MCR Technologies Weigh Shark TLO User manual

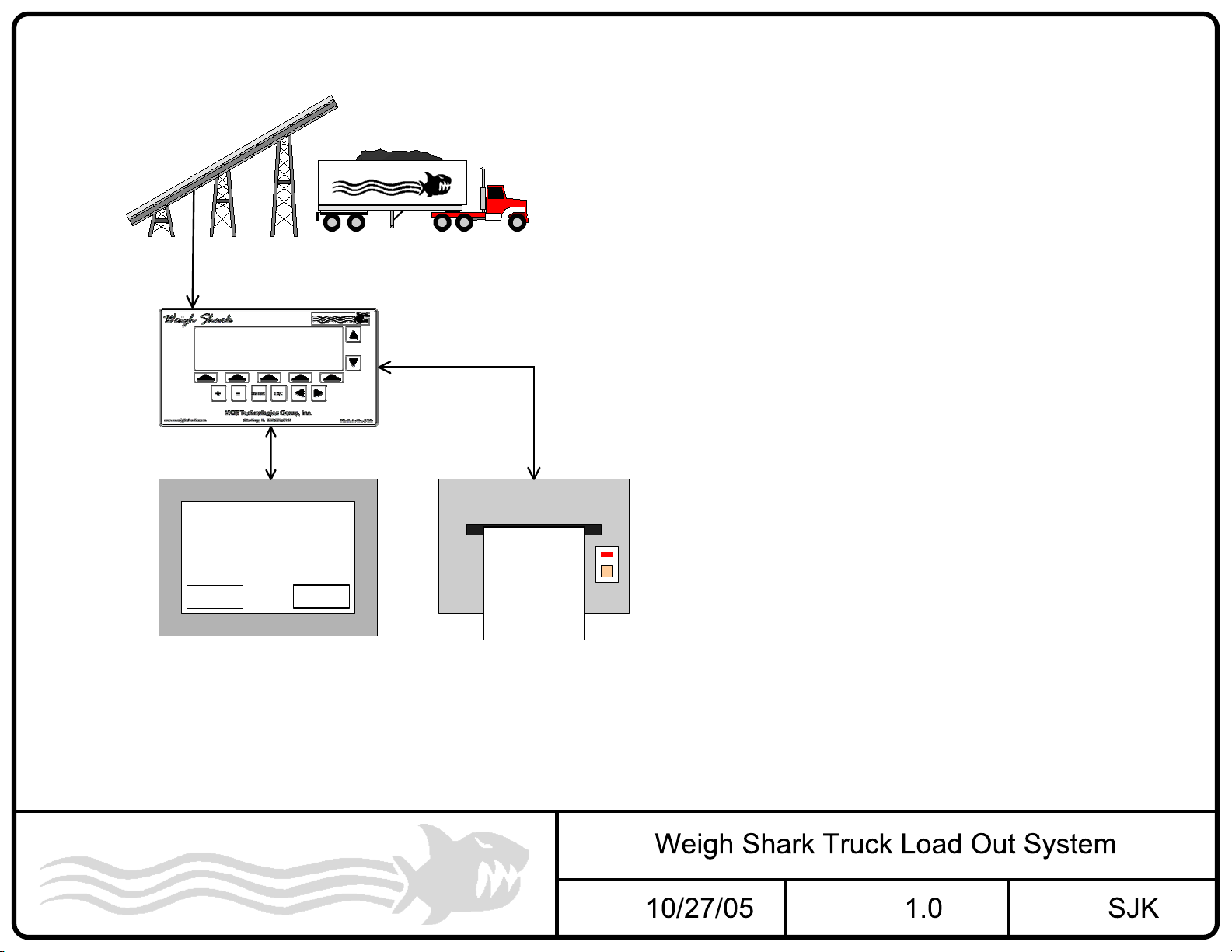

Truck Load Out

MCR Technologies Group, Inc.

P.O. Box 1016

Sterling, IL. 61081

815.622.3181

www.weighshark.com

12/17/2018

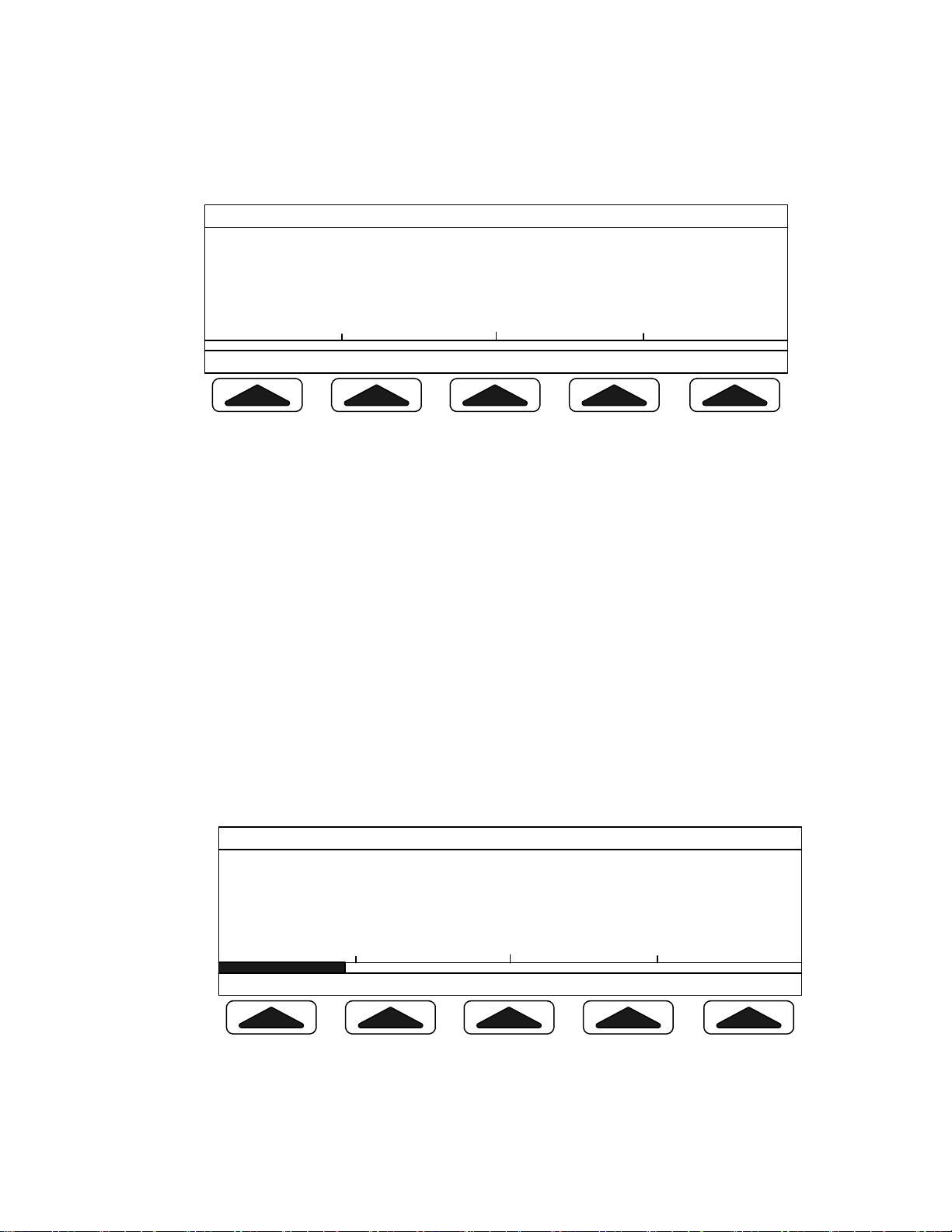

Scale 1

Truck ID: ACME1234

Weight: 75.25 tons

Target Weight: 75.25 tons

CLEAR

Basic Operation

Step 1:

Clear Weight.

Step 2:

Enter Target weight.

Step 3:

Enter Truck IDNumber.

Step 4:

Start Conveyor.

Step 5:

Scale stops conveyor or Feeder

when it reaches the Target weight.

Step 6:

Print Ticket which includes ID No.

6" Mono-Chrome or Color Touch

screen

Date: REV: By:

Truck ID: ACME1234

Weight: 75.25 tons

Fill Time: 8.5 min

ACME Materials

(123) 555-1212

Ticket Printer

PRINT

MCR Technologies Group, Inc.

P.O. Box 1016

Sterling, IL 61081

Ph. 815-622-3181 Fax. 815-622-0819

Email: [email protected]

TLO Setup Guide

TLO Integrator Setup for Ethernet

1. Ensure Crossover Cable is installed to TLO Ethernet port

2. Verify IP Address on TLO is 192.168.0.99. If not, it will NOT communicate with the Integrator.

3. On Integrator, scroll up to Truck Load-Out Setup > press ENTER

4. On 1st line, press (+) or (-) to turn TLO ON

5. Scroll down to cutoff > press ENTER then press EDIT

6. Set value to desired amount (ex: 0.25 Tons) > press APPLY

7. Scroll to MIN TARGET > press ENTER then press EDIT

8. Set to desired value (ex. 2.00 Tons) > press APPLY

9. Scroll to MAX TARTGET > press ENTER then press EDIT

10. Set to desired amount (ex: 10.00 Tons) > press APPLY

11. Press EXIT

TLO Setup

1. Press TARGET WEIGHT

2. Set target weight (ex: 4.00 Tons) > press ENTER

3. Press START

Ethernet

Crossover Cable

TLO Setup Guide

TLO Integrator Setup for RS 485

1. Press I/O

2. Scroll down to Serial Ports > press ENTER

3. Go to RS 485 > press ENTER then press EDIT

4. Press (+) to scroll to MODBUS RTU > press APPLY

5. Press SETUP

6. Scroll up to Truck Load-Out Setup > press ENTER

7. On 1st line, press (+) or (-) to turn TLO ON

8. Scroll down to cutoff > press ENTER then press EDIT

9. Set value to desired amount (ex: 0.25 Tons) > press APPLY

10. Scroll to MIN TARGET > press ENTER then press EDIT

11. Set to desired value (ex. 2.00 Tons) > press APPLY

12. Scroll to MAX TARTGET > press ENTER then press EDIT

13. Set to desired amount (ex: 10.00 Tons) > press APPLY

14. Press EXIT

TLO Setup

1. Press TARGET WEIGHT

2. Set target weight (ex: 4.00 Tons) > press ENTER

3. Press START

RS 485

Circuit Board

TLO Example

The following is an example Truck Load out set up. The system

will do the following:

•Target Weight must be between 5 and 25 tons.

•A new Target Weight must be entered after every truck.

•The feeder will be shut off .25 tons before the Target Weight is

reached.

•The Truck Fill Timer will accumulate until the loading is complete

and the weight is cleared.

•Use an external push button, wired to Input 4, to Start the

loading.

•Wire the feeder to Output 1.

•Touch screen will be used to control truck load out.

Software settings:

•Setup>Truck Load Out Setup menu

oTruck Load Out = ON.

oRequire Truck ID = NO

oClear ID on Complete = NO

oRequire Input = NO

oAuto Print Ticket = NO

oAuto Clear Target = YES

oStop Time On = Clear

oCutoff = .25

oMin. Target = 5

oMax. Target = 25

•I/O>Inputs>Input 4

oFunction = Truck Load Out Start

oWhen Input is: = ON

oFilter Preset = 50ms

•I/O>Outputs>Output 1

oFunction = Truck Cutoff

oAction = ON

Hardware Settings:

•Wire push button to Input 4

•Wire feeder relay to Output 1

Operation

1. Enter Target Weight.

2. Press Start push button or Start on touch screen. Truck accumulator will clear

to 0.00 and Output 1 will turn ON.

3. When the Truck accumulator is .25tons from Target Weight Output 1 will turn

Off.

4. Press Clear to complete load. This will also clear the Target weight to 0.00.

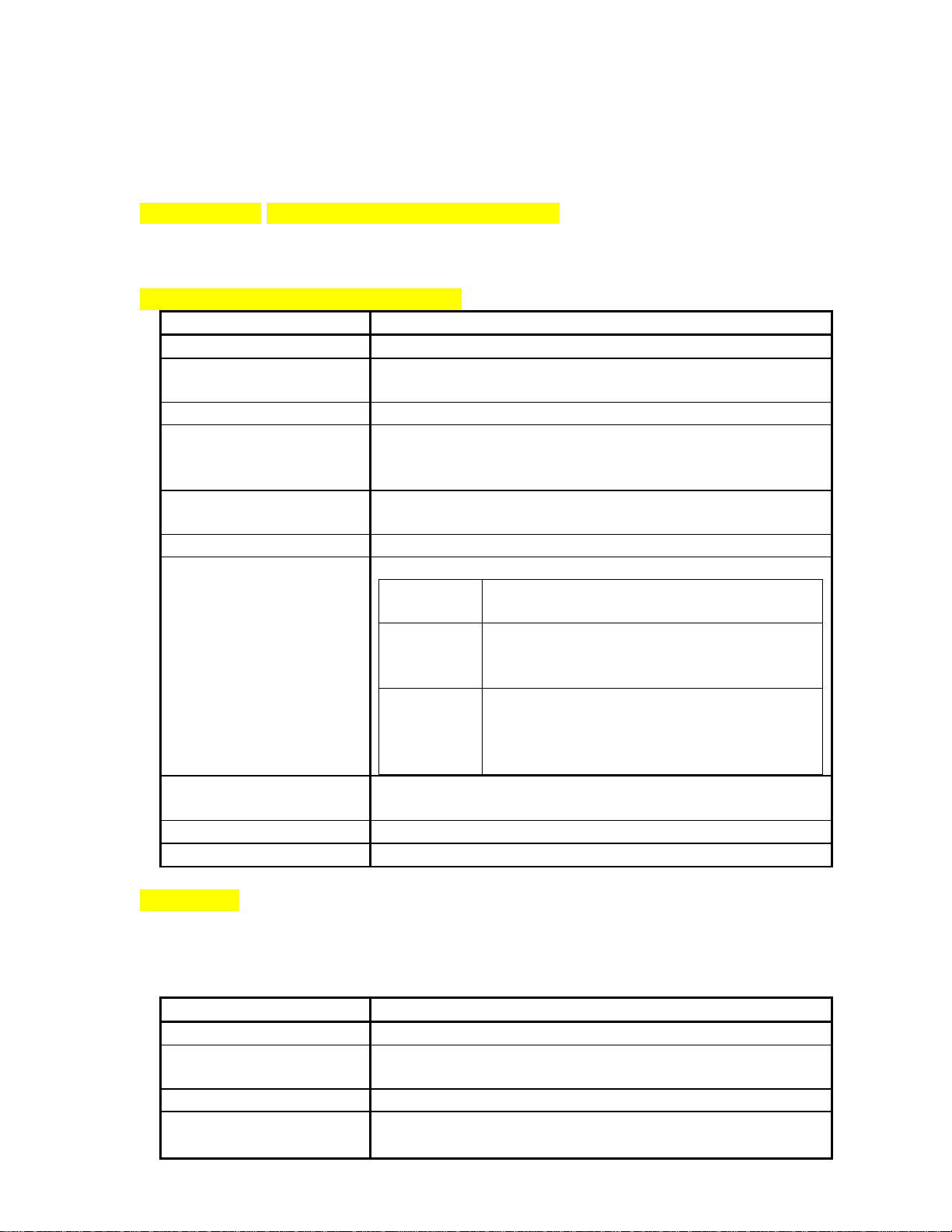

Truck Load Out (TLO)

The TLO software can be configured to work with the scale keypad, external

touch screen, external push buttons or a combination of the above. The TLO uses

its own accumulator so there is no conflict with any of the 4 main totalizers.

Programming Setup at the Belt Scale Integrator

Settings for the TLO system can be found at Setup>Truck Load Out Setup

menu.

SETUP>Truck Load Out Setup Menu

Setting

Description

Truck Load Out On/Off – Enables the Truck Load Out system.

Require Truck ID On/Off – Requires a Truck ID to be entered before

the load can begin.

Clear ID on Complete On/Off – Clears Truck ID at completion of load.

Require Input On/Off – Requires a digital input to be activated

before the load can begin. The input and configured

in the I/O menu.

Auto Print Ticket On/Off – Automatically print a truck ticket on

completion of load. Requires optional ticket printer.

Auto Clear Target On/Off – Clear Target weight at completion of load.

Stop Timer On Controls Truck fill timer.

Output Truck fill timer is stopped when the

Truck Output turns off.

Clear Truck fill timer is stopped when the

load is complete and the operator

Clears the weight.

Min. Rate Truck fill timer accumulates time only

when the Rate is above the Minimum

Rate setting found in the

SETUP>Calibration Setup menu.

Cutoff The amount to subtract from the Target weight to turn

off the Cutoff output.

Min. Target Minimum allowable Target weight

Max. Target Maximum allowable Target weight

TLO Inputs

Any of the 4 digital Inputs can be configured for the following functions. Inputs

can be configured under I/O>Inputs menu.

I/O>Inputs

Function

Description

Truck Load Out Clear Clears Truck accumulator when the load is complete.

Truck Load Out Stop Stops the truck load out process and turn off outpu

ts.

(This should NOT be used as an E-Stop.)

Truck Load Out Start Starts the Truck load out process

Truck Load Out Enable

If setting Require Input = ON then this input needs to

be ON for truck load out to start.

TLO Outputs

Any of the 4 digital Outputs can be configured for the following function.

Outputs can be configured under I/O>Outputs menu.

I/O>Outputs

Function

Description

Truck Output

On when loading starts, off when Target weigh is reached.

Truck Ready All the requirements are met for the loading to start.

Truck Done On when accumulator reaches Target Weight – Truck Cutoff

weight.

Truck Cutoff On when loading starts, off when Target Weight – Truck Cutoff

Weight is reached.

TLO output function table.

Truck Output

Truck Ready

Truck Done

Truck Cutoff OFF

OFF

OFF

OFF

ON

ON

ON

ON

A B C D E

ATarget Weight > 0 and

Target Weight <= Max Target and

Target Weight >= Min Target and

Truck ID Entered* and Truck Input ON*

BStart

CTruck Weight >= Target Weight - Cutoff Weight

DTruck Weight >= Target Weight

EClear

*When Enabled

GND

Output 1

Output 2

Output 3

Output 4

+24Vdc

General Purpose

Outputs

100mA Sinking Max

at 24Vdc*

Truck Load Out Control Wiring

Date: 6/23/05 REV: 1.0 By: SJK

MCR Technologies Group, Inc.

P.O. Box 1016

Sterling, IL 61081

Ph. 815-622-3181 Fax. 815-622-0819

Email: [email protected]

CR

* 100mA Max

current draw on all

24Vdc sources

combined

Existing Conveyor or Feeder

Start/Stop Circuit

MC1

STOP

CR

CR - Customer supplied

24Vdc coil control relay.

START

MC1

TLO Operation with Scale Screen (Weigh Shark integrator)

When the TLO system is Enabled there are 2 extra options under the VIEW

menu, Truck Total and Trucks. Use the ▲and ▼keys to move the cursor to the

Truck Total option and press ENTER. This will open the Truck Load out screen.

Tr uck Loadout

>Tr uck I D: ACME01

Tar get : 15. 00t ons

Tot al : 0. 00t ons Rat e: 0. 00t ph

Ready - Pr ess St ar t

St ar t EXI T

1. Enter Truck ID. Use the ▲and ▼keys to move the cursor to Truck ID. Press

ENTER to open the Truck ID edit screen. Press button under EDIT to begin

editing the Truck ID. Use the + and – keys to change the value. Use the ◄

and ►keys to move between each column. Press APPLY to apply settings

and exit.

2. Enter Target weight. Use the ▲and ▼keys to move the cursor to Target.

Press ENTER to open the Target edit screen. Press button under EDIT to

begin editing the Target weight. Use the + and – keys to change the value.

Use the ◄and ►keys to move between each column. Press APPLY to apply

settings and exit.

If Target weight is between the Maximum and Minimum settings then the

screen will display “Ready – Press Start”. If setting, Require Truck ID, is set to

ON then a Truck ID will be required before load can begin. If setting, Require

Input, is set to ON then the input configure as Truck Load Out Enabled must be

ON before the load can begin.

3. Press button under Start to clear the accumulator and begin loading truck.

Press Stop at anytime to stop the loading process.

Tr uck Loadout

>Tr uck I D: ACME01

Tar get : 15. 00t ons

Tot al : 3. 40t ons Rat e: 325. 23t ph

Loadi ng. . .

St op EXI T

4. When Loading is completed press Clear to complete load. If setting, Clear

Truck ID, is set to ON the Truck ID will be cleared. If setting, Auto Clear

Target, is set to ON then the Target weight will also be cleared.

Tr uck Loadout

>Tr uck I D: ACME01

Tar get : 15. 00t ons

Tot al : 15. 00t ons Rat e: 0. 00t ph

Tr uck Ful l - Pr ess Cl ear

Cl ear EXI T

5. Truck Load out is complete; the system is ready for the next truck.

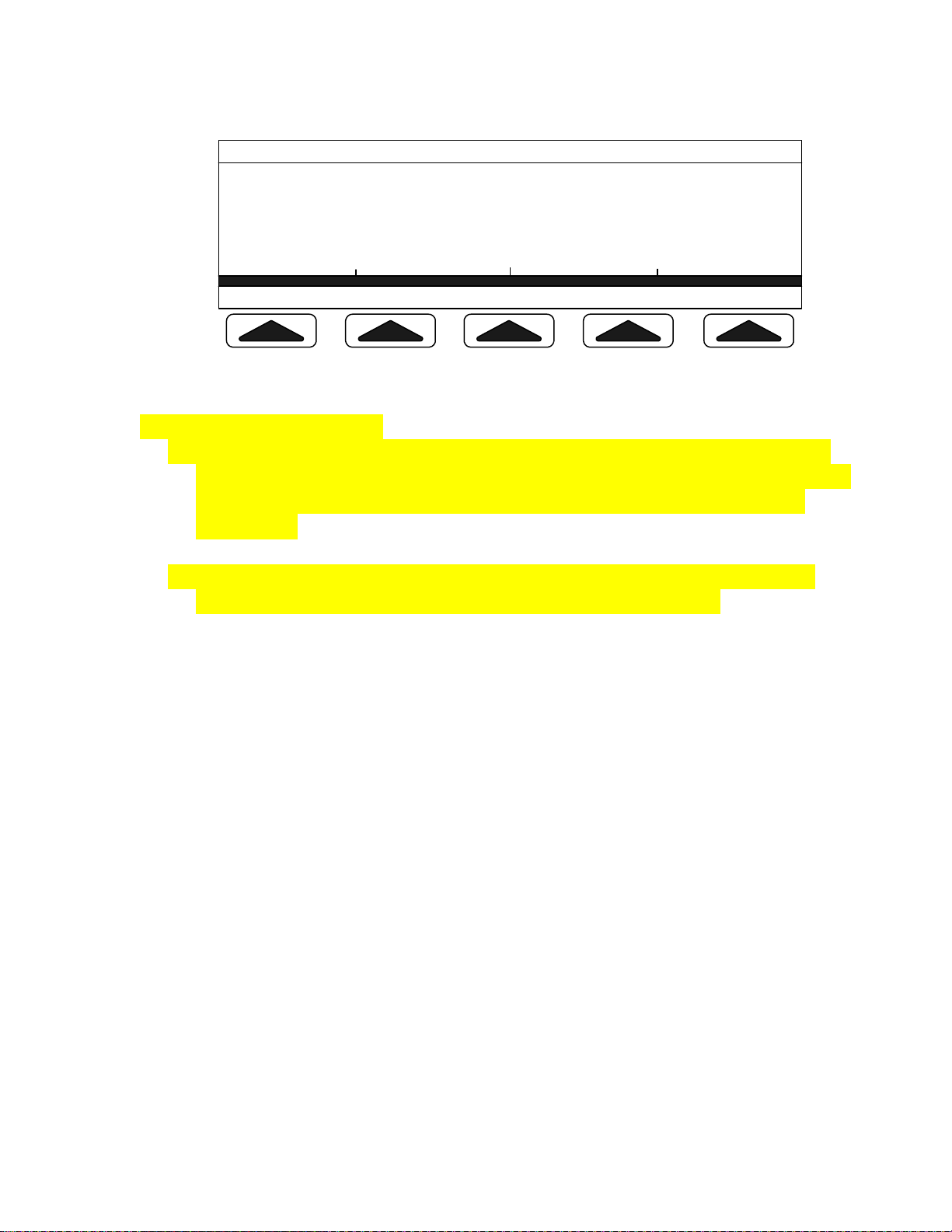

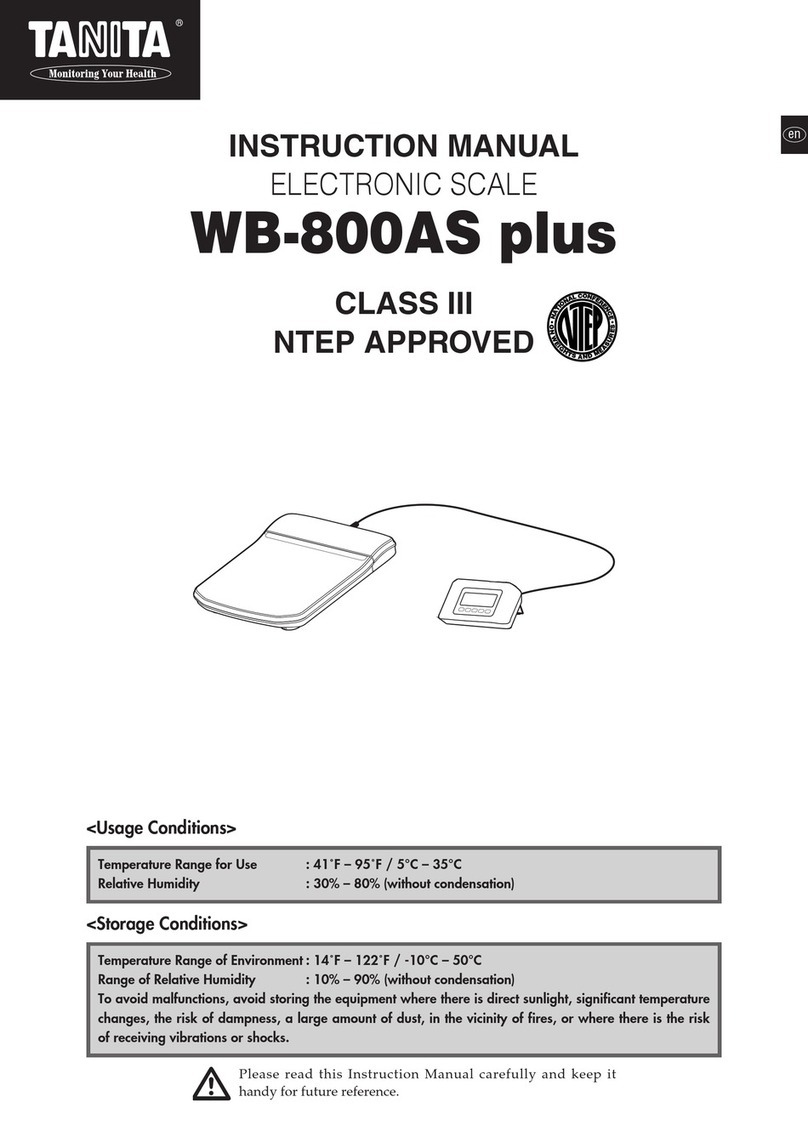

TLO with COLOR Touch Screen

1. Enter Truck ID. Press the Truck ID Button on touch screen to

edit the Truck ID. Press ENT in the top left corner of the screen

to accept changes. If you are not tracking by Truck # go to

next step.

2. Enter Target Weight. Press the Target Weight button to edit

the Target Weight. Press Enter to accept changes.

If Target weight is between the Maximum and Minimum

settings then the screen will display “Ready – Press Start to

continue”. If setting, Require Truck ID, is set to ON then a

Truck ID will be required before load can begin. If setting,

Require Input, is set to ON then the input configure as Truck

Load Out Enabled must be ON before the load can begin.

3. Press Start button to clear accumulator and begin loading

truck. Press Stop at anytime to stop the loading process.

Display will now show the loading process.

4. When Loading is completed press Clear to complete load. If

setting, Clear Truck ID, is set to ON the Truck ID will be cleared.

If setting, Auto Clear Target, is set to ON then the Target weight

will also be cleared.

5. Truck Load out is complete; the system is ready for the next

truck.

6. Addition Screens show history for the loading.

TLO Truck Summary Screen at scale integrator.

Under the VIEW menu of the scale integrator use the ▲and ▼keys to move

the cursor to the Trucks option and press ENTER. This will open the Trucks

Summary screen.

Page 1 >Tr ucks: 13

Tot al Wei ght : 194. 25t ons

Tot al Fi l l Ti me: 1. 34hr s

Avg Tr ucks/ Hour : 9. 70

Cl ear EXI T

Page 2 >Avg Tr uck Wei ght : 14. 94t ons

Avg Fi l l Ti me: 6. 18mi n.

Avg Tar get Er r or : 0. 06t ons

Avg Rat e: 145. 05t ph

Cl ear EXI T

Page 3 >Last Cl ear 03: 35 11/ 10/ 2005

Cl ear EXI T

Pressing Clear will clear the Truck summary and change the Last Clear value to the

current time and date. The information will update at the completion of every truck

load.

Other MCR Technologies Scale manuals

Popular Scale manuals by other brands

Tanita

Tanita WB-800AS plus instruction manual

Rice Lake

Rice Lake INT700 Technical manual

Torbal

Torbal AD Series Quick reference guide

KERN

KERN FCB 6K-5 operating instructions

Precision Weighing Balances

Precision Weighing Balances PWBWS 3 instruction manual

Beurer

Beurer Personenwaage PS 06 Series operating instructions