Medicus 2956M5 Parts list manual

HT485-INS-LAB-RevB14

1

2956M5 - PHYSICIAN MECHANICAL SCALE

ASSEMBLY AND OPERATION INSTRUCTIONS

PLEASE SAVE THESE INSTRUCTIONS FOR FUTURE USE

Tools required for assembly: Phillips screwdriver, wrench (included)

SAFETY GUIDELINES—PLEASE READ BEFORE USE

WARNING: Important! Read and understand these

instructions before assembling or using the Physician

Mechanical Beam Scale. Ensure the scale is assembled

as described in this document before use. If the scale

is not properly assembled and adjusted, personal injury

and/or damage to the scale could result.

WARNING:

DO NOT use this product without proper

instruction from a healthcare professional.

WARNING: If components are damaged or missing,

contact Medicus Health immediately. DO NOT use

substitute parts.

WARNING: Notice for California Customers- California

Proposition 65 WARNING: This product contains a

chemical known to the State of California to cause

cancer and reproductive or developmental harm.

WARNING: Medicus Health assumes no responsibility

for any damage or injury caused by improper assembly

or use of this product.

INTENDED USE

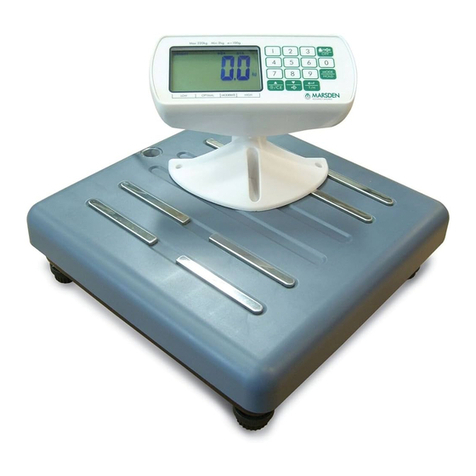

The intended use of the Physician Mechanical Beam Scale,

shown in Fig. 1, is the measurement of body weight and

height. It is ideal for use in health clinics and doctor practices.

The designation of this product meets the OIML international

Recommendation R76.

UNPACKING

Unless the scale is to be used immediately, retain box and

packaging materials for storage until use is required.

1. Carefully remove all components from the carton.

2. Inspect all components.

3. If damage is evident to the contents, please notify the carrier

and your GF authorized distributor.

ASSEMBLY

Refer to pictures at right during assembly.

Pillar Installation

1.

Set the scale base on a at, dry working surface such as a table.

2. Install the pillar in the scale base frame bracket, with scale

face facing platform, as shown in Fig. 2.

3. Install the eight bolts and washers that secure the pillar to the

scale base. Use a Phillips screwdriver to tighten the bolts.

wheel

pillar

platform

frame

height rod

weighing

ruler

Fig. 1: Physician

Mechanical Beam Scale

bolt

bolt

pillar

frame

bracket

accessory

poise weight

main poise weight

force lever

counterpoise

weight

zero poise

weight

zero

adjusting

screw

steelyard rod

pillar

head

weighing

ruler

Fig. 2: Pillar Installation

platform

frame

HT485-INS-LAB-RevB14

2

Steelyard Rod Attachment

1. Place the scale on a table or at working

surface as shown in Fig. 3.

2. The long lever extends through the

center of base length. Wires are wrapped

around the long lever at the factory,

securing it to the base, to prevent

movement during shipping. Wrapped

wire locations are shown in Fig. 3.

Remove and discard these wires.

3. Insert the wrench in the small hole in

front of the steelyard rod (the steelyard

rod is inside the pillar). Use the wrench

hook to pull the steelyard rod hook over

the long lever, as shown in Fig. 4 and 5.

4. Push the long lever frontward, then hook

the steelyard rod bearing on the long

lever pivot.

Info: Ensure the force lever assembly

linkage is centered and properly aligned.

The linkage must float freely in order for

the scale to weigh properly. To see the

linkage, tip the scale slightly to one side

and look up underneath the top weigh

beam.

5. Gently place the scale upright on the

oor.

Height Rod Installation

1. Install the height rod back-side slots

over the two pillar front-side bolts and

slide the height rod down until securely

attached to the pillar as shown in

Fig. 6 and 7.

2. Use the included wrench to tighten the

two hex head bolts as shown in Fig. 8. Do

not overtighten.

Wheel Installation

1. Align wheel bracket with scale platform

so that the wheel bracket side with holes

is against frame back and wheels face

outward.

2. Install the two screws and washers that

secure the wheels to the scale base as

shown in Fig. 9 and 10.

3. Ensure wheels are level.

4. Use Phillips screwdriver to tighten the

screws.

see Fig. 4

wrapped wire locations

Fig. 3: Steelyard Rod Attachment

Fig. 5: Steelyard

Rod Attached

to Long Lever

Fig. 4: Attach

Steelyard Rod

to Long Lever

wrench

wrench

steelyard rod

hook

long lever

Fig. 7: Height

Rod Attached

to Pillar

Fig. 8: Tighten

Attachment

Bolts

Fig. 6: Attach

Height Rod

to Pillar

height rod back slot

shown attached to

pillar front bolt

bolt

wrench

slot

(large end)

bolt

height

rod

pillar

Fig. 10

Wheels Attached

to Base

Fig. 9

Attach Wheels

to Base

bracket

base

wheel

platform

screws

frame

pillar

HT485-INS-LAB-RevB14

3

Counterpoise Weight Installation

1. Position the main poise weight in the slot at

390 lb / 180 kg, and position the accessory poise

weight at zero, as shown in Fig 11.

2. Position the 50 lb / 20 kg counterpoise weight in

the rst slot, as shown in Fig. 12 and Detail A.

3. The scale capacity is now 490 lb / 220 kg.

OPERATION

Info: Ensure scale is on a level, stable surface

when in use. Do not place the scale on a soft

surface such as carpet; this could result in

inaccurate weight measurement.

Moving the Scale

1. Hold the two pillar side faces to keep the front side of the platform away from the ground and

rotate the scale backward.

2. Roll scale carefully on both wheels.

3. Return the scale gently to upright position.

CLEANING AND MAINTENANCE

• Toremovedustanddirt,wipescalegentlywithaclean,soft,dampcloth.

• Todisinfect,wipescalegentlywithaclean,soft,clothdampenedwithdisinfectant.

Zero Adjustment

To ensure accurate weight measurement, zero adjustment should be performed after assembly

and before use.

1. Ensure the scale is on a level, at surface.

2. Check the scale’s eye loop area— ensure the scale pointer is equally balanced between the top

and bottom of eye loop area. Gently use your nger to hold the scale pointer until it touches

the bottom of the eye loop area. Release the scale pointer and let it move freely up and down

within the eye loop area until it settles in the eye loop area center.

3. If the scale does not settle in the center of the eye loop area (it is not balancing properly),

adjust the small zero balance weight. Use a screwdriver to turn the zero adjusting screw; this

will cause the zero balance weight to move accordingly.

Info: When the scale pointer settles in the center of the eye loop area, it is properly

balanced.

TROUBLESHOOTING

Problem Solution

Zero balance of

beam

The weigh beam must be balanced so that the scale pointer comes to rest in the center of the eye loop area when both

poise weights are set at zero. Adjust the balance by turning the zero adjusting screw at the left end of the weigh beam.

Beam does not move

freely

1. Ensure the beam pointer is not touching the side of the eye loop.

If the beam pointer is touching the side of the eye loop, proceed to step 2.

2. Ensure the linkage is centered and properly aligned. The linkage must oat freely in order for the scale to measure

weight accurately. To see the linkage, tip the scale slightly to one side and look up underneath the top weigh beam.

Scale platform rocks

excessively

When you push down on any corner of the platform, you should not feel any signicant rocking. Ensure the scale is always

installed on a level, stable surface. Do not place the scale on a soft surface such as carpet.

Beam does not

move during weight

measurement

1. The poise weights may be set to a higher weight than the person’s actual weight: Reset the weights to a lower weight.

2. Ensure the steelyard rod is properly connected and aligned as previously described.

Fig. 11 Fig. 12

Detail

A

See Detail

A

HT485-INS-LAB-RevB14

4

Made in China

SPECIFICATIONS

Maximum weight capacity 490 lb / 220 kg, using 50 lb / 20 kg counterpoise weight. See Counterpoise Weight Installation

Graduation 0.25 lb / 100 g

Height rod range 24 inch - 84 inch / 60 cm - 210 cm

Minimum value of height per division 0.25 inch / 5 mm

Platform size 14.76 inch x 10.83 inch / 375 mm x 275 mm

Overall dimensions (L x W x H) 20.87 inch x 10.83 inch x 58.46 inch / 530 mm x 275 mm x 1485 mm

LIMITED WARRANTY

SCOPE OF WARRANTY

Medicus Health warrants to the original purchaser only that it will replace or repair components, at our sole discretion, that are defective

in material or workmanship under normal use and service. All warranties are conditioned upon the proper use of the products strictly in

accordance with good commercial practice and applicable MH instructions and manuals, including proper use and maintenance. To the

extent that a component is warranted by a third party, MH conveys all of its rights under that warranty to the original purchaser, to the

extent permitted. This limited warranty shall only apply to defects that are reported to GF’s customer service team within the applicable

warranty period and which, upon examination by MHor its authorized representative, prove to be a warranty item. This limited

warranty is not transferable. Within the guidelines set forth in this document, this product is warranted for two years. The applicable

warranty period shall commence from date of shipment to the original customer, unless there is an expiration date on the component in

which case the warranty shall expire on the earlier of warranty period or the expiration date.

OBTAINING WARRANTY SERVICE

A Customer Service Representative must authorize warranty service. Please contact the Customer Service department by calling

877-514-1140, or by e-mailing a request to sales@medicus-health.com. Specific directions will be provided by the Customer Service

Representative. Failure to abide by the specific directions will result in denial of the warranty claim.

EXCLUSIONS

The warranty does not cover and GF shall not be liable for the following:

1) Defects, damage, or other conditions caused, in whole or in part, by misuse, abuse, negligence, alteration, accident, freight damage,

tampering or failure to seek and obtain repair or replacement in a timely manner;

2) Products which are not installed, used, or properly cleaned and maintained as required in the official manual for the applicable

product;

3) Products considered to be of a non-durable nature including, but not limited to: casters, filters, fuses, gaskets, lubricants, and

charts;

4) Accessories or parts not provided by MH;

5) Charges by anyone for adjustments, repairs, replacement parts, installation or other work performed upon or in connection with

such products which are not expressly authorized in writing, in advance, by GF;

6) Any labor or shipping charges incurred in the replacement part installation or repair;

7) Costs and expenses of regular maintenance and cleaning; and

8) Representations and warranties made by any person or entity other than GF.

ENTIRE WARRANTY, EXCLUSIVE REMEDY AND CONSEQUENTIAL DAMAGES DISCLAIMER

THIS WARRANTY IS GF’S ONLY WARRANTY AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED. GF MAKES NO IMPLIED

WARRANTIES OF ANY KIND INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

IF ANY MODEL OR SAMPLE WAS SHOWN TO THE CUSTOMER, SUCH MODEL OR SAMPLE WAS USED MERELY TO ILLUSTRATE THE

GENERAL TYPE AND QUALITY OF THE PRODUCT AND NOT TO REPRESENT THAT THE PRODUCT WOULD NECESSARILY CONFORM

TO THE MODEL OR SAMPLE IN ALL RESPECTS. THIS WARRANTY IS LIMITED TO THE REPAIR OR REPLACEMENT OF THE DEFECTIVE

PARTS. GF SHALL NOT BE LIABLE FOR AND HEREBY DISCLAIMS ANY DIRECT, SPECIAL, INDIRECT, INCIDENTAL, EXEMPLARY OR

CONSEQUENTIAL DAMAGES, INCLUDING, BUT NOT LIMITED TO: DAMAGES FOR LOSS OF PROFITS OR INCOME, LOSS OF USE,

DOWNTIME, COVER, OR EMPLOYEE OR INDEPENDENT CONTRACTOR WAGES, PAYMENTS AND BENEFITS.

The warranties contained herein contain all the representations and warranties with respect to the subject matter of this document,

and supersede all prior negotiations, agreements and understandings with respect thereto. The recipient of this document hereby

acknowledges and represents that it has not relied on any representation, assertion, guarantee, warranty, collateral contract or other

assurance, except those set out in this document.

For additional information on this product or this warranty, please contact a Customer Service Representative.

NOTES:

1) Additional terms and conditions may apply.

2) Freight claims must be notated on the Bill of Lading and must be made with immediacy. The ICC regulations govern specific

requirements for freight claims. Failure to abide by those regulations may result in a denial of the freight claim. MH will assist you

in filing the freight claim.

3) Claims for any short shipment must be made within thirty (30) days of the invoice date.