MEFE—Mitchell Engineering Food Equipment Pty Ltd

23 Storie Street Clontarf QLD 4019 Australia

Page 2

+617 3283 4536

Free AU 1800 669 006

Contents

1. Introducon.................................................................................................................... 3

1.1 Technical Specicaons ........................................................................................... 3

1.2 Machine Noise.......................................................................................................... 3

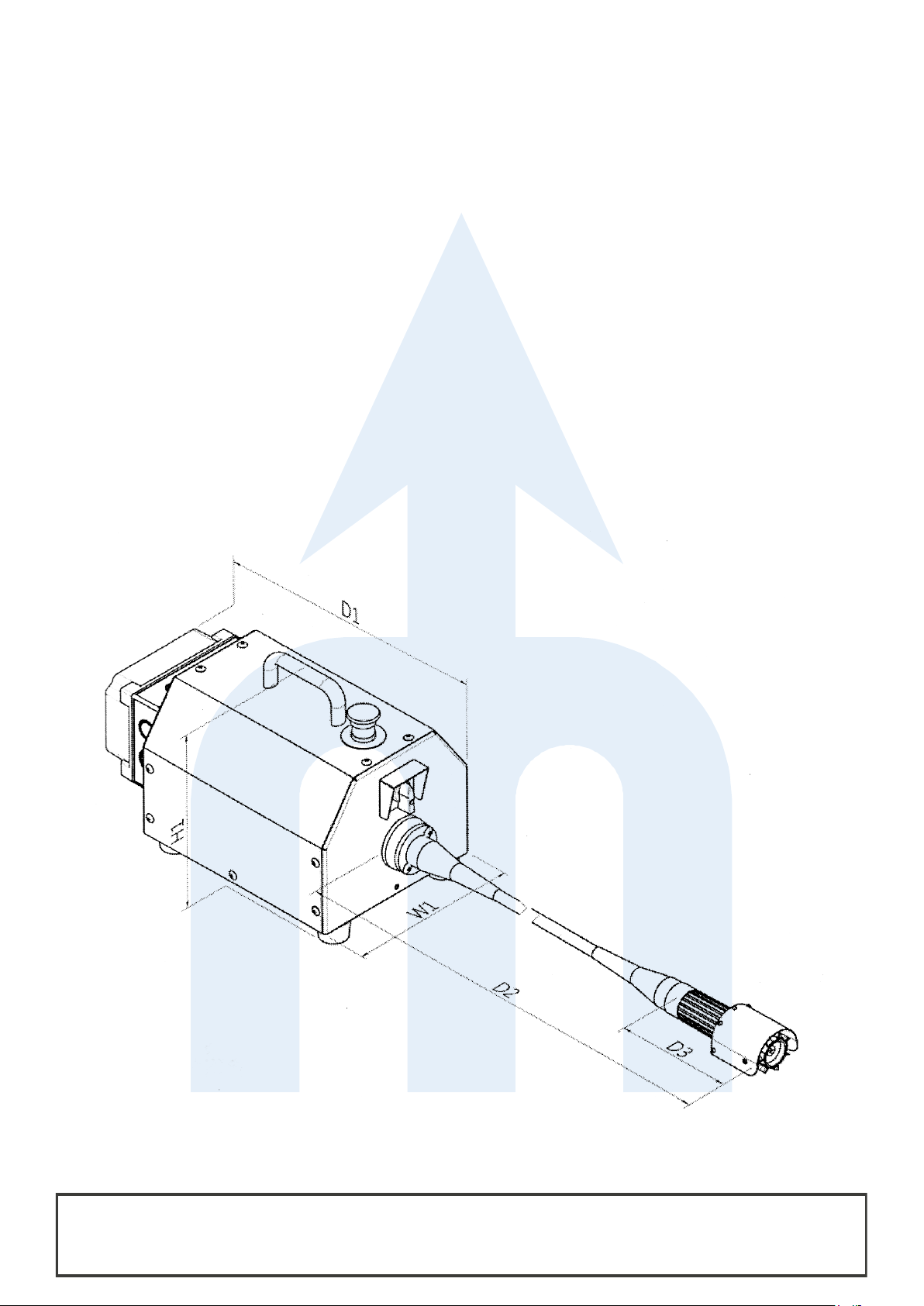

1.3 Machine Dimensions................................................................................................ 4

1.4 Machine Dimensions Diagram ................................................................................. 4

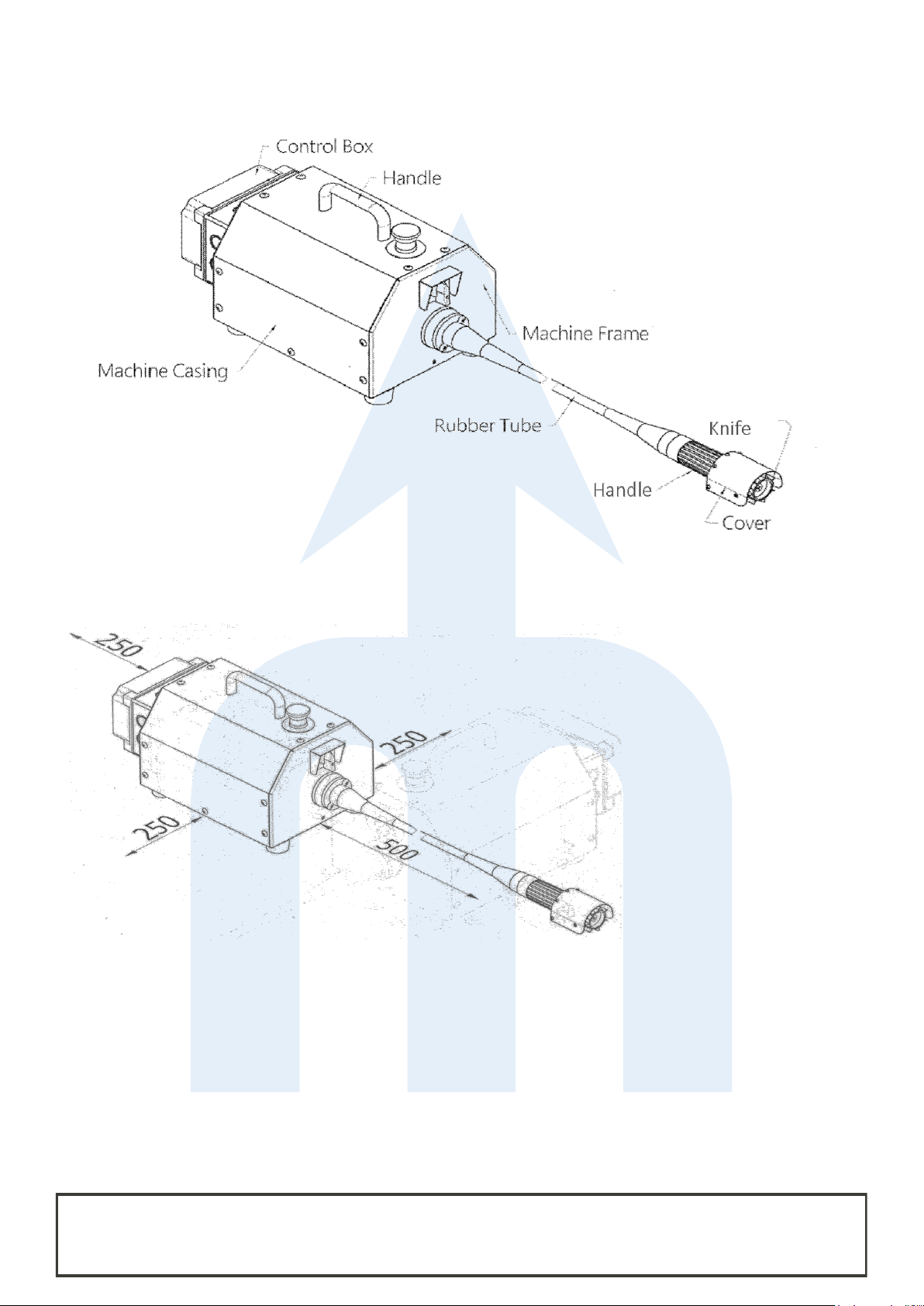

1.5 Labelled Diagram of Parts........................................................................................ 5

2. Installaon...................................................................................................................... 5

2.1 Direcon of Rotaon................................................................................................ 5

2.2 Choosing the Appropriate Locaon ......................................................................... 6

2.3 Power Supply Requirement ..................................................................................... 6

2.4 Connecng Power Source Wires.............................................................................. 6

2.5 Checking Power Wire Connecon............................................................................ 6

3. Operaon........................................................................................................................ 7

3.1 Safety Measures....................................................................................................... 7

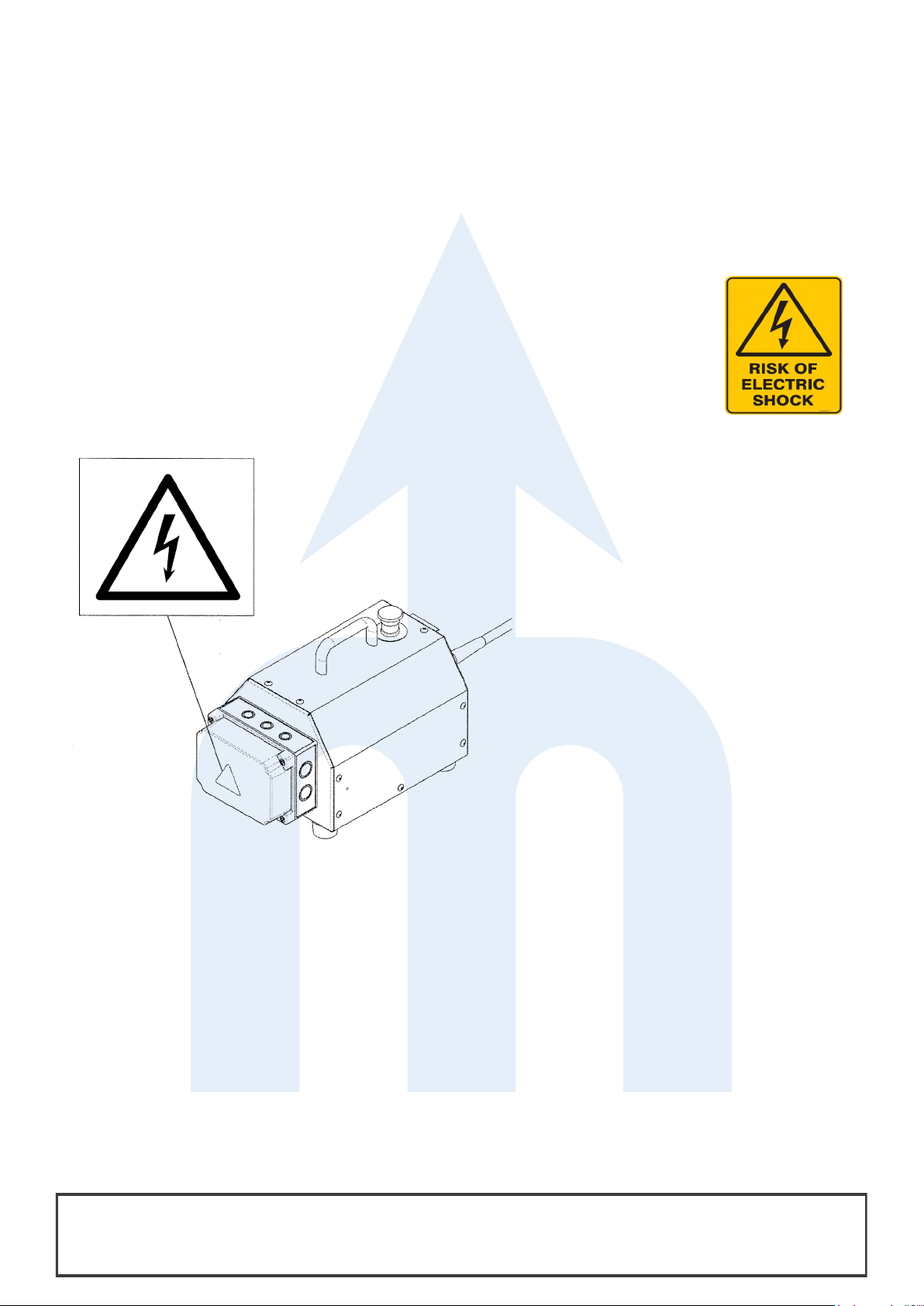

3.2 Warning Plate........................................................................................................... 7

3.3 Warning Plate Diagram ............................................................................................ 7

3.4 Before Use................................................................................................................ 7

3.5 During Use................................................................................................................ 7

3.6 Aer Use................................................................................................................... 8

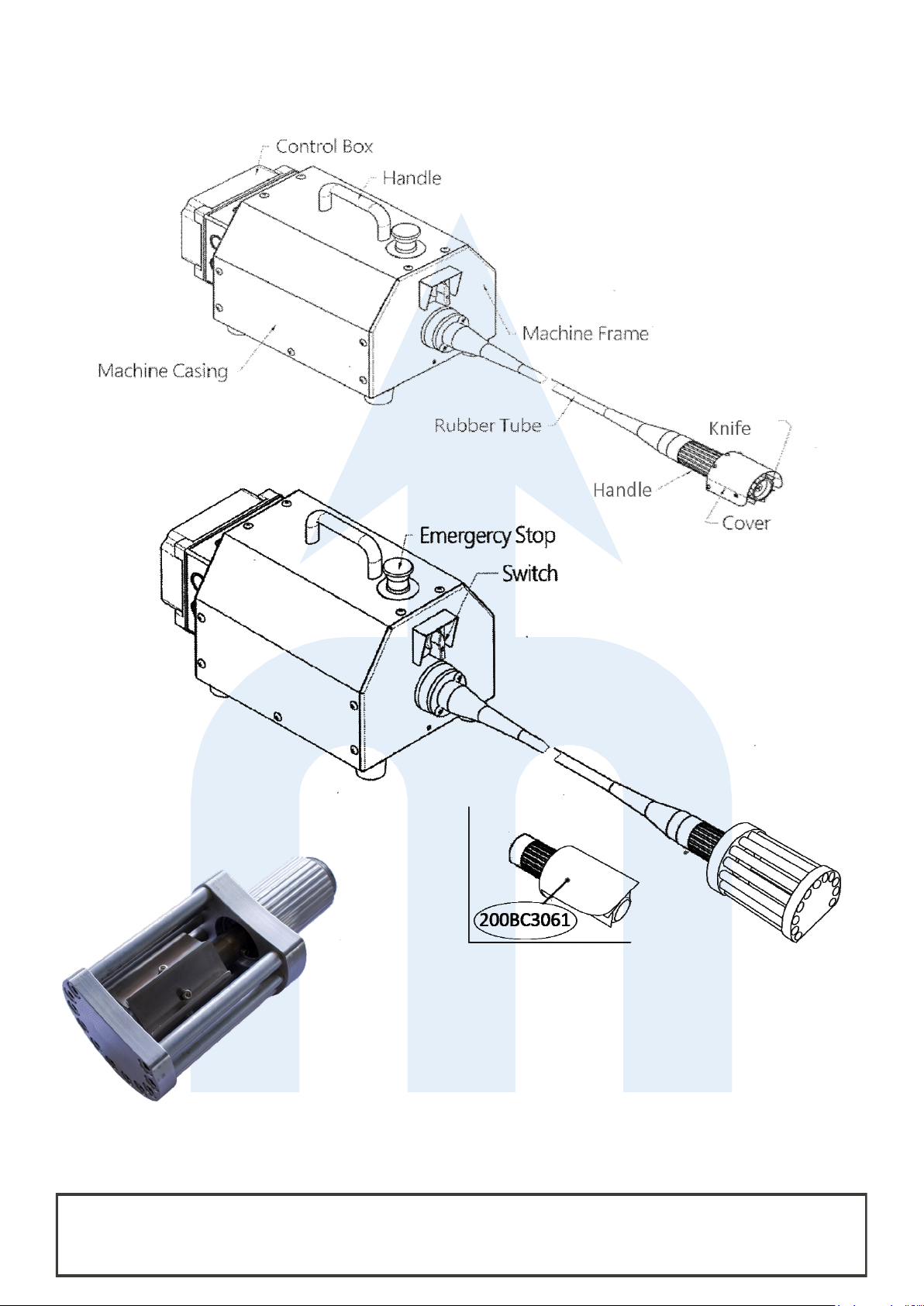

3.7 Emergency Stop ....................................................................................................... 8

3.8 Starng Up and Stopping ......................................................................................... 8

4. Instrucons for Use........................................................................................................ 8

4.1 General Instrucons................................................................................................. 8

4.2 CAT 200BC Scaling Fish............................................................................................. 9

4.3 CAT 200BCEPS Animal Scraping ............................................................................... 9

4.4 CAT 200BCES Animal Shaving................................................................................... 9

4.5 Cleaning and Washing.............................................................................................. 9

4.6 Maintenance ............................................................................................................ 10

5. Fault Finding................................................................................................................... 10

6. Exploded Drawing Diagram ........................................................................................... 10

7. Spare Parts...................................................................................................................... 11