Issue Date March 1, 2018

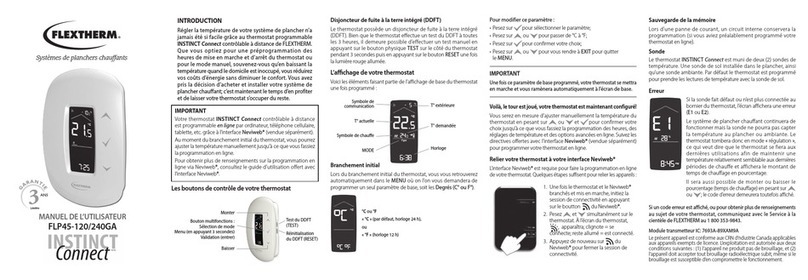

NT10 Series

RS-485 Modbus RTU Networking Room Thermostats for Fan Coil Units

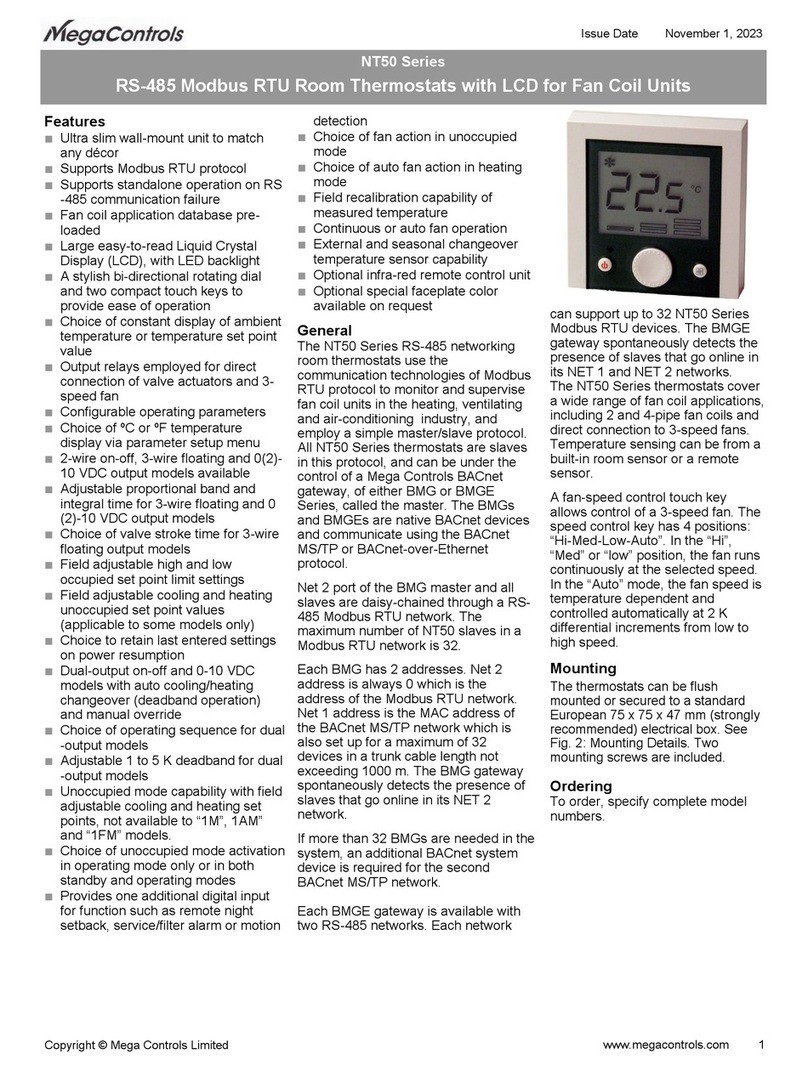

support up to 32 NT10 Series

Modbus RTU devices. The BMGE

gateway spontaneously detects the

presence of slaves that go online

in its NET 1 and NET 2 networks.

The NT10 Series thermostats

cover a wide range of fan coil

applications, including 2 and 4-pipe

fan coils and direct connection to 3

-speed fans. Temperature sensing

can be from a built-in room sensor

or a remote sensor.

A fan-speed control touch key

allows control of a 3-speed fan.

The speed control key has 4

positions: “Hi-Med-Low-Auto”. In

the “Hi”, “Med” or “low” position,

the fan runs continuously at the

selected speed. In the “Auto”

mode, the fan speed is

temperature dependent and

controlled automatically at 2 K

differential increments from low to

high speed.

Ordering

To order, specify complete model

numbers.

www.megacontrols.com 1

Copyright © Mega Controls Limited

Features

■ Ultra slim wall-mount unit to match

any decor

■ Supports standalone operation on RS

-485 communication failure. A power

reset must be carried out on

thermostat before this can take place.

■ Fan coil application database pre-

loaded

■ Large easy-to-read Liquid Crystal

Display (LCD), with LED backlight

■ A stylish bi-directional rotating dial

and two compact touch keys to

provide ease of operation

■ Choice of constant display of ambient

temperature or temperature set point

value

■ Output relays employed for direct

connection of valve actuators and 3-

speed fan

■ Configurable operating parameters

■ Choice of ºC or ºF temperature

display via parameter setup menu

■ 2-wire on-off, 3-wire floating and 0-10

VDC output models available

■ Adjustable proportional band for 3-

wire floating and modulating models

■ Adjustable integral time for

modulating models

■ Choice of valve stroke time for 3-wire

floating output models

■ Field adjustable high and low

occupied set point limit settings

■ Field adjustable cooling and heating

unoccupied set point values

(applicable to some models only)

■ Choice to retain last entered settings

on power resumption

■ Dual-output on-off and 0-10 VDC

models with auto cooling/heating

changeover (deadband operation)

and manual override

■ Choice of operating sequence for dual

-output models

■ Adjustable 1 to 5 K deadband for dual

-output models

■ Unoccupied mode capability with field

adjustable cooling and heating set

points, , not available to “1M”, 1AM”

and “1FM” models.

■ Choice of unoccupied mode activation

in operating mode only or in both

standby and operating modes

■ Window contact closure to shut down the

FCU and lock out all thermostat functions

■ Provides one additional digital input

for function such as remote night

setback, service/filter alarm or motion

detection

■ Choice of fan action in unoccupied

mode

■ Choice of auto fan action in heating

mode

■ Field recalibration capability of

measured temperature

■ Continuous or auto fan operation

■ External and seasonal changeover

temperature sensor capability

■ Optional infra-red remote control unit

■ Optional special faceplate color

available on request

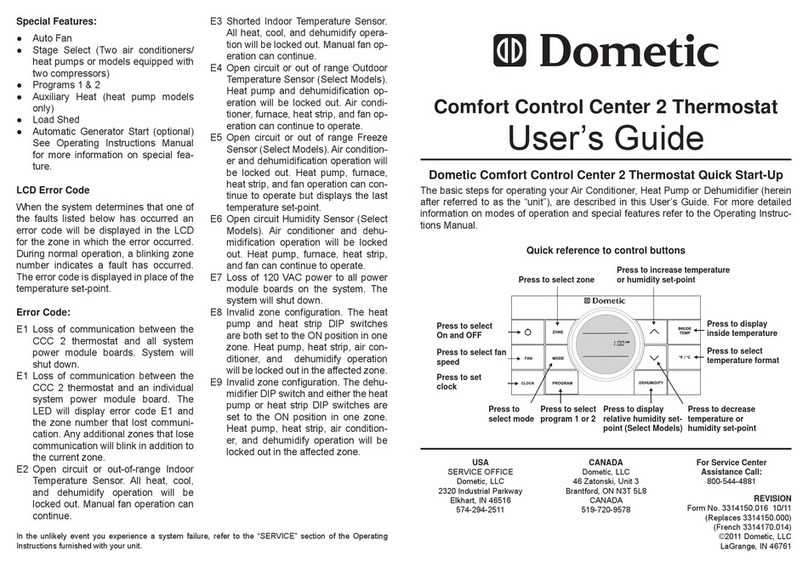

General

The NT10 Series RS-485 networking

room thermostats use the communication

technologies of Modbus RTU

communication protocol to monitor and

supervise fan coil units in the heating,

ventilating and air-conditioning industry,

and employ a simple master/slave

protocol. All NT10 Series thermostats are

slaves in this protocol, and can be under

the control of a Mega Controls BACnet

gateway, either BMG or BMGE Series,

called the master. The BMGs and

BMGEs are native BACnet MS/TP

devices and communicate using the

BACnet MS/TP or BACnet-over-Ethernet

protocol. The master can also be a

Modbus network supervisor.

The master and all slaves are daisy-

chained through a RS-485 Modbus RTU

network. The maximum number of NT10

slaves in a Modbus RTU network is 32.

Each BMG has 2 addresses. Net 2

address is always 0 which is the address

of the Modbus RTU network. Net 1

address is the MAC address of the

BACnet MS/TP network which is also set

up for a maximum of 32 devices in a

trunk cable length not exceeding 1000 m.

The BMG gateway spontaneously

detects the presence of slaves that go

online in its NET 2 network.

If more than 32 BMGs are needed in the

system, an additional BACnet system

device is required for the second BACnet

MS/TP network.

Each BMGE gateway is available with

two RS-485 networks. Each network can