Page 1 of 7

INTRODUCTION

The MSI-6260CS Series crane scales are best calibrated using a remote indicator such as the MSI-

3750CS, MSI-9850, or the MSI-9750A Handheld. Calibration procedures using these devices are covered

in their respective User Guides. If above listed remote devices are not in use with the MSI-6260CS, the

only way to calibrate it is through the Comm. Port using the Terminal Access Mode. MSI recommends

having test weights of at least 50% capacity to properly calibrate the Crane Scale. The calibration

procedures will operate with as little as 12.5% of capacity, though rated accuracy cannot be guaranteed.

For details of Multi-Point, Certified, or other specialized calibrations, refer to full version of MSI-6260CS

User’s Guide.

The following procedure describes how to perform a standard, single point

calibration for a single load cell MSI-6260CS Crane Scale. Some menu items may

appear slightly different than shown, depending upon actual software application

version. However, those relative to Scale Calibration are accurate.

REQUIRED EQUIPMENT:

1) PC or terminal with terminal program and RS-232 serial port.

2) Serial Communications cable, PN: 501705-0001.

3) Known calibration test weight between12.5 and 100% of the scale’s capacity.

ACCESSING EMBEDDED CELL SCALE

The MSI-6260CS Crane Scale is controlled by an embedded MSI-9000 CellScale. All scale functions

& operating parameters are stored within the MSI-9000.

1) Set the terminal program to emulate an ASCII terminal.

2) Set the terminal programs port protocol to 9600 Baud, no parity, 8 data bits and 1 stop bit.

3) Disable flow control in the terminal program.

4). Turn scale ON.

5). Connect the MSI-6260CS comport to the PC serial port with the 501705-0001 serial cable.

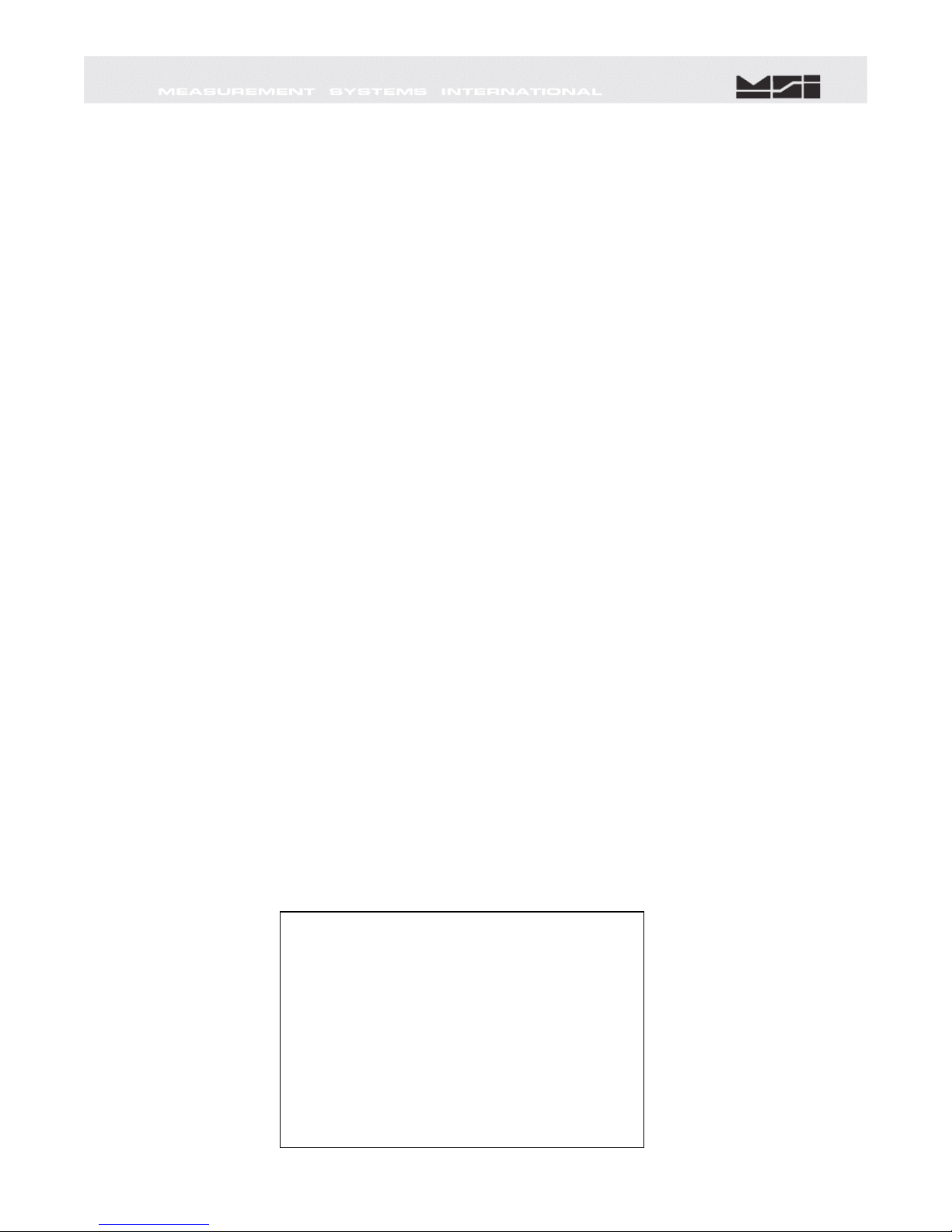

6). From PC, press ENTER. Main Cell Scale Manu will appear.

Select Channels/Calibration press 1.

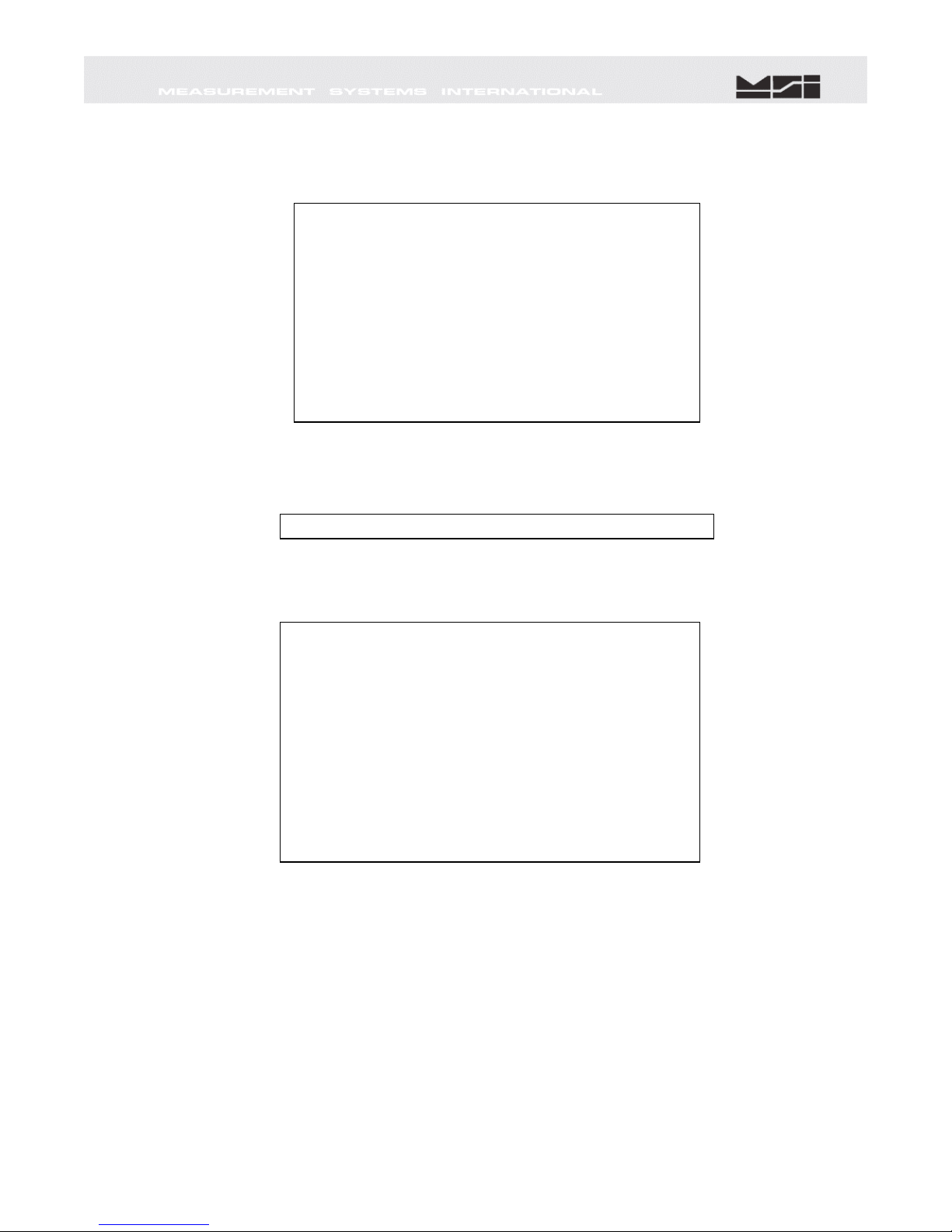

---------- MSI 9000 - CellScale ------------------------

-(c) 2005 Measurement Systems International -

----------------------------------------------------------------

13:48:06 01/01/08

(1) Channels/Calibration

(2) Communications

(3) Display

(4) Feature Locks/Passwords

(5) Product IDs

(6) Set Points

(7) System

(8) About...

Enter choice: