Rev. 10/19 © 2015 McNeilus Truck and Manufacturing, Inc.

3

Preface

Be careful to minimize ow restrictions. Do not close any downstream valve during normal operation without

adding external relief protection. A resulting pressure spike could cause lter damage and/or personal injury. If a

downstream valve must be used, this valve must be locked in the open position during MFS operation.

The MFS is to be used solely for the purpose of providing auxiliary ltration. It is not intended to be used as a

power unit or in conjunction with other components for the purpose of performing work.

▪ Never start up or run a dry pump. This will cause galling, seizing or destructive wear between the rotors,

end plates and casting.

▪ The Mobile Filtration System is designed for the transfer and ltering of hydraulic and lubrication oils only.

It is not to be used for highly volatile uids such as gasoline or paint thinners. Please contact factory for uses

other than those specied.

▪ The maximum operating temperature for the MFS is 150° F. Higher temperatures could damage the hoses.

▪ Since minimum repair service is generally required on these units, it is recommended that any failed parts

be replaced with new parts. See the replacement parts list in section 5.

▪ Electric motor warnings for the 1 ½ HP model is as follows:

- 1 ½ HP electric motor draws 12.6/6.3 amps at 115/230 volts, 60 Hz at full load. Starting current is

approximately 88/44 amps at 115/230 volts, 60 Hz. A proper circuit breaker should be installed to protect the

motor and meet national and local electric codes. Recommended size for an extension cable is 12-3 conductor

with a maximum length of 25 feet.

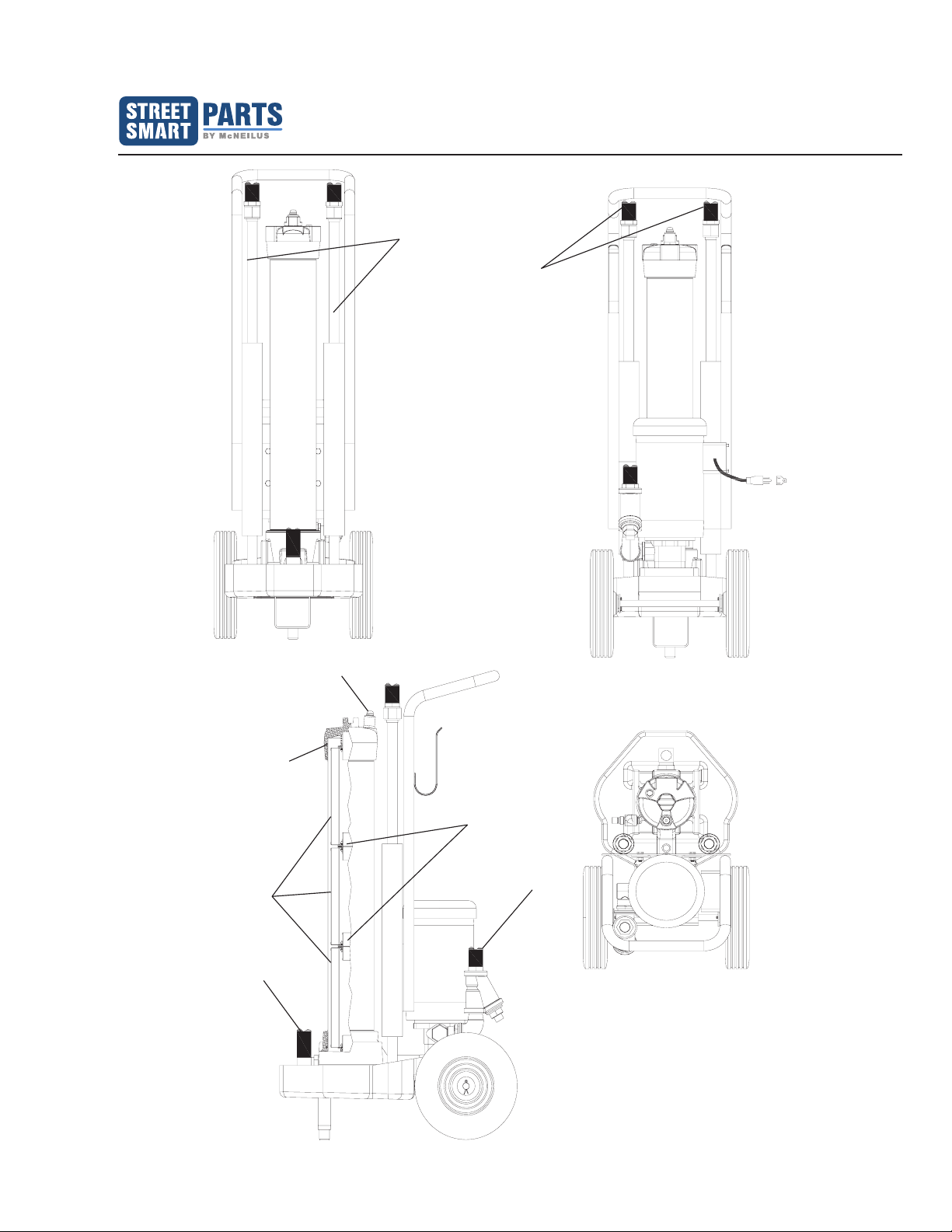

1.0 Connecting the MFS to the uid reservoir

NOTE

Black hoses with quick disconnects are supplied with

MFS model 1148220.

(Quick disconnect Wands are sold separately - 1148220)

Clear hoses and wands are supplied with

MFS model 1131722.

1. Connect the supplied inlet hose to the inlet port on the MFS. Then connect the inlet hose to the reservoir quick

disconnect, or connect the wand to the inlet hose and place tube inside reservoir opening.

2. Connect the supplied outlet hose to the outlet port on the MFS. Then connect the outlet hose to the reservoir

quick disconnect, or connect the connector tube to the outlet hose and place tube inside reservoir opening.

3. Check that the power source being utilized complies with the requirements of the ltration cart motor before

actual hook-up.

4. Switch on the Mobile Filtration System’s motor. Visually check that the uid is actually being pumped through

the MFS and out of the outlet hose.