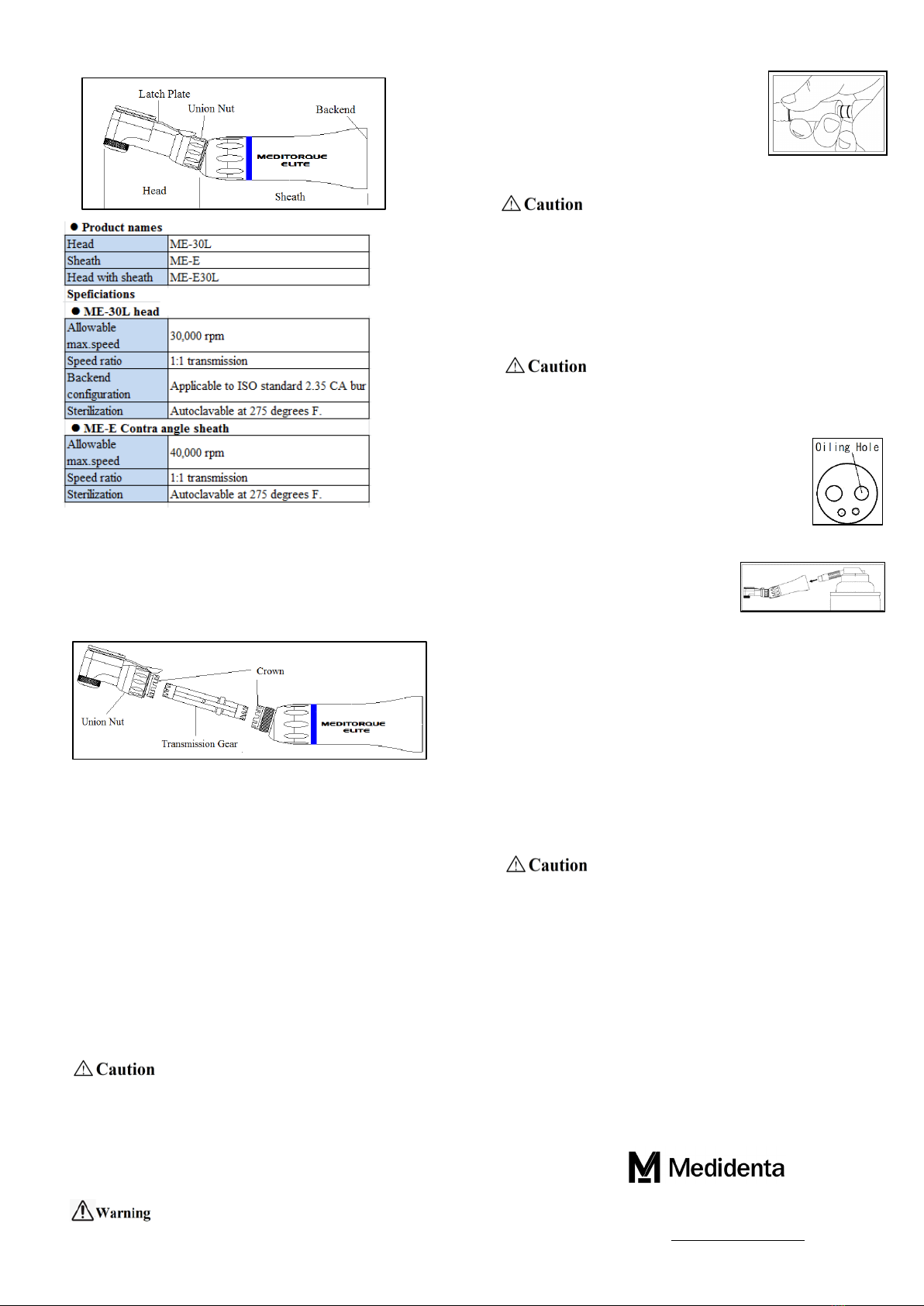

3. ME-E30L E-type Contra angle

3-1. Description of parts and specifications

The head is replaceable. The following heads are available:

ME-20ML…..Miniature latch head, 20k rpm

ME-40L……..Latch head, 40k rpm

E-40LP……...Latch head, pushbutton type, 40K rpm

ME-40FGP… FG head, pushbutton type, 40K rpm

3-2. Removal/installation of head from/into sheath

Removal:

Swing the latch plate out.

Remove the head from sheath, turning the union nut

counterclockwise.

Pull the transmission gear out from the head.

Installation:

Insert the transmission gear into the head. Engage the crown of

the head with that of contra angle sheath, then turn the union

nut.

3-3. Installation/removal of bur onto/from head

Install the head into the sheath. Install it onto the air-motor.

Swing the latch plate out.

Insert a bur into chuck hole all the way until the end of bur

shank touches the back of the chuck. Swing the latch plate back

until it is locked with a snap at center position of the collar of

the contra angle head.

Remove the bur by following these steps in reverse order.

Make sure that the bur is securely installed onto the head onto

Make a trial run before use.

The replacement of the but must be executed after the contra

angle us installed onto the air-motor.

The ISO standard 2.35 CA bur must be used. Do not

use a worn-out bur, as excess pressure will be applied to the

chuck assembly.

When the air-motor and attachments are used, take the

patients’ safety primarily into consideration.

4. Installation/removal of nosecone and contra angle (attachment)

onto/from air-motor.

Installation:

Insert the sleeve of the air-motor into the

backend of the attachment all the way until

it is securely locked with a snap.

Removal:

Hold the air-motor with one hand and the

attachment with the other hand.

Pull the attachment out from the air-motor.

Do not separate the overlapped hands

until the Lock is released.

5. Lubrication

Medidenta recommends I-Spray for lubrication. The air-motor, nose

cone and contra angle handpiece must be lubricated after each use and

each autoclaving.

Neglecting to lubricate or lack of lubricating oil may cause

premature failure. This would be considered a misuse and will void

the warranty.

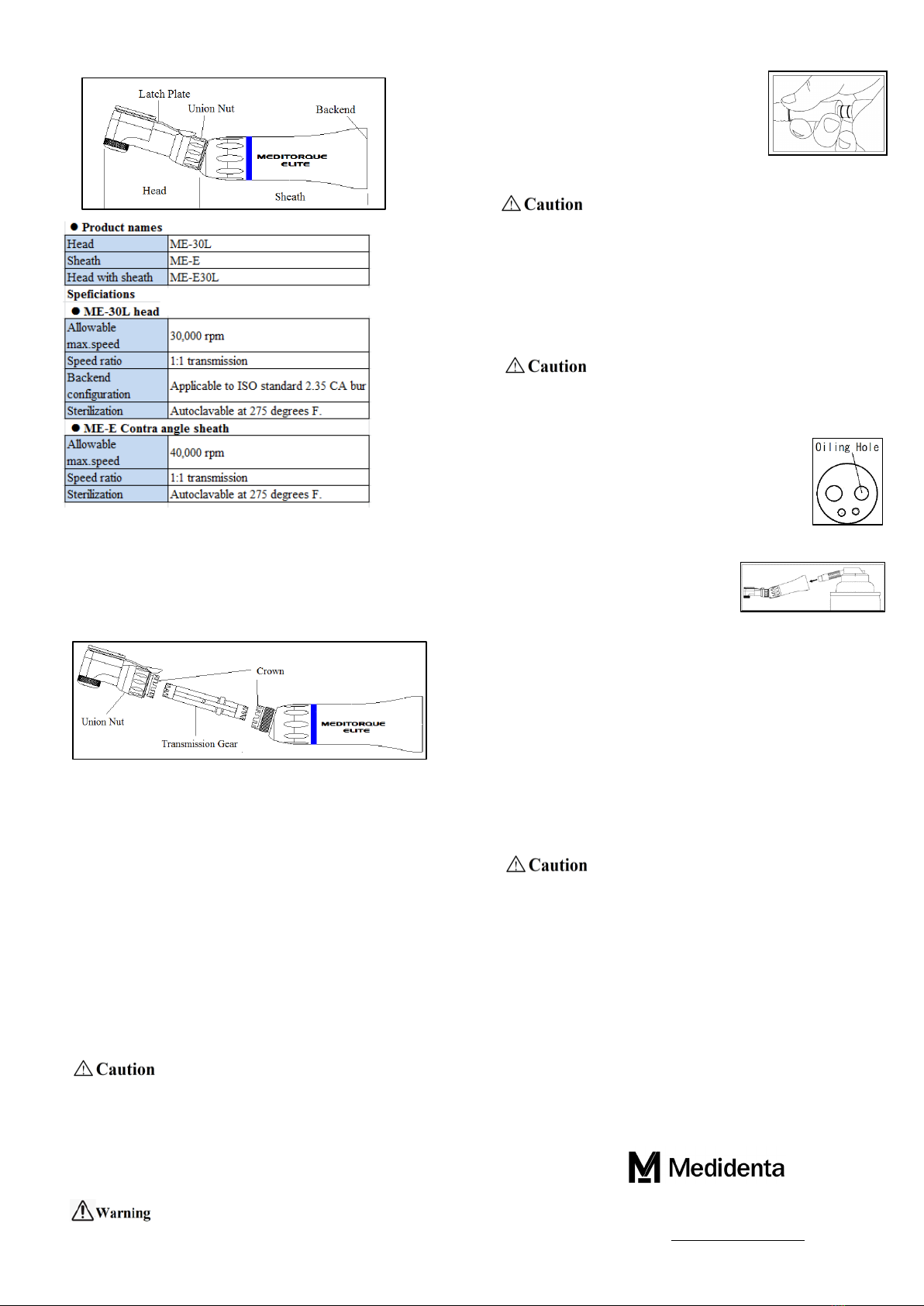

5-1. Air-motor

Remove the straight nose cone or the contra angle

handpiece from the air-motor.

Inject the handpiece spray for a few seconds into

the oiling hole (drive-air pipe) as indicated to the

right.

5-2. Nose cone and contra angle (attachment)

Inject the handpiece spray for a few

seconds into the backend of the nose

cone or contra angle as indicated

below:

Use the spray nozzle provided with your purchase of

After lubrication make a trial run.

6. Sterilization

Medidenta recommends autoclave sterilization only. For the first

use, the air-motor, nose cone and contra angle must be sterilized.

Before sterilization, clean the surface of the air-motor, nose cone and

contra angle with a damp cloth. Lubricate them. As for the contra

angle, remove the head from the sheath.

Put them individually into a sterilization pouch.

Autoclave them at 275 degrees F. for 20 minutes.

Allow a minimum of 20 minutes for the drying cycle.

Do not use dry heat sterilization or cold sterilization.

Do not use chemicals to clean the handpiece.

Do not immerse the air-motor in ultrasonic bath or boiling

wa ter.

7. Warranty

Manufacturer warranties the motor for 12 months, the contra angle for 3

months and the nose cone for 10 months. Warranty is subject to

observance of the maintenance instructions, cautions, and normal use.

Note:

Medidenta and the manufacturer reserve the right to analyze and

determine the cause of any failure. Warranty is void, if breakage,

accident, or any other issues are caused by the neglect of

maintenance, cautions, warnings or unauthorized repairs.

Manufacturing for:

3575 W. Post Road, Las Vegas, NV 89118

U.S.A.

E-mail: orders@medidenta.com

Toll free #1-800-221-0750