Page 2 / IM 178

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Receiving Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 3

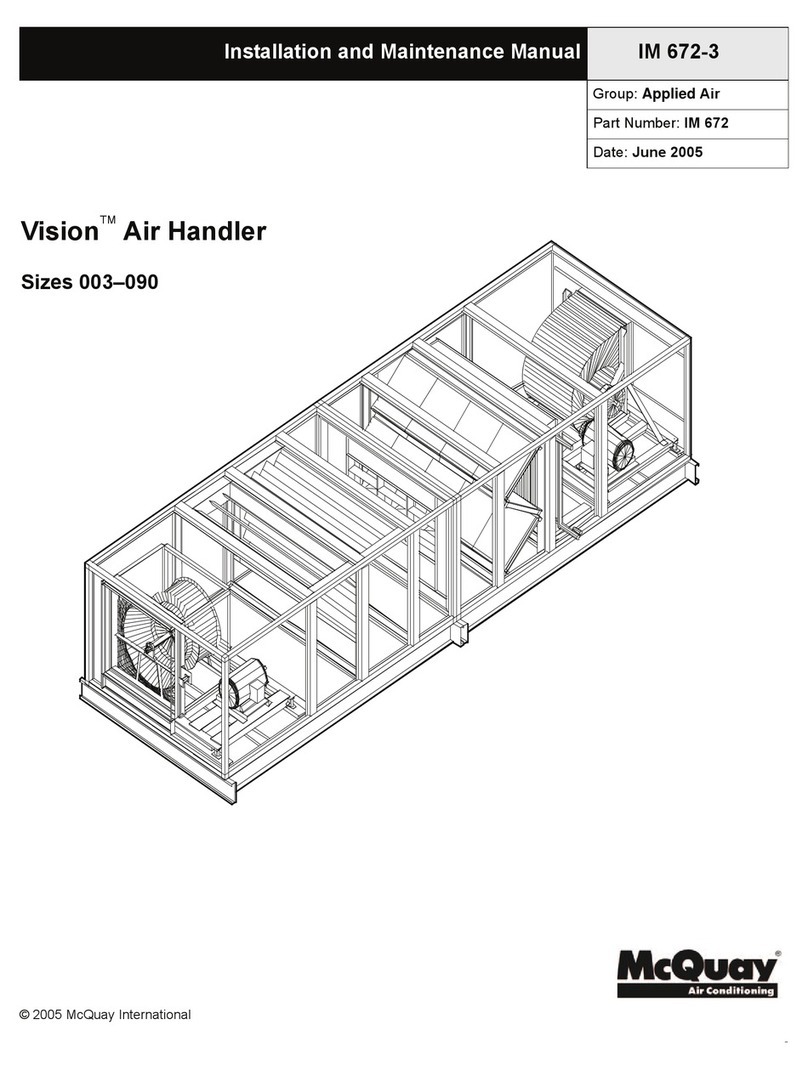

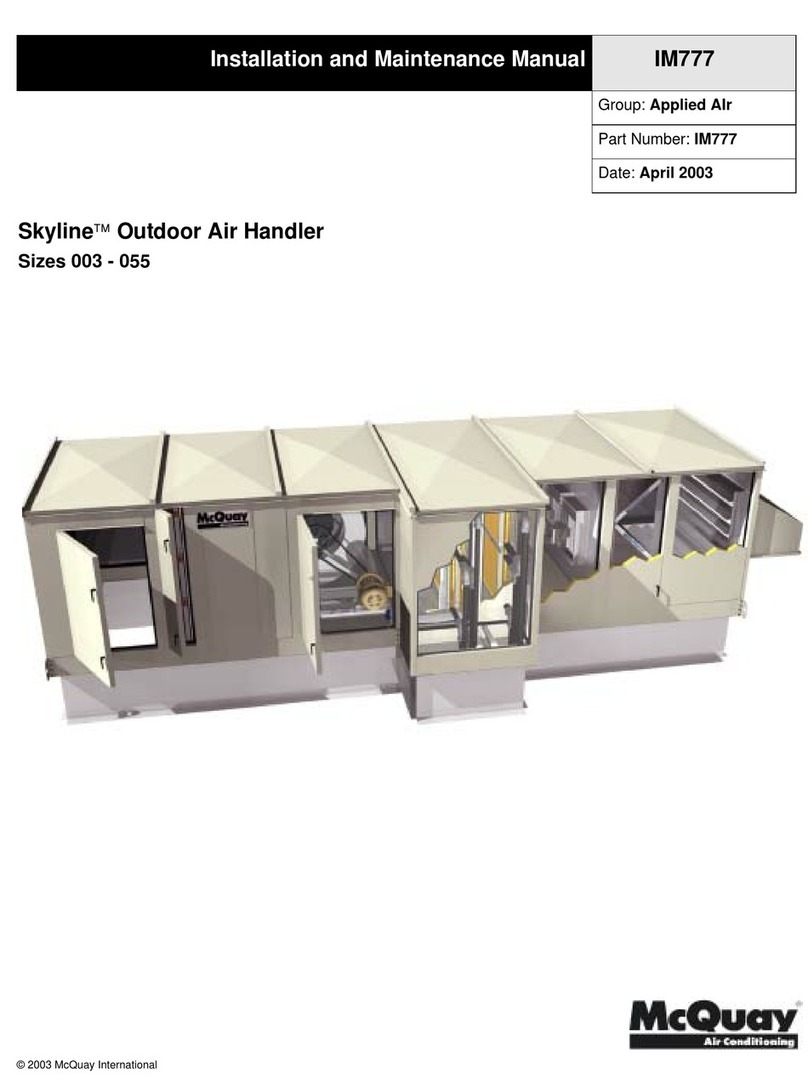

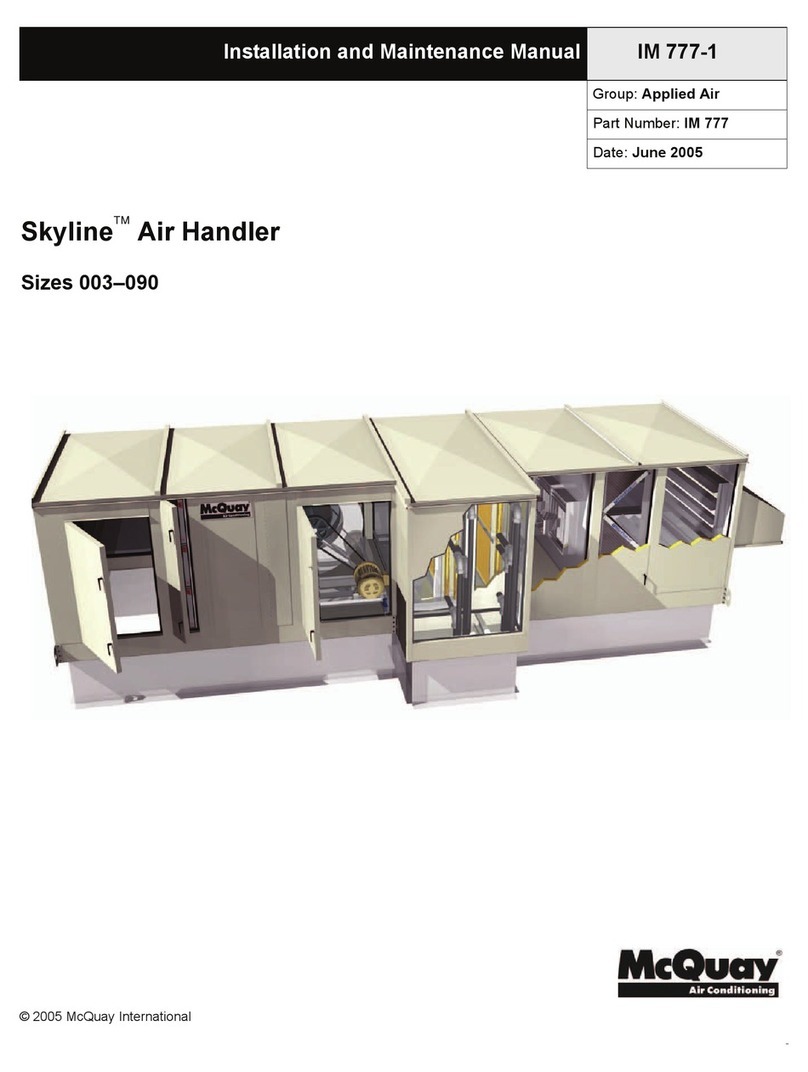

Unit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Typical Component Locations . . . . . . . . . . . . . . . . . . . 4

Control Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Control Panel Locations . . . . . . . . . . . . . . . . . . . . . . . . 6

Controls, Settings, and Functions . . . . . . . . . . . . . . . . 8

Mechanical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Roof Curb Assembly and Installation . . . . . . . . . . . . . 11

Post and Rail Mounting . . . . . . . . . . . . . . . . . . . . . . . 13

Rigging and Handling . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installing Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installing Duct Static Pressure Sensor Taps . . . . . . . 15

Installing Building Static Pressure Sensor Taps . . . . 16

Condensate Drain Connection . . . . . . . . . . . . . . . . . . 17

Field Refrigerant Piping and Charging of DX Coils . . 17

Unit Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Vestibule Assembly Instructions . . . . . . . . . . . . . . . . 21

Damper Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cabinet Weatherproofing . . . . . . . . . . . . . . . . . . . . . . 25

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Field Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Field Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Preparing Unit For Operation . . . . . . . . . . . . . . . . . . . . . 29

Relief Damper Tie-down . . . . . . . . . . . . . . . . . . . . . . . 29

Spring Isolated Fans . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Adjustment of Scroll Dampers . . . . . . . . . . . . . . . . . . 30

Adjustment of Supply Fan Thrust Restraints . . . . . . . 30

Adjustment of Seismic Restraints . . . . . . . . . . . . . . . 31

Sequences of Operation . . . . . . . . . . . . . . . . . . . . . . . . 32

Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Fan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Economizer Operation . . . . . . . . . . . . . . . . . . . . . . . . 32

Cooling Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Heating Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Typical Power Circuits With Controls. . . . . . . . . . . . . 35

Table of Contents

Typical Compressor Staging Outputs . . . . . . . . . . . . 35

Typical Main Control Circuit (VAV Units) . . . . . . . . . . 36

Typical Main Control Circuit (CAV-ZTC Units) . . . . . . 37

Typical Main Control Circuit (CAV-DTC Units). . . . . . 38

Typical Actuator Control Circuit . . . . . . . . . . . . . . . . . 39

Typical Supply/Return Fan Control Circuit . . . . . . . . 39

Typical Gas Furnace Control Circuit . . . . . . . . . . . . . 40

(Modulating Burner, Mixed Air Intake)

Typical Electric Heat Control Circuit (Multistage) . . . 41

Unit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Enthalpy Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Phase Voltage Monitor . . . . . . . . . . . . . . . . . . . . . . . . 42

Remote Monitor Panel . . . . . . . . . . . . . . . . . . . . . . . . 42

External Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Smoke Detectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Freeze Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Mixed Air Temperature Alarm. . . . . . . . . . . . . . . . . . . 43

Duct High Pressure Limit . . . . . . . . . . . . . . . . . . . . . . 43

Variable Inlet Vanes . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Convenience Receptacle/Section Lights . . . . . . . . . . 44

Check, Test and Start Procedures. . . . . . . . . . . . . . . . . 46

Before Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Fan Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Economizer Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . 47

Cooling System Start-up . . . . . . . . . . . . . . . . . . . . . . 47

Heating System Start-up . . . . . . . . . . . . . . . . . . . . . . 47

Air Balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Final Control Settings . . . . . . . . . . . . . . . . . . . . . . . . . 50

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . 55

Unit Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Gas Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Bearing Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Setscrews . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Supply Fan Wheel-to-Funnel Alignment . . . . . . . . . . 57

Winterizing Winter Coils . . . . . . . . . . . . . . . . . . . . . . . 57

Service and Warranty Procedure . . . . . . . . . . . . . . . . . . 58

In-Warranty Return Material Procedure . . . . . . . . . . . 58

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Product Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Installation and maintenance are to be performed only by qualified personnel who are familiar with local codes

and regulations, and experienced with this type of equipment. Caution: Sharp edges and coil surfaces are a

potential injury hazard. Avoid contact with them.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com