© 2012 Pentair Technical Products 89055585

- 2 -

TABLE OF CONTENTS

RECEIVING THE AIR CONDITIONER .............................................................................................................................................................. 3

HANDLING AND TESTING THE AIR CONDITIONER ................................................................................................................................. 3

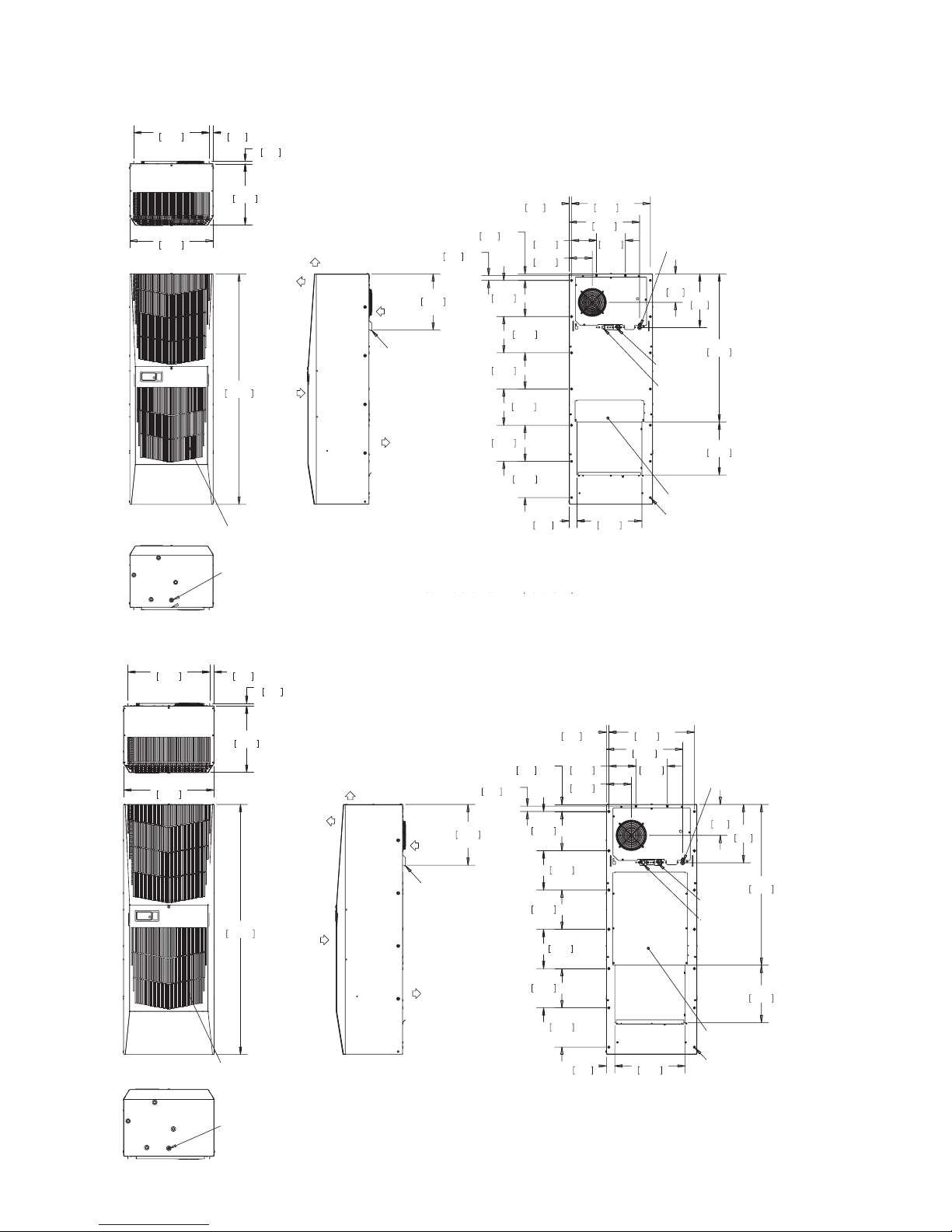

DIMENSIONAL DRAWINGS ............................................................................................................................................................................. 4

20000 BTU/Hr. (G572026GXXX, G572026G2XX) ............................................................................................................................. 4

20000 BTU/Hr. (G572046G15X) ............................................................................................................................................................ 4

HOW TO READ MODEL NUMBERS ............................................................................................................................................................... 5

INSTALLATION INSTRUCTIONS ..................................................................................................................................................................... 5

TECHNICAL INFORMATION ............................................................................................................................................................................ 7

Sequence of Operation ........................................................................................................................................................................... 7

Heating .................................................................................................................................................................................................. 7

Cooling .................................................................................................................................................................................................. 7

Standard and Optional Component Operation ............................................................................................................................. 7

Thermostat ........................................................................................................................................................................................... 7

Head Pressure Control ..................................................................................................................................................................... 7

Contactor .............................................................................................................................................................................................. 8

Freezestat ............................................................................................................................................................................................. 8

Time Delay Relay ................................................................................................................................................................................ 8

200 V to 230 V Transformer (G572026G2XX only) .................................................................................................................. 8

Phase Monitor (G572046GXXX only) .......................................................................................................................................... 8

460 V to 230 V Transformer (G572046GXXX only) .................................................................................................................. 8

230 V to 10 V Transformer (optional) .......................................................................................................................................... 8

230 V to 24 V Transformer and Relay (optional) ...................................................................................................................... 8

Refrigerant Properties Chart (R407c).................................................................................................................................................. 9

Unit Characteristics .................................................................................................................................................................................10

Functional Data ........................................................................................................................................................................................10

Wire Diagrams and Schematics ..........................................................................................................................................................11

G57 208V 1-Phase Generic Wire Diagram (actual unit options may vary) ..................................................................11

G57 208V 1-Phase Generic Schematic (actual unit options may vary) ........................................................................12

G57 230V 1-Phase Generic Wire Diagram (actual unit options may vary) ..................................................................13

G57 230V 1-Phase Generic Schematic (actual unit options may vary) ........................................................................14

G57 400/460V 3-Phase 50/60hz Generic Wire Diagram (actual unit options may vary) ........................................15

G57 400/460V 3-Phase 50/60hz Generic Schematic (actual unit options may vary) ..............................................16

SERVICE DATA ...................................................................................................................................................................................................17

Components List ......................................................................................................................................................................................17

MAINTENANCE .................................................................................................................................................................................................18

Compressor ...............................................................................................................................................................................................18

Inlet Air Filter .............................................................................................................................................................................................18

How To Remove, Clean or Install a New Inlet Air Filter ..............................................................................................................18

Condenser and Evaporator Air Movers ............................................................................................................................................19

Refrigerant Loss........................................................................................................................................................................................19

TROUBLE SHOOTING ......................................................................................................................................................................................20

Basic Air Conditioning Trouble Shooting Check List ..................................................................................................................20

Symptoms and Possible Causes: ........................................................................................................................................................21

WARRANTY ........................................................................................................................................................................................................22

RETURN AND REPAIR POLICY ......................................................................................................................................................................22

LIMITATION OF LIABILITY ..............................................................................................................................................................................23