MEDO LA-28B User manual

Printed in Thailand

For Maintenance Operators

LA type Medo Compressor for Septic Tank (blower),

Spare Parts Replacement Manual

/$$/$%/$(/$$/$%/$(+(0/$%

CAUTION Please read this manual carefully and fully understand the contents

before maintenance and management.

Manufacturer : NITTO KOHKI CO., LTD.

9-4, Nakaikegami 2-Chome, Ohta-ku,

Tokyo, 146-8555, Japan

Tel : 81-3-3755-1111

Fax : 81-3-3753-8791

URL : http://www.nitto-kohki.co.jp/e/

Distributor : U.S.A :

NITTO KOHKI U.S.A., INC.

46 CHANCELLOR DRIVE,

ROSELLE, ILLINOIS 60172, U.S.A.

Tel : +1-630-924-8811

Fax : +1-630-924-0808

www.nittokohki.com

Europe :

NITTO KOHKI EUROPE GMBH

GOTTLIEB-DAIMLER-STR. 10,

71144 STEINENBRONN,

GERMANY

Tel : +49-7157-989555-0

Fax : +49-7157-989555-40

www.nitto-kohki.eu/

NITTO KOHKI EUROPE GMBH UK Branch

UNITA5, LANGHAM PARK

INDUSTRIAL ESTATE, MAPLE ROAD,

CASTLE DONINGTON,

DERBYSHIRE, DE74 2UT,

UNITED KINGDOM

Tel : +44-1332-653800

Fax : +44-1332-987273

www.nitto-kohki.eu/

Safety Caution Be sure to observe the following

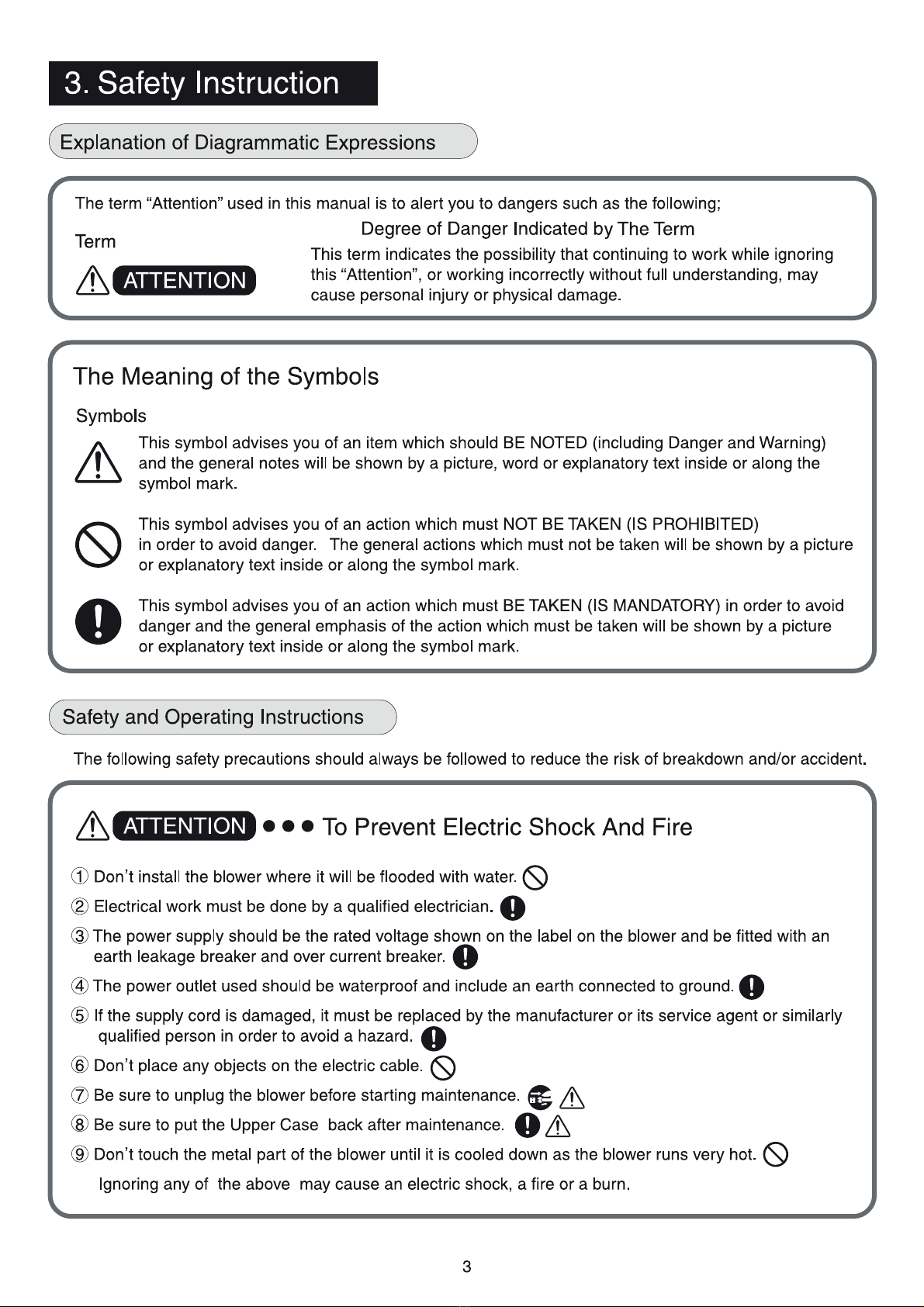

Description of pictorial indication (term and indications)

Be aware that the term (caution) used in this manual indicates danger as follows:

Term Level of danger indicated by the term

CAUTION This term indicates the supposed possibility of injury or property damage

if an operation is performed in disregard of this caution or a wrong

RSHUDWLRQLVSHUIRUPHGZLWKRXWVXI¿FLHQWXQGHUVWDQGLQJRIWKLVFDXWLRQ

Be aware that the symbols used in this manual are described as follows:

Symbol Indication of symbol

This symbol informs you that there is a description to call attention to a hazard (danger /

warning included). The detailed contents (general caution in the case at left) are described

in or near this symbol with a picture, a term, a directive statement, or the like.

This symbol informs you of (prohibited) acts to avoid danger. The detailed prohibited

acts (general prohibited act in the case at left) are described in or near this symbol with a

picture, a directive statement, or the like.

This symbol informs you of (compulsory) acts to be surely required to avoid danger.

The detailed acts to be surely required (general compulsory act in the case at left) are

described in or near this symbol with a picture, a directive statement, or the like.

Items requiring extra attention

CAUTION Prevention of electrical shock and ignition accident

①Do not install the blower where there is a risk that the blower is submerged or covered

with snow.

②For the blower power supply, use a waterproof electric outlet.

③For the power supply, use 100 VAC with a ground fault interrupter and an overcurrent

circuit breaker equipped.

④The electric work must always be conducted by an expert engineer.

⑤Do not place anything within approximately 50 cm from the blower.

⑥Do not put anything on the power cord.

⑦Be sure to disconnect the power plug from the electric outlet before disassembling the

blower.

⑧Be sure to put the removed top cover back after inspecting the blower.

⑨%HVXUHWRSXWWKHUHPRYHG¿OWHUFRYHUEDFNDIWHULQVSHFWLQJWKHEORZHU

)DLOXUHWRREVHUYHWKHVHFDXWLRQVPD\FDXVHDQHOHFWULFVKRFNDFFLGHQWRUD¿UH

⑩Be sure to wear working gloves or the like at disassembly or repair.

Failure to observe this may cause a burn.

Be sure to observe the following to prevent a malfunction or an accident with the blower.

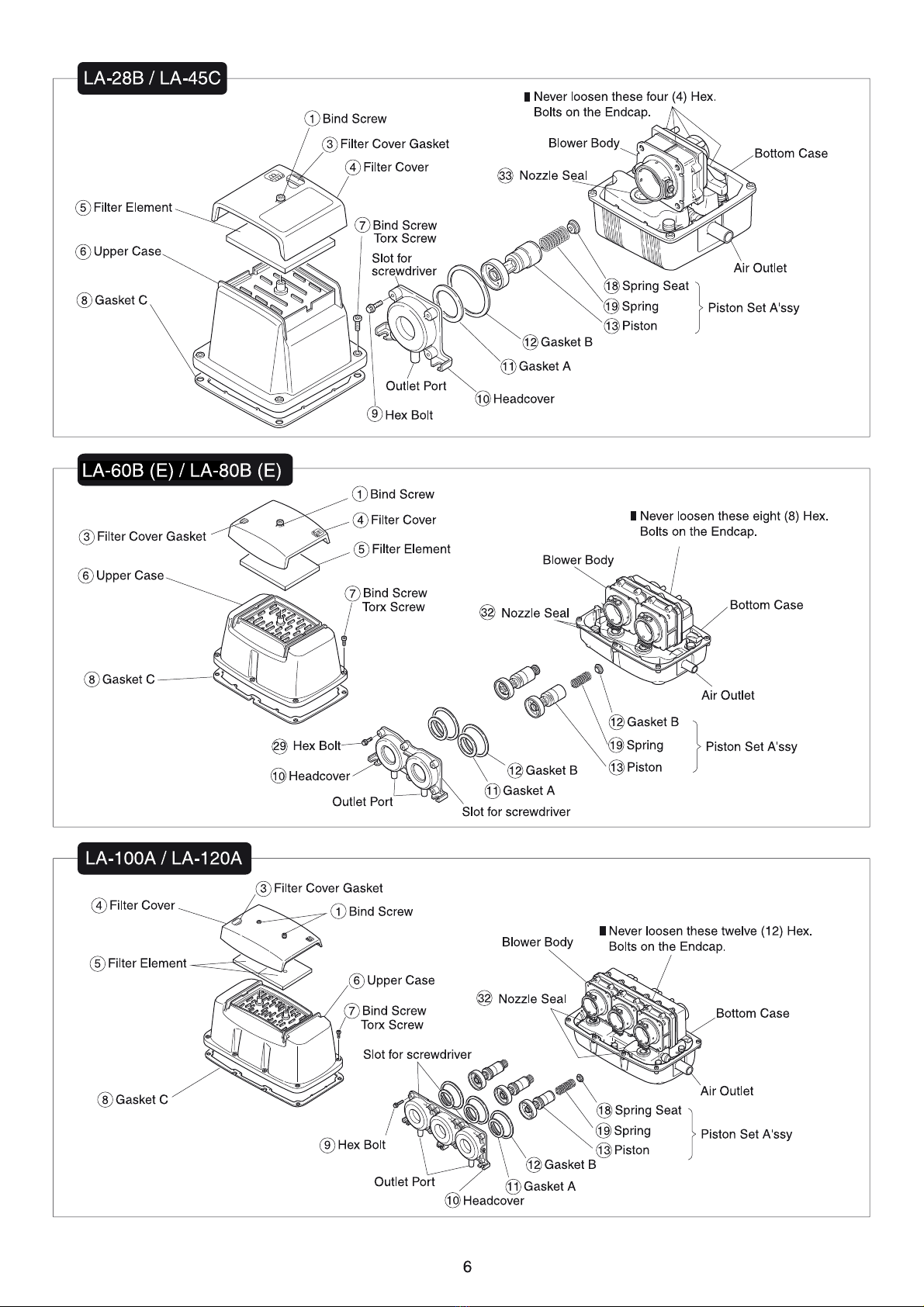

Structure of spare

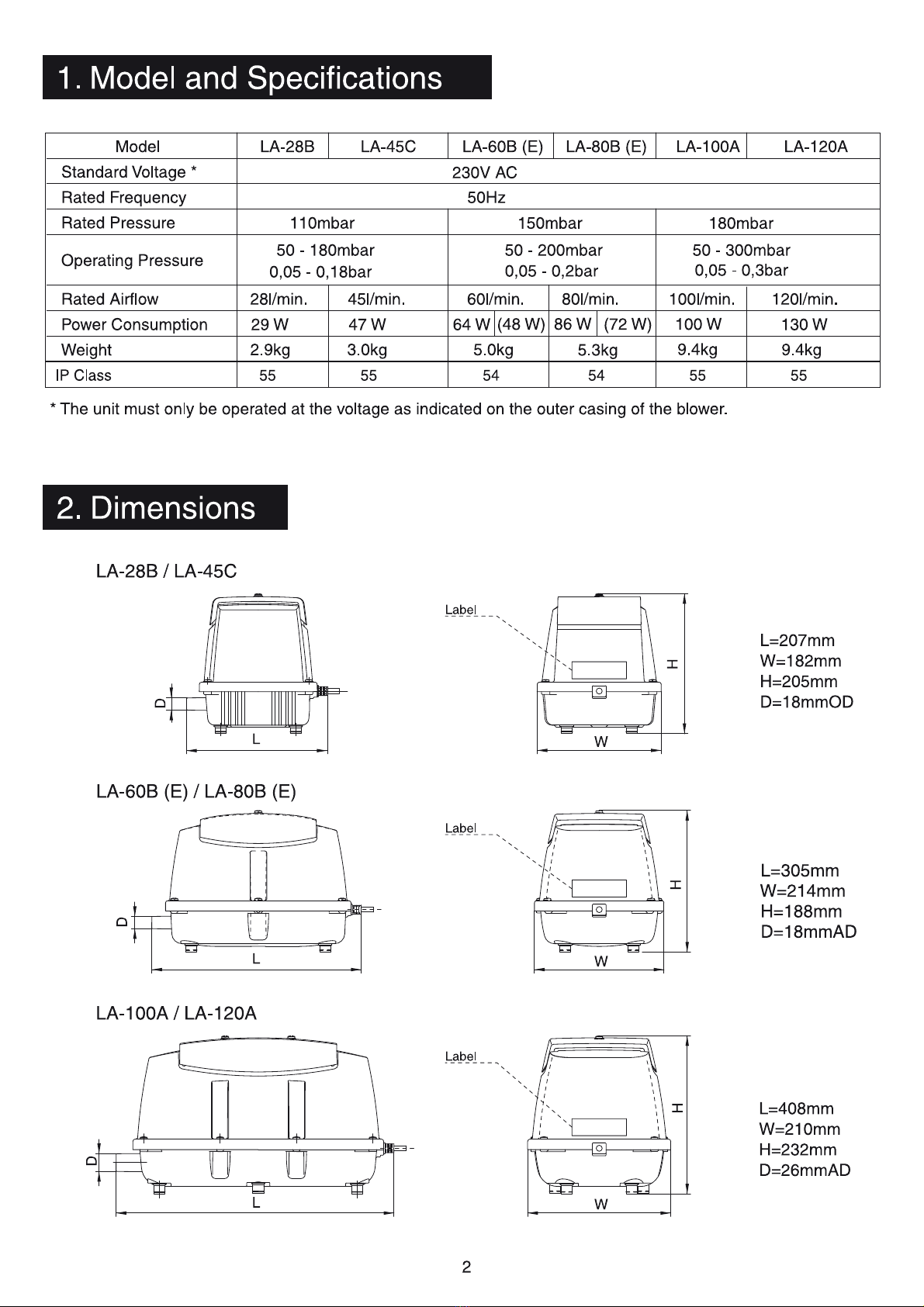

Model Part No. Part name Q’ty Model Part No. Part name Q’ty

LA-60A

LA-60B

LA-60E

LA-80A

LA-80B

LA-80E

HEMLA-80B

LB03132 Piston ASSY 2 LA-60A

LA-60B

LA-80E LP30585 Spring 18.1×49 2

LP12155 Spring seat 2

LQ02730 Filter element 1 LA-60E LP30620 Spring 18.1×48 2

LQ01043 Gasket A 2 LA-80A

LA-80B LQ02743 Spring 18×49.7 2

LQ01042 Gasket B 2

<60Hz ONLY>

LA-80A

LA-80B

HEMLA-80B

LQ05425 Spring 18.1×49.7 2

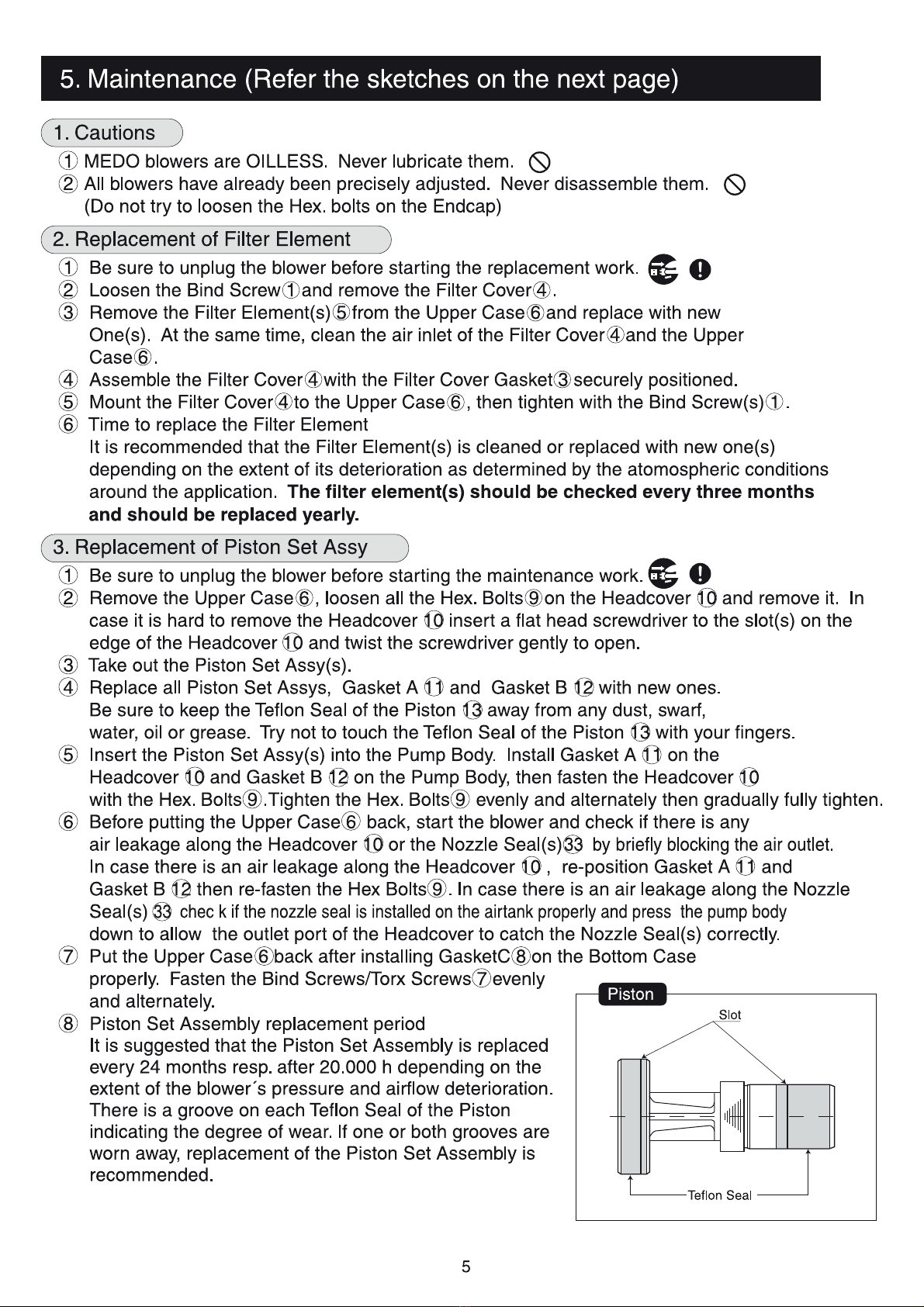

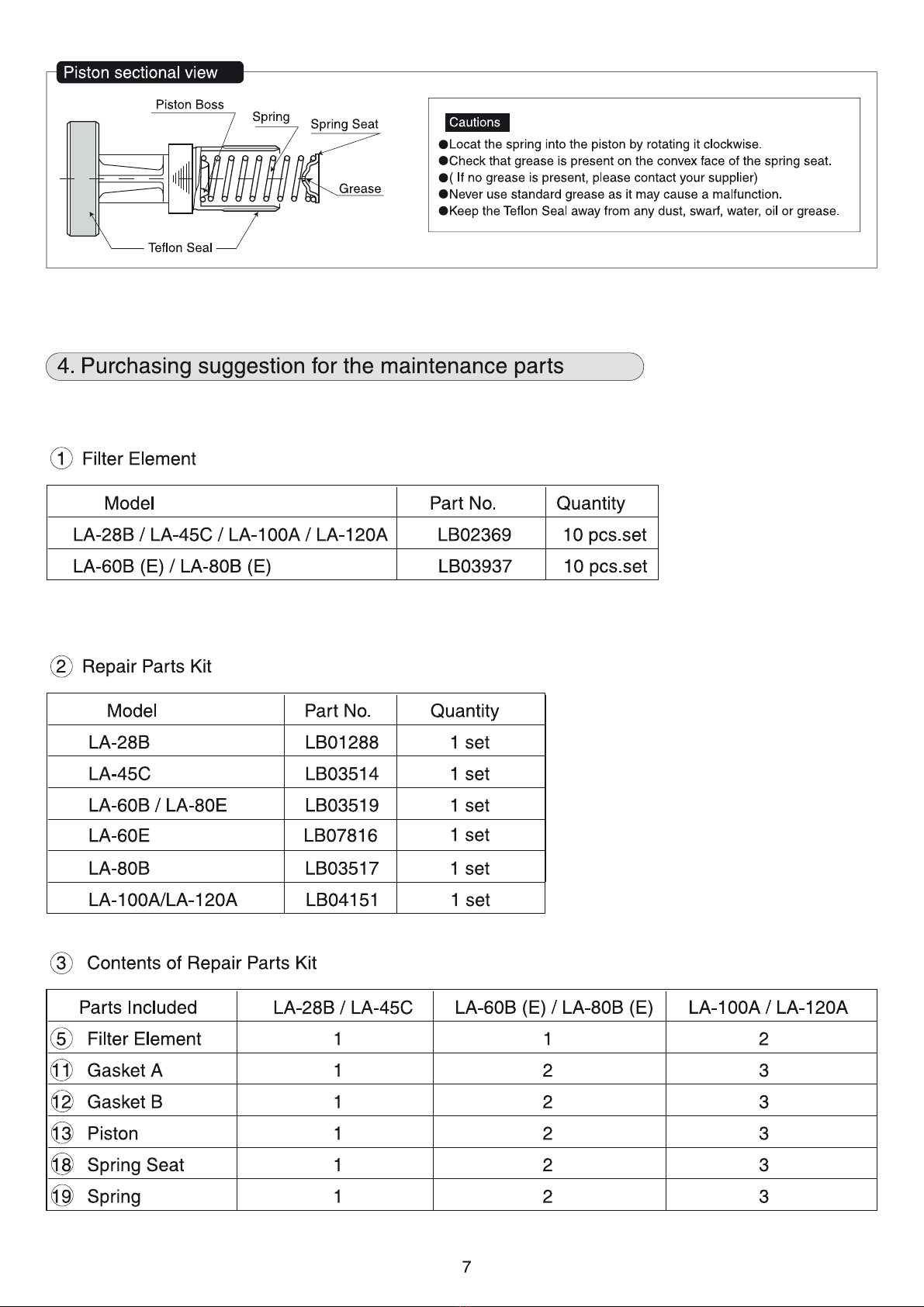

Piston cross-sectional view

Sliding part (black)

Grease

Spring Seat

Spring

Piston Boss CAUTION

●Fix the spring into the piston by rotating

it clockwise.

●Check that grease is present on the

convex face of the spring seat.

(If no grease is present, please contact

your supplier)

●Never use standard grease as it may

cause a malfunction.

●Keep the Sliding part away from dust,

swarf, water, oil or grease.

1. Precautions

(1) Our blower is an oil-free type; therefore, never lubricate the blower.

(2) The main unit of the blower is precisely adjusted; therefore, never disassemble the unit.

(Never loosen the eight hexagonal-head bolts on the rear of the main unit.)

&OHDQLQJDQGUHSODFHPHQWRI¿OWHUHOHPHQW

(1) Be sure to perform cleaning or replacement after disconnecting the power plug from the electric

outlet.

(2) Loosen the

①Bind screw, and remove the ③Filter cover.

(3) Take out the ④Filter element from the ⑤Upper Case, replace the element with new one or

FOHDQWKHHOHPHQW$WWKLVPRPHQWZLSHGXVWRIIWKH¿OWHUHOHPHQWPRXQWLQJIDFHDQGVXFWLRQ

port of the ⑤Upper Case with a cloth or the like.

(4) Clean the

④Filter element as follows

(a) Beat the ④)LOWHUHOHPHQWWRGURSGXVWVXI¿FLHQWO\

(b) If the element is severely dirty, use a neutral detergent to wash it, rinse it well, and dry it in the

shade.

&RQ¿UPWKDWWKH②Filter Cover Gasket is attached to the ③Filter cover.

(6) Be sure to mount the ③Filter cover, and secure it with the ①Bind screw.

:KHQUHSODFLQJWKH¿OWHUHOHPHQWEHVXUHWRXVHDJHQXLQH¿OWHUHOHPHQW)DLOXUHWRREVHUYH

this may cause a malfunction.

+RZWRUHSODFHWKHSLVWRQ

(1) Be sure to perform replacement after disconnecting the power plug from the electric outlet.

(2) Remove the

⑤Upper Case, loosen the ⑧Hexagonal-head bolts using a box wrench, and

remove the ⑨Head Cover. If the gasket is glued too tightly to remove the cylinder cover, insert

DÀDWEODGHVFUHZGULYHULQWRWKHJURRYHIRUÀDWEODGHVFUHZGULYHURIWKH⑨Head Cover and

gently separate them.

(3) Pull out the ⑮3LVWRQVHW¿OWHUHOHPHQWDVIROORZV

(4) Replace the

⑮Piston set, ⑩Gasket A, and ⑪Gasket B with new ones. Be absolutely careful

not to let dirt, oil, or other foreign matter attach to the sliding part (black part) of the ⑫Piston

assembly. Do not touch the moving parts as much as possible. (For the ⑮Piston set re-

placement, be sure to replace two sets of the assemblies at the same time.)

(5) Insert the

⑮Piston set into the ⑯Blower main unit, mount the ⑩Gasket A on the ⑨Head

Cover, mount the ⑪Gasket B on the ⑯Blower main unit without displacement, and tighten

the ⑨Head Cover with the ⑧Hexagonal-head bolts. When tightening the ⑧Hexagonal-head

EROWVWLJKWHQWKHPXQLIRUPO\ELWE\ELWDQGWLJKWHQWKHP¿UPO\DWWKHHQG

(6) For LA-60A and 80A, lightly press the ⑨Head Cover of the ⑯Blower main unit.

(This operation is performed to ensure the ⑰Nozzle seal and discharge port peripheral seal.)

$IWHUDVVHPEO\FRQQHFWWKHSRZHUSOXJWRWKHHOHFWULFRXWOHWDQGRSHUDWHWKHSURGXFW&RQ¿UP

that there is no air leakage from the ⑨Head Cover, ⑰Nozzle seal, and other areas while

EORFNLQJWKHGLVFKDUJHQLSSOHZLWK\RXU¿QJHU,IDLUOHDNDJHLVIRXQGWLJKWHQWKH⑧Hexagonal-

head bolts uniformly again, or check to see whether the ⑩Gasket A and ⑪Gasket B are

appro-priately placed.

(8) If there is no problem, put the ⑤Upper Case on the ⑯Blower main unit and tighten six pieces

of the ⑥%LQGVFUHZVXQLIRUPO\ELWE\ELWDIWHUFRQ¿UPLQJWKDWWKH⑦Gasket C is securely placed.

([SORGHG9LHZ/$$/$$

⑯Blower

Main Unit

Never loosen these eight(8) Hex.

Bolts on the Endcap.

Air Outlet

Bottom Case

Slot for screwdriver

Outlet Port

⑰Nozzle Seal

⑫Piston ASSY

⑬Spring

⑭Spring Seat ⑮Piston Set

⑩Gasket A

⑪Gasket B

⑦Gasket C

⑧Hexagonal-Head Bolts

⑨Head Cover

②Filter Cover Gasket

④Filter Element

⑤Upper Case

①Bind Screw

⑥Bind Screws

③Filter Cover

([SORGHG9LHZ/$%/$(/$%/$(

①Bind Screw

③Filter Cover

④Filter Element

⑥Bind Screws

⑦Gasket C

⑧Hexagonal-Head Bolts

⑩Gasket A

⑪Gasket B ⑫Piston ASSY

⑬Spring

⑭Spring Seat ⑮Piston Set

⑯Blower

Main Unit

Never loosen these eight(8) Hex.

Bolts on the Endcap.

Air Outlet

Slot for screwdriver

Bottom Case

⑨Head Cover

②Filter Cover Gasket

⑤Upper Case

Outlet Port

Other manuals for LA-28B

1

This manual suits for next models

7

Table of contents

Other MEDO Blower manuals