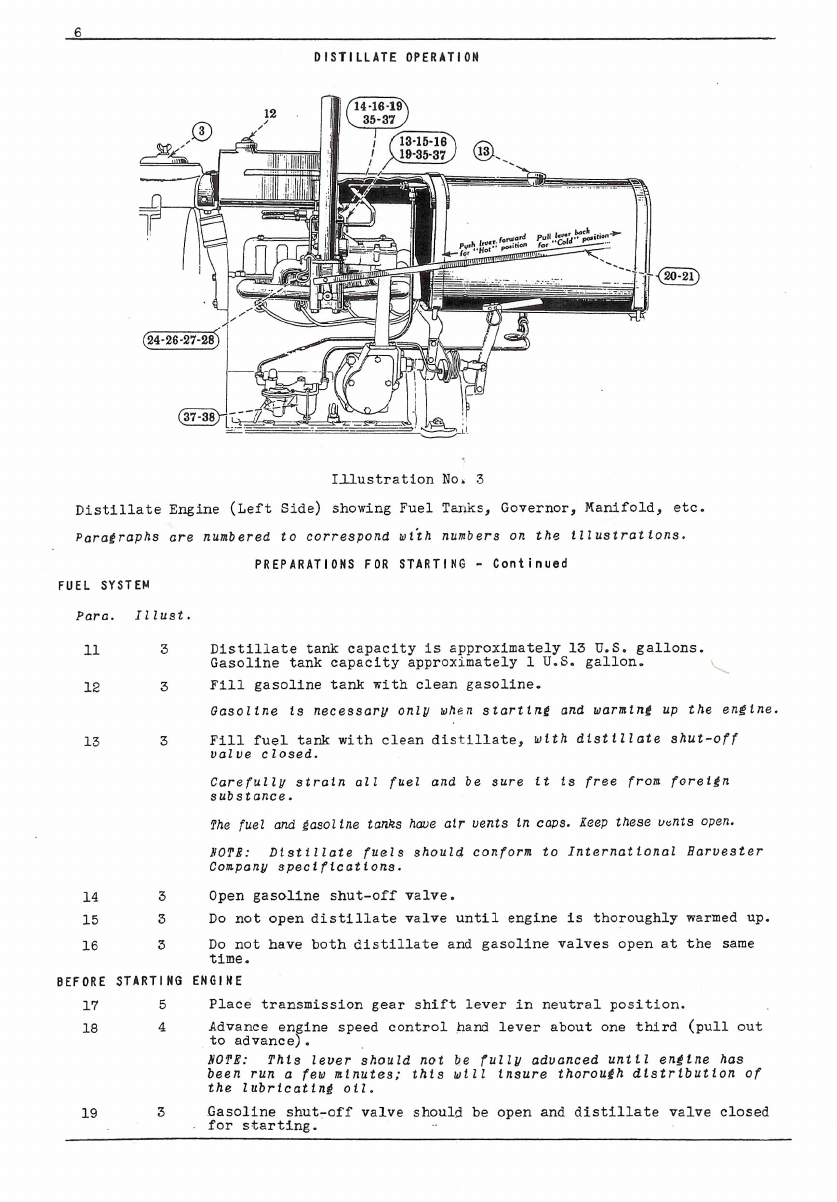

DISTILLATE OPERATION

Illustration No,

3

Distillate Engine (Left Side) showing Fuel Tanks, Governor, Manifold, etc.

~aragraphsare

FUEL SYSTEM

Para. I1lust.

11

3

12

3

numbered to correspond wiih numbers on the illustrations.

PREPARATIONS FOR STARTING

-

Continued

Distillate tank capacity

is

approximately 13

U.S.

gallons.

Gasoline tank capacity approximately

1

U.S.

gallon.

Fill gasoline tank with clean gasoline.

Gasoline is necessary only when starting and warming up the engine.

Fill fuel tank with clean distillate,

with distillate shut-off

value closed.

Carefully strain

011

fuel and be sure it

is

free from foreign

substance.

The fuel and gas01 ine tanks have air uents in caps. Ieep these u&S open.

NOTB:

Distillate fuels should confora to International Baruester

Company specipicat ions.

Open gasoline shut-off valve.

Do not open distillate valve until engine

is

thoroughly warmed up.

Do not have both distillate and gasoline valves open at the same

time.

BEFORE STARTING ENGINE

17

5

Place transmission gear shift lever in neutral position.

4

Advance en ine speed control hand lever about one third (pull out

to advance$.

NOTB:

This lever should not be fully aduanced until engine has

been run a few mtnutes; this wtll insure thoraufh distribution of

the lubricating oil.

19

3

Gasoline shut-off valve should be open and distillate valve closed

.

for starting.

DISTILLATE OPERATION

Paragraphs arz numbered to correspond with numbers on the tllustrations.

MANIFOLD HEAT

CONTROL

Para. Illust

.

20

3

Push the manifold heat control lever on left side of

fuel tank forward all the way. This sets the heat

control valve on manifold, in "Hotn

or

starting posi-

tion.

It ts important that control lever be properly

set to correspond with fuel being used and operating

conditions.

When starting on gasoline and operating.on distillate,

it

will

be desirable to keep the valve in "Hot"

position most of the time unless the weather is very

hot. In hot weather with a heavy load on the

engine, good results may be obtained with this valve'

in intermediate or "Cold11 position, but generally,

better results

will

be secured if the intake manifold

is

kept hot when using distillate. If not kept hot,

fuel

will

not be properly vaporized and dilution of

the crankcase lubricating oil, as well as imperfect

regulation of engine will result.

...

NOTE:-

If engine is to be operated when temperatures

are below 3Z0

F.,

see special instructions for Cold

Weather Operation. pages

17

and

18.

TO

START

ENGINE

23

4

Retard spark by moving spark control lever all the

way to the left.

3

Push up on the choke rod all the way.

....

When engine is cold and magneto grounded, crank engine

rapidly three or four revoluttons.

3

and

4

Move spark lever to starting position, about one-

quarter open, move choke rod one-half open and crank

engine using quick up-strokes until engine starts. The

use of choke for starting

will

vary depending on temper-

ature and altitude.

Do not use choke to enrich fuel mixture except when

starting the engine.

h'ever operate engine with choke

partly on.

As

soon as engine starts, the choke should be adjusted

to where the engine runs without missing,

and as the

engine warms up the choke should be gradually opened

all the way.

Advance spark control lever.

NOTE:-

Do not start the engine with the spark lever

ful ly advanced, as there is danger of a "back-fire" or

"kick" uhich may injure the operator.

....

See that oil pressure indicator is registering pressure.

DISTILLATE OPERATION

Sprh

leuer

(starting position)

Illustration No.

4

-

Engine.Controls.

Paragraphs are numbered to correspond with numbers on the

illustrations.

TO

START ENGINE

-

Continued

Para. Illust.

....

Should engine stop on distillate,it can be

started by cranking if it is hot enough.

.

.

.

.

If enzine has been stopped on distillate and is cold,

close distillate shut-off valve and drain carburetor

fuel bowl.

Then

proceed in accordance with starting

engine instructions.

.

If difficulty is experj.enced,see Correctfue Xeasures,

on page

33.

EilGINE SPEED CONTROL

Since the governor maintains constant engine speed

under variable loads, the engine speed control hand

lever should be used only to reduce the speed of

the engine below normal operating speed; with

engine speed control hand lever retarded, very

little load can be handled by the engine.

AFTER

ENGINE

IS

WARMED

UP

35

3

After engine

is

thoroughly warmed up, change over

to operate on distillate by closing gasoline shut-

off valve tight, and quickly open distillate

valve.

Never have both valves .open, or partly open, at the

same tine, otherwise distillate wtl2 mix with gaso-

line, making

it

unsatisfactory for starting.

36

4

Advance spark and engine speed control levers for

load to

be

handled.

DISTILLATE

OPERATION

Para2raphs are nunbered to correspond with numbers on the tllustralions.

TO

STOP ENGINE

Para. Illust.

37

S

Close distillate shut-off valve and immedihtely

open gasoline valve.

Run

engine on gasoline

2

or

3

minutes, long enough to empty fuel lines of

distillate and fill lines and fuel bowl with

gasoline. This

will

insure having gasoline in

the fuel bowl for starting.

Close fuel shut-off valve.

Set spark control to full retz.rd position.

Note:- It

ts

important that the fuel bowl

is

not

filled

ulth

distillate when engine 1s started as

this

makes the engine difficult, and under most

conditions Impossible to start.

39

.....

The engine can be stopped quickly in emer-

gencies

by

retarding spark all the

way.

dote:-

If

adjustment

of

the

carburetor should be

necessary,

follow

the instructions on

age

10.

START

49

TRACTOR

.,...

Place left foot on clutch pedal and press down

firmly, holding in this position;

this

disengages

the clutch. Clutch must always be disengaged while

shifting gears.

Nove gear shifting lever to desired speed.

Gently release pressure on clutch pedal; this

engages clutch

and

causes tractol- to move. Do not

drive with foot resting on clutch pedal.

GEAR

SHIFTING

1

43

b;

5

Aluays disengage clutch before

maktrlg

a

gear

shift.

N

-

Neutral

i

1st

-

Low speed forserd

2nd

-

1nter:nediate speed

f

orvtard

I

3rd

-

High speed fornard

E

I

R

-

Heverse

Illustration No.

5

Showing different posi-

tions of gear shifting lever.

DISTILLATE CARBURETOR

(I"

DOWIDRAFTI(1HC MODEL 1-10]

-

Deshiption

Starting shutter shaft

and

lever assembly.

Fuel pipe connection

and

screen

retainer.

Fuel adjusting screw.

Idling adjusting screw.

Idle throttle adjusting screw.

The

I

H

CModel 8-10 Carburetor

is

of

conventional downdraft, plain tube can-

struction,

and

is mounted on

a

hot-spot

manifold with adjustable heat control.

me

Proper rmrture of fuel and

air

is

controlled by the main fuel adjustment Illustration No.

6

(see

Ref. No.

4)

and

the idle fuel

adjustment

(No.

5).

The throttle position to give the

pro

er

idllng engine

speed

is

controlled

by

the idle throttle stop screw (x0.6P.

XOPd:

The carburetor

is

correctly

set

when shipped from the factory.

If

setting has been disturbed,the following procedure should

be

followed:.

Before

starting

the

engine, set the main fuel adjusting

screm

(No.

4)

242to

3

turns open and the idle fuel adjusting

screw

(No.

5)

1-1/2 to 2-1/2 turns

open. Also set manifold heat control valve in "Hot" position.

WAIN FUEL ADJUSTMEW1

After starting, allow engine to

run

on gasoline about

20

minutes rith engine

speed control hand lever fully advanced and manifold heat control-valve in

"Rot" position.

Have

radiator completely oovered during this period. Before

turning over to distillate

and

rith

s

rk in1/2 advanced position, slowly

screw main fuel adlusting

screw

(No.4Yin

until

engine slows dmslightly,

then turn

over

to distillate. Now turn adjusting

screl

in

until engine starts

to miss

Or

operate unsteadily, then unscrew until steady running is obtalned

at this speed. For best operation

and

minimum dilution, keep adjustment

as

lean

as

p0rsible. Screw in for lean and but for rich load mixture.

IDLE FUEL ADJUSTMENT

Retard englne speed control hand lever to about 1/4 advance, spark l/2 advance.

Screw

in idle throttle stop

screa

(No.

6)

until the engine speed increases

slightly.

Now

screa

idle fuel adjusting

screa

(No.

5)

until engine

runs

steadily. Unscrew idle throttle stop

screw

(No.

6)

until the engine idles at

desired speed with engine speed control hand lever in full retard position.

Idle adjusting screw turns

In

for rich and out far lean mixture.

CARE

OF CARBURETDR

The fuel screen should

be

cleaned occasionally. Fuel screen

is

removed by

unscrewing fuel line fitting

(No.

3).

Flange nuts which hold carburetor to

manifold should

be

checked periodically for tightness.

NOPE:

Periodically cheek the screws fastening the fuel bowl to fuel bowl

cover

and

see

that cover

screws

are

kept tight to avoid

any

air leak past

the

fuel bowl

cover

gasket.

HOT SPOT MANIFOLD

-

DISTILLATE OPERATION

A

full range of mixture temperatures

is

available

by

changing the setting of

the

heat control valve on the hot spot manifold.

The

engine should never be

operated on kerosene

or

distillate rith the valve in

all

"Cold* position.

At

normal air temperatures, the valve should

be

in 1/2 to 3/4 "Hotmwhen operat-

ing on

kerosene

or

distillate.

At

loner temperatures,

50°

to

35'

,

the valve

should be 3/4 to full "Hot".

At

loner temperatures, the valve shaold

be

in

full "Hot" positlon and the winterfront closed. For

satisfactory

cold weather

operation on distillate, the winterfront must be closed, the amount depend-

ine on load

and

temoerature.

GASOLINE OPERATION

Ill~strationNo.

7

-

Fuel Tank and Connectiaxs

Parolrnphs

ore

numbered to correspond vith numbers on the illustrotions

PREPARATIONS FOR START1

NG

FUEL

SYSTEM

Para. Illust.

7

Fuel tank capacity

is

approximately 13

U.S.

gallons.

Fill fuel tank with clean gasoline. Carefully

strain all fuel and be sure it is free from

foreign substance.

7

Open fuel tmk shut-off valve under the fuel tank.

The fuel

tank

has

an

air vent in cap. Keep this

vent open.

....

NOT%:-

If Tractor

has

been in storage

lor

o

lone

period.

see

special instructions on poles

34

and

35.

If enline is

to

be operated

when

temperatures

ore

be lo^

32"

P..

see

special instructlone for cold

K'eather Operation. poles

17

and

18.

NOTI:-

Winterfront furnished when ordered.

GASOLINE

OPERATION

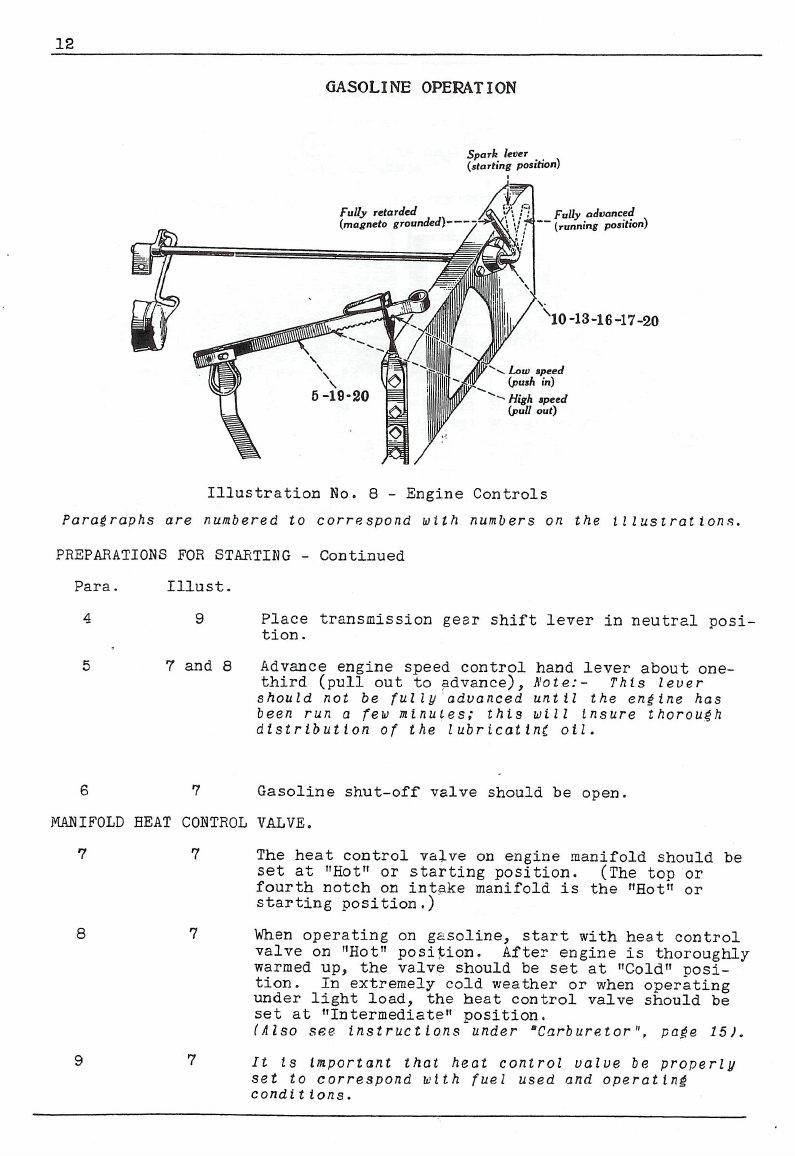

Spark

lever

(starting position)

Illustration No.

8

-

Engine Controls

Paragraphs are numbered to correspond with numbers on the illustrations.

PREPARATIONS FOR STAETING

-

Continued

Para. Illust.

4

9

Place transmission gezr shift lever in neutral posi-

tion.

5

7

and

8

Advance engine speed control hand lever about one-

third (pull out to advance),

Aiote:- This lever

should not be fully advanced until the engine has

been run a few minutes; this will insure thorough

distribution of the lubricating oil.

6

7

Gasoline shut-off valve should be open.

IW

IFOLD

HEAT

CONTROL

VALVE.

The heat control valve on engine manifold should

be

set at "Hotv or starting position. (The top or

fourth notch on intake manifold

is

the "Hot" or

starting position

.)

When operating on gzsoline, start with heat control

valve on "Hotu position. After engine

is

thoroughly

warmed up, the valve should be set at VoldUposi-

tion. In extremely cold weather or when operating

under light load, the heat control valve should

be

set at "Intermediaten position.

(Also see instructions under *Carburetor1', page

151.

It is important that heat control valve be properly

set to correspond wtth fuel used and operating

condit ions.

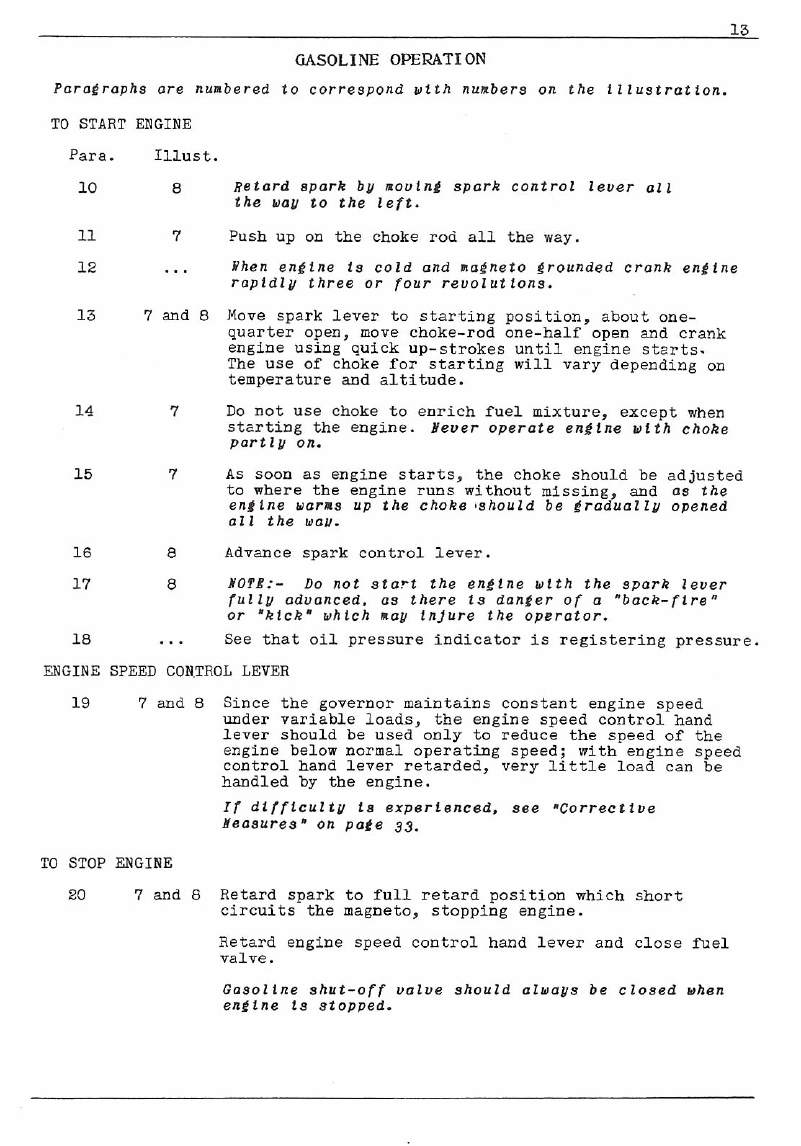

GASOLINE

OPERATION

PnroCrophs ore nunbered to correspond vtth nunbers

on

the lllustrotion.

TO

START ENGINE

Para.

10

11

12

13

8

Retard spark by novlnl spark control leuer 011

the

way

to the left.

7

Push up on the choke rod all the way.

...

When sngtne is cold

and

laeneto grounded cronk engine

roptdlu three or four revolutions.

7

and

8

Move spark lever to starting position, about one-

quarter open, move choke-rod ine-half.open and crank

engine using quick up-strokes until engine starts.

The use of choke for starting will varv deoendine

on

.

.

---.

---

temperature and altitude.

7

DO

not use choke to enrich fuel mixture, except when

starting the engine.

Uevsr

operote engtna with choke

partly

on.

7

As

soon as engine starts, the choke should be adjusted

to where the engine runs without missing, and

os the

enline raras up the choke ,should be eradually opened

011

the

wnu.

8

Advance spark control lever.

8

YO?#:-

Do

not start the engine wlth the spork lever

lullu aduanced.

os

there

ts

danger of

n

"back-firen

or

'kick' vhich sou injure the opcrotor.

...

See that ail pressure indicator

is

registering pressure.

ENGINE SPEED CONTROL LEVER

7

and

8

Since the governor maintains constant engine speed

under variable loads, the engine speed control hand

lever should be used only to reduce the speed of the

engine below normal operating speed; with engine speed

control hand lever retarded, very little load can

be

handled by the engine.

I1 dllftculty is experienced, see .Correcctue

aeosures" on pole

33.

TO

STOP ENGINE

20

7

and

8

Retard spark to full retard position which short

circuits the magneto, stopping engine.

Retard engine speed control hand lever and close fuel

valve.

Gasoline shut-off uolve should oluaus be closed when

eneine is stopped.

GASOLINE

OWRATION

Paraeraphs

ore

numbered to correspond aith numbers on

the

illustrations.

TO START TRACTOR

Para. Illust.

21

7

and

9

GEm

SHIFTING

24

9

Place left foot on clutch pedal and press down firmly,

holding in this position; this disengages the clutch.

Clutch must always be disengaged while shifting gears.

>%Ye gear shifting lever to desired speed.

Gently release pressure on clutch pedal; this engages

clutch and causes tractor.to move.

Do not drlve wlth

foot resting on clutch pedal.

Always disengage clutch before making a gear

shift.

N

-

Neutral

1st

-

Low

speed forward

2nd

-

Intermediate speed

forward

3rd

-

High speed forward

H

-

Reverse

Showing different posi-

tions of gear shifting lever.

15

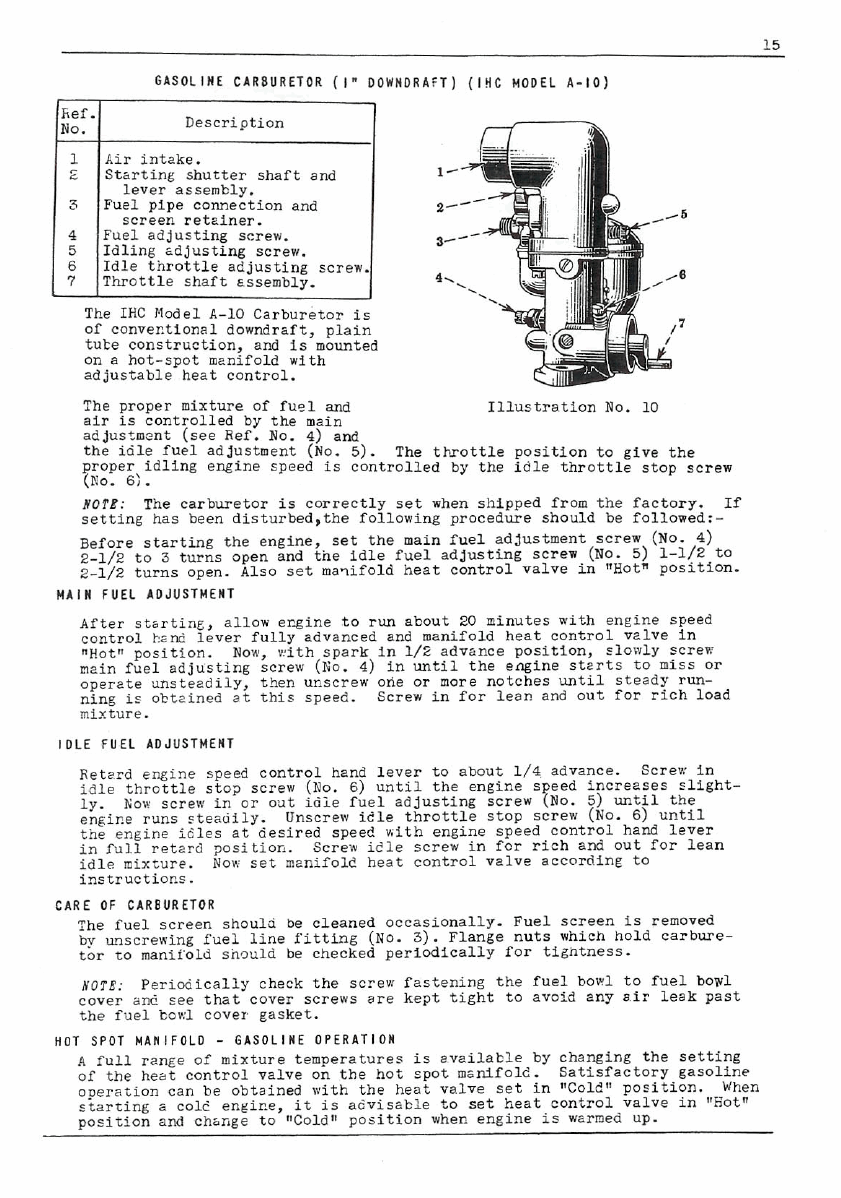

GASOLINE CARaURETOR

(I"

DOWNDRAFT) (IHC MODEL 1-10]

Description

Air

intake.

starting %utter shaft

and

I:

I

lever assembly.

Fuel Dim connection and

I

re

etin

I

Fuel adjusting screw.

Idling zdjusting

screw.

Idle throttle adjusting screw.

Throttle shaft Essembly.

The

IHC

Modeld-10 Carburetor

is

of conventional downdraft, plain

tute construction, and

is

mounted

an

a

hat-s~otmznifold with

ad justable- heat control.

Illustration

No.

10

The proper mixture of fuel

and

air

is controlled by the main

adjustment

(see

Ref.

No.

4)

and

the idle fuel adjustment

(No.

5). The throttle position to give the

proper idling engine speed

is

controlled by the idle throttle stop screw

(No.

6:.

NOTE:

The carburetor

is

correctly set when shipped from the factory.

If

setting has been disturbed,the following procedure should be fallowed:-

Before starting the engine, set the main fuel adjustment

screw

(No.

4)

2-1/2 to

3

turns open and tne idle fuel adjusting screw

(NO-

5) 1-1/2 to

2-l/2 turns open. Also set maqifold heat control valve in 'Hot" position.

After stbrtinc, allow ergine to

run

about 20 minutes with engine speed

conti-01

bznd

lever fully advanced

and

manifold heat control velve in

.Hot" position.

Now,

vith spark in l/2 advance position, slowly screw

main fuel adjusting screw

(ko.

4)

in

until the engine starts to

miss

or

operete unsteadily, then

unscrew

one

or

more

notches until steady run-

ning is obtcined at this speed. Screw in for lean and out

for

rich load

mixture.

IDLE FUEL ADJUSTMENT

Retzrd engine speed control hand lever to about 1/4 advance. Screw in

idle throttle stop

screw

(No.

6)

until the engine speed increzses slight-

ly.

Nor

screw

in

or

out idie fuel adjusting screw

(No.

5) until the

engine runs steadily. Unscrew idle throttle stop screw

(No.

6)

until

the engine idles at desired speed with engine speed control hand lever

in full retgrd 2osition. Screw idle screw in for rich and out for lean

idle mixture. Now set menifole heat control velve accorbing to

instrUCtionB.

CARE OF CARBURETOR

The fuel

screen

should

be

cleaned

occasionally.

Fuel sereen

is

removed

bv

unscrewing fuel line fitting (No.

3).

Flange nuts which hold carbure-

tbr

to manifold snould

be

checked periodically for tigntness.

NOTE:

Periodically check the screw fastening the fuel bow1 to fuel boy1

cover

an6

see

that

cover

screws

are

kept tight to avoid 2ny

sir

leak

past

the fuel bou;l cover gasket.

HOT SPOT MANIFOLD

-

GASOLINE DPERATION

A

full range

of

mixture temperatures

is

available by changing the setting

of the heat control valve on the hot spot msnifold. Satisfactory gasoline

operation

can

be

obtained with the heat valve set in "Cold' position. When

starting

s

~016engine,

it

is

advisable to set heat control valve in

"Hot"

position and chsnge to "Cold" position when engine

is

wzrmed up.

ENGINE SPEED CONTROL

LEVEfi

The lever on the left hand side of the fuel tank is the engine speed

control lever.

The rated or governed speed is 1650 R.P.M. for full load, which gives

a fast idling (no-load)

speed

of approximately

1800

R.P.M.

Inportant!

Por

all-round satlsfoctory operatlon. the engine should

not be ldlad down to

a

speed below

300

to

400

R.P.I.

GOVERNOR CONTROL ADJUSTEIENT

The governor is set at the factory and should require no adjustaent.

STEERING AND BRWLES

The brakes take hold when the front wheels are swung to the extreme

right or left, thus czusing either of the rear wheels to lock, and the

tractor to pivot in its course

of

travel. The question as to which

rear

wheel locks depends on the direction of steering; for exemple,

when front wheels are turned to left, the left rear wheel lacks and

tractor pivots

to

the left.

TO

STOP

TRACTOR

Disengage clutch by pressing down firmly on clutch pedal, then move

gear shifting lever to neutral position.

Use

the brakes if necessary.

SnFETY

FIRST:-

Stop power Coke-off before dismounting from tractor.

Be

sure gear shift lousr ts

1"

neutral posltlon before

dlsmountlng from tractor.

TO STOP ENOINE

See instructions for stopping engine:-

Distillate

operatlon

-

page

9.

G080line Operation

-

pole

13.

Rote: If adlustaent

of

the carburetor snould be neeesaory. follow

instructions iluen on pages

10

ond

15.

REAR

WHEELS

Cnntlon

-

dfter

a

neu troctor hos been run.0 short tine.

or

the rear

wheels hove been reamed or changed position, ttlhten the rear uheel

hub bolt nuts. See other Rear Yheel instructions on page

44.

Be sure expanding set screw (when used) is released when tightening

up on rear axle clamp bolts.

DRAW

BAR

.YARNING'

DO

not hitch to the troctor at

my

polnt except to the drav bor.

DO not ottenpt to pull vhen drav

bar

is rimved.

Draw bar and brace bolts nust be kept tleht

Alu~ysuse drow bar

and

braces.

tdtso

see

page

45

for

'Outek

Atlochable' drow

bnrl.

COLD WEATHER OPERATION

If

Tractor is to be operated when temperature is below

32O

F.

certain

protective precautions are necessary.

Use "Wintern engine and transmission lubricants.

(Sea

"Lubrtcatlon

Chart").

Use a good grade of engine oilhaving the proper body, with

a

loa

cold test, suitable for existing climatic conditions.

Use

kerosene in magneto coupling.

-

-

Transmission oil must be light enough to flow in prevailing atmosphere

temperature. If transmission lubricant available

is

too heavy dilute

sufficiently with lighter oil so

it

will

flow readily.

Failure of transmission lubricant to flaw readily

will

soon cause

bearings to be without oil.

ENGINE

STARTING

Have oil in engine crankcase light enough that engine

will

not be too

stiff to crank.

If

desired, during very cold weather, the engine oil in the crankcase

pan

can

be completely drained each night.

Do

this while the oil is

warm so

it

will

drain freely.

Before

refilling, warm ail thoroughly and pour into crankcase just

before starting the engine, as this

will

insure oil thin enough

to

pass through screen over pump suction, also preventing condensation of

moisture in crankcase pan.

Filling fuel tank at end

of

day's run wil1,prevent moisture from

collecting in the tank.

Use

a

high test winter grade

of

gasoline for starting.

If

engine has been idle far any length of time check crankcase pan,

fuel tank and fuel bawl for any ice formation before starting.

If

trouble is

experienced,

see

.Correclloe

Xeasures',

pale

33.

also

see

nogneto instructions

on

pot6

32.

Table of contents